STS DTM.OCS.S User manual

Inhalt

Operating manual

Digital Transmitter DTM.OCS.S / DTM.OCS.S/N

Doc. No. 10.00.0430

Version: 01.11.2018

These operating instructions must be read by the operator before operation and installation!

Translation of the original operating manual

2 Doc-Nr. 10.00.0430

Operating manual Digital Transmitter DTM.OCS.S / DTM.OCS.S/N

Inhalt

Doc-Nr. 10.00.0430 3

1Introduction ............................................................................6

1.1 Requirements/Basics.....................................................6

1.2 Abbreviations.................................................................6

1.3 Limitation of Liability ......................................................6

1.4 Copyright Protection ......................................................7

1.5 Spare Parts....................................................................7

1.6 Guarantee Provisions ....................................................7

1.7 Customer Service ..........................................................7

1.8 Registered Trademarks .................................................8

1.9 Reference Documentation.............................................8

2Safety ......................................................................................9

2.1 Intended Use..................................................................9

2.2 Explanation of Symbols .................................................9

3Product overview .................................................................10

4Commissioning of the Digital Transmitter ........................11

4.1 Unpacking....................................................................11

4.2 Safety Notes ................................................................11

4.3 Notes on Installation ....................................................11

4.4 Installation....................................................................12

5Communication with the DTM.OCS.S transmitter ............13

5.1 Summary......................................................................13

5.2 Physical interface.........................................................13

5.3 Software interface........................................................13

5.3.1 Modbus.........................................................13

5.3.2 General Modbus message frame structure..14

5.4 Modbus STS commands .............................................14

5.4.1 STS command structure...............................14

5.4.2 Sensor response ..........................................14

5.4.3 List of STS commands.................................15

5.4.3.1 MEASURE ....................................15

5.4.3.2 Supported pressure units..............17

5.4.3.3 Supported temperature units ........18

5.4.3.4 GETPROBE..................................18

5.4.4 STS Modbus commands under the

magnifying glass...........................................19

Operating manual Digital Transmitter DTM.OCS.S / DTM.OCS.S/N

Inhalt

4 Doc-Nr. 10.00.0430

6Modbus standard commands .............................................21

6.1 Read pressure value (P)..............................................21

6.1.1 Command (Hex-Code, Function Code 4).....21

6.1.2 Interpretation start index 0: Measured

pressure value..............................................21

6.2 Read temperature-value (T).........................................21

6.2.1 Command (Hex-Code, Function Code 4).....21

6.2.2 Interpretation start index 1: Measured

temperature value.........................................21

6.3 Read pressure and temperature in one command ......22

6.3.1 Command (Hex-Code, Function Code 4).....22

6.4 Read maximum pressure (Nominal pressure, PMAX)....22

6.4.1 Command (Hex-Code, Function Code 3).....22

6.4.2 Interpretation start index 200+201:

Nominal pressure..........................................22

6.5 Read minimal pressure (Zero-point pressure, PMIN) ....23

6.5.1 Command (Hex-Code, Function Code 3):....23

6.5.2 Interpretation start index 202+203: Zero-

point pressure...............................................23

6.6 Read maximum temperature (end of temperature

range, TMAX)..................................................................24

6.6.1 Command (Hex-Code, Function Code 3).....24

6.6.2 Interpretation start index 204+205: End of

temperature range........................................24

6.7 Read minimal temperature (start of temperature

range, TMIN) ..................................................................24

6.7.1 Command (Hex-Code, Function Code 3).....24

6.7.2 Interpretation start index 206+207: Start of

temperature range........................................24

6.8 Read PMAX, PMIN, TMAX, TMIN together in one

command .....................................................................24

6.8.1 Command (Hex-Code, Function Code 3).....24

6.9 Change device’s Modbus address...............................25

6.9.1 Command (Hex-Code, Function Code 16)...25

6.10 Read serial number......................................................25

6.10.1 Command (Hex-Code, Function Code 3).....25

6.11 Read Firmware version................................................25

6.11.1 Command (Hex-Code, Function Code 4).....25

7Technical Data......................................................................27

8Maintenance..........................................................................28

8.1 Cleaning the Membrane...............................................28

8.2 Recalibration ................................................................28

8.3 Disposal .......................................................................28

Operating manual Digital Transmitter DTM.OCS.S / DTM.OCS.S/N

Inhalt

Doc-Nr. 10.00.0430 5

9Troubleshooting...................................................................29

9.1 Error messages when using STS Modbus

commands ...................................................................29

9.2 Error messages when using Modbus standard

commands ...................................................................29

9.2.1 General.........................................................29

9.2.2 Exception codes...........................................29

10 Appendix...............................................................................30

10.1 Mapping of Modbus command codes..........................30

11 Revision history ...................................................................31

Index..............................................................................................32

Operating manual Digital Transmitter DTM.OCS.S / DTM.OCS.S/N

Introduction

Doc-Nr. 10.00.0430 6

1 Introduction

1.1 Requirements/Basics

You need basic knowledge of Modbus.

1.2 Abbreviations

Abbreviation

Meaning

DTM

Digital Transmitter

OCS

Open Communication System

P

Pressure

PZP

Zero-point pressure

PN

Nominal pressure

T

Temperature

DW

Data word

DB

Data byte

PDU

Protocol Data Unit

@

at

Tab. 1: Abbreviations

1.3 Limitation of Liability

All information and notes in these instructions have been put

together under consideration of the applicable standards and

provisions, the state of the art and our many years of insights and

experiences.

The manufacturer assumes no liability for damage due to:

Non-observation of these instructions

Non-intended use

Use of untrained staff

Unauthorized conversions

Technical changes

Use of unapproved spare and wear parts

The actual scope of delivery may deviate from the expectations

and illustrations here in special designs, utilization of additional

order options or due to the latest technical changes.

Apart from this, the obligations agreed on in the supply contract,

the general terms and conditions and the delivery conditions of the

manufacturer and the statutory rules applicable at the time of

conclusion of the contract shall apply.

Operating manual Digital Transmitter DTM.OCS.S / DTM.OCS.S/N

Introduction

Doc-Nr. 10.00.0430 7

Warranty

The manufacturer guarantees for the function of the applied

process technology and the indicated performance parameters.

The warranty period shall commence at the time of delivery of the

device to the customer.

Components shall be excluded from the guarantee and claims for

defects if the damage has been caused by wear.

1.4 Copyright Protection

The operating instructions must not be provided to any third parties

without the written consent of the manufacturer.

NOTE!

The content, texts, drawings, pictures and other

illustrations are copyright-protected and subject to

the commercial property rights. Any abusive

utilization is punishable.

Reproductions of any kind and form - even in excerpts - as well as

use and/or disclosure of the contents shall not be permitted without

written declaration of the manufacturer.

1.5 Spare Parts

ATTENTION!

Wrong or defective spare parts may cause

damage, malfunction or total failure.

Therefore:

→Only use genuine spare parts of the

manufacturer.

Purchase spare parts through the authorized dealer or directly from

the manufacturer. Address on the reverse.

1.6 Guarantee Provisions

For guarantee provisions, see "General terms and conditions".

1.7 Customer Service

Our customer service will be available for technical information.

Information on the relevant contact can be provided by phone, fax,

email or online at all times; see manufacturer's address on the last

page.

Operating manual Digital Transmitter DTM.OCS.S / DTM.OCS.S/N

Introduction

8 Doc-Nr. 10.00.0430

1.8 Registered Trademarks

Any brand and product names are registered trademarks of the

respective companies and organizations.

1.9 Reference Documentation

MODBUS over Serial Line, Specification & Implementation

Guide V1.0

http://www.modbus.org

Modbus Standard Library section

MODBUS Application Protocol Specification V1.1

http://www.modbus.org

Modbus Standard Library section

STS Website

http://www.stssensors.com

Datasheets and general product information

Operating manual Digital Transmitter DTM.OCS.S / DTM.OCS.S/N

Safety

Doc-Nr. 10.00.0430 9

2 Safety

2.1 Intended Use

The intended use of the Digital Transmitter DTM.OCS.S and

DTM.OCS.S/N is the measuring of pressure and temperature

and the transmitting of the values in real time to the interface

RS485 using Modbus RTU protocol.

The use in acids / bases is only possible to a limited extent.

Application and medium compatibility must be coordinated with

STS before commissioning or when ordering.

Only use the device as intended.

All information in the operating instructions must be complied with.

The operator shall be solely liable for any damage at non-intended

use.

2.2 Explanation of Symbols

Warning Notes

Warning notes are marked with symbols in these operating

instructions. The notes are preceded by signal words that

express the scope of the danger.

Comply with the notes and act with caution to avoid accidents,

injury and property damage.

ATTENTION!

… indicates a potentially dangerous situation that

may cause slight or minor injury if not avoided.

CAUTION!

… indicates a potentially dangerous situation that

may cause property damage if not avoided.

Advice and Recommendations

NOTE!

… highlights useful advice and recommendations,

as well as information for efficient and interference-

free operation.

Operating manual Digital Transmitter DTM.OCS.S / DTM.OCS.S/N

Product overview

10 Doc-Nr. 10.00.0430

3 Product overview

Fig. 1: Product overview Digital Transmitter DTM.OCS.S

1 Operating and safety instructions

2 Digital Transmitter

The operating manual can be downloaded from the STS

homepage.

Operating manual Digital Transmitter DTM.OCS.S / DTM.OCS.S/N

Commissioning of the Digital Transmitter

Doc-Nr. 10.00.0430 11

4 Commissioning of the Digital Transmitter

4.1 Unpacking

The digital transmitter is delivered in product-specific packaging

that protects it outstandingly under regular transport conditions.

Check the packaging for outward damage. Take out the transmitter

carefully and without applying any force.

4.2 Safety Notes

CAUTION!

Check the values on the rating plate, and

particularly the pressure range. These values must

correspond to the required technical data. The

seals are made of Viton (FPM), unless the order

confirmation states differently.

ATTENTION!

Have your device installed by specialists. Observe

the national safety provisions when installing and

operating the digital transmitter.

CAUTION!

Excessive vibrations, impact and pressure peaks

may falsify measurements and damage the digital

transmitter.

CAUTION!

Protect the digital transmitter from overload and

abrasion stress with titanium housing.

4.3 Notes on Installation

ATTENTION!

Connect the digital transmitter to depressurized

systems only.

Do not connect to systems under pressure!

Operating manual Digital Transmitter DTM.OCS.S / DTM.OCS.S/N

Commissioning of the Digital Transmitter

12 Doc-Nr. 10.00.0430

NOTE!

Some digital transmitters are delivered with a

yellow protective cap for the pressure connection.

Remove the flap before you use the digital

transmitter.

Do not connect the digital transmitter in the direct proximity of

motors, pumps, valves, heat sources or other possible

interference sources.

Protect the membranes from damage. Do not touch the

membranes.

Digital transmitter with cable output: Avoid damage to the cable

jacket. Observe the maximum permitted medium temperature of

the cable in the respective data sheet.

Do not kink/excessively bend the cable or route it over sharp

edges. Avoid abrasion points.

Reduce tension of the cable and the cable socket to the

minimum.

Observe the max. tightening torque of 30 Nm.

CAUTION!

Ensure that the connection at the digital transmitter

is closed again carefully with the yellow protective

cap after disconnecting the cable from the digital

transmitter!

4.4 Installation

Refer to the instruction leaflet enclosed with the Digital Transmitter.

Operating manual Digital Transmitter DTM.OCS.S / DTM.OCS.S/N

Communication with the DTM.OCS.S transmitter

Doc-Nr. 10.00.0430 13

5 Communication with the DTM.OCS.S transmitter

5.1 Summary

Communication with the DTM.OCS.S is accomplished via an

RS485 serial interface using Modbus protocol transfers at 9600

baud. STS specific, proprietary commands are transmitted as

ASCII strings embedded in Modbus compatible data frames.

Modbus standard function codes are supported as well.

The following settings apply:

Type

Setting

Transmission mode

Modbus RTU

Default address

24010

Transmission rate

9600 baud

Data bits

8

Parity

None

Stop bits

2

Tab. 2: Settings

5.2 Physical interface

For communication with the DTM.OCS.S, a suitable interface such

as a Modbus compatible RS485-USB converter must be employed.

5.3 Software interface

5.3.1 Modbus

Modbus is a master-slave communication protocol.

Slave devices will never communicate with each other.

Modbus telegrams in the RTU mode always begin with the

address (0 - 247) and a function code (FC Code). Then the data

words (DW) follows. 2 bytes with the CRC checksum form the

conclusion.

The function code indicates to the device what action to

perform.

Communication states (transmit/receive/cancel) are controlled

via timeouts.

The byte sequence for transmission of data words and the CRC

checksum is defined as follows:

Data words: Hi –Lo byte

CRC: Lo –Hi byte

For the communication with the DTM.OCS.S, standard Modbus

commands (Function Codes 3, 4 and 16) and a custom STS

function code (0x64 [10010]) are used.

Operating manual Digital Transmitter DTM.OCS.S / DTM.OCS.S/N

Communication with the DTM.OCS.S transmitter

14 Doc-Nr. 10.00.0430

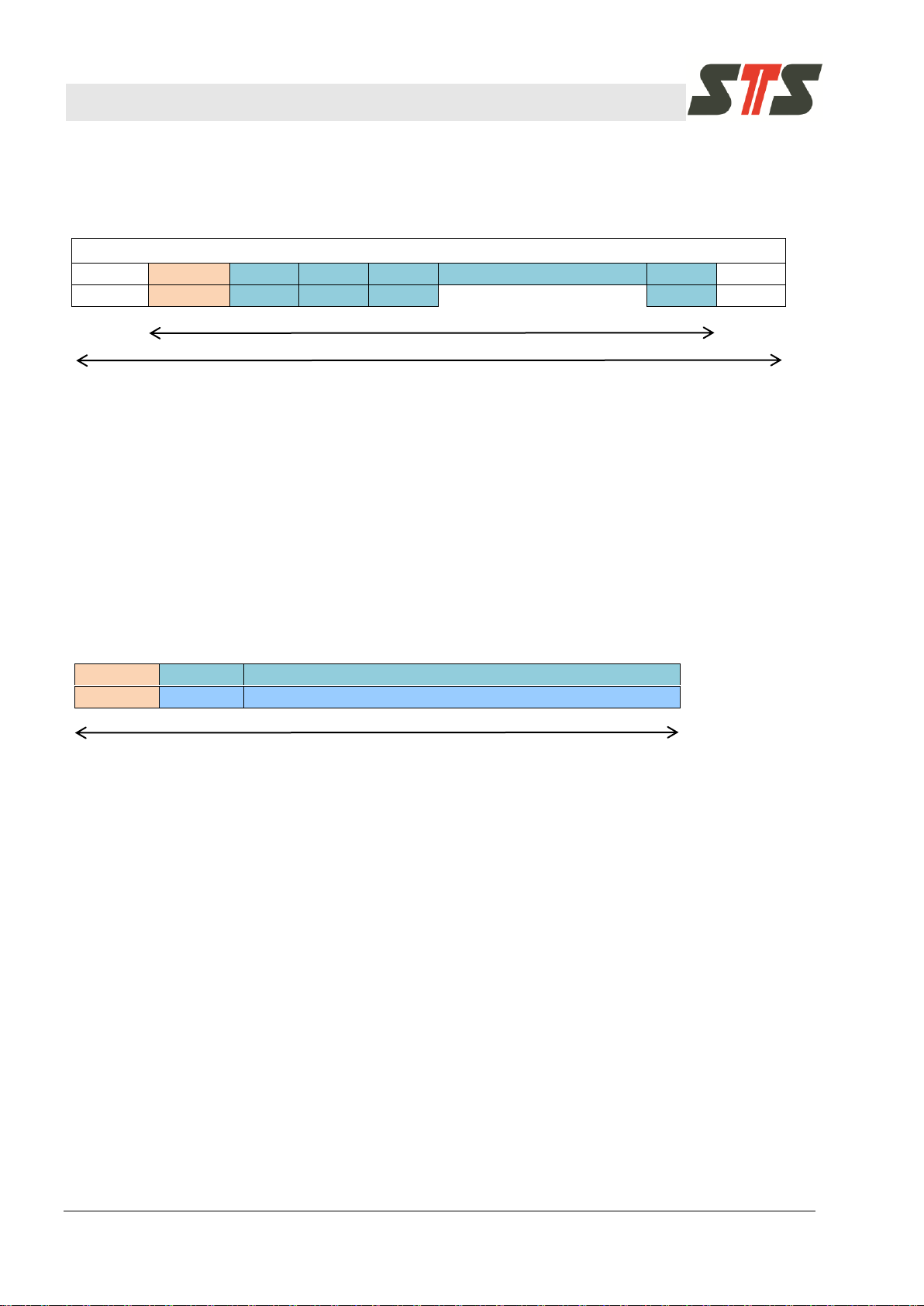

5.3.2 General Modbus message frame structure

Message frame:

Modbus message (command or response)

Address

FC Code

DW1

DW2

DW3

………………………

DWn

CRC

1 byte

1 byte

2 bytes

2 bytes

2 bytes

2 bytes

2 bytes

Modbus PDU

Modbus Serial Line PDU

Tab. 3: Modbus message frame

The number of data words can be derived from the definition of the

respective commands. The CRC checksum is divided into two

individual bytes with the low byte being transmitted first, followed

by the high byte. The CRC checksum is calculated using address,

function code and the data words. If the message is faulty (e.g. an

invalid CRC checksum is provided), no response is given.

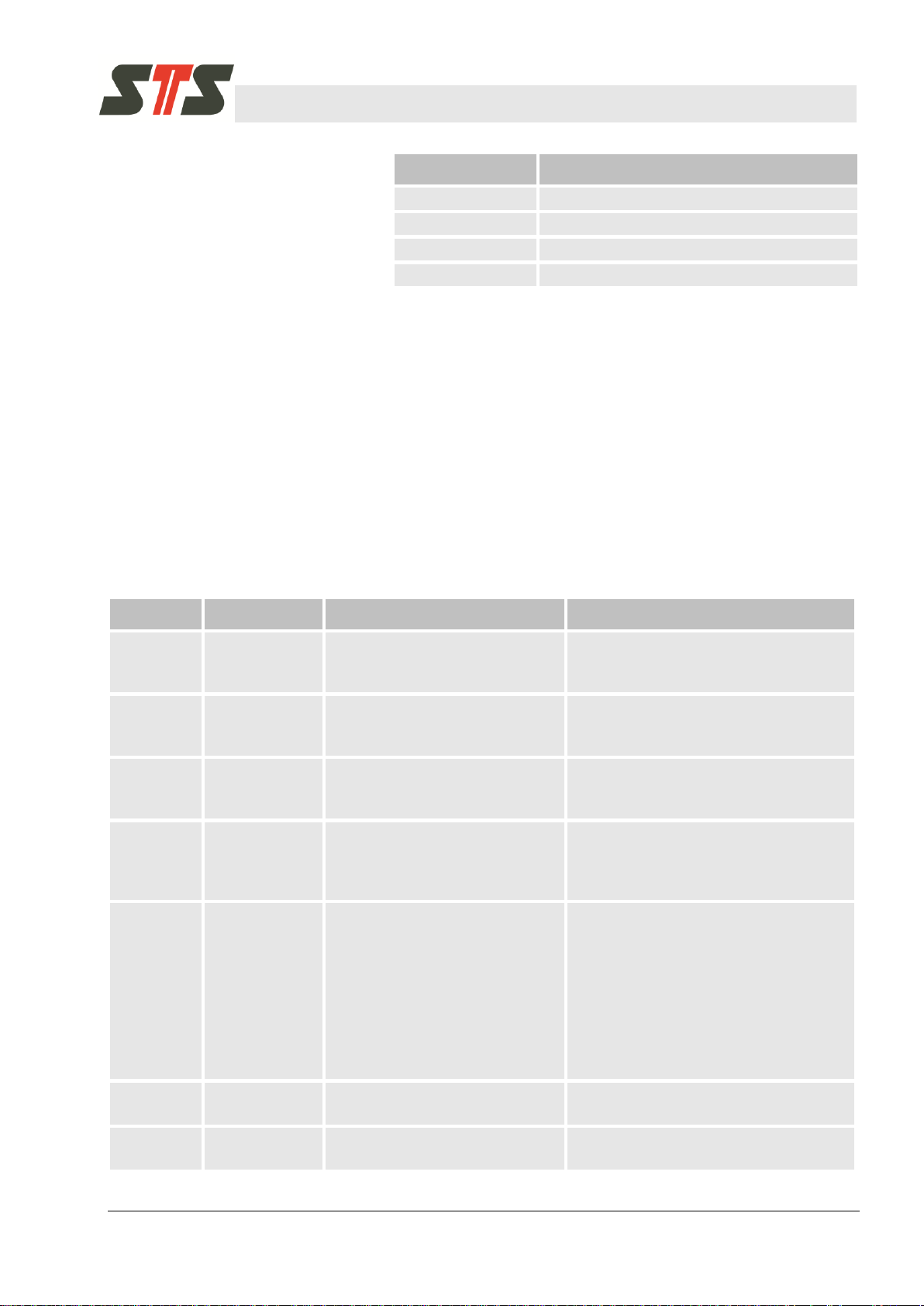

5.4 Modbus STS commands

5.4.1 STS command structure

For the communication with the DTM.OCS.S, a custom STS

function code is used: 0x64 (10010).

FC Code

data size

STS command and its parameter(s) (ASCII encoded strings)

0x64

N

1 ≤N ≤250 bytes

Modbus PDU

Tab. 4: STS command structure

The STS command and its parameter(s) are encoded as readable

ASCII text strings.

As they are embedded in the PDU’s payload field, the data frame

remains Modbus RTU compatible.

5.4.2 Sensor response

As required to be compliant with the Modbus standard, a sensor

response is carried out only upon a request from the master

device. The reply is embedded in the PDU’s payload, encoded as

readable ASCII text strings.

Provided a valid Modbus message frame was received, the reply

will contain the requested data, preceded by the received

command string (without parameters). Additionally, the

DTM.OCS.S returns one of the following status messages and

appends it to the requested data:

Operating manual Digital Transmitter DTM.OCS.S / DTM.OCS.S/N

Communication with the DTM.OCS.S transmitter

Doc-Nr. 10.00.0430 15

Status message

Description

OK

Command has been executed successfully

FAIL

Command execution has been failed

BUSY

The device is busy, try again later

ERROR

Internal error

Tab. 5: Status messages

For a detailed example please see chapter 5.4.4.

5.4.3 List of STS commands

Listed below are the provided STS commands and their associated

parameters. Commands may be called with multiple parameters

combined.

5.4.3.1 MEASURE

The MEASURE command reads out the currently present pressure

and temperature.

Parameter

Example

Exemplary answer

Description

(no

parameters)

MEASURE –P 2.9004 –PU

mH2O –T 27.6 –TU °C

reads out currently measured values

using default settings

2.9004 mH2O, 27.6 °C)

-PU

-PU mbar

MEASURE –P 284.44 –PU mbar

–T 27.6 –TU °C

returns the pressure in the requested

unit

284.44 mbar, 27.6 °C

-TU

-TU K

MEASURE –P 284.44 –PU mbar

–T 300.8 –TU K

returns the temperature in the

requested unit

284.44 mbar, 300.8 K

-UO

-UO 0.1

MEASURE –P 3.0004 –PU

mH2O –T 27.6 –TU °C

adds an offset to the measured

pressure value (the current default unit

is used)

3.0004 mH2O, 27.6 °C

-UG

-UG 2.0

MEASURE –P 5.8008 –PU

mH2O –T 27.6 –TU °C

multiplies the measured pressure value

UG times (the default unit is used)

NOTE! If a user offset (UO) is used then

the displayed pressure pdis calculated

as follows

(pmis the measured pressure value):

pd= UG × (pm+ UO)

5.8008 mH2O, 27.6 °C

-TARE_V

-TARE_V 6.87

-

sets tare

6.87 mH2O

-DTW_V

-DTW_V 2.7

-

sets distance to water

2.7 mH2O

Operating manual Digital Transmitter DTM.OCS.S / DTM.OCS.S/N

Communication with the DTM.OCS.S transmitter

16 Doc-Nr. 10.00.0430

Parameter

Example

Exemplary answer

Description

-REF_V

-REF_V 0.45

-

sets the reference value tare and dtw

are referring to

0.45 mH2O

-SAVE

-SAVE

-

used to save the provided settings

NOTE! Provided settings will only be

saved permanently, if “-SAVE” is used

along with “magic number”.

-M

-M 1234567890

-

“magic number” used for permanently

saving the settings.

Tab. 6: MEASURE command parameters

Examples

Read out temperature but instead of returning the value in the

default unit, return it in Kelvin:

“MEASURE –TU K”

Change the default pressure unit to mWC:

“MEASURE -PU mWC -M 1234567890 -SAVE”

Set distance to water to 2.7 mWC and the reference value to 0.45:

“MEASURE -DTW_V 2.7 -REF_V 0.45 -M 1234567890 -SAVE“

Reset dtw and tare settings:

“MEASURE -DTW_V 0 –TARE_V 0 -REF_V 0 -M 1234567890

-SAVE“

Operating manual Digital Transmitter DTM.OCS.S / DTM.OCS.S/N

Communication with the DTM.OCS.S transmitter

Doc-Nr. 10.00.0430 17

5.4.3.2 Supported pressure units

Unit

Description

mH2O

Meter of water column at 4 °C

cmH2O

Centimeter of water column at 4 °C

mmH2O

Millimeter of water column at 4 °C

ftH2O

Water column at 4 °C (in ft)

mWS

Meter of water column at 4 °C

mWK

Meter of water column at 4 °C

mWG

Meter of water column at 4 °C

mmWG

Millimeter of water column at 4 °C

inWG

Water column at 4 °C (in inches)

mWC

Meter of water column at 4 °C

mmWC

Millimeter of water column at 4 °C

inWC

Water column at 4 °C (in inches)

ftWC

Water column at 4 °C (in ft)

mNN

Meter of water column at 4 °C

mCE

Meter of water column at 4 °C

inHG

Mercury column (in inches)

mFC

Meter of fluid column

mmFC

Millimeter of fluid column

inFC

Fluid column (in inches)

mFG

Meter of fluid column

mmFG

Millimeter of fluid column

mbar

Millibar

bar

Bar

psi

Pound-force per square inch

Pa

Pascal

Operating manual Digital Transmitter DTM.OCS.S / DTM.OCS.S/N

Communication with the DTM.OCS.S transmitter

18 Doc-Nr. 10.00.0430

Tab. 7: Pressure units

hPa

Hectopascal

kPa

Kilopascal

MPa

Megapascal

GPa

Gigapascal

N/m2

Newton per square meter

kN/m2

Kilonewton per square meter

MN/m2

Meganewton per square meter

GN/m2

Giganewton per square meter

N/mm2

Newton per square millimeter

kN/mm2

Kilonewton per square millimeter

5.4.3.3 Supported temperature units

Unit

Description

°C

Degree Celsius

°F

Degree Fahrenheit

K

Kelvin

Tab. 8: Temperature units

5.4.3.4 GETPROBE

The GETPROBE command queries the available measurement

channels of the addressed sensor device.

Parameter

Example

Exemplary answer

Description

-LIST

-LIST

GETPROBE -LIST “-CH” -CH0

Pressure -CH1 Temperature

lists the sensor’s available channels

Tab. 9: GETPROBE command parameters

Example

List the sensor’s available channels:

“GETPROBE -LIST”

Operating manual Digital Transmitter DTM.OCS.S / DTM.OCS.S/N

Communication with the DTM.OCS.S transmitter

Doc-Nr. 10.00.0430 19

5.4.4 STS Modbus commands under the magnifying glass

Below a very detailed example including hex codes on a byte level

is presented to allow a more comprehensive understanding of the

command structure.

We use the command “MEASURE” (see chapter 5.4.3.1) as

illustrating example.

We assume the sensor address is 12310 and that its available

channels are pressure and temperature.

The following Modbus code must therefore be sent to the sensor

(numbers in hex format if not stated otherwise):

device

address

FC

code

data

size

------------------------- data --------------------------

--------- crc ---------

byte

code:

7B

64

07

4D

45

41

53

55

52

45

8A

B4

interpret

ation:

(7B16=12310

)

‚M‘

‚E‘

‚A‘

‚S‘

‚U‘

‚R‘

‚E‘

CRC

low

CRC

high

transmit sequence

Now let’s say the sensor returns a pressure of 10.2500 mH2O and

a temperature of 27.2 °C.

The expected answer (embedded in the Modbus frame payload)

then would be:

“MEASURE -P 10.2500 -PU mH2O -T 27.2 -TU °C OK;”

Expressed as byte code this leads to:

device address

FC code

data size

-------------------- data ---------------------

byte code:

7B

64

2F

4D

45

41

53

55

52

45

20

2D

interpretation:

(7B16=12310)

‚M‘

‚E‘

‚A‘

‚S‘

‚U‘

‚R‘

‚E‘

‚ ‘

‚-‘

transmit sequence

start of sequence

Operating manual Digital Transmitter DTM.OCS.S / DTM.OCS.S/N

Communication with the DTM.OCS.S transmitter

20 Doc-Nr. 10.00.0430

--------------------------------------------- data ---------------------------------------------

byte code:

50

20

31

30

2E

32

35

30

30

20

2D

50

55

interpretation:

‚P‘

‚ '

‚1‘

‚0‘

‚.‘

‚2'

‚5'

‚0'

‚0'

‚ '

‚-'

‚P'

‚U'

transmit sequence

--------------------------------------------- data ---------------------------------------------

byte code:

6D

48

32

4F

20

2D

54

20

32

37

2E

32

20

interpretation:

‚m‘

‚H'

‚2‘

‚O‘

‚ ‘

‚-'

‚T'

‚ '

‚2'

‚7'

‚.'

‚2'

‚ '

transmit sequence

----------------------------------- data -----------------------------------

----- crc -----

byte code:

2D

54

55

20

C2

B0

43

20

4F

4B

3B

40

39

interpretation:

‚-‘

‚T'

‚U‘

‚ ‘

‚C‘

‚ ‘

‚O‘

‚K‘

‚;‘

CRC

low

CRC

high

transmit sequence

Please note that UTF-8 encoding is used for the text strings. In the

example above this applies to the string “°C”, resulting in the byte

code 0xC2B043 (marked cyan).

end of sequence

This manual suits for next models

1

Table of contents

Popular Transmitter manuals by other brands

Brähler Systems

Brähler Systems INFRACOM ICen IV operating instructions

Williams Sound

Williams Sound Hearing Helper T800 Manual and user guide

Motorola

Motorola EX600 user guide

Javad

Javad TRIUMPH-1 Configuration Example

Endress+Hauser

Endress+Hauser cerabar S PROFIBUS-PA operating instructions

CAME

CAME TOP Series user guide