STS 1660 User manual

Page 1

OPERATOR’S MANUAL

MODEL 1660

INTRODUCTION

The Series 1660 designates a family of high voltage surge testers that are intended for the testing

of coils and windings of all types for defects and weaknesses within the winding. These include

such obvious defects as turn-to-turn shorts and layer insulation failures and weaknesses.

Specifications

Input Requirements

110 Volts +/

-

15%, 50/60 Hz,

1

.

5

/

1

A

Output Voltage

400

–

5000 Volts Peak

Pulse Energy

Variable to 0.25 Watt

-

Seconds

Maximum Operatin

g Range

Temperature: 0

–

40 deg. C

Relative Humidity: 5 – 85 % Non-Condensing

Altitude: 0 – 3000 m

Vibration: 0 – 2 g

Dimensions (WxHxD)

48.26 cm x 13.34 cm x 44.45 cm

Weight

20 kg

The measurement terminals on the Model 1660 Surge Tester are rated for

measurement category I as defined in IEC International Standard EN 61010-

1. Measurement category I is for measurements performed on circuits not

directly connected to mains. Do not use this equipment for measurements in

measurement categories II, III, or IV. Do not use this equipment for any

purpose other than as described in this manual.

Page 2

PRINCIPLE OF OPERATION

While the surge tester is essentially a dielectric tester, unlike the typical Hipot tester, it is used to

test for internal weaknesses and faults rather than for weaknesses and faults between electrically

isolated elements such as wiring to frame or winding to winding.

Insure the unit is operated within the following environmental specifications:

Temperature: 0 – 40 Degrees C.

Relative Humidity: 0 – 85%, Non-condensing

Vibration: 2 g. maximum

Ventilation: No special requirements

Of prime consideration and importance in the layout and installation of a test station is to

insure the safety both of the operator and any visitors or casual bystanders, invited or

otherwise. As a general rule it is suggested that each test area be in a location with

minimum distractions.

As shipped from the factory, the Model 1660 Surge Tester is configured as a bench top

unit. If desired, the unit may be rack mounted with user supplied slides.

One of the more important ways to promote safety is through operator training. Benefits

of training are twofold. First, thorough training promotes safety, which may significantly

reduce injuries on the job. Second, it ensures adequate testing of the product which helps

increase product reliability.

An additional consideration in any test station is operator comfort. This is affected by the

operator’s position, which includes the chair, table, test equipment, the object under test

and the test procedure itself. Locate the unit so that the operator has easy access to all

controls and connectors. The chair and work bench or table should be nonconductive and

the table as large as possible to allow sufficient room for the test equipment and the

object under test. Studies should be made of the test requirements and work habits and

steps taken to ensure that any unusual or unnatural motion is not required and to

eliminate any repetitive motions that may produce injuries such as carpel tunnel

syndrome.

CAUTION: The use of high voltage test equipment can be hazardous

to personnel. It is advised that all involved in the use of this equipment

be made aware of this fact, and that a thorough study be made of any

hazards involved in the contemplated usage of the equipment.

Reference should be made to safety material furnished with the unit

and to the Basic Facts booklet accompanying this manual, which

includes additional material on safety considerations.

•This unit is equipped with a three-prong grounding type line

plug. It is essential that it be utilized only with a mating three-

terminal receptacle, properly grounded in accordance with

electrical codes.

•This unit is designed for indoor use.

Page 3

After the equipment has been installed, a careful study should be made of the test station

to determine what, if any, safeguards are needed. It is suggested that any electrical test

station involving voltages in excess of 42.4 volts peak (approximately 30 volts RMS)

should be equipped with safeguards. These should operate both for the protection of the

operating personnel and for the protection of casual bystanders. At the minimum,

safeguards should prevent the operating personnel or casual bystanders from coming into

contact with the test circuit. In the event electrical interlocks of any sort are required,

either to insure that guards are in place, or to insure that the operator’s hands are in a safe

location, we will be happy to provide suggestions and schematics for safety interlocking

our test equipment.

The test procedure should be well thought out to ensure that it adequately tests the

product to the desired criteria but that the procedure does not require the operator to

perform tasks that are unsafe. The product should never be touched during a test.

Good safety practice dictates labeling of hazards properly. Since high voltage testing can

be hazardous, the work station should be labeled. Naturally, the location of the label

should be carefully selected so that it can be placed in a location that will do the most

good. In some cases, this may be on the test instrument itself, and in others, it may be in

a location directly in front of the operator, somewhat removed from the instrument.

A final word about high voltage testers. Generally, commercial high voltage test

equipment is not in itself hazardous. The hazards come about when the equipment is

improperly used. These testers, when used properly and in a safe manner, can be a check

on the quality and reliability of your product. If used incorrectly and without proper

consideration for safety, they represent a hazard for both operating personnel and casual

bystanders. We strongly recommend proper training for all personnel involved in testing.

Page 4

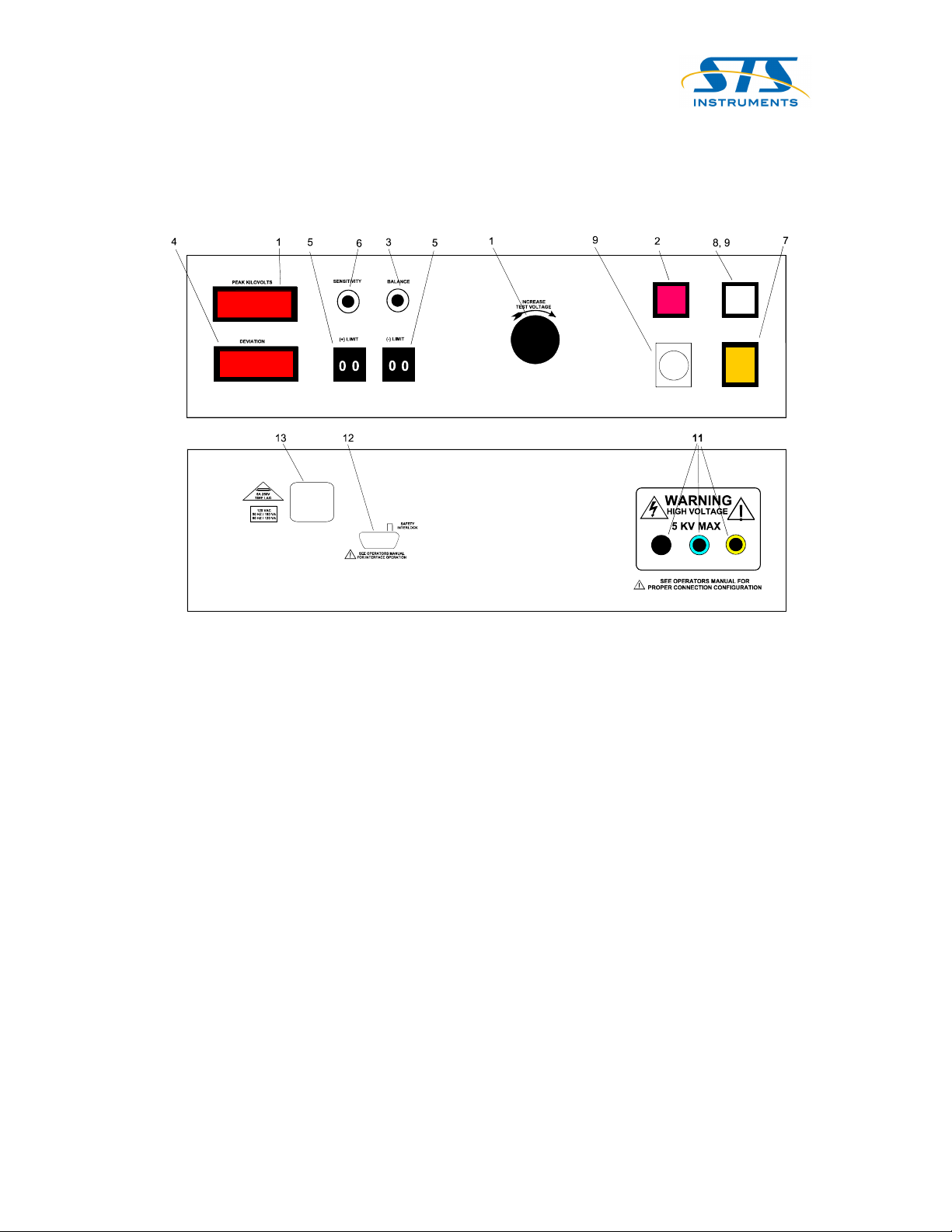

CONTROLS AND INDICATORS

In using this equipment, it must be kept in mind that maladjustment of the controls can

completely smother the indications. This can be avoided by fully understanding the various

adjustments and by following the suggested procedures. We will first review the important

adjustments and then outline procedures.

1. VOLTAGE CONTROL – This knob adjusts the actual voltage applied during test.

Since some regulation exists in the power supply, the voltage control should be

adjusted under actual test conditions. The voltmeter reads actual peak test voltage at

the output terminals.

2. RESET SWITCH – The Reset Switch is depressed to stop a test cycle before

completion or clear reject signals.

3. BALANCE CONTROL – This control is used to adjust the reference voltage to

establish a zero reading with a known good part. A Balance reading of 10 (full CW)

indicates minimum volts or very low Return Signal for part under test.

4. DEVIATION METER – This meter indicates the difference between back EMF and

the reference voltage. Deviation meters will normally read zero with a good part and

up or down scale for defective or wrong parts.

5. LIMIT SWITCH – These thumbwheel controls to set the accept/reject limits.

6. SENSITIVITY CONTROL – This control adjusts meter sensitivity and is normally

set as necessary to keep meter readings nominal with the normal variation of parts

and at the same time, provide adequate sensitivity to pick out defective parts. A

Sensitivity Dial reading of 10 (full CW) produces minimum sensitivity and a lower

Return Signal from part under test to the metering circuits.

Page 5

7. POWER SWITCH - Mounted in the lower right corner of the panel, this switch is

used to control input power. Normal position of this switch is top edge depressed.

8. TEST SWITCH – Mounted above Power Switch. The Test Switch is used to initiate

the automatic time cycle. When the preset time cycle is completed, the test voltage

will be turned OFF. However, if the switch is held in the TEST position, this will

override the timer and the unit will remain ON until the switch is released.

9. PILOT LAMP – This lamp mounted in the power switch indicates that the AC power

is ON.

10. DWELL TIMER – Located below the Reset Switch is the adjustment for Dwell

Time. Adjust to times required between .1 & 5 seconds.

11. TERMINALS – (back panel ) Separate High Voltage terminals are provided for the

pulsing circuits and the indicator circuits, color coded as follows:

BLACK --- POSITIVE PULSE OUTPUT & GROUND

BLUE --- NEGATIVE PULSE OUTPUT

YELLOW --- POSITIVE INDICATOR INPUT

NOTE: In all units, Black is internally jumpered to chassis ground.

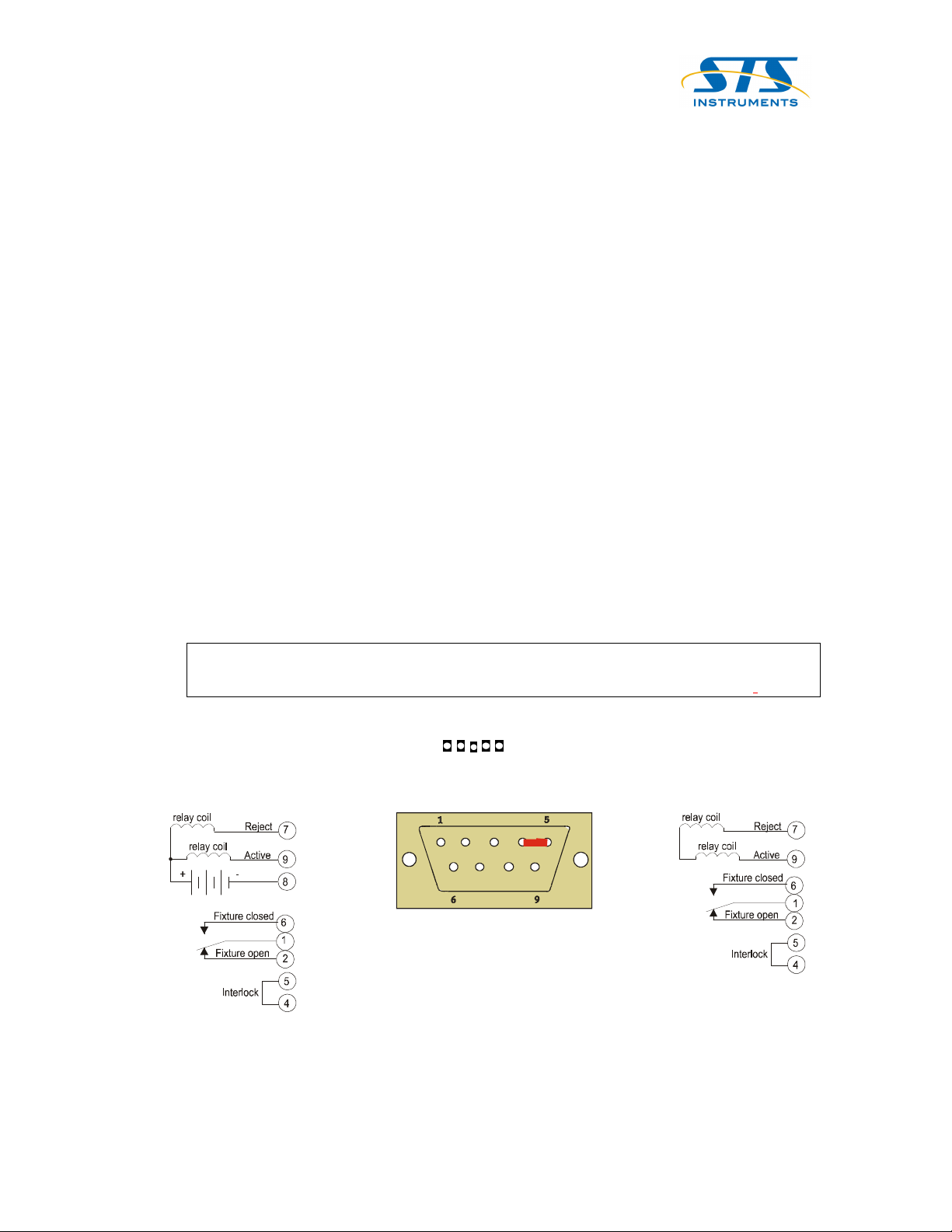

12. REMOTE INTERFACE – (back panel)

13. MODULAR LINE CORD ASSEMBLY – (back panel)

THE INTERFACE CONNECTOR MUST BE PLUGGED INTO

THE SOCKET BEFORE TESTER WILL OPERATE

.

PLUG WIRING

WIRING WIEW SHOWN

9-PIN DSUB PLUG

150-766-002

Customer Interface 1660

(with external power supply)

Customer Interface 1660

(with internal 5 volt supply)

Diagrams and descriptive information on this page are intended to be

illustrative only and not specific instructions. To obtain optimum

performance in any particular application, a certain amount of

experimentation is generally required to establish the proper test

configuration, parameters and operating procedure.

In addition, internal modifications in the Surge Tester are sometimes

needed to obtain peak performance for specific applications. For high

production applications: particularly, those involving more than one test,

automatic sequencing equipment is available. This includes standard

systems for testing armatures, stators, and typical coils. Consult factory

for assistance. (Most common used methods are A & B) Please note that

lead modification may be required for some of the following testing

configurations.

______________________________________________________

A. IRON CORE WINDINGS SUCH AS TRANSFORMERS,

CHOKES, RELAYS, ETC., FOR OPENS, SHORTS AND

GROUNDS.

NOTES:

1. This setup will detect turn-to-turn shorts in any of the windings.

To check unused windings for opens, simply short leads and retest,

tester will indicate short unless winding is open.

2. If ground test and winding-to-winding shorts test is required, add

dotted ground circuit. Multiple tests should be made with winding

leads reversed between the tests.

______________________________________________________

B. SIMPLE WINDINGS, SUCH AS MOTOR AND

GENERATOR FIELDS, FOR OPENS, SHORTS AND

GROUNDS.

NOTES:

1. This technique will detect turn-to-turn and layer-to-layer shorts in

salient pole windings and in some types of distributed windings.

2. If ground test is desired, add dotted ground circuit and make two

tests with winding leads reversed between the tests.

_________________________________________________

C. MULTIPLE WINDINGS, SUCH AS MOTOR AND

GENERATOR STATORS, FOR OPENS, SHORTS AND

GROUND.

NOTES:

1. Individual tests should be made on each winding, with connections

changed between tests as shown.

2. If coupling between windings is insufficient to detect all winding

faults, additional tests should be made with winding leads

reversed.

3. If ground test is desired, add dotted ground circuits.

4. If windings are identical, calibration resistors may be omitted.

D. DISTRIBUTED WINDINGS, SUCH AS

POLYPHASE AND SPLIT PHASE STATORS

FOR OPENS, SHORTS AND GROUNDS.

NOTES:

1. Two tests should be made with lead 1 and 3

interchanged between tests.

2. If windings are not identical, calibration resistor may

require change when leads are interchanged.

3. If ground test is desired, add dotted ground circuit.

_________________________________________________

E. MOTOR AND GENERATOR ARMATURES FOR

POOR

CONNECTIONS, OPENS AND SHORTS.

NOTES:

1. Armature must be indexed or rotated during test.

_________________________________________________

F. MOTOR AND GENERATOR ARMATURES FOR

OPENS, SHORTS AND GROUNDS.

NOTES:

1. Armature must be indexed or rotated during test.

2. Pick off contacts must not be staggered in relation to

commutator bars.

3. This test especially sensitive to insulation weakness.

4. If ground test desired, add core contact and dotted

ground circuit.

TYPICAL TEST TECHNIQUES

Page 6

Page 7

PRODUCTION TEST SETUPS

THE INTERFACE CONNECTOR MUST BE PLUGGED INTO

THE SOCKET BEFORE TESTER WILL OPERATE

.

Using a typical known “good” part, set up unit according to the following procedure:

A. Adjust Sensitivity Full CW, Voltage Full CCW, Balance approximately midway, set

Limit Controls to 9.9, and set Dwell Timer for desired time.

B. Connect part per technique selected.

C. Press and hold Test Switch and raise voltage to approximately ¼ the value to be used.

D. Adjust Balance Control for zero meter reading.

E. Increase Voltage to desired value.

F. Readjust Balance Control as necessary to maintain zero meter reading.

G. Release Test Switch.

The unit is now balanced with the sample good part, and operating at minimum

sensitivity.

To determine proper sensitivity setting, test parts with known defects, as well as a

representative group of good parts, and note deviation readings obtained. Then

adjust sensitivity control and balance, as necessary, to obtain a usable deviation (at

least 0.1) with a “minimum defect” and a nominal reading of zero with good parts.

Selection and preservation of suitable “good” and “defective” samples will simplify

repeat setups.

In the absence of suitable defective parts, it is suggested that a synthetic defective

part be produced by taking a known good part and adding a single shorted loop

equivalent to 1% of the turns of the part. The ends of the loop should be soldered to

ensure good conductivity and should fit snugly around the coil. The loop NEED

NOT be in electrical contact with the remainder of the winding. The inductive effect

will be sufficient to simulate a defect.

From the pattern of readings obtained, establish acceptance limits and in the case of

Series 1660 equipment, adjust limit controls accordingly.

After completion of setup, operating personnel should be carefully instructed in the

test procedures and properly cautioned regarding any potential hazards involved.

Safety training of the operator is an essential part of the production test setup.

CAUTION: (RISK OF ELECTRIC SHOCK)

Be sure tester installation is in accordance with

instructions. The actual production test setup should then

be made only by qualified technical personnel.

Page 8

REPEAT SETUPS

Repeat setups are most easily accomplished using “good” and “defective” samples

selected during the initial setup. If these are available, the repeat setup becomes a matter

of simply adjusting the various switches and controls to the required values and then

adjusting the balance control with the good sample, and the sensitivity control with the

defective sample.

Checking back and forth two or three times with the two samples will result in a setup

duplicating the original … that is, showing a nominal reading of zero with a good part

and the original deviation with the defective part.

Alternatively, repeat setups can be made simple by returning all controls, including the

balance and the sensitivity controls, to their original position. If this approach is used, it is

still a wise idea to check the balance with a known good part.

Page 9

TEST PROCEDURES

Check dwell timer for desired setting:

Production Test Procedures are quite simple:

A. PRESS & RELEASE TEST SWITCH - If meter reading exceeds limits established in

setup procedure, defects exist. If not, the part is acceptable. To check inactive

windings for opens, simply short circuit leads of these windings, one at a time, and

note if meter reads downscale. If not, winding is open.

B. With Series 1660 units, operator observance of the meter is unnecessary. Simply

operate test switch. After about 1/2 second, for defective parts, the reject lamp will

come ON and the buzzer will sound.

C. As an aid to the operator, it is suggested that typical samples of various defects be

kept available for use in refreshing the memory.

D. It is also important that the operator be familiar with any heating effects that may

occur in the product so as to be able to distinguish these effects from defects.

E. In some cases, reverse readings are an indication of acceptance; for example, the

checking of armatures for opens, per Technique E. The operator should, of course,

be properly instructed in regard to such situations.

CAUTION:Test Procedures should be carried out only by

personnel who have been thoroughly instructed as to the

nature of the procedure, the hazards involved, and the

necessary safety precautions.

CAUTION: D

well Time

can increase safety hazards.

The operator should be instructed that the TEST light

must be dark before removing clip leads. Set Dwell

Time to minimum necessary.

Page 10

Maintenance

Routine maintenance should include the following:

1. Function Check

At least once per shift verify calibration by the methods described in the

“Installation and Safety” on page 7.

2. Safety Inspection

A. Daily – Check test leads for damage. Leads should be inspected for cracks or

deterioration. Rear panel terminals should be inspected for excessive wear,

cracks or loose components.

B. Monthly – Check line cord on tester for damage, deterioration and ground

lead integrity. Check line receptacle for ground integrity.

3. Annual Service

All testers should be returned to the factory at least once per year for calibration

and certification.

Replacement Parts List; Model 1660

Part Number Qty. Description

102-051-903 1 HV Dual Test Lead, Blue & Yellow Plug

102-055-909 1 HV Single Test Lead, Black Plug

150-822-002 2 Fuse, 3.15A 250V GDC 5x20mm Time Lag

350073 1 Lamp, Reject 327 28V

350098 1 Lamp, HV On 382 14V.08a

330081 1 Red P/B Lens & Lamp Holder

330082 1 White P/B Lens & Lamp Holder

995-028-901 1 Safety Interlock Plug Assy., 9-Pin

Optional Parts List; Model 1660

Part Number Qty. Description

150-766-002 1 D-Connector, 9-Pin

150-787-003 1 Housing, D-Connector, 9-Pin

WARNING: (RISK OF ELECTRIC SHOCK)

DO NOT REMOVE COVER. NO USER SERVICEABLE PARTS

INSIDE, PLEASE REFER SERVICIING TO QUALIFIED SERVICE

PERSONNEL.

Page 11

REPAIR SERVICE

Complete calibration and repair services are offered at our Ardmore, Oklahoma manufacturing

facility. Calibrations are to original factory specifications and are traceable to National

Standards. A certificate of conformance accompanies each repaired tester.

A Return Material Authorization (RMA) number must be obtained from STS Instruments before

returning any instrument for repair. Please contact STS at 1-800-421-1921, 580-223-4773 or

(including insurance) for the return of the instrument to STS must be prepaid by the customer.

Testers sent for repair should be shipped prepaid and insured to:

STS INSTRUMENTS

Attn: RMA #

801 Hailey Street

Ardmore, Oklahoma 73401

Inside the container with the tester, put the name and telephone number of someone to contact if

the Service Dept. has questions regarding the repair and someone to advise of billing. Please

indicate your “ship to” address – no P.O. Boxes, please.

Subject to weight restrictions, testers are normally returned to the customer via UPS ground with

the actual shipping charges prepaid and added to the invoice. Premium shipping and alternate

carriers can be provided upon customer request. Freight charges will vary according to the

method/carrier specified.

Factory service is based upon an hourly rate with a one-hour minimum charge per tester. Parts

needed to bring the testers back to factory specifications are extra.

Altered testers cannot be certified. All non-STS parts will be removed and the customer charged

to bring the tester back to original factory specifications before calibration will be attempted.

From time to time testers are received that may be inadvisable to repair due to age, condition

and/or obsolescence of parts from suppliers. Customers are notified.

Non-warranty repairs carry a limited warranty of 90 days on services and replacement parts only.

Defects in our repair work or any parts replaced will be corrected at no charge if the defect occurs

within 90 days from shipment from our factory.

If difficulty arises during the 90-day period that is due to a secondary defect, which could not

normally be detected during the original service procedure, it will be repaired and a charge made

only for parts used.

WARNING:

Field repairs, oth

er than routine replacement test probe

assemblies and fuses are not recommended due to the risk of high

voltage shock. It is recommended that defective equipment be

returned to the factory for repair.

Page 12

1 YEAR LIMITED WARRANTY POLICY

All products are covered by our standard limited warranty: Your new instrument is

warranted to be free from defects in workmanship and material for a period of (1) year from date

of shipment and we will repair or replace any such product we find to be so defective upon its

prepaid return to us. This warranty is void if the product has been tampered with, or subjected to

gross misuse, and is exclusive of all others, expressed or implied. In case products of other

manufacturers are specified as an option by the customer, the warranty of that manufacturer will

apply to such items, and our responsibility is limited to assisting the customer in filing warranty

claims with the manufacturer responsible. In the event that the prepaid return of an instrument to

our Ardmore, Oklahoma plant is impractical and the customer desires on-site warranty, we expect

payment for the actual incurred travel and out-of-factory expense of our factory representative.

A Return Authorization (RA) must be obtained from STS Instruments before returning

any instrument for warranty service. Please contact STS at 1-800-421-1921, (580) 223-4773 or

is important that the instrument is packed in its original container for safe transport. If the

original container is not available, please contact our customer support center for proper

instructions on packaging. Damages sustained as a result of improper packaging will not be

honored. Transportation costs (including insurance) for the return of instrument for warranty

service must be prepaid by the customer.

Except as provided herein, STS Instruments makes no warranties to the purchaser of this

instrument and all other warranties, expressed or implied (including, without limitation,

merchantability or fitness for a particular purpose) are hereby excluded, disclaimed and waived.

Any non-authorized modifications, tampering or physical damage will void your

warranty. Elimination of any safety systems will void this warranty. This warranty does not

cover batteries or accessories not of STS Instruments manufacture. Parts used must be parts that

are recommended by STS Instruments as an acceptable specified part. Use of non-authorized

parts in the repair of this instrument will void the warranty.

STS Instruments certifies that this instrument was calibrated using standards that are

traceable to the National Institute of Standards and Technology (NIST). Most safety compliance

agencies such as UL recommend that your instrument be calibrated on a twelve-month cycle.

Page 13

DECLARATION OF CONFORMITY

Manufacturer’s Name:

STS Instruments, Inc.

Manufacturer’s Address:

801 Hailey Street

Ardmore, Oklahoma 73401

USA

Declares that the product:

Surge Tester

Model Name:

Model 1660

Conforms to the directives and standards identified in this declaration

EU Directives:

89/336/EEC

Electromagnetic Compatibility Directive, amended by 93/68/EEC

73/23/EEC

Low Voltage Directive

Standards:

EMC: EN 61000-4-2: 1995 “Electromagnetic Discharge immunity test”

EN 61000-4-3: 1998 “Radiated, radio frequency, electromagnetic field immunity test”

EN 61000-4-4: 1995 “Electrical Fast Transient/burst immunity test”

EN 61000-4-5: 1995 “Surge immunity test:

EN 61000-4-6: 1996 (Incorporating Amendment No. 1) “Immunity to Conducted disturbances,

inducted by radio-frequency fields”

EN 61000-4-11: 1994 “Voltage dips, short interruptions and voltage variations immunity test”

EN 61326 (CISPR 16: 1993 “Specification for radio disturbance and immunity measuring

apparatus and methods”)

Safety: EN 61010-1: 2001 “Safety requirements for electrical equipment for measurement,

control, and laboratory use”

The technical documentation required to demonstrate that the product meets the requirements of the

directives listed in this declaration is available for inspection by the relevant enforcement authorities.

CE mark first applied:

2004

Table of contents

Other STS Test Equipment manuals