STROMBERG e-FIRE User manual

STROMBERG e-FIRE OWNER’S MANUAL

8BA MODELS

Made by Stromberg in England

SSP 9018V1

If you need further information

or assistance, please contact

your Stromberg dealer,

or e-mail us direct at:

tech@stromberg-97.com

or log on to our Tech Center at:

stromberg-97.com

THANK YOU

for choosing a Genuine Stromberg e-FIRE

electronic distributor for your Flathead Ford.

This Owner’s Manual will make installation and

adjustment as safe and trouble free as possible.

It contains several warnings, cautions and notes.

Please read them all. It also includes important

information about the Stromberg warranty and

what to do if you need help.

If you experience any difficulties with distributor

installation & timing, please check the detailed

Troubleshooting section of this manual first.

There is help available at the Stromberg Tech

Center: www.stromberg-97.com. And you can

contact us direct: tech@stromberg-97.com

WARNINGS AND NOTES:

These instructions must be read and fully understood

before beginning installation, otherwise installation

should not be attempted. Failure to follow these

instructions, including illustrations, may void your

warranty and could result in poor performance, vehicle

damage, property damage, severe personal injury or

death. If you need information or assistance, please

contact your Stromberg dealer or email us direct:

tech@stromberg-97.com

WARNING:

Correct distributor installation and set up is critical

to engine performance, so a thorough knowledge of

vehicle mechanical and electrical systems is required.

Stromberg recommends installation by a professional

mechanic only. An improperly installed or adjusted

distributor may void your warranty and may cause poor

engine performance or damage, property damage,

personal injury or death.

WARNING:

This e-FIRE distributor (12v negative or 6v positive

ground) should be used with a 1.5 Ohm (Ω) coil. Coils

with a higher Ohm rating (often called ‘internally

resisted’) will reduce power to the ignition module

leading to unreliable performance. Remove or bypass

any external ballast resistor or resistor wire. If your

engine has a starter bypass wire, you can leave it in

place. DO NOT use a low resistance or HEI coil. A coil

with LESS than 1.5 Ohms resistance could cause

the ignition module to overheat, misfire and fail

prematurely. This will invalidate the warranty.

WARNING:

This distributor is not designed for use with engines

or transmissions requiring computer-control. Use

with these applications may cause damage. This

distributor is not designed for MARINE or AIRCRAFT

applications.

NOTE: This product is legal only for use off-road or

on pre-emission controlled motor vehicles/

engines. In the USA, this means pre-1966

domestic vehicles certified to California

standards, pre-1968 domestic vehicles

certified to federal standards and all

pre-1968 foreign vehicles.

WARNING:

Before installation, please verify that the vehicle’s

electrical system is in good working order. This includes,

but is not limited to, spark plugs and plug wires, battery,

battery cables, generator or alternator, starter, starter

solenoid and its wiring. Any damaged or improperly

operating components can cause additional resistance

in the circuits and must be replaced prior to installing

the distributor. Failure to do so may result in poor

performance, and could cause a fire resulting in property

damage, serious personal injury or death.

READ THIS FIRST

1. PRE-INSTALLATION CHECKLIST

A) Inspect your new Stromberg e-FIRE distributor

for possible shipping damage. Check you have

the correct model for your application. Model

details are clearly marked on the distributor

packaging and ID plate.

WARNING:

DO NOT proceed unless your vehicle’s electrical

system matches that clearly marked on your

new e-FIRE distributor. The wrong polarity will

cause the e-FIRE ignition module to fail and void

your warranty.

B) Stromberg recommends the use of a traditional,

points style 1.5 Ohm ignition coil for both 12v and

6v e-FIRE distributors. That’s 1.5 Ohm primary

resistance measured across the low tension

positive and negative terminals. 1.5 Ohm coils

are sometimes called 6v or 9v coils, though in

practice, ignition coils are not designed for a

specific voltage input. Please refer back to the

previous page for further advice.

C) With a 12 volt e-FIRE model, battery voltage

measured at the coil’s positive terminal with the

engine running, must not exceed 14 volts at any

RPM level. With a 6 volt model, aim for no more

than 8 volts in the charging circuit, under no

load (ie. no lights, no heater etc.)

WARNING:

Excessive voltage can lead to overheating and

ignition module failure.

D) DO NOT use solid core (typically copper) spark

plug wires, which lack resistance and do not

suppress Electromagnetic/Radio Frequency

Interference (EMI/RFI) which can damage the

e-FIRE ignition module. Stromberg recommends

e-FIRE suppression style high performance spark

plug wires.

E) Unlike a points distributor, electronic ignition

needs a reliable, independent power feed and

quality ground (earth) connections. On 6 volt

models, choose a power source as near to

the ignition key as possible. Check all ground

connections and even run an additional engine

ground if required.

1

USE E-FIRE HIGH PERFORMANCE

SPARK PLUG WIRES.

Designed for optimum performance with your e-FIRE

electronic distributor, Stromberg e-FIRE spark plug

wires mix strong fire power with high level RFI/EMI

resistance. The spiral-wound, stainless steel

suppression core is protected by tough fiberglass

reinforcing braid for strength and flexibility. And the

100% silicone insulation resists high temperatures,

moisture, oil and chemicals, and protects against

arcing and voltage leaks. With low 500 Ohm/ft

resistance, they get more energy into your plugs too.

For easy installation, the 90-degree cap terminals

and boots are pre-fitted for smarter ‘distributor

first’ installation. This also leaves you free to use the

supplied 90-degree spark plug boots or choose your

own hot rod terminals. All leads are designed to fit

through your flathead

plug wire looms or

tubes, and they’re cut

to length, too, with an

extra-long coil wire

to reach your firewall.

2

F) This e-FIRE distributor fits all of the different

Ford 8BA front covers (distributor mounts). If it

is too tight and the flange won’t sit down onto

the cylinder head, the hole might be rusted or

corroded, so open it out to the OE spec - 3/4in

(19mm). Please note that the slot in the end

of the shaft is used for Stromberg in-house

assembly and pre-ship testing only. Every e-FIRE

distributor is machine tested before boxing to

check timing and high tension function to the

spark plugs.

2. REMOVE EXISTING DISTRIBUTOR

A) Disconnect the vehicle’s battery. Remove the

condenser and any radio suppressors. They are

not required, nor compatible with the Stromberg

e-FIRE distributor. Disconnect the distributor low

tension wire at the coil.

WARNING:

Always disconnect your vehicle’s battery, making

sure the ignition is off and the engine is cool before

performing any work. Failure to do so may result

in sparks or burns, and cause a fire or explosion,

resulting in property damage, serious personal

injury or death.

B) If you are replacing the original Ford Loadomatic

distributor, carefully disconnect the vacuum

advance line at the distributor and carburetor.

It is not required by the e-FIRE distributor. Plug

the vacuum line port in the carburetor.

C) Disconnect the spark plug wires from the

distributor cap. To make replacement easier

on the new distributor, label each wire with its

destination cylinder number.

D) Remove the cap from the original distributor

and make a note or mark where the rotor points

BEFORE removing the distributor from the

engine. THIS IS VERY IMPORTANT! Take a photo!

Now remove the clamp and the old distributor

from the engine.

3. INSTALL NEW DISTRIBUTOR

A) If you are simply replacing another distributor,

smear the drive gear with a little engine

assembly lube and install the new e-FIRE

distributor into the 8BA timing cover engaging

the drive gear into the camshaft gear so that

the rotor points in the same direction as your

old one did (you marked it, remember?). As the

distributor seats down onto the head, the rotor

will spin clockwise as the gears engage, so you

will need to start further counter-clockwise

(about 40 degs) to end up in the right spot.

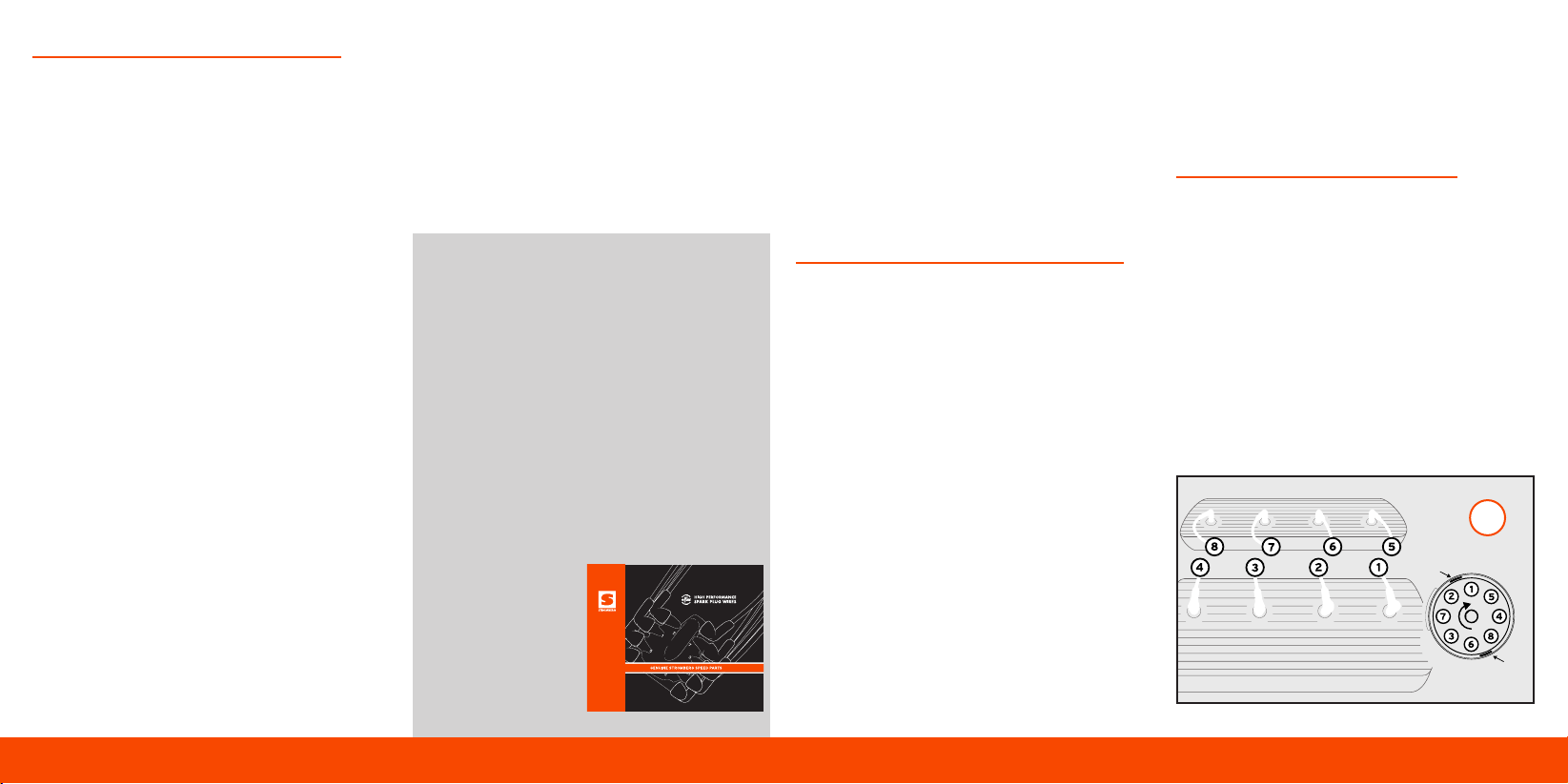

B) If you are building a new engine, crank it to

Top Dead Center on the compression stroke of

Number One cylinder (See A) and install the new

CLIP

CLIP

A

e-FIRE distributor with the rotor pointing

to your Number One plug terminal on the

cap. We recommend the Ford Service Manual

designated Number One as shown in A. If your

engine has a timing mark, crank the engine

until the pointer lines up with the mark on the

crank pulley on the compression stroke.

C) Install the bolt, spring washer and clamp

(See B). Do not overtighten the bolt. Check

that the distributor flange sits flat on the

mounting surface.

D) Connect the spark plug wires following the

correct firing order and cylinder positions (See

A). The distributor turns clockwise.

E) 12 volt negative ground e-FIRE distributors have

red and black low tension wires. Connect the

black wire to the negative ( - ) side of the ignition

coil. Connect the red wire to the positive ( + )

side of the ignition coil or other power source

controlled by the ignition switch (See C).

3

CLIP

CLIP

B

C

D

F) If your ignition has a primary circuit ballast

resistor or wire, connect the red wire to the

ignition switch side of the ballast resistor (See D).

If the position of the ballast resistor or wire is not

known, connect the red wire direct to the ignition

switch or to a switched live on the fuse box - on

the key side of the fuse.

G) On a 6 volt positive ground model, remove the

ignition switch (power) wire from the negative

( - ) coil terminal and connect the black module

wire to the same negative terminal. Connect the

white wire to that ignition switch power wire. DO

NOT attach the white wire to the ignition coil.

(See E). Connect an insulated AWG 20 copper

stranded wire from the positive coil terminal

direct to a good quality chassis ground.

Note: Most early Ford 6 volt positive ground coils were

ballast resisted. If possible connect the white module

wire to the switched ignition side of the resistor (often

located under the dashboard).

H) Terminals are supplied. Use standard auto wire

- 20 gauge (1.5mm) 15 amp – to lengthen any

wires. Crimp tightly or solder (best) the joints and

insulate all connections. Do not pull on the wires

causing them to tighten inside the distributor

cap. The wires must allow movement of the

timing adjustment plate, yet not interfere with

any moving parts (See F).

WARNING:

DO NOT reverse the polarity of the wires from the

advice above. It will damage the ignition module

irreparably and void the warranty.

I) 12 volt negative ground e-FIRE distributors are

compatible with most Capacitor Discharge Ignition

units. Follow the manufacturer’s instructions,

connecting the black wire to the CDI unit as if

connecting your low tension wire. The red wire

is connected to the same switched power source

as the CDI unit. DO NOT connect the red wire to

the coil. 6 volt positive ground models are NOT

compatible with CDI units.

4

CLIP

CLIP

F

E

6

6. TROUBLESHOOTING

Every single e-FIRE distributor is factory-tested

before shipping to check advance from idle up

through the rpm range, and high tension function

to the spark plugs. Experience has shown that our

ignition modules are very robust. So if you have

a problem, please read this before contacting

Stromberg or your dealer.

A) If the engine will not start after installation,

begin with the usual diagnostics. Are your plug

wires connected properly? Do you have fuel?

Is there a spark out of the coil into the cap? If

the engine runs, but won’t pick up, do you need

to adjust the timing?

B) Your old points distributor may run fine with

weak input voltage, but any electronic distributor

will struggle without a reliable power source and

a good ground (earth). This is VERY important,

especially on 6 volt models where under-

charged batteries, hidden ballast resistors,

high-resistance coils, old wiring and worn starter

motors can leave your e-FIRE without the power

it needs. Please check it still gets a good 6 or 12

volts WHEN CRANKING the starter.

C) The above also applies if the engine runs roughly,

especially at higher rpm. If so, use a jumper

cable to connect the e-FIRE power wire direct

to the battery. If running improves, this usually

indicates low voltage to the module, often caused

by a ballast resistor or a high Ohm coil. So try

connecting the power wire to a more direct

source, like the ignition switch. And/or swap the

coil to the recommended 1.5 Ohms. Performance

will also be compromised if the ground (earth)

is poor. So check for good continuity from the

e-FIRE module mounting plate to ground.

D) Remember, too, that the electronic module is

a switch for the coil. It does not govern spark

strength. And if it sparks to one plug, it should

spark to them all.

E) If at any point the module is wired incorrectly,

supplied with excess voltage or the polarity

reversed, it may fail and void your warranty. For

further troubleshooting tips, visit the Stromberg

Tech Center at: www.stromberg-97.com

7. MAINTENANCE

A) The e-FIRE 8BA distributor is designed for low

maintenance. The top shaft bearing is sealed for

life, with a separate seal to stop oil entering the

distributor body. The oilite bearing at the bottom

also requires no maintenance. After an initial

running period, we recommend that you check

and retighten the distributor clamp along with

all electrical connections, including the spark

plug wires.

B) Further down the road, a little annual aftercare

can pay dividends. A single drop of light oil on

the felt pad under the rotor will help keep the

advance plate moving, for example. And while

you should aim to keep water and road salt out

of the distributor, it is known that air inside any

distributor cap becomes ionized and attracts

moisture which can cause corrosion over time.

All of the e-FIRE steel internal parts are zinc

plated, but a light spray of water displacement

lube to the advance mechanism (under the

module plate), will keep the advance weights

moving as they should.

C) Stromberg e-FIRE service parts are recommended

for reliable fit and service life. Always use

Stromberg e-FIRE ignition modules.

4. START THE ENGINE

WARNING:

If your vehicle has a manual transmission, verify

that it is not in gear and that the parking brake is

on before starting. With an automatic transmission,

confirm that it is in ‘park’ or ‘neutral’ before

starting. Failure to do so may result in unintended

vehicle movement causing property damage,

serious personal injury or death.

A) Connect the battery and start the vehicle as usual.

Some fine tuning of the distributor timing may be

required both to start the engine and set the static

timing at idle (See Section 5. Engine Timing). Pay

particular attention to any knocking, pinking or

detonation sound under engine load, which may

indicate excess advance. If so, stop the vehicle,

retard the static timing a little (See H) and

test again.

B) Run the engine to full operating temperature,

then check it idles and revs freely and take it for

a test drive. If you suspect any problems, stop

the engine immediately and refer to Section

6. Troubleshooting.

WARNING:

Too much distributor advance can cause engine

detonation, which can damage an engine very

quickly. If you hear detonation, stop the engine

immediately and retard the timing.

WARNING:

DO NOT leave the ignition switched on when the

car is not running, as this can cause permanent

overheating damage to the coil and ignition module.

5. ENGINE TIMING

A) To adjust the initial (static) timing on this

distributor turn the body counter-clockwise to

advance engine timing or clockwise to retard

(See H). The adjustment is sensitive - one degree

at the distributor is two degrees at the crank.

Always remember to tighten the clamp bolt. For

best results, use the engine’s timing marks and a

timing light. The recommended static timing for

a stock 8BA engine is 4 degrees BTDC (Before

Top Dead Center). Different settings may

be required for non-standard engines and

differences in local gasoline.

B) The e-FIRE distributor provides a further 22

degrees maximum mechanical advance at

around 2600rpm. While the e-FIRE allows

adjustment of the total advance, for most

customers, there is no need to change the

factory setting.

WARNING:

Always take considerable care when adjusting

distributor timing. Failure to do so may result in

property damage, severe personal injury or death.

5

CLIP

CLIP

H

8

Warranty Exclusions

Stromberg does not warrant products which are

damaged as a result of improper installation or

application, including but not limited to:

1. Failing to follow or deviating from any installation

guidance provided by Stromberg, including

incorrect wiring, a coil with insufficient resistance,

excess voltage, and reversed polarity.

2. Modifying or altering the distributor beyond

factory specifications, outside what could be

considered tuning for optimum performance

3. Subjecting the product to adverse conditions,

overheating, abuse, neglect, accident, collisions,

dirt or contaminants, water or corrosion, or faulty

repair; and improper adjustment.

4. Stromberg also does not warrant, and disclaims

all liability for, products used for racing, or any

non-automotive, marine, or aircraft application

or purpose.

Stromberg is the sole and final judge of whether a

product is covered by the warranty. In the event that

Stromberg determines that a defect in material or

workmanship exists, Stromberg’s responsibility is strictly

limited to the repair or replacement of the defective

product or parts, as Stromberg elects, and the return

of the repaired or replaced product or parts to the

Purchaser, freight prepaid. Stromberg has no other

obligation, and makes no other warranties – whether

express or implied.

As used herein, the term ‘Purchaser’ shall mean

the original purchaser or consumer of the

Stromberg product. The Limited Warranty is

restricted to the Purchaser. The warranty is not

assignable or otherwise transferable.

NOTES:

7

8. WARRANTY

All Stromberg products receive numerous

checks and tests to ensure optimum quality and

performance. Stromberg also takes customer

support very seriously, and this extends to fair

Limited Warranty terms and procedures across

our full product range as outlined below.

Stromberg warrants its new products to be free

from defects in material and workmanship for

one (1) year from the date of original purchase

by the Purchaser.

Limited Warranty

STROMBERG PROVIDES NO WARRANTY EITHER

EXPRESS OR IMPLIED OTHER THAN THIS

LIMITED WARRANTY. STROMBERG EXPRESSLY

DISCLAIMS ALL IMPLIED WARRANTIES OF

ANY KIND INCLUDING, BUT NOT LIMITED

TO, MERCHANTABILITY AND FITNESS FOR A

PARTICULAR PURPOSE. IN NO EVENT SHALL

STROMBERG OR ITS AGENTS, EMPLOYEES,

OFFICERS, DIRECTORS, RELATED ENTITIES

OR SUCCESSORS, BE LIABLE FOR SPECIAL,

INCIDENTAL, CONSEQUENTIAL, OR PUNITIVE

DAMAGES ARISING OUT OF, OR IN CONNECTION

WITH, PRODUCTS OR SERVICES SOLD, WHETHER

BASED IN WARRANTY, CONTRACT, TORT

(INCLUDING NEGLIGENCE AND STRICT LIABILITY),

OR ANY OTHER LEGAL THEORY. STROMBERG’S

MAXIMUM LIABILITY SHALL NOT EXCEED THE

PURCHASE PRICE OF THE PRODUCT. STROMBERG

NEITHER ASSUMES, NOR AUTHORIZES ANY OTHER

PERSON TO ASSUME FOR US, ANY OTHER LIABILITY

IN CONNECTION WITH THE SALE OF THIS GENUINE

STROMBERG PRODUCT. STROMBERG DOES NOT

WARRANT WHATSOEVER ANY ACCESSORIES OR

PARTS SUPPLIED BY OTHER MANUFACTURERS.

Any implied warranty determined to be applicable is

limited in duration to the duration of this warranty. This

warranty gives you specific legal rights. However, you

may also have other rights that may vary from state

to state or province. This Limited Warranty constitutes

the entire understanding between Stromberg and

the Purchaser.

Warranty Procedure

To claim under this Limited Warranty:

1. CONTACT US FIRST! You can email us at warranty@

stromberg-97.com. Most distributor issues are simple

and can be addressed quickly with email advice. Please

remember to check Section 6. Troubleshooting and

look for further advice on the Stromberg Tech Center

at www.stromberg-97.com

2. If you cannot contact us, contact the place of

purchase, providing the dated purchase receipt and

a clear description of the problem.

3. If the product needs replacement, we will provide a

Return Goods Authorization (RGA) number and an

address for return. We will provide a replacement

on return of the product so enclose your RGA

number and a return address. NO RETURNS WILL

BE ACCEPTED WITHOUT AN RGA NUMBER. No

replacements will be shipped without return of the

original product.

DO NOT send products directly to Stromberg without

our prior notice. Stromberg assumes no responsibility

for products sent directly to Stromberg.

Table of contents

Other STROMBERG Automobile Accessories manuals