Stryten Energy M Series User manual

M-SERIES

1

Li510 LITHIUM-ION BATTERIES

SERVICE MANUAL

WARNINGS AND GENERAL INFORMATION

Observe these Instrucons and keep

them located near the baery for future

reference. Work on the baery should

only be carried out by qualied personnel.

While working on baeries wear

protecve eye-glasses

and clothing.

Cauon – parts of the baery may carry

dangerous voltages. Be careful when

handling cables.

Keep baery dry.

DO NOT smoke.

DO NOT dispose of the baeries in a re.

DO NOT dispose of the baery in

normal waste.

DO NOT include baery with lead acid

baery recycling.

Explosion and re hazard. Avoid short

circuits. Avoid electrostac charges and

discharges/sparks.

Keep children away from baeries.

DO NOT pressure wash.

- Lithium Baeries are heavy. Make sure

they are installed securely.

- Handle with care, avoid mechanical shock.

- Do not li or pull up on power or

communicaon cables.

- Avoid wearing any loose metallic items

such as jewelry, watches, or bracelets

- Corrosive contents! Do not open. Avoid

contact with contents of a damaged

baery.

- To avoid the release of harmful gases,

avoid deeply discharging, charging

when damaged, and improperly charging

the baery.

- Use cered insulated safety tools for

installaon. Any work procedures

and tools used should be in compliance to

EN 60900 or similar standard.

Baery may require recycling in

accordance with local laws. Contact Stryten

Energy or regulatory authories for further

informaon. DO NOT include baery with

lead acid baery recycling.

Tray liing at this area.

Li510

Previously LiFT FORCE LPX 2.0

2

M-SERIES

Do not break the warranty seals of any

baery without authorizaon from Stryten

Energy Service! Breaking a warranty seal

without authorizaon from Stryten Service

will void the warranty.

Stryten Energy Move Power Service 1-866-462-2288 strytenncc@stryten.com

Li510

Before working on any baery, a Stryten

Energy ServiceMAX cket must be created!

Contact Stryten Energy customer service if

you need assistance creang a ServiceMAX

cket.

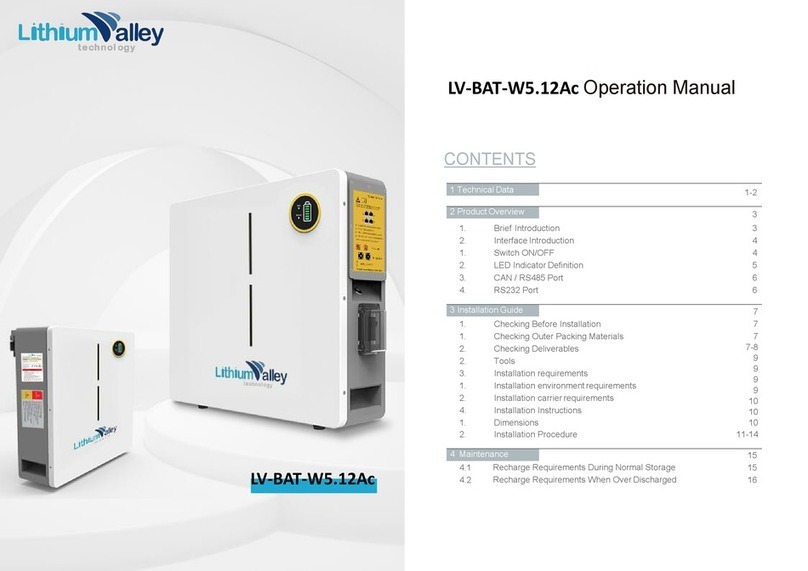

TABLE OF CONTENTS

Baery System Diagram ................................................................................................................................................... 3

Major Components............................................................................................................................................................ 4

Idenfying Li510 Baery Informaon ............................................................................................................................ 4

Opus Baery Data Display ............................................................................................................................................... 5

Baery Power Switch LEDs .............................................................................................................................................. 6

Periodic Maintenance ....................................................................................................................................................... 7

Fully charging the baery ............................................................................................................................................. 7

Keeping power and aux contacts on charger connector clean ................................................................................. 7

Checking cable from baery to Forkli ...................................................................................................................... 8

General Operaonal Consideraons ........................................................................................................................... 8

Troubleshoong Issues During Baery Operaon ....................................................................................................... 8

SOC on Opus display does not match Forkli BDI display ......................................................................................... 8

Forkli goes into “turtle” mode at high or low SOC .................................................................................................. 9

Baery quickly drops to low state of charge aer charging ..................................................................................... 9

Baery beeps for 15 seconds and stops with Over Current CHG warning .............................................................. 9

Forkli will not operate – All zeros displayed on Opus display ............................................................................... 10

Forkli will not operate – All values displayed on Opus display are normal ......................................................... 10

Forkli will not operate – Low SOC Alert ................................................................................................................. 10

Troubleshoong Issues During Baery Charging ........................................................................................................ 11

Opus displays High temperature warning during charge ........................................................................................ 11

Troubleshoong M-Series X-3 and X-7 charger communicaon problems:........................................................... 11

Instrucons for downloading charger records from Stryten Energy M-Series X-3 and X-7 chargers.....................13

Service/repair of REMA320 and REMA640 Charger connectors ............................................................................... 15

3

M-SERIES

Li510 BATTERY SYSTEM DIAGRAM

Li510

M-Series

X-3 and X-7 1ph 24v 1ph 36v ELi

M-SERIES

4

MAJOR COMPONENTS

Components used by Operators, most commonly

serviced:

Charger Connector – Delivers power from charger.

DIN320 or DIN640, per current requirements. Uses aux

pins for communicaons with charger

Forkli cable and connector – Delivers power to

forkli, connector type per customer specicaon

Power Buon and Buzzer – Acvates baery, alert

operator of warnings as needed

Opus Display – Provides baery informaon to

Operator such as State of Charge (SOC) and other

status informaon

Components interior to the baery, not typically

serviced:

Power Modules – Congured in series and/or parallel

to achieve baery voltage and capacity per customer

requirements

BMS – Controls System operaon, Monitors Power

Modules

Power Contactors – Controlled by BMS. Used to

Isolate truck while charging and as needed for system

safety events

Charger and Forkli Fuses – Protect against system

overcurrent

Baery Tray – Protects components and provides

ballast for forkli

Power Bus – Power distribuon to and from individual

Power Modules

CANbus and Safety Line – Between BMS and all

modules.

IDENTIFYING Li510 BATTERY

INFORMATION

Every Li510 baery has a label plate on the lid of

the baery which idenes the following baery

informaon:

• Nominal Voltage

• Max Charge Voltage

• Capacity in Ahrs

• Energy in kWh

• Weight, in kg and lbs

• Model number

• Serial Number

Before servicing a Li510 baery, make sure to note

the model and serial number of the baery, in the

event that this informaon needs to be provided to

Stryten Energy Service. (See below)

Li510

M-SERIES

5

Li510

OPUS BATTERY DATA DISPLAY

The Opus Display shows State of Charge (SOC), baery

temperature, voltage and current. The display is used

primarily by the Operator to monitor SOC in between

charging breaks. (See below)

If the BMS detects a warning or alarm condion, it will

show the warning or alarm on the display. (See below)

For warnings, the buzzer will beep once per second.

Otherwise, the baery operates as normal. For alarm

condions, the buzzer beeps 3 mes per second for

15 seconds, to alert the operator that the baery will

shut o and forkli operaon will be disabled in 15

seconds.

Once the alarm condion is removed, the baery

can be restarted with the power/reset buon. When

troubleshoong a Li510 baery, be sure to note the

values displayed on the Opus screen before, during

and aer baery problems occur.

The following Warnings, Alarms and Alerts

may be displayed on the Opus during normal

operaon:

Low SOC Warning – typically the most common

warning, indicang that the baery needs to be

charged soon

Low SOC Alert – If the Baery reaches 0% SOC, the

baery will shut itself o in order to protect itself.

The buzzer beeps 3 mes per second for 15 seconds,

to alert the operator that the baery will shut o and

forkli operaon will be disabled in 15 seconds. If a

baery shuts o with a low SOC Alert, it can be reset

one me, aer which the forkli must immediately

return to the charging area so that the baery can be

charged

Low Voltage Alarm – If following a Low SOC Alert, the

baery is not immediately charged and connues to

be used, the baery will further protect itself with

a Low Voltage Alarm. Aer the Low Voltage Alarm

occurs, the baery cannot be reset and the forkli

must be towed back to the charging area

Low Voltage Warning – If the baery is at low SOC

and the forkli is performing work that puts a heavy

power load on the baery, a Low Voltage Warning

may occur. This is another indicaon that the baery

needs to be charged.

High or Low Temperature Warning – If the baery

gets within 5C of its high or low temperature limits, a

warning will be displayed on the Opus

High or Low Temperature Alarm – If the baery

exceeds its high or low temperature limits, an alarm

will be displayed on the Opus. The buzzer will beep

rapidly for 15 seconds, aer which the baery will

shut down for protecon.

The following Warnings, Alarms and Alerts

may be displayed on the Opus during error

condions:

Please Check CAN Communicaon – If this alarm

occurs during charging, it is typically indicave of

a communicaon error between the charger and

baery. This alarm is usually resolved by servicing

of the AUX pins on the charger connector on the

baery and / or the Aux pins on the charger’s

output connector. If this error occurs during forkli

operaon, with no charger present, it may

indicate a CAN communicaon error inside

M-SERIES

6

Li510

On / O buon LED Green LED Red

System in Standby mode O O

System acve, no alarm or warning detected Once per second O

Warning O Once per second

Alarms O Three per second

Buon pressed for less than 5s to Reset

Warnings / Alarms On as long as buon is pressed O

Buon pressed for more than 5s to move

from acve to Standby mode O On as long as buon is pressed

Buon is pressed in standby mode and the system

is moved into acve mode On as long as buon is pressed O

the baery, in which case contact Stryten Energy

Service to arrange for factory repair.

Over Current CHG Alert – This Alert is typically

indicave of a loose current shunt in one of the

power modules. It typically occurs when the forkli is

operang, and results in the baery powering down

aer issuing an alarm beep for 15 seconds. In some

cases the problem may stop aer the baery is reset,

however this issue, once presented, usually reoccurs

with increasing frequency. If this message occurs,

contact Styrten Energy Service to arrange for factory

repair.

Plug Removed DIS Alert – This Alert is typically

indicave of a loose current shunt in one of the power

modules. It typically occurs when the baery is put

on charge, and results in the baery powering down

aer issuing an alarm beep for 15 seconds. In some

cases the problem may stop aer the baery is reset,

however this issue, once presented, usually reoccurs

with increasing frequency. If this message occurs,

contact Stryten Energy Service to arrange for factory

repair.

Safety line Alert – This Alert indicates that either one

of the Power Modules has detected a problem or that

one of the internal CAN communicaon lines is loose.

If this message occurs, contact Stryten Energy Service

to arrange for factory repair.

Plausibility Error – The BMS has detected inconsistent

readings between Power Modules in the baery. This

may indicate that a module has a blown fuse, a low

voltage cell block, or some other unusual condion. If

this message occurs, contact Stryten Energy Service to

arrange for factory repair.

BATTERY POWER SWITCH LEDs

The Li510 Baery power/reset switch has two LEDs

that are also used to indicate status of the baery.

The power / reset switch is located on the gland pod,

on top of the baery, on the same side of the gland

pod as the buzzer.

To power the baery on, press and hold the Power/

Reset buon unl it turns green (aprox 1s). To power

the baery o, press and hold the Power/Reset buon

unl it turns red (aprox 5s). When troubleshoong a

baery, make sure to note the status of the switch

LEDs (See below)

M-SERIES

7

Li510

PERIODIC MAINTENANCE

Fully charging the baery

In order to keep all the cells in the baery balanced, it

should be fully charged to 100% State of Charge (SOC) at

least once per week and ideally once per day, as shown

on the M-Series X-3 and X-7 charger screen below.

12

LiFTFORCE 2.0 Service manual

Confidential material of Stryten Energy

Periodic Maintenance

Fully charging the battery

In order to keep all the cells in the battery balanced, it should be fully charge to 100% State of Charge

(SOC) at least once per week and ideally once per day, as shown on the Fury charger screen below

In order to make sure that the battery is fully charged, plug the battery into the charger and do not

disconnect the battery until the “Complete” status is shown on the charger. Make sure that the weekly

charging schedule allows adequate time for the battery to get a full charge once per week and ideally

once per day

In order to make sure that the baery is fully

charged, plug the baery into the charger and do not

disconnect the baery unl the “Complete” status

is shown on the charger. Make sure that the weekly

charging schedule allows adequate me for the

baery to get a full charge once per week and ideally

once per day.

Keeping power and aux contacts on charger

connector clean

Make sure that the blue coding key is installed

properly and that the interior mang surfaces of the

2 power pins and 4 aux pins on the charger connector

are clean. Clean the interior of the pins with either

95% ethanol or 91% isopropyl alcohol and swabs.

This should be done at least every six months in a

clean facility and more oen for facilies with large

amounts of airborne material.

13

LiFTFORCE 2.0 Service manual

Confidential material of Stryten Energy

Keeping power and aux contacts on charger connector clean

Make sure that the blue coding key is installed properly and that the interior mating surfaces of the 2

power pins and 4 aux pins on the charger contactor are clean. Clean the interior of the pins with either

95% ethanol or 91% isopropyl alcohol and swabs. This should be done at least every six months in a

clean facility and more often for facilities with large amount of airborne material

REMA640 Charger connector contacts

REMA320 Charger connector contacts

REMA640 Charger connector contacts

REMA320 Charger connector contacts

13

LiFTFORCE 2.0 Service manual

Confidential material of Stryten Energy

Keeping power and aux contacts on charger connector clean

Make sure that the blue coding key is installed properly and that the interior mating surfaces of the 2

power pins and 4 aux pins on the charger contactor are clean. Clean the interior of the pins with either

95% ethanol or 91% isopropyl alcohol and swabs. This should be done at least every six months in a

clean facility and more often for facilities with large amount of airborne material

REMA640 Charger connector contacts

REMA320 Charger connector contacts

When the blue coding key is inserted properly, the

baery voltage will be visible through the hole in the

top of the connector. See the secon on servicing the

charger connector if the coding key is not installed

properly.

14

LiFTFORCE 2.0 Service manual

Confidential material of Stryten Energy

When the blue coding key is inserted properly, the battery voltage will be visible through the hole in the

top of the connector. See the section on servicing the charger connector if the coding key is not installed

properly.

M-SERIES

8

Li510

Checking cable from baery to Forkli

Check the connector to the forkli to make sure that

it is inserted ghtly. Also check the exit point of the

baery compartment to make sure that the power

cables to the forkli are not rubbing on any metal

surface where they could be abraded.

15

LiFTFORCE 2.0 Service manual

Confidential material of Stryten Energy

Checking cable from battery to Forklift

Check the connector to the forklift to make sure that it is inserted tightly. Also check the exit point of the

battery compartment to make sure that the power cables to the forklift are not rubbing on any metal

surface where they could be abraded

15

LiFTFORCE 2.0 Service manual

Confidential material of Stryten Energy

Checking cable from battery to Forklift

Check the connector to the forklift to make sure that it is inserted tightly. Also check the exit point of the

battery compartment to make sure that the power cables to the forklift are not rubbing on any metal

surface where they could be abraded

General operaonal consideraons

Make sure that the baery is kept clean and dry

• Never clean the system or system parts using a

vapor jet or spray water.

• Dirt and water may enter the system and cause

major damage.

• Use only a moist and clean coon cloth for cleaning.

• Avoid chlorine-based disinfectant wipe-downs.

Do not let the baery sit for long periods of me at

low state of charge.

Before being placed in storage the baery should be

charged to 50 % SOC, powered o, and disconnected

from both the vehicle and the charger.

The Li510 Lithium Material Handling Baery system

has a very low self-discharge and can be put into

storage for up to 12 months. It must then be

recharged

If baeries are taken out of service, they should be

stored in a dry and frost free room.

TROUBLESHOOTING ISSUES DURING

BATTERY OPERATION

SOC on Opus display does not match Forkli

BDI display

The Li510 baeries use NMC chemistry. If the Forkli

Baery Discharge Indicator (BDI) is congured for

lead acid or some other type of lithium chemistry,

the SOC displayed by the Opus may not match the

SOC displayed by the forkli BDI. For example, in the

images below, the Opus display on the top is showing

100% SOC and the forkli BDI on the boom is

showing 90% SOC.

M-SERIES

9

Li510

The discrepancy on the previous page in displayed SOC

values is normal when the truck BDI is congured for

lead acid or some other lithium chemistry. Check with

the forkli dealer and/or forkli technical support

to congure the truck BDI for NMC lithium. If this is

not possible, use the SOC displayed by the Opus to

gauge the baery SOC and ignore the SOC displayed

on the forkli BDI. The following table should be used

when seng up a Forkli BDI to be used with Li510

baeries.

Nominal

Voltage

0% SOC 100%

SOC

Undervoltage

alarm

Overvoltage

alarm

24V 22.4 V 28.8 V 20.3 V 29.8 V

36V 32.0 V 41.2 V 29.0 V 42.5 V

48V 44.8 V 57.7 V 40.6 V 59.5 V

72V 64.0 V 82.4 V 58.0 V 85.0 V

80V 67.2 V 86.5 V 60.9 V 89.3 V

96V 89.6 V 115.4 V 81.2 V 119.0 V

Forkli goes into “turtle” mode at high or low SOC

If the Forkli BDI is congured for lead acid or some

other type of lithium chemistry, the Forkli BDI may

limit the operaon at either the high voltage or low

limit of the baery. In this case, it will be necessary

to work the forkli dealer and/or forkli technical

support to congure the truck BDI for NMC lithium.

Use the table on the previous page to verify that the

working voltage range of the baery is supported by

the Forkli’s drive electronics and set the Forkli’s

BDI accordingly.

Baery quickly drops to low state of charge aer

charging

If the baery quickly drops to a low state of charge

aer charging, this may be a sign of a loose current

sensor inside the baery. Indicaons that the Low SOC

Warning is likely due to a loose current shunt are:

1. Typically the voltage reading will be higher than

normal for a low SOC baery. For a 36v baery, the

voltage that corresponds to 6% SOC is approximately

34V. If the baery voltage shown at low SOC is

signicantly higher than this, it could indicate a loose

current sensor.

2. If a current shunt is loose, typically there will be

a current of ~-65A displayed, even if the forkli is

staonary and not moving.

While the forkli can be operated safely at a false low

SOC, the warning beeping from the baery may be

objeconable to operators. If this error occurs, please

take a picture of the Opus display and baery serial

number, and contact Stryten Energy Customer service,

as this is not a eld repairable issue.

Baery beeps for 15 seconds and stops with Over

Current CHG warning

This error indicates a faulty current sensor internal to

the baery. Typically a current of ~70A is displayed,

even though the baery is not on charge. If this error

occurs, please take a picture of the Opus display and

baery serial number, and contact Stryten Energy

Customer service, as this is not a eld repairable issue.

M-SERIES

10

Li510

Forkli will not operate – All zeros displayed on

Opus display

This indicates that there is an internal CAN

communicaon problem within the baery. If this

error occurs, please take a picture of the Opus display

and baery serial number, and contact Stryten Energy

Customer service, as this is generally not a eld

repairable issue.

Forkli will not operate – All values displayed on

Opus display are normal

If the forkli does not operate and the Opus display

does not indicate any problems, the rst thing to

check is to conrm that the forkli cable from the

baery is mated properly to the connector on the

forkli.

If there are no obvious problems with the connecon

from the baery to the forkli, disconnect the

baery from the forkli and measure the voltage

on the baery terminals. If the baery is in normal

operang mode (LED on the power switch is slowly

ashing green) and the baery is not being charged,

the baery voltage should be present at the output

terminals of the baery. If baery voltage is present,

the problem is likely with the forkli. Contact the

forkli dealer and/or forkli technical service for

further support.

If there is no voltage on the baery’s output cable

when the baery is powered on, not charging and

disconnected from the forkli, it will be necessary

to open the baery for further troubleshoong.

Contact Stryten Energy Customer service to open

a ServiceMAX cket before proceeding. Make sure

to provide pictures of the Opus display and baery

serial number, voltage readings and any pernent

informaon about how and when the forkli stopped

working.

The forkli output cables are fused, so the next step

aer receiving authorizaon from Stryten Energy

is to check the connuity of the fuse on the forkli

cable. If the fuse is not open, the next thing to check

is the contactor for the forkli cable. All baeries

have a contactor on the posive cable and some

modules have a contactor on the negave cable as

well. Contact Stryten Energy customer service for

assistance troubleshoong the contactors if the

problem appears to be with the contactors.

Forkli will not operate – Low SOC Alert

If the SOC of the baery drops below 10%, the baery

will beep once per second and a low voltage

warning will be shown on the Opus display

M-SERIES

11

Li510

If the SOC drops to 0%, the baery will beep rapidly

for 15 seconds and turn o. The reset buon can be

pressed once to get the vehicle to the charger. Aer

that, the baery remains turned o in order to avoid

further damage. The vehicle now has to be towed to

the charge with auxiliary means.

TROUBLESHOOTING ISSUES DURING

BATTERY CHARGING

Opus displays High temperature warning

during charge

If a baery is being charged at close to its temperature

limits, the baery will display a warning. The warning

occurs when charging temperature reaches 45C or

drops to 5C.

The M-Series X-3 and X-7 chargers will never charge

a Li510 baery above or below its allowable charge

temperature limits. When the baery reaches 45C, the

M-Series X-3 and X-7 chargers will reduce its output

current to slow the rate of heang. If the baery ever

reaches 50C, the M-Series X-3 and X-7 chargers will

stop charging and wait for the baery to cool before

resuming charging.

In addion to displaying a warning, baeries with

BMS rmware versions prior to 2.8.7 will emit a

slow warning beep (once per second) if the charging

temperature exceeds 45C or drops below 5C. This

beeping is intended as a warning only, as the baery

is sll operang within its safe limits and can sll

safely charge. However this beeping has caused some

confusion with customers, as beeping during charging

is disconcerng to operators. This has caused some

operators to stop the charger at 45C when the baery

starts to beep, even though the baery is sll well

within its allowable charge temperature.

Beginning with BMS rmware version 2.8.7, Li510 will

no longer beep when they reach 45C while charging

on a M-Series X-3 and X-7 charger. Because the

M-Series X-3 and X-7 chargers will never allow the

baery to reach 50C or drop to 0C, there is no need

to warn the user as these limits are approached.

Customers with BMS rmware prior to 2.8.7 may

contact Stryten Energy service to schedule a rmware

update if desired. Customers with older rmware

should be aware that if the baery is charging at

temperatures between 45C and 49C, a slow beep

of once per second is normal, and not a cause for

concern.

Troubleshoong M-Series X-3 and X-7 chargers

communicaon problems:

If any errors are encountered while charging a Li510

baery, the M-Series X-3 and X-7 chargers will stop

and display an error message.

If an error occurs while charging, hit the down buon

(V) to the right of the display and check the Error

Details for addional informaon. Take a picture of

the main charger screen and Error Details screen in

case assistance is needed from Stryten Energy service.

M-SERIES

12

Li510

If there is a connecon problem with the baery, one

of several errors may be displayed.

1) “No CANbus communicaon” Error

2) “Lost communicaon with baery” Error

3) “BMS reported not ready to charge” Error

Whenever an error occurs during charging, the

rst troubleshoong step is to determine if the

problem is with the baery or charger.

a. Check the baery with other chargers i. If the

baery fails on other chargers, it is a baery problem

ii. If the baery works on other chargers, it is problem

with the original charger.

b. check the charger with other baeries i. If the

charger works with other baeries, it is a baery

problem ii. If the charger does not work with any

baeries, it is problem with charger.

If problem is with the baery connecon

Check to make sure that the pins on the baery and

charger are clean so that they will make good contact.

Check to make sure that none of the pins are loose.

Next, check the Aux pins with a mulmeter

The AUX pin connecons for a REMA320 charger

connector are shown below:

M-SERIES

13

Li510

The AUX pin connecons for a REMA640 charger

connector are shown below:

For both REMA320 and REMA640 charger connectors,

the boom two pins on the connector are the CAN

bus communicaons lines.

When the Opus display is aached the resistance

between these two pins should read ~60 ohms. When

the Opus is disconnected, they should read ~120

ohms.

For REMA320 connectors, the two top pins are the

safety line pins.

For REMA640 connectors, the two middle pins are the

safety line pins.

There should be 5v between the + on the le and the -

on the right.

If the readings are not as shown above, the aux pins

will need to be repaired.

INSTRUCTIONS FOR D0WNLOADING

CHARGER RECORDS FROM STRYTEN

ENERGY FURY CHARGERS

1) Obtain a Stryten Energy USB sck from your Stryten

Energy Service Authorized Representave.

2) Insert the USB sck into the USB port of the

charger.

3) While the charger is wring logs to the USB sck,

a message will be displayed on the M-Series X-3 and

X-7 chargers. Do not remove the USB sck while

the charger is wring log les. This will take about a

minute.

M-SERIES

14

Li510

4) When the charger has nished wring its log les, it

will display a message to say that it has completed the

transfer and that the USB sck can now be removed.

5) If you have mulple chargers, you can download

charger records from all of the chargers using the

same USB sck

6) Once you have downloaded all of the logs from

your chargers, you can send the USB sck back to your

Stryten Energy Service Authorized Representave for

analysis. Or to save me, you can email the les.

In the USB sck directory, go to the aw-chargers ->

in-box directory. Under that directory will be a folder

for each charger, named with the serial number of the

charger. In each charger folder, there will be a zip le

with the logs from that charger. Email each of these

zip les to your Stryten Energy Service Authorized

Representave.

The USB sck can be re-used to download charger

records mulple mes. Each me that records are

downloaded from a charger, a new zip ll will be

added to the folder for that charger. The number

aer the dash in the zip le name is the date and

me that the log was created. In the example above,

the logs for charger serial number 1826000029

were downloaded twice. The second zip le was

downloaded on April 8, 2021 at 12:42:16, so it is

the most recent of the two les. When sending

les to your Stryten Energy Service Authorized

Representave for analysis, you only need to send to

send the most recent les.

7) Please contact your Stryten Energy Service

Representave or email strytenncc@stryten.com for

addional help.

M-SERIES

15

Li510

SERVICE/REPAIR OF REMA320 AND

REMA640 CHARGER CONNECT0RS

Note – the procedure below shows a REMA320

connector. Servicing and repair of a REMA640

charger connector is idencal to the REMA320,

except that there is an unused third pair of aux

contacts, which is the top pair of contacts.

1) Check posion of baery voltage key. Take picture

of connector from front in order to verify that the

connector is replaced in the correct posion aer the

connector is serviced. (note – the picture below is

from a 36v baery. Other voltages will have the key in

a dierent posion).

2) Remove the power cable clamp and strain relief

cable es. (See below and top right)

3) Remove the voltage key. This is done from the back

of the connector. Using a needle nose pliers, gently

squeeze together the clips on the end of the key that

hold the key into place. Push slightly and the key will

come out from the front of the connector.

M-SERIES

16

Li510

4) Gently open the lid of the connector, using a small

screwdriver inserted into the hole le by the voltage

key to li up the lid.

5) Back the pins out of the connector housing and

service/repair/replace as needed.

If the exisng pins or harness are too damaged for

eld repair, replacement harnesses can be ordered

from Stryten Energy. The length of the harness will

vary depending on the baery model. Contact your

Stryten Energy service representave to determine

the correct part number to order for your baery

model. Make sure to give them the baery serial

number and model number.

6) Replace Power and Aux pins

The posive power pin (power cable with red jacket)

goes to the locaon marked + on the housing.

The negave power pin (power cable with black

jacket) goes to the locaon marked – on the housing.

The safety loop 5v pin (on red aux wire) goes to the

top aux pin posion of the REMA320 (middle posion

for REMA640), on the side closest to the negave

(black) power lead.

The safety loop Gnd pin (on black aux wire) goes to

the top aux pin posion of the REMA320 (middle

posion for REMA640), on the side closest to the

posive (red) power lead.

Both the CAN pins (on blue and white aux wires)

go into the boom set of aux pins, using a “pilot

adaptor”, which must be installed with the notch in

the adaptor facing up.

CAN high pin (on white aux wire) goes on the side

closest to the posive (red) power lead.

CAN low pin (on blue aux wire) goes on the side

closest to the negave (black) power lead.

Baery REMA Pinout

M-SERIES

17

Li510

7) Replace lid to the connector, making sure that the

aux pins are all fully inserted, so that the notches in

the pins all line up.

8) Before replacing the voltage key, make sure that all

pins are fully inserted in the housing. If any pins are

not all the way forward, repeat step 8.

9) Replace clamp to hold the power cables to the

connector, making sure not to pinch the aux comm

cable.

10) Use double zip es for strain relief, so that the

aux cable cannot get snagged and pulled from the

connector. Make sure that there is enough play in the

aux cable for the cable and connector to move from

side to side without pung strain on the aux cable.

Tighten the zip es so that the cut ends are towards

the interior of the cables

©2023 Stryten Energy Alpharea, GA 30005 SE1021 1/23

STRYTEN ENERGY

USA/PR 877.462.4636 CAN 800.268.2698 MEX +52 5543527927

Other manuals for M Series

5

This manual suits for next models

1

Table of contents

Other Stryten Energy Camera Accessories manuals