PREFACE

THESTRONGXENONSUPERTROUPER®isadirectcurrentfollowspotlight

systemcompletewithaxenonlamphouse,powersupply,opticalsystem,andaoorstandandyoke

assembly.Anoptionalsix-color,selfcancellingboomerang(OrderNo.7201188;seeFigure7)may

beorderedwithnewequipment,oritcanbeaddedatalaterdate.

ONLY THE SPECIAL XENON POWER SUPPLIES manufactured by Strong

Internationalcanbeusedwiththexenonspotlight.

Forinstallationandoperationofthepower

supply,seetheinstructionmanualfurnishedseparately.

THEXENONLAMPHOUSEutilizesadeepellipsedichroicmetalreectordesignedto

operateinaxedpositionwithahorizontallymountedxenonbulbasthelightsource.Aheatlteris

locatedinthefrontofthelamphousetoreducetheheatattheopticalsystemandcolorboomerang.

ONLY XENON BULBS designed for horizontal operation should be used in this

spotlight.Thelamphouseisdesignedforusewiththestandard2000watthorizontaltheatrebulb,

andanoptionalAdapterKit(OrderNo.7201192)allowsuseof1000and1600wattbulbs.Seethe

listinginthismanualfortheapprovedtypesandnecessaryadapters.

ADJUSTMENTCONTROLforpositioningthexenonbulbislocatedattherearof

thelamphouse.Theadjustmentsareforthehorizontal,vertical,andfocuscontrolofthebulb.

THELAMPHOUSE INSTRUMENTPANELisequipped withan ammeterand

runningtimemeter.Theammeterindicatestheoperatingcurrentofthelamp,andtherunningtime

meterrecordsthenumberofhoursthelamphasoperated.Thexenonbulbisignitedandextinguished

byuseoftheLAMPswitchmountedontheinstrumentpanel.

THELAMPBLOWER,internallywiredinthelamp,operateson115V.ACandis

requiredtokeep thesealson thebulbatasafeoperatingtemperature. Thisblower willoperate

continuouslyuntilpoweristurnedoffatthemainlineswitchtothexenonpowersupply.Anair

owswitchinthelamphousepreventsoperationofthexenonlampiftheblowerisnotoperating,or

ifairowisinadequate.Ifadditionalcoolingisrequired(i.e.50Hertzpowersource),anoptional

ExhaustBlowerAssembly(7201036;seeFigure8)maybemountedtothetopofthelamphouse.

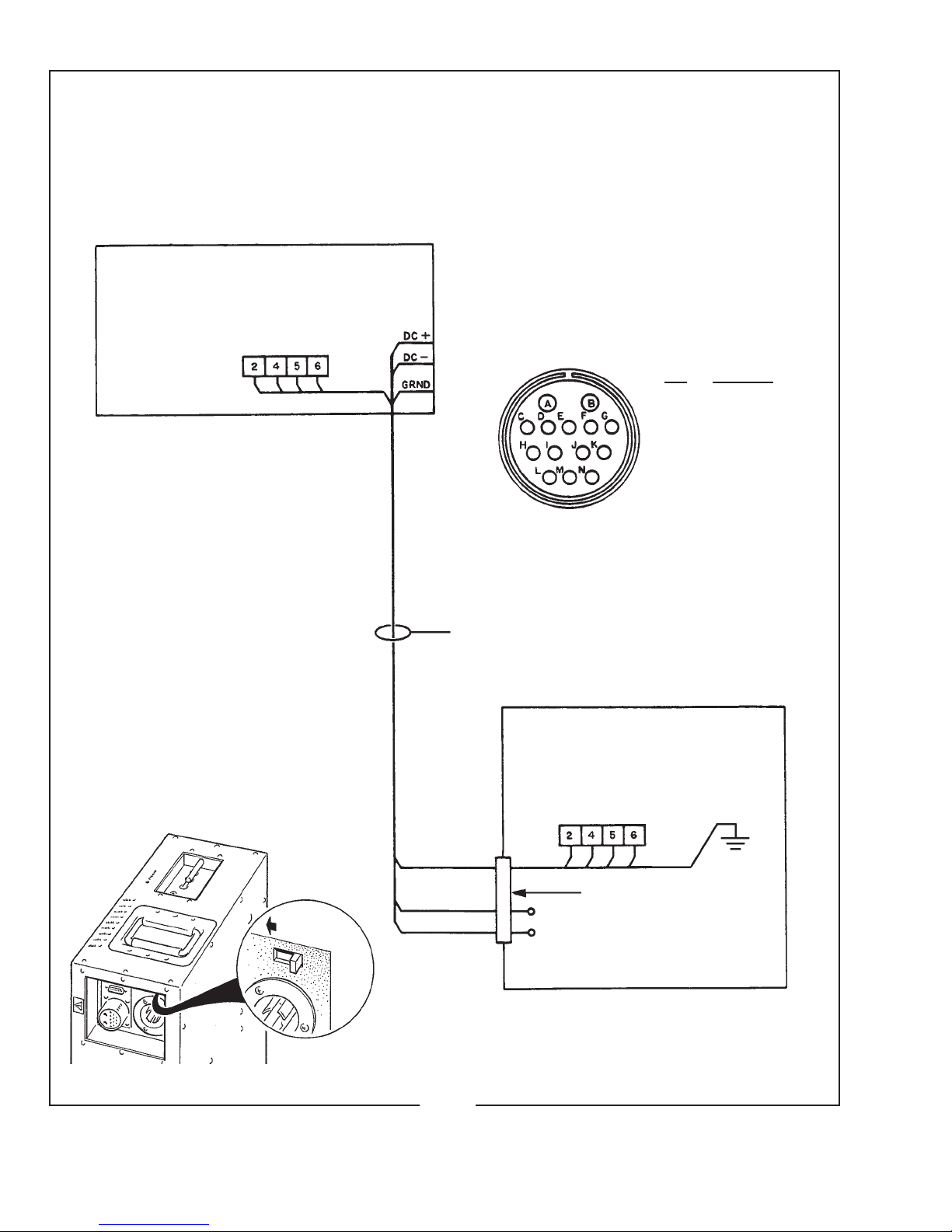

THELAMPHOUSEissuppliedwitha11foot(3.35m)cablecontainingthetwoDC

leads,thegroundlead,andallACcontrolleads.Thecableterminatesinamultiple-pinMSconnector

tomatetoacorrespondingreceptacleonthexenonpowersupply.

WHENTRANSPORTINGthefollowspotlight,itisrecommendedthatthexenonbulb

beremovedfromthelamphouseandplacedinitsoriginalshippingcartonwiththeprotectivecover

onthebulbtopreventbreakage.

XST/001