Page 16 11/07/00

3.1 RECOMMENDATIONS FOR THE USER

•Keep this booklet with care near the appliance for any fur-

ther consultation.

•For good working and validity of the guarantee, ask for

the unit to be serviced annually by a qualified engineer.

•All the installation operations have to be made exclusively

by professional qualified people in respect of the safety

regulations in force. An incorrect installation, caused by

not observing the manufacturer’s instruction can cause

damage to people, animals or things for which the manu-

facturer can not be considered responsible.

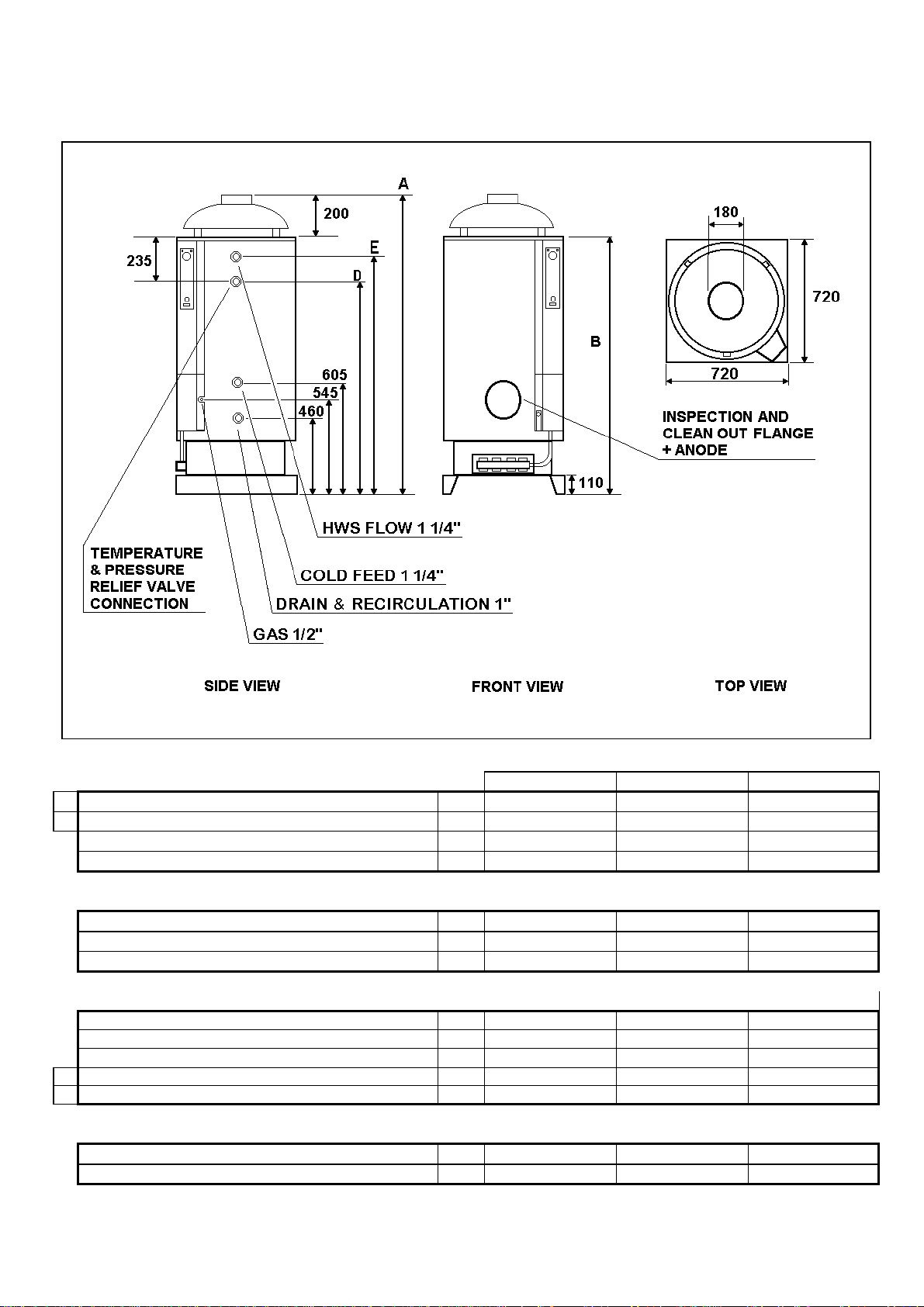

•The appliance has been manufactured for hot water pro-

duction: any other use of it has to be considered dangerous

and not suitable.

•The appliance is not to be installed in damp rooms; it has

to be protected from water splashes and other liquids, to

avoid anomalies to electrical and thermal devices.

•Installation has to be carried out by professional qualified

people according to the safety regulations in force.

•Packaging parts (i.e. plastic bags, polystyrene, wood,

clips, nails etc.) can be harmful to children and should be

carefully disposed of immediately.

•Read carefully the instructions and the advice contained in

this booklet concerning safety, installation, use and main-

tenance.

•If the appliance is sold or transferred to a new owner,

make sure that this booklet stays with the appliance, so

that the new owner or installer can consult it.

•Do not place anything upon the appliance.

•To avoid damages caused by low temperatures, if the ap-

pliance has to be left unused for a long period in a non-

heated room, it is recommended the unit is drained com-

pletely.

•The manufacturer is not responsible for faults, break

downs or for water leakage from the plant caused by low

temperatures.

•To get the best efficiency of the appliance and to comply

with the guarantee, we advise you to adhere to these in-

structions, to have the appliance checked by professional

qualified people and to use only original spare parts and

kits supplied by the manufacturer.

3.2 STARTING THE APPLIANCE

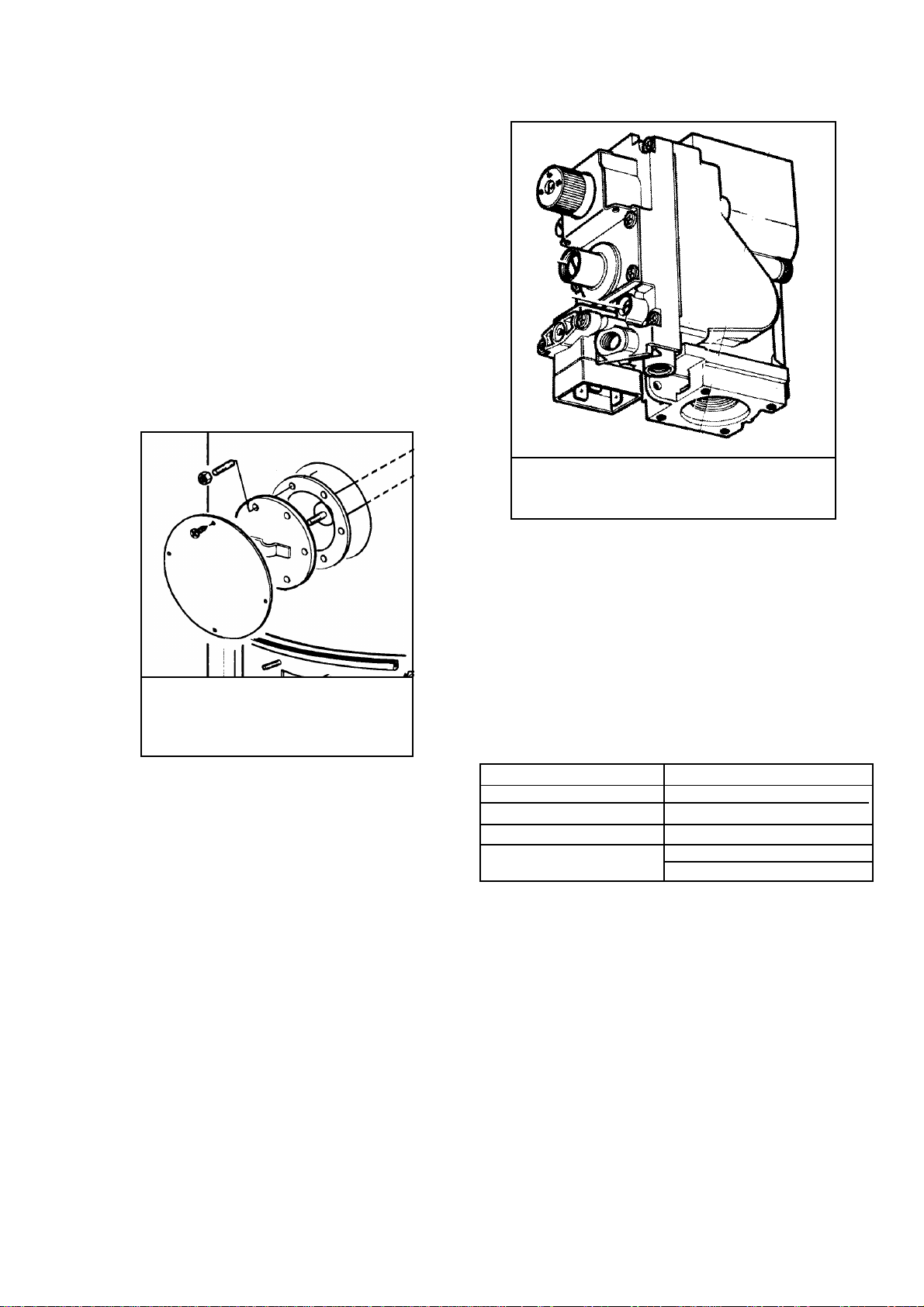

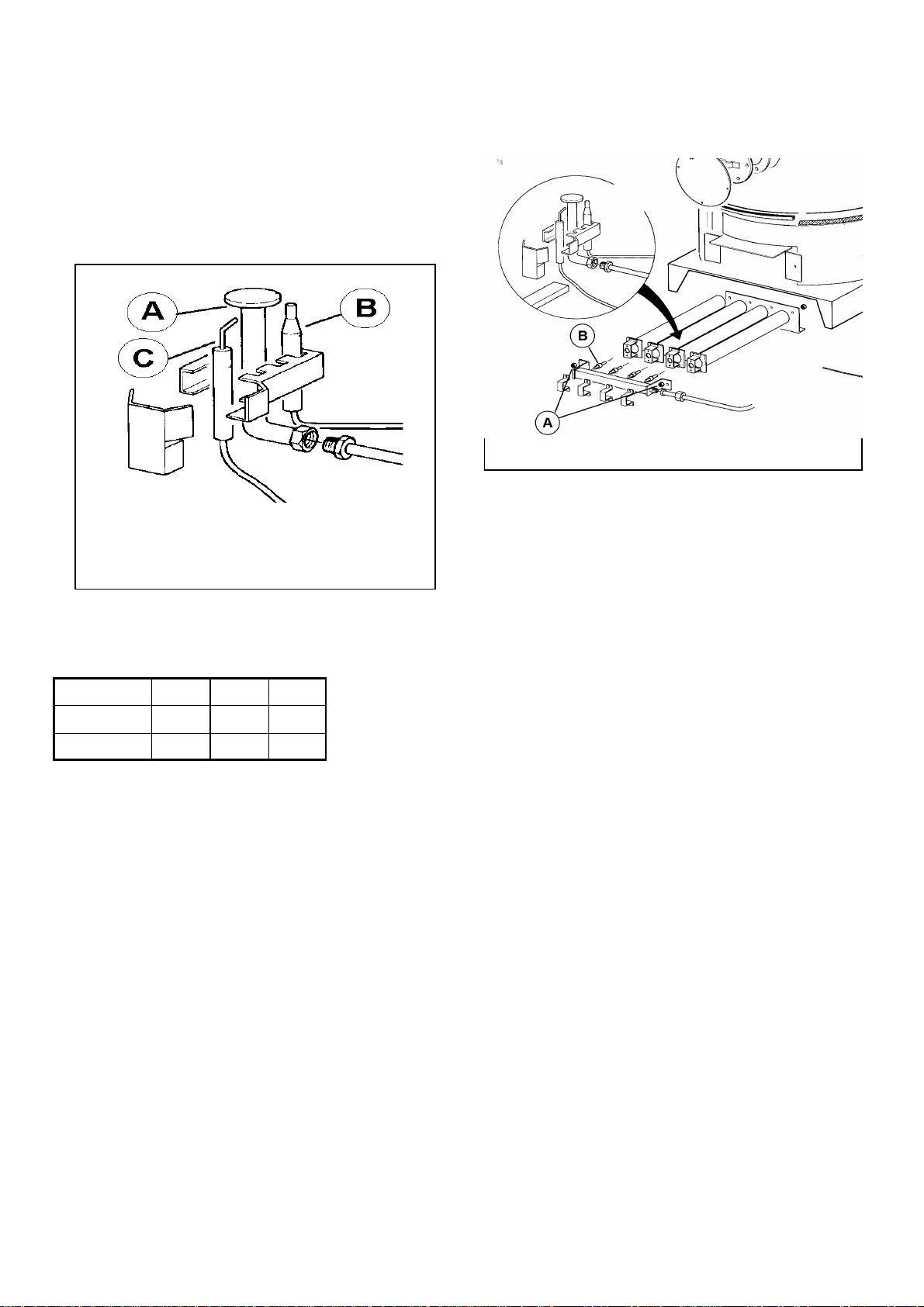

1. PILOT FLAME IGNITION: push and turn the knob of the

gas valve in the pilot position; push the knob and light the

burner through the piezo-electric ignition on the valve.

Keep the knob pushed for some seconds, and leave it by

checking that the pilot burner flame is established. Repeat

if the pilot flame extinguishes.

2. PRINCIPAL BURNER IGNITION: push and turn the

knob to the On position.

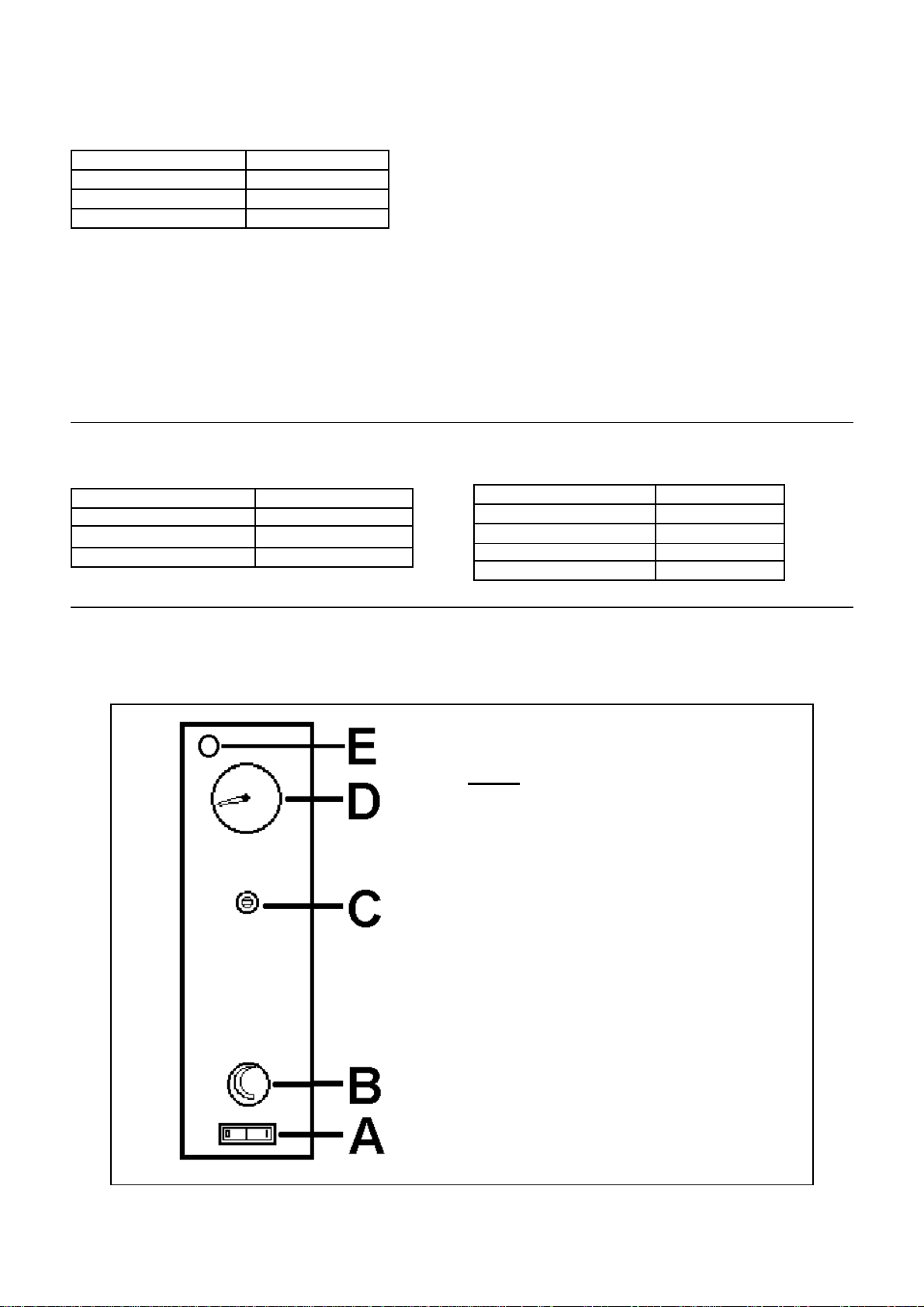

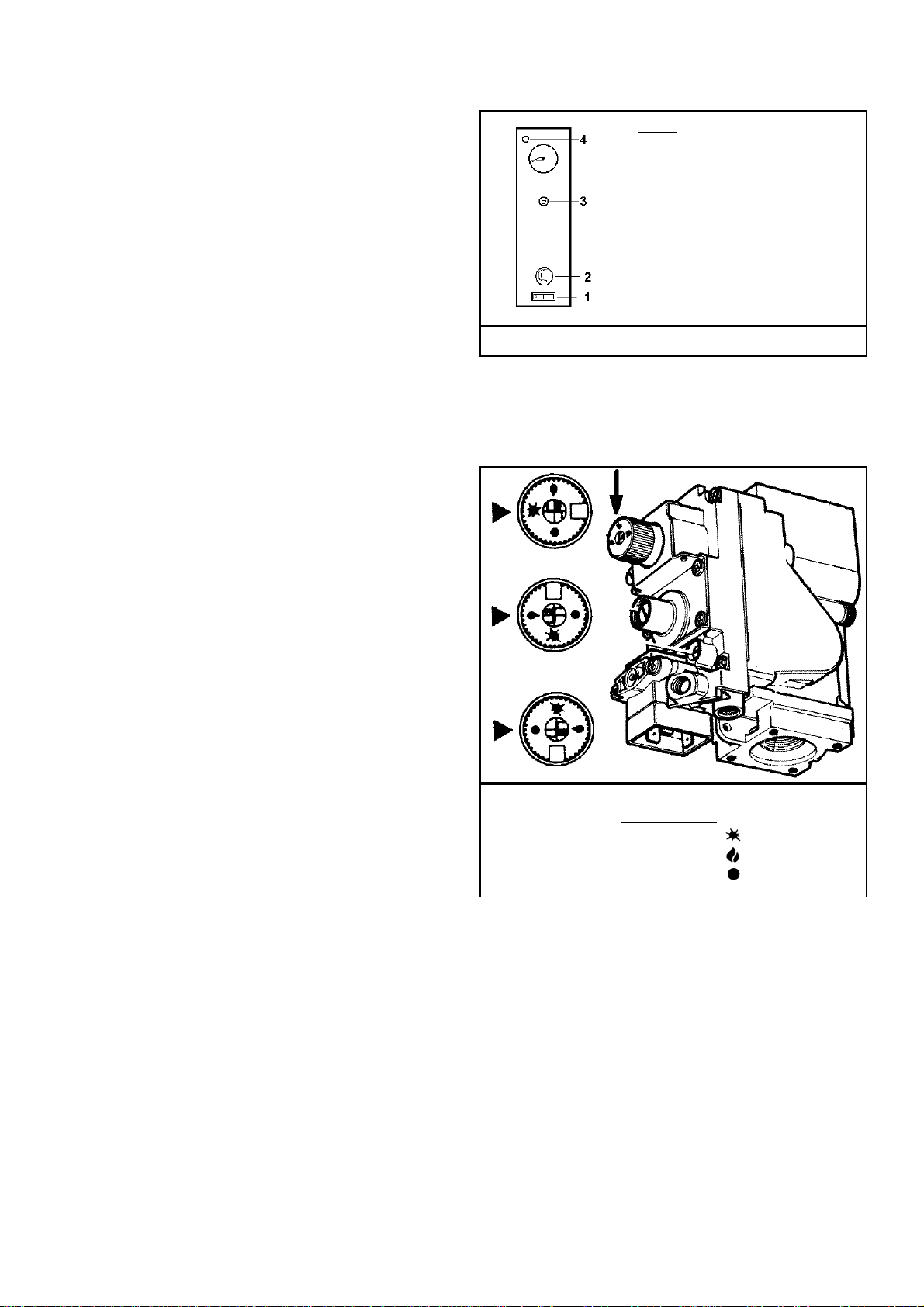

3. set the switch on the ON position “I”;

4. set the control thermostat indicator to the desired water

temperature (min. 40° max. 70°).

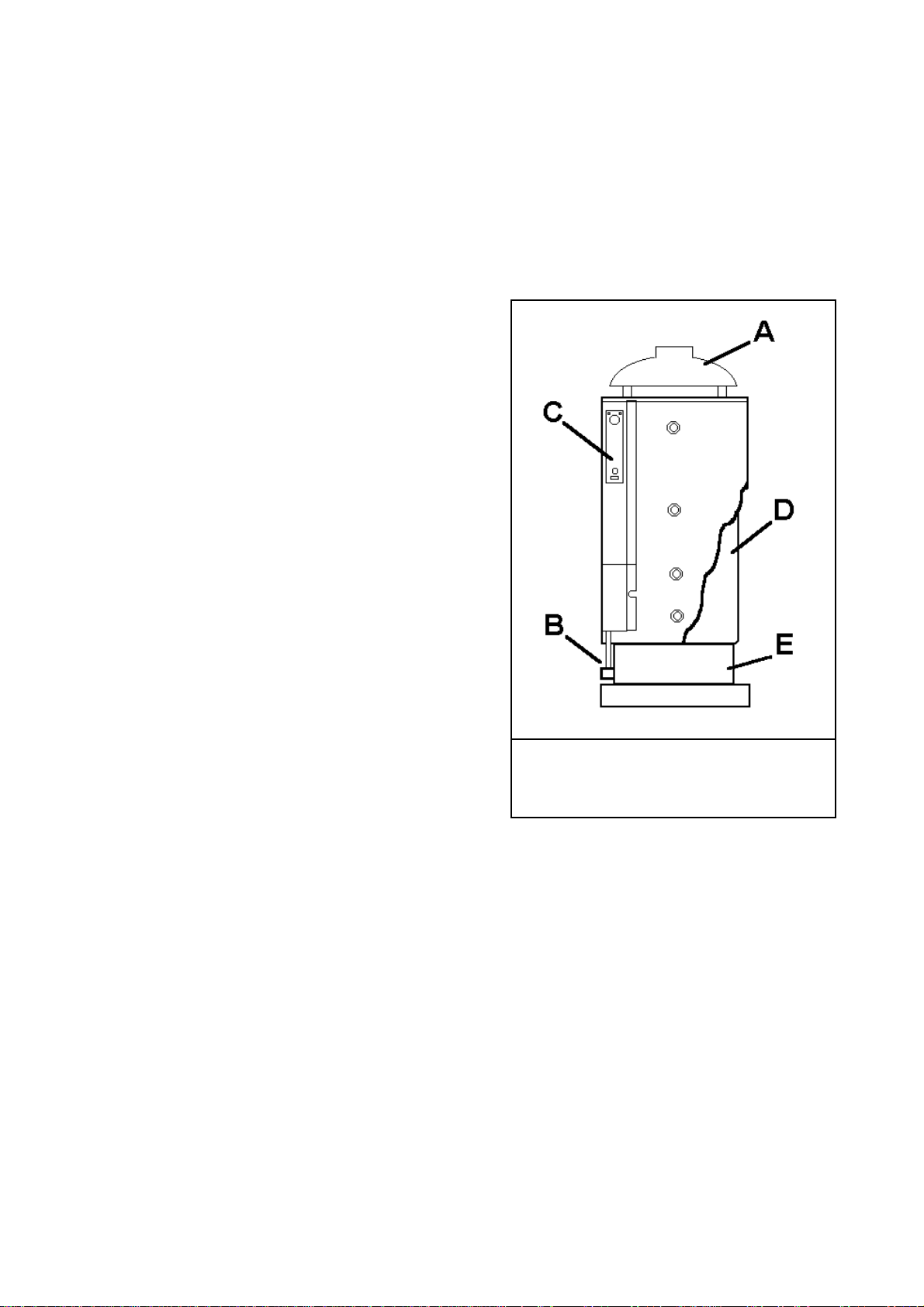

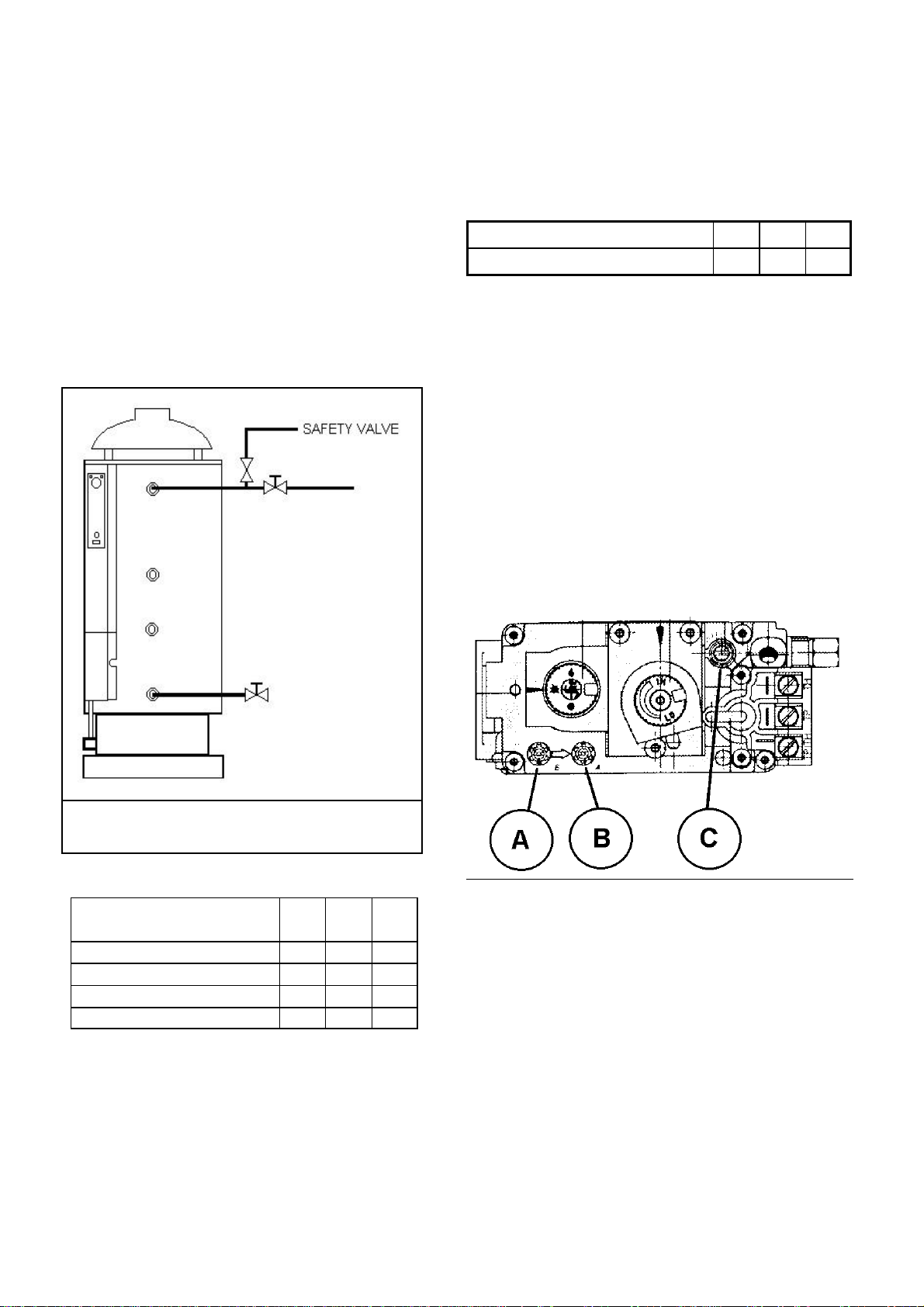

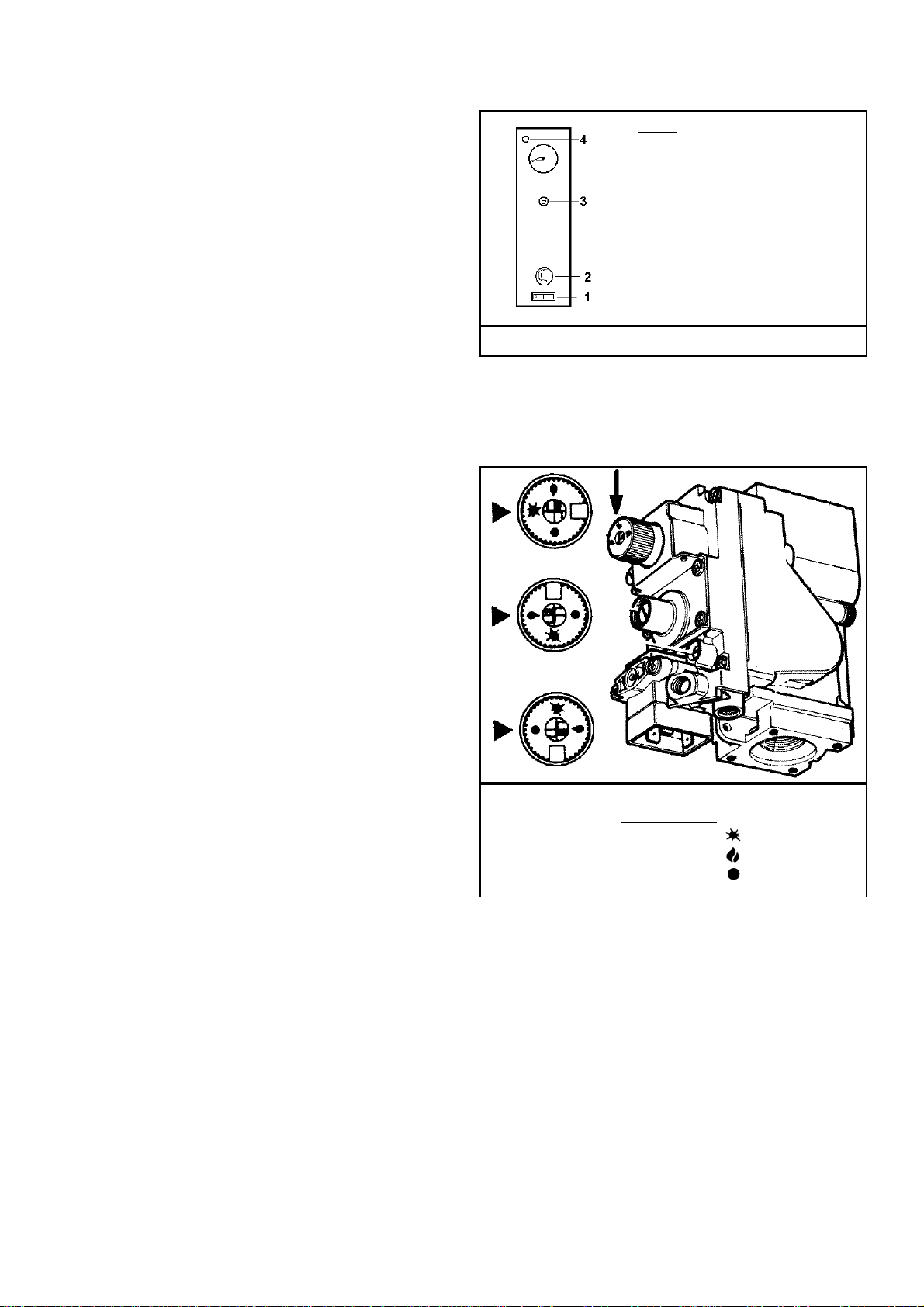

Fig 3.2 / 1

KEY:

1 –ON/OFF Switch

2 –Water temperature thermostat

3 –Safety limit thermostat

(exhausting gas)

4 –Safety limit ther

light

To check the operating of the thermostat, turn the knob 2

(pict. 3.2/1) to the lower value and check that the burner ex-

tinguishes. Turn the knob again to the previous pre-set value

and check for a proper ignition of the burner.

From this moment on the water heating phase begins: the

burner will operate until the water temperature reaches the

temperature set at point 2: at this moment the principal

burner switches off (the pilot burner remains alight); the

burner will operate again if the temperature goes below the

pre-set value (i.e. a lot of hot water is used).

FLUE GAS SAFETY OPERATING: the appliance has a

flue gas spillage thermostat which operates in case of im-

proper exhausting of the combustion gases (i.e. if the chim-

ney is blocked). If this happens, the red light (4) will be illu-

minated and the gas supply to the principal burner is

stopped. To reset push the button under the cover cap plug

(3) in order to restart again the appliance.

Fig 3.2 / 1

Gas valve knob

Position: PILOT

ON

OFF