Stromag HGE Series Service manual

Gear limit switch

Type series HGE

Document No.: 152-00000 F

Date: 10/2017

EKM-0119

Mounting/operating instructions

EN-GB

Stromag GmbH

Hansastraße 120

D-59425 Unna

Tel.: +49 (0) 2303 102-0

Fax: +49 (0) 2303 102-201

www.stromag.com

Contents

1 Introduction................................................................................................................................1

1.1 About this documentation........................................................................................................................... 1

1.1.1 Target group............................................................................................................................................ 1

1.1.2 Use/storage............................................................................................................................................. 1

1.2 Using the documentation correctly............................................................................................................. 2

1.2.1 Text formats.............................................................................................................................................2

1.2.2 Definition of terms....................................................................................................................................2

1.3 Warranty and liability.................................................................................................................................. 3

1.3.1 Guarantee................................................................................................................................................3

1.3.2 Copyright................................................................................................................................................. 3

2 For your safety...........................................................................................................................3

2.1 Safety concept of the documentation......................................................................................................... 3

2.2 Required personnel qualifications...............................................................................................................4

2.3 Intended use...............................................................................................................................................4

2.3.1 Application limits......................................................................................................................................4

2.3.2 Approvals.................................................................................................................................................4

2.4 Non-intended use....................................................................................................................................... 4

2.5 EC Declaration of Conformity..................................................................................................................... 4

2.5.1 Standards applied....................................................................................................................................5

2.6 Possible residual risks................................................................................................................................ 5

2.6.1 Mechanical dangers.................................................................................................................................5

2.6.2 Thermal dangers......................................................................................................................................5

2.6.3 Electrical danger......................................................................................................................................5

2.7 Safety symbols/pictograms in the documentation...................................................................................... 5

2.7.1 Warning symbols..................................................................................................................................... 5

2.7.2 Hazard classifications..............................................................................................................................5

2.7.3 Mandatory symbols..................................................................................................................................6

2.7.4 Note......................................................................................................................................................... 6

2.7.5 Environmental protection/recycling..........................................................................................................6

2.8 GTES safety devices.................................................................................................................................. 6

2.9 Safety symbols/pictograms on the GTES................................................................................................... 7

2.10 Wear personal protective equipment..........................................................................................................7

2.11 Basic responsibilities of the operator and personnel.................................................................................. 7

2.12 Safe handling of rotating components........................................................................................................ 7

2.13 Safe handling with hot surfaces..................................................................................................................7

2.14 Safe handling with electrical hazards......................................................................................................... 7

2.14.1 Responsibility of the operator.................................................................................................................. 8

2.14.2 Applying the five safety rules...................................................................................................................8

2.14.3 IP protection type and class.....................................................................................................................8

2.14.4 Electromagnetic compatibility.................................................................................................................. 8

2.15 Environmental protection............................................................................................................................8

3 Transport and storage.............................................................................................................. 9

3.1 Transport.................................................................................................................................................... 9

3.1.1 Unpacking................................................................................................................................................9

3.2 Scope of delivery........................................................................................................................................ 9

3.2.1 Pre-mounting condition............................................................................................................................9

3.3 Storage..................................................................................................................................................... 10

4 Technical specifications......................................................................................................... 10

4.1 Product data............................................................................................................................................. 10

4.1.1 Dimensions............................................................................................................................................10

4.1.2 Mechanical specifications......................................................................................................................10

4.1.3 General information............................................................................................................................... 13

4.1.4 Specific electrical values and position of the contact.............................................................................13

4.1.5 Contact positions................................................................................................................................... 16

II Mounting/operating instructions Gear limit switch Type series HGE • No. 152-00000 F • 10/2017

4.1.6 Type code..............................................................................................................................................17

4.2 Dimensional drawing................................................................................................................................ 18

4.3 Marking on the product.............................................................................................................................18

5 Construction and function......................................................................................................19

5.1 Switch sizes..............................................................................................................................................19

5.2 Component designations..........................................................................................................................20

5.3 Design, task and function of the assembly groups................................................................................... 20

5.3.1 Electrical connections............................................................................................................................21

5.3.2 Mounting position...................................................................................................................................21

5.3.3 Drive flange............................................................................................................................................22

5.4 Optional equipment available................................................................................................................... 22

5.4.1 Design with additional potentiometer.....................................................................................................22

5.4.2 Adjustment of the potentiometer with drive via a torsionally-stiff coupling.............................................23

5.4.3 Adjustment of the potentiometer when the drive is over gear wheels................................................... 23

5.4.4 Design with heating resistor...................................................................................................................24

6 Assembly..................................................................................................................................25

6.1 Special safety guidelines.......................................................................................................................... 25

6.2 Conditions for assembly and fixing...........................................................................................................25

6.2.1 Special tools.......................................................................................................................................... 25

6.2.2 Assembly precision................................................................................................................................25

6.2.3 Tightening torques.................................................................................................................................26

6.2.4 Requirements for the connecting components...................................................................................... 26

6.3 Assembly mechanics................................................................................................................................26

6.3.1 Assembly of the housing (design without flange).................................................................................. 26

6.3.2 Assembly of the housing (design with flange)....................................................................................... 27

6.4 Electrical assembly...................................................................................................................................27

6.4.1 Insert the connection cable into the GTES............................................................................................ 28

6.4.2 Connect the contacts.............................................................................................................................28

6.4.3 Connect the heating...............................................................................................................................28

6.4.4 Connect the earth conductor................................................................................................................. 29

6.5 Connection diagrams................................................................................................................................29

6.5.1 Electrics................................................................................................................................................. 29

6.6 Switching point adjustment.......................................................................................................................29

6.6.1 Normal adjustment "V50".......................................................................................................................31

6.6.2 Fine adjustment “FV50”......................................................................................................................... 32

6.6.3 Double fine adjustment "DFV"............................................................................................................... 33

6.6.4 Normal adjustment "V70".......................................................................................................................34

6.6.5 Fine adjustment “FV70”......................................................................................................................... 34

6.6.6 Block adjustment "BV"........................................................................................................................... 35

6.6.7 Block adjustment "BFV".........................................................................................................................36

6.7 Mount the cover........................................................................................................................................37

6.8 Correct disposal/recycling of operating and auxiliary materials................................................................37

7 Operation..................................................................................................................................37

7.1 Special safety guidelines.......................................................................................................................... 37

7.2 Initial commissioning.................................................................................................................................37

7.3 Use........................................................................................................................................................... 37

7.3.1 Operating conditions..............................................................................................................................38

7.4 Recommissioning..................................................................................................................................... 38

7.5 Decommissioning..................................................................................................................................... 38

7.5.1 Temporary decommissioning.................................................................................................................38

7.5.2 Final decommissioning.......................................................................................................................... 38

8 Maintenance and inspections................................................................................................ 38

8.1 Special safety guidelines.......................................................................................................................... 38

8.2 Measures for environmental protection.................................................................................................... 38

8.3 General points.......................................................................................................................................... 38

8.4 Maintenance and inspection intervals.......................................................................................................38

III

Mounting/operating instructions Gear limit switch Type series HGE • No. 152-00000 F • 10/2017

8.4.1 Cleaning.................................................................................................................................................39

9 Troubleshooting...................................................................................................................... 39

9.1 Operational issues and their solutions......................................................................................................39

10 Disassembly.............................................................................................................................39

10.1 Special safety guidelines.......................................................................................................................... 39

10.2 Removing the GTES.................................................................................................................................39

10.3 Final decommissioning............................................................................................................................. 39

11 Ordering spare parts............................................................................................................... 40

11.1 Data for ordering spare parts....................................................................................................................40

11.2 Service address........................................................................................................................................40

12 EC Declaration of Conformity................................................................................................ 41

IV Mounting/operating instructions Gear limit switch Type series HGE • No. 152-00000 F • 10/2017

1 Introduction

1.1 About this documentation

Stromag GmbH, hereafter referred to as Stromag, recommends referring to the dimensional drawing for techni-

cal details such as dimensions, weights in kg, tolerances, tightening torques and operating material required for

assembly, such as safety devices and lubricants.

Should this information be necessary during assembly, a corresponding point in these mounting/operating in-

structions will be referenced on the dimensional drawing.

A dimensional drawing is supplied as a separate document and can be requested additionally from Stromag

Customer Care, see section 4.2. For this, the information on ordering spare parts is required, see section 11.1.

For the purpose of simplification, the following designations are used in the mounting/operating instructions.

• Mounting/operating instructions will be referred to as Documentation in the following.

• The gear limit switch HGE, will be referred to as GTES in the following.

This documentation makes it easier for the operator to familiarise himself with the GTES and to use it for its

intended application.

This documentation covers various GTES designs. The figures used are partly by way of example only. The

specific design of the supplied GTES is shown in the dimensional drawing, see section 4.2.

The documentation contains important instructions on how to operate the GTES safely, properly and economi-

cally. Observing the documentation helps to avoid dangers, to reduce repair costs and down times and to in-

crease the reliability as well as the operating life of the GTES. Read the documentation carefully and thoroughly.

1.1.1 Target group

The documentation is limited to use by qualified as well as trained personnel.

The documentation must be read and applied by every person that is assigned with performing at least one of

the following tasks:

• transport

• assembly

• use

• maintenance and inspections

• troubleshooting

• disassembly

• disposal of operating and auxiliary materials

1.1.2 Use/storage

This documentation must always be kept to hand at the operation location of the GTES. The documentation

must then be integrated into the overall documentation of the machine and into the safety concept.

When selling the GTES, the documentation must also be passed on.

1

Mounting/operating instructions Gear limit switch Type series HGE • No. 152-00000 F • 10/2017

1.2 Using the documentation correctly

1.2.1 Text formats

The following symbols/figures are used for special text positions in the documentation:

Symbol Explanation

● Indicates bulleted lists

— Indicates subordinate bulleted lists

► Indicates handling instructions and information in the safety guidelines

1. 2. 3. et seq. Indicates work steps

Fig. 1, 2, 3, et seq. Numbering of figures

A, B, C, et seq. Indicates areas in the figures

a, b, c, et seq. Indicates dimensions

Indicates position numbers in the figure

(1)/(2)/(3) Indicates position numbers in the text

1.2.2 Definition of terms

Operator

The operator is the businessperson/company that operates the GTES for its intended use or has it operated by

qualified as well as trained personnel.

Trained personnel

Trained personnel include persons who can prove they have been trained by Stromag or in accordance with the

technical documentation provided by Stromag. They are able to carry out the work assigned to them and avoid

known dangers.

User

The user is the person that has been trained by the operator and assigned with the use of the GTES.

Qualified personnel

Qualified personnel are those that are able to carry out the work assigned to them and identify and avoid any

possible dangers as a result of their professional training, knowledge and experience, as well as knowledge of

the applicable standards and guidelines.

Qualified personnel are employees of the operator or those that have been authorised to carry out the work.

Qualified electrician

A qualified electrician is someone who is trained and has knowledge and experience of electrical equipment. As

such, qualified electricians must have knowledge of the applicable standards and guidelines, be able to assess

the work assigned to them and identify and avoid potential hazards.

2Mounting/operating instructions Gear limit switch Type series HGE • No. 152-00000 F • 10/2017

1.3 Warranty and liability

The "General trade and delivery terms and conditions of delivery" of Stromag always apply.

Stromag shall not recognise any warranty or liability claims for personal and material damage if they result from

one or more of the following causes:

• non-intended use of the GTES (see also "Intended use"), see section 2.3

• Failure to observe the information, instructions and prohibitions in this documentation

• unauthorised constructional modifications to the GTES

• insufficient monitoring of parts which are subject to wear and tear

• maintenance work performed improperly or too late

• catastrophic events caused by external influences or force majeure

1.3.1 Guarantee

The "General trade and delivery terms and conditions of delivery" of Stromag always apply.

1.3.2 Copyright

This documentation is a certified document as per the terms of the law against unfair competition.

The copyright is held by:

Stromag GmbH

Hansastraße 120

D-59425 Unna

Germany

This documentation is intended for the operator of the GTES and his personnel. It contains text and drawings

which, without the express permission of the manufacturer, must not be

• reproduced,

• distributed or

• made available to others in any other way, either in full or in part.

Non-compliance will result in damages being sought.

2 For your safety

2.1 Safety concept of the documentation

In accordance with the risk assessment carried out, the safety concept in this documentation is structured in the

following way:

• The general safety guidelines for the operator and the user are listed in this section.

• Section-related safety guidelines are listed at the start of the respective section.

• Safety guidelines related to handling must be followed before each safety-related work step.

3

Mounting/operating instructions Gear limit switch Type series HGE • No. 152-00000 F • 10/2017

2.2 Required personnel qualifications

The following table shows the qualifications specified for the different tasks.

Task Personnel

Transport Trained personnel

Assembly Qualified personnel

Initial commissioning Qualified personnel

Operation Qualified personnel

Preventive maintenance Qualified personnel

Troubleshooting Qualified personnel

Decommissioning Qualified personnel

Disassembly, disposal Trained personnel

• Only employ qualified or trained personnel.

• Do not authorise people whose ability to react is impaired, for example by the influence of drugs, alcohol,

medication or similar. Observe the specific national age guidelines.

• Observe all other nationally-applicable guidelines of the respective country of use.

2.3 Intended use

Gear limit switches of type series HGE are universal, mechanical switchgear for general, industrial applications.

They consist of a two-stage spur gear and a contact space for a maximum of eight contacts. From the gearbox,

a number of revolutions on the input shaft will be reduced to less than one revolution on the cam disc. The gear

switches are used there particularly when reductions and transmissions that are very precise and free of back-

lash appear.

The operation of the GTES is permissible only with the properly installed and functional IP protection class and

by adhering to the technical specifications of the specified operating conditions.

2.3.1 Application limits

The application limits are defined in the technical specifications, see section 4.1. The GTES must not be used in

potentially explosive areas.

2.3.2 Approvals

Overview of the respective national and international approvals of the GTES, see section 4.1.6.

2.4 Non-intended use

Any use other than the intended use of the GTES may lead to dangerous situations.

• Only use the GTES for its intended use in accordance with the details in this documentation, especially in

observing the application limits given in the technical specifications.

• Reconstruction, retrofitting or modification of the construction or individual equipment parts, with the aim of

changing the application range or the usability of the GTES, should be avoided.

• Do not use the GTES as a climbing aid.

Claims for any damage that results from non-intended use are exempted. The operator bears sole responsibility

for damage caused by non-intended use.

2.5 EC Declaration of Conformity

The GTES is supplied with an EC Declaration of Conformity, see section 12. The EC Declaration of Conformity

certifies that the GTES complies with the essential health and safety requirements of the Machinery Directive in

terms of its design, including with the amendments applicable at the time of the declaration.

4Mounting/operating instructions Gear limit switch Type series HGE • No. 152-00000 F • 10/2017

2.5.1 Standards applied

An overview of the applied harmonised standards can be found in the EC Declaration of Conformity supplied.

2.6 Possible residual risks

Residual risks are particular dangers that cannot be eliminated when using the GTES, despite its safety-orienta-

ted construction.

Residual risks are not obviously recognisable and could be the source of a possible injury or health risk.

Special reference is made to possible residual risks in the following:

2.6.1 Mechanical dangers

Danger due to rotating parts during:

• operation without separating protective equipment or safety shut-down

2.6.2 Thermal dangers

Danger resulting from contact with hot surfaces/components when:

• optional heating is installed

• work is carried out on the GTES without personal protective equipment

2.6.3 Electrical danger

Danger due to contact with live components:

• when defect

• with an open housing cover

• caused by improper work on live components

2.7 Safety symbols/pictograms in the documentation

The following safety symbols/pictograms and indications of particularly important details are used in the docu-

mentation.

2.7.1 Warning symbols

Required safety guidelines are indicated in the documentation through pictograms and in addition begin with

signal words that emphasise the extent of damage to be expected.

The safety guidelines are structured as follows:

SIGNAL WORD

Type and source of the hazard

Possible consequences of non-observance, as well as explanations of the source of the hazard.

► Measures/handling instructions to be followed in order to avoid hazards or any damage.

2.7.2 Hazard classifications

The safety symbol in conjunction with the signal word means:

DANGER

Indicates an immediate high risk danger, which can lead to death or serious physical injury if not avoi-

ded.

5

Mounting/operating instructions Gear limit switch Type series HGE • No. 152-00000 F • 10/2017

CAUTION

Indicates a possible medium risk danger, which can lead to death or serious physical injury if not avoi-

ded.

ATTENTION

Indicates a possible low risk danger, which can lead to slight or medium physical injury or material

damage if not avoided.

2.7.3 Mandatory symbols

Basic protection

As basic protection when working, always wear the listed personal protective equipment.

Mandatory symbols Explanation

Wear protective clothing

Wear hand protection

Wear foot protection

Wear head protection

2.7.4 Note

NOTE

Indicates special user tips and other particularly useful or important information for efficient work as

well as economical use.

2.7.5 Environmental protection/recycling

ENVIRONMENTAL HAZARD

Indicates environmental hazards as well as measures for environmental protection.

RECYCLING

Indicates measures for recycling or disposal of components as well as auxiliary and operating materi-

als.

2.8 GTES safety devices

The GTES does not have any safety devices of its own.

Rotating components of the GTES that can cause hazards after assembly due to pulling in, must be secured by

the machine operator.

6Mounting/operating instructions Gear limit switch Type series HGE • No. 152-00000 F • 10/2017

2.9 Safety symbols/pictograms on the GTES

The GTES is equipped with the following safety symbols/pictograms.

Prohibition signs Explanation

Observe the instructions in the documentation.

Do not step on or use as a climbing aid!

2.10 Wear personal protective equipment

Personal protective equipment must be worn for all work to be carried out, see section 2.7.3. The wearing of

personal protective equipment must be monitored by the operator. It may be the case that the operator has to

meet additional measures.

2.11 Basic responsibilities of the operator and personnel

The following fundamental responsibilities of the operator and personnel must always be observed when han-

dling the GTES.

• After assembling the GTES, a risk analysis of the workplace must be carried out by the operator on the com-

plete machine. In addition to the documentation, operating instructions must be created.

• In addition to the documentation, observe and instruct adherence to general legal and other binding regula-

tions on accident prevention and protection of the environment. Such obligations can also, for e.g., affect the

handling of hazardous substances or the provision/wearing of personal protective equipment.

• Supplement the documentation with your own instructions, including supervisory and reporting obligations for

specific operational matters, e.g., with regards to the organisation of work, work sequences and appointed

personnel.

• Never make changes, additions or conversions to the GTES without the manufacturer's approval. If any

changes are made to the GTES that impair safety, they must be reported to Stromag immediately.

• Only use genuine spare parts.

2.12 Safe handling of rotating components

The following safety guidelines must always be observed when handling rotating components.

• Before commencing work, shut down the machine and secure it from switching back on.

• Never operate the machine without separating protective equipment.

• After inspection and maintenance work, remount the separating protective equipment.

2.13 Safe handling with hot surfaces

The following safety guidelines must always be observed when dealing with hot surfaces:

• Before commencing any work, first allow the hot surfaces to cool down.

2.14 Safe handling with electrical hazards

7

Mounting/operating instructions Gear limit switch Type series HGE • No. 152-00000 F • 10/2017

2.14.1 Responsibility of the operator

The operator is responsible for ensuring that the machine is operated in a technically perfect condition:

• The operator must ensure that electrical units are only mounted, modified and maintained by a qualified elec-

trician or under the direction of a qualified electrician, in line with electrotechnical regulations. The operator

must further ensure that the electrical equipment and units comply with electrotechnical regulations.

• Live parts must be protected against accidental contact.

• If a defect is detected in an electrical unit, i.e. if it does not comply or no longer complies with electrotechni-

cal regulations, the operator must ensure that the defect is repaired immediately, and that the electrical unit

is not used in a defective condition if it presents an immediate danger.

• Work on electrical units is only to be performed by qualified electricians in accordance with electrotechnical

regulations. Observe all other nationally-applicable guidelines of the respective country of use.

2.14.2 Applying the five safety rules

The five safety rules must be always observed and applied when working on electrical units.

• disconnect

• secure against reconnection

• de-energise

• earth and short-circuit

• cover or shield any adjacent live parts

If it is not possible to de-energise the unit due to compelling reasons, e.g. when connecting the GTES, the oper-

ator must ensure that:

• the type of instruments or tools used in this work eliminate danger due to electric shock or arcing

• such tasks are only assigned to personnel qualified to work on live parts

• further technical, organisational and personal safety measures are determined and performed if required,

which ensure adequate protection from danger due to electrical shock or arcing

2.14.3 IP protection type and class

After all work that requires the protective casing to be removed or disabled, re-establish the protection class and

perform an operational check before reconnection.

2.14.4 Electromagnetic compatibility

The GTES has been constructed and marketed in compliance with relevant legal harmonisation regulations. It is

the operator's responsibility to ensure that EMC regulations for the machine are observed.

For any further questions or additional support required, please contact Stromag Customer Care.

2.15 Environmental protection

The following instructions must always be observed in order to protect the environment.

• After the final decommissioning/disposal of the GTES, ensure that the individual components, as well as any

possible auxiliary and operating materials, are disposed of in an environmentally-friendly way.

• Recycle all metal and plastic components.

8Mounting/operating instructions Gear limit switch Type series HGE • No. 152-00000 F • 10/2017

3 Transport and storage

3.1 Transport

NOTE

Be particularly careful when transporting the GTES in order to avoid damage caused by external

forces or careless loading and unloading. Depending on the type and duration of the transportation,

corresponding transportation locks have been provided. Remove the transport lock only when begin-

ning assembly, see section 6.3.

The information marked on the packing pieces must be observed.

During transportation, avoid:

► water condensation resulting from severe temperature fluctuations

► impacts

3.1.1 Unpacking

The transportation route is decisive in terms of the type of packing. The information marked on the packing

pieces must be observed.

RECYCLING

Dispose of the packaging material according to the local guidelines properly and in an environmental-

ly-friendly way.

3.2 Scope of delivery

On receipt, check the delivery for completeness using the packing list. Possible damage during transportation

and/or missing parts must be reported immediately, see section 11.2 for the address.

3.2.1 Pre-mounting condition

The GTES is supplied assembled and ready for operation, and is prepared for direct assembly in the machine.

NOTICE

Damage to the machine due to the incorrect adjustment of the GTES

When the GTES has not been adjusted, traverse movements of the machine can lead to damage.

► Before commissioning the machine, always adjust the GTES first in accordance with the specifica-

tions in the mounting/operating instructions.

9

Mounting/operating instructions Gear limit switch Type series HGE • No. 152-00000 F • 10/2017

3.3 Storage

ATTENTION

Damage to the GTES due to incorrect storage

Incorrect storage can lead to damage to the components of the GTES. Only store the GTES under

the following conditions:

► Do not store outdoors.

► Store in a dry and dust-free place.

► Do not expose to aggressive media.

► Avoid mechanical vibrations.

► Storage temperature: same as the ambient temperature during operation, avoid rapid temperature

fluctuations.

► Maximum relative humidity, 60 %.

For storage periods longer than 12 months, the general condition of all parts and the packing must be checked

regularly. Stromag’s Customer Care can provide you with information on this, please refer to section 11.2 for the

address.

NOTE

Details for storage on the packing pieces that go beyond the requirements specified here, must be

observed.

4 Technical specifications

4.1 Product data

4.1.1 Dimensions

For assembly of the housing cover, a clearance space in transverse direction of the height of the housing cover

must be provided.

For the cable entry point, the minimum bending radius of the customer connecting cable must be observed.

4.1.2 Mechanical specifications

NOTE

The shift in revolutions is considered with the viewing direction to the shaft.

If necessary, the maximum input speed can be higher for short time operation. Consulting with Stro-

mag is required.

10 Mounting/operating instructions Gear limit switch Type series HGE • No. 152-00000 F • 10/2017

Gearbox - Table 1 for contacts 80, 81, 88, 90, 90G with cam discs 40° FV70

Nominal revolutions

usable revolutions

with 40° cam disc

Castor revolutions of the

drive shaft after each side

Mechanical Hysteresis

Max. input speed [min-1]

Min. input speed

for alternating operation

[rpm]

Min. drive torque for

switching a single contact

[Nm]

Max. drive torque

for forced opening

of a single contact [Nm]

Contact

80, 90,

90G

Contact 88 Contact

80/81

Contact

90, 90G

Contact 88

9,5 10,67 1,333 0,073 0,097 250 3,638 1,819 0,364 0,20 0,371

18 18,29 2,286 0,125 0,166 250 6,236 3,118 0,624 0,20 0,300

22 22,40 2,800 0,154 0,203 250 7,639 3,820 0,764 0,20 0,281

29 29,64 3,705 0,203 0,269 250 10,108 5,054 1,011 0,20 0,261

35 44,44 5,556 0,305 0,403 500 15,158 7,579 1,516 0,10 0,141

70 76,19 9,524 0,523 0,691 500 25,984 12,992 2,598 0,10 0,124

85 93,33 11,667 0,640 0,846 500 31,831 15,915 3,183 0,10 0,120

100 107,25 13,406 0,736 0,972 500 36,576 18,288 3,658 0,10 0,117

115 123,50 15,437 0,847 1,120 750 42,118 21,059 4,212 0,10 0,115

155 155,56 19,444 1,067 1,410 750 53,052 26,526 5,305 0,10 0,112

180 194,18 24,272 1,332 1,760 750 66,223 33,112 6,622 0,10 0,109

230 230,30 28,788 1,580 2,088 1000 78,544 39,272 7,854 0,05 0,058

260 264,08 33,010 1,811 2,394 1000 90,064 45,032 9,006 0,05 0,057

305 313,21 39,152 2,148 2,839 1000 106,820 53,410 10,682 0,05 0,056

345 352,36 44,045 2,417 3,194 1000 120,172 60,086 12,017 0,05 0,055

460 476,00 59,500 3,265 4,315 1000 162,338 81,169 16,234 0,05 0,054

715 740,44 92,556 5,079 6,712 1000 252,526 126,263 25,253 0,05 0,052

11

Mounting/operating instructions Gear limit switch Type series HGE • No. 152-00000 F • 10/2017

Gearbox - Table 1 for contacts 51 with cam discs 40° FV70

Gearbox - Table 1 for contacts 52, 53 with cam discs 40° FV50

Nominal revolutions

usable revolutions

with 40° cam disc

Castor revolutions of the

drive shaft after each side

Mechanical Hysteresis

Max. input speed [min-1]

Min. input speed

for alternating operation

[rpm]

Min. drive torque for

switching a single contact

[Nm]

Max. drive torque

for forced opening

of a single contact [Nm]

Cont-

Contact 51,

52

Cont-

Contact 51,

52

Cont-

act 53

9,5 10,35 1,650 0,097 250 0,085 5,093 0,20 0,256

18 17,74 2,829 0,165 250 0,146 8,731 0,20 0,233

22 21,74 3,465 0,203 250 0,178 10,695 0,20 0,227

29 28,76 4,585 0,268 250 0,236 14,152 0,20 0,220

35 43,13 6,875 0,402 500 0,354 21,221 0,10 0,114

70 73,93 11,786 0,690 500 0,606 36,378 0,10 0,108

85 90,56 14,438 0,845 500 0,743 44,563 0,10 0,106

100 104,06 16,590 0,971 500 0,853 51,206 0,10 0,106

115 119,83 19,103 1,118 750 0,983 58,965 0,10 0,105

155 150,94 24,063 1,408 750 1,238 74,272 0,10 0,104

180 188,41 30,037 1,757 750 1,545 92,713 0,10 0,103

230 223,47 35,625 2,084 1000 1,833 109,962 0,05 0,053

260 256,24 40,850 2,39 1000 2,101 126,089 0,05 0,052

305 303,91 48,450 2,835 1000 2,492 149,548 0,05 0,052

345 341,90 54,506 3,189 1000 2,804 168,241 0,05 0,052

460 461,87 73,631 4,308 1000 3,788 227,273 0,05 0,051

715 718,46 114,538 6,701 1000 5,892 353,536 0,05 0,051

12 Mounting/operating instructions Gear limit switch Type series HGE • No. 152-00000 F • 10/2017

4.1.3 General information

- independent from the size of the housing

Information Value Comment

Operating time 100 % Suitable for continuous operation

Radial force drive max. 200 N Maximum permissible shear force Fmax

Axial force max. 300 N Maximum permissible axial load of the shaft

Ambient temperature -40°C to +85°C

-30°C to +85°C (for contact 51, 52, 53)

Max. permissible relative humidity 0 to 60 %

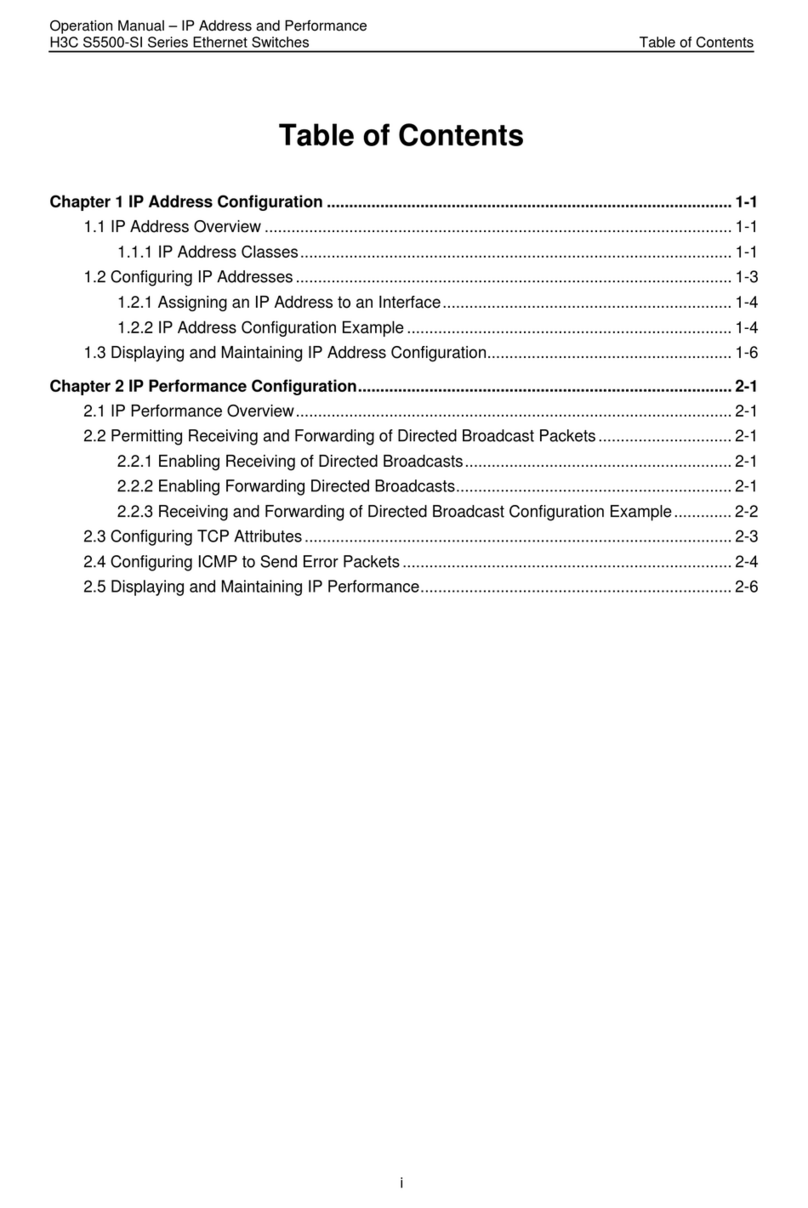

4.1.4 Specific electrical values and position of the contact

EKM-0113

81 3

1

4

2

22

12

21

11

88

3

1

4

2

80

90

90G

12

4

3

21 22

1211

21

43

A) B)

C)

Fig. 1

A80/90/90G: Circuit changeover quick ac-

tion with electrically isolated contact

bridges

C88: Double opener circuit quick action

with contact bridges electrically isolated

from each other

B81: Circuit changeover button with electri-

cally isolated contact bridges

1, 2, 3, 4,

11, 12,

21, 22

Connection points

13

Mounting/operating instructions Gear limit switch Type series HGE • No. 152-00000 F • 10/2017

EKM-0114

51 2

4

1

313

21

14

22

52 22

14

21

13

53

54 4

3

4

3

21 1413

21 22

3 4

D) E)

G)

F)

Fig. 2

D51: Circuit changeover with twin break

electrically isolated contact bridges

G54: Circuit breaker switch

E52: Circuit changeover quick action with

twin break contact bridges electrically iso-

lated from each other

1, 2, 3, 4,

13, 14,

21, 22

Connection points

F53: Circuit changeover button with twin

break contact bridges electrically isolated

from each other

14 Mounting/operating instructions Gear limit switch Type series HGE • No. 152-00000 F • 10/2017

Alternating current AC

Contact Con-

tact

materi-

al

Switc

hing

sys-

tem

Con-

nection

Func

tion

Electrical data Operat-

ing life

Temper-

ature

Designation

Circuit as a changeover

Circuit as an NC contact

Silver

Gold (SPS application)

Quick break switch

Switch

Screw connection; 0,75 - 2,5 mn² AWG 20 ... 14

Forced opening2)

Connecting cable switching power according to EN 60947-5-1

AC-15

Connecting cable switching power according to EN 60947-5-1

AC-12

Ith continuous thermal current

Ui rated insulation voltage

Mechanical Operating life

Service temperature

513) ● ● ● ●

2.5A

230V1)

6A

250V

30x106

-30°C …

+85°C

523) ● ● ● ● ● 10A -25°C …

+80°C

533) ● ● ● ● ● 1x106

54 ● ● ● ● ● 6A 30x106-30°C …

+85°C

80 ● ● ● ● ● 3A

10A 400V

10x106-40°C …

+85°C

81 ● ● ● ● ● 3A

90 ● ● ● ● ● 1A

90

G● ● ● ● ● 0.25A 230V1)

88 ● ● ● ● ● 1.5A 230V1) 1,5x106-55°C …

+85°C

1) Values for resistive load

2) EN 60947–5–1

3) Gold contacts for switching power < 24V – 100mA

15

Mounting/operating instructions Gear limit switch Type series HGE • No. 152-00000 F • 10/2017

Direct current DC

Contact Con-

tact-

mate-

rial

Switc

hing

sys-

tem

Con-

nection

Func

tion

Electrical data Operat-

ing life

Temper-

ature

Designation

Circuit as a changeover

Circuit as an NC contact

Silver

Gold (SPS application)

Quick break switch

Switch

Screw connection;

0,75 - 2,5 mn² AWG 20 … 14

Forced opening2)

Connecting cable switching power

according to EN 60947-5-1

DC-13

Connecting cable switching power

according to EN 60947-5-1

DC-12

Ith continuous thermal current

Ui rated insulation voltage

Mechanical Operating life

Service temperature

513) ● ● ● ● 4A

24V1)

6A

250V

30x106

-30°C …

+85°C

523) ● ● ● ● ● 6A 10A -25°C …

+80°C

533) ● ● ● ● ● 6A 1x106

54 ● ● ● ● ● 1A 6A 30x106-30°C …

+85°C

80 ● ● ● ● ● 1A

110V1)

10A 400V

10x106-40°C …

+85°C

81 ● ● ● ● ● 1A

90 ● ● ● ● ● 0.5A

90G ● ● ● ● ● 0.5A 0.25A 110V1)

88 ● ● ● ● ● 1.5A 24V1) 1,5x106-55°C …

+85°C

1) Values for resistive load

2) EN 60947–5–1

3) Gold contacts for switching power < 24V – 100mA

4.1.5 Contact positions

The required dimensions and weights in kg can be obtained from the respective GTES dimensional drawing.

This can be requested as a separate document from Stromag’s Customer Care department.

16 Mounting/operating instructions Gear limit switch Type series HGE • No. 152-00000 F • 10/2017

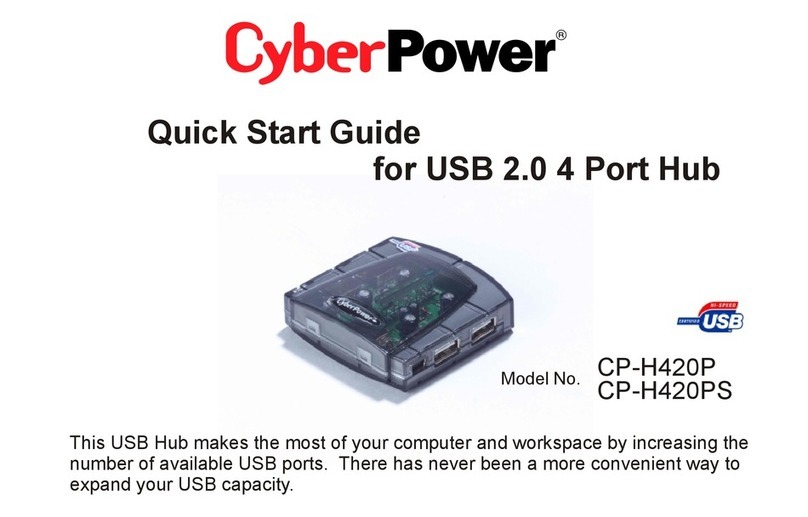

Table of contents

Other Stromag Switch manuals

Popular Switch manuals by other brands

Moxa Technologies

Moxa Technologies TN-5305 Series Hardware installation guide

Ascent

Ascent AT5200 FTTX EDFA Quick reference guide

Edimax

Edimax ES-5160G+ install guide

Leviton

Leviton PowerSwitch DS30-AX installation instructions

Zonet

Zonet ZFS3408EP Product data

StarTech.com

StarTech.com MSTMDP123DP instruction manual