Stuart RE3011C User manual

Operation Manual (EN)

Diaphragm pump

2-headed

Model:

► RE3011C

RE3011C

2016-06-06

France

Bibby Scientific

Bâtiment le Deltaparc

Silic pars Nord 2

7 rue du Canal, BP 55437 Villepinte

95944 ROISSY Charles de Gaulle,

France

Tel: +33 (0) 1 48 63 78 00

Fax: +33 (0) 1 48 63 78 01

www.bibby-scientific.fr

North & South America

Bibby Scientific US

t/a Techne Inc.

3 Terri Lane, Suite 10

Burlington, NJ 08016, USA

Toll Free (in NA): 800-225-9243

Tel: +1 609 589 2560

Fax: +1 609 589 2571

www.bibby-scientific.com

UK

Bibby Scientific Limited

Beacon Road, Stone

Staffordshire

ST15 0SA, UK

Tel: +44 (0)1785 812121

Fax: +44 (0)1785 810405

www.bibby-scientific.com

Middle East

Bibby Scientific Middle East Ltd.

PO Box 27842, Engomi 2433

Nicosia

Cyprus

Tel: +357 22 660 423

Fax: +357 22 660 424

www.bibby-scientific.com

Asia

Bibby Scientific –Singapore

Prudential Tower, Level 26

30 Cecil Street

Singapore 049712

Tel: +65 6631 2976

Fax: +44 (0)1785 810405

www.bibby-scientific.com

Contents

RE3011C 3

Contents

1Important Information.............................................................................................................4

1.1 General Information..................................................................................................................4

1.2 Target Groups...........................................................................................................................4

1.3 Intended Use.............................................................................................................................4

1.4 Use for an Unauthorized Purpose ............................................................................................4

1.5 Safety Devices..........................................................................................................................5

1.6 Meaning of the Warning notes..................................................................................................5

1.7 Product Standards, Safety Regulations....................................................................................5

2Basic Safety Instructions.......................................................................................................6

2.1 General Information..................................................................................................................6

2.2 Electricity...................................................................................................................................6

2.3 Mechanical Systems.................................................................................................................6

2.4 Hazardous Substances.............................................................................................................7

2.5 High Temperatures ...................................................................................................................7

3Description ..............................................................................................................................8

3.1 Design.......................................................................................................................................8

3.2 Principle of Operation ...............................................................................................................8

3.3 Gas ballast................................................................................................................................8

3.4 Areas of Application..................................................................................................................9

3.5 Pump head circuitry ..................................................................................................................9

3.6 Materials of the medium-affecting pump parts..........................................................................9

3.7 Scope of Delivery......................................................................................................................9

4Technical Data.......................................................................................................................10

4.1 Dimensions .............................................................................................................................10

4.2 Intake Pressure / Pumping Speed –Diagram ........................................................................10

4.3 Device Data.............................................................................................................................11

5Installation and Operation....................................................................................................12

5.1 Unpacking...............................................................................................................................12

5.2 Installation and Connection.....................................................................................................12

5.3 Operation ................................................................................................................................12

5.4 Storage....................................................................................................................................12

5.5 Scrap Disposal........................................................................................................................12

6Maintenance and Servicing..................................................................................................13

6.1 General Requirements............................................................................................................13

6.2 Maintenance Performed by the User......................................................................................13

6.2.1 Disassembly............................................................................................................................14

6.2.2 Assembly.................................................................................................................................14

6.2.3 Test.........................................................................................................................................15

6.3 Maintenance by the Manufacturer ..........................................................................................15

6.4 Damage Report.......................................................................................................................15

7Troubleshooting....................................................................................................................16

8Spare Parts Overview...........................................................................................................17

8.1 Service kit................................................................................................................................17

8.2 Spare parts view .....................................................................................................................17

8.2.1 Spare parts list........................................................................................................................18

- Damage Report

- Declaration of Conformity

Important Information

4 RE3011C

1 Important Information

1.1 General Information

The Diaphragm Pump conform to the following directives:

2006 / 42 / EC

Machinery Directive

2014 / 30 / EC

Electromagnetic Compatibility Directive

The CE sign is located on the rating plate. Observe the binding national and local regulations

when fitting the pump into installations.

1.2 Target Groups

This Operating Manual is intended for the personnel planning, operating and maintaining

Diaphragm Pump.

This group of people includes:

Designers and fitters of vacuum apparatus,

Employees working on commercial laboratory and industrial vacuum technology applica-

tions and

Service personnel for diaphragm pumps

The personnel operating and maintaining the diaphragm pump must have the technical

competence required to perform the work that has to be done. The user must authorize the

operating personnel to do the work that has to be done. The personnel must have read and

understood the complete Operating Manual before using the diaphragm pump.

The Operating Manual must be kept at the place of use and be available to the personnel

when required.

1.3 Intended Use

The layout of the diaphragm pump must be appropriate for the conditions of use. The

user bears the sole responsibility for this.

The diaphragm pump may only be operated under the conditions stated

–in the "Technical Data" section,

–on the type plate, and

–in the technical specification for the order concerned.

Diaphragm pumps are approved for extracting, pumping and compressing gases and va-

pours. If these gases and vapours are toxic or explosive, then the user must observe the

currently valid safety regulations for this application. Special types of diaphragm pumps

are available for aggressive and explosive gas mixtures.

1.4 Use for an Unauthorized Purpose

It is forbidden to use the pump for applications deviating from the technical data stated on

the type plate or the conditions stated in the supply contract, or to operate it with missing or

defective protective devices.

Important Information

RE3011C 5

1.5 Safety Devices

Measures such as the following are for the safety of the operating personnel:

electrical connection with a protective conductor (operating mode S1) and an earthing

plug,

Motor protection switch (thermal) and

“Hot Surface" label on the pump body - warning notice

The diaphragm pump must not be operated without these elements.

1.6 Meaning of the Warning notes

Take note of the warning notices. They are in the following box:

CAUTION ! / WARNING !

Hazard which may lead to serious injuries or material damage.

1.7 Product Standards, Safety Regulations

The Diaphragm Pump meetsthe following product standards:

DIN EN ISO 12100:2011-03

Safety of machinery -

General principles for design - Risk assessment and risk reduction

DIN EN ISO 13857:2008-06

Safety of machinery - Safety distances to prevent hazard zones being reached

by upper and lower limbs

DIN EN 1012-2:2011-12

Compressors and vacuum pumps - Safety requirements -

Part 2: Vacuum pumps

DIN EN ISO 2151:2009-01

Acoustics - Noise test code for compressors and vacuum pumps - Engineering

method (grade 2)

DIN EN 60204-1:2014-10

Safety of machinery - Electrical equipment of machines -

Part 1: General requirements

DIN EN 61000-6-2:2011-06

DIN EN 61000-6-4:2011-09

Electromagnetic compatibility (EMC) -

Part 6-2: Generic standards - Immunity for industrial environments

Part 6-4: Generic standards - Emission standard for industrial environments

DIN EN 61010-1/A1:2015-04

Safety requirements for electrical equipment for measurement, control and

laboratory use - Part 1: General requirements

DIN EN 50110-1:2014-02

Operation of electrical installations

Directive 2012/19/EC

Electrical and electronics - old devices (WEEE)

Directive 2011/65/EC

Dangerous materials in electrical and electronics devices (RoHS)

China - RoHS

Environment protection law - China 2007-03

The following additional safety regulations apply in the FR Germany:

BGV A3

Electrical equipment and operating materials

VBG 5

Power-driven machines

BGR 120

Guidelines for laboratories

BGI 798

Hazard assessment in the laboratory

BGG 919 (VBG 16)

Accident prevention regulations for "compressors"

BGR 189 (BGR 195;192;197)

Use of protective working clothes

Observe the standards and regulations applying in your country when you use the dia-

phragm pump.

Basic Safety Instructions

6 RE3011C

2 Basic Safety Instructions

2.1 General Information

Warning notices must be observed. Disregarding them may lead to damage to health and

property.

The diaphragm pump must be operated by personnel who can detect impending dangers

and take action to prevent them from materialising.

The manufacturer or authorized authorised workshops will only service or maintain the dia-

phragm pump if it is accompanied by a fully completed damage report. Precise information

about the contamination (also negative information if necessary) and thorough cleaning of

the diaphragm pump are legally binding parts of the contract.

Contaminated diaphragm pumps and their individual parts must be disposed of in accor-

dance with the legal regulations.

The local regulations apply in foreign countries.

2.2 Electricity

The diaphragm pump of operation mode S1 is supplied. When the location of operation

mode S1 devices is changed, please note that the testing must be repeated in accordance

with DIN EN 0105, DIN EN 0702 and BGV A2.

The local regulations apply in foreign countries.

Please note the following when connecting to the electrical power supply system:

The electrical power supply system must have a protective connector according to DIN

VDE 0100-410 (IEC 60364-4-41).

The protective connector must not have any breaks.

The connecting cable must not be damaged.

2.3 Mechanical Systems

Improper use can lead to injuries or material damage. Observe the following instructions:

Only operate the diaphragm pump with hoses of the specified dimensions.

The maximum permissible pressure of 1 bar at the suction connection must not be ex-

ceeded.

Hazardous substances must be separated out as far as this is technically possible before

they reach the pump.

External mechanical stresses and vibrations must not be transmitted to the pump. Only

use flexible NW 8 laboratory hoses for connecting diaphragm pumps.

The overpressure generated at the pressure port must not exceed 1 bar.

The pump must not be used to suck up fluids. Lay the exhaust pipe so that it slopes

downwards, so allowing condensate to flow out of the pump. Collect the condensate and

dispose of it in an environmentally compatible manner.

Prevent dyes exuding.

Maintain a space of least 20 mm between the pump and adjacent parts in order to enable

the pump to cool.

CAUTION !

Solid particles in the pumping medium impair the pumping action and can lead to

damage. Prevent solid particles penetrating into the pump.

Basic Safety Instructions

RE3011C 7

2.4 Hazardous Substances

The operating company bears the responsibility for the use of the diaphragm pump.

Hazardous substances in the gases to be pumped can cause personal injuries and property

damage. Pay attention to the warning notices for handling hazardous substances.

The local regulations apply in foreign countries.

Combustible Gases

Examine before switching on whether that can form gas combustible gas/air mixtures which

can be promoted! Consider the regulations of the guideline 1999/92/EC.

Explosive gases

The Diaphragm pump RE3011C is not certified according to ATEX guidelines 94/9/EC.

Aggressive gases

The Diaphragm pump RE3011C is designed for extracting contaminated gases!

Especially aggressive gases have to be explicitly checked for material resistance as de-

scribed in chapter 3.6 and, if necessary, modified.

Poisonous gases

Use a separator when pumping poisonous or harmful gases. Prevent such substances from

leaking out of the appliance or pump. Treat these substances according to the applicable

environmental protection regulations.

Test the strength and leak-tightness of the connecting lines and the connected apparatus.

Prevent environmental poisons, e.g. mercury, getting into the diaphragm pumps.

Fulfil the requirements, for example:

German Hazardous Substances Regulation (GefStoffV) of 01. December 2010

Regulations 2006/121/EC (classification, packaging and identification of hazardous sub-

stances),

Manufacturer's safety data sheets on hazardous substances.

2.5 High Temperatures

The diaphragm pump may heat up as a result of the temperature of the gas being pumped

and through compression heat.

Prevent the following maximum permissible temperatures from being exceeded.

+ 40 °C for the environment, and

+ 60 °C for the gas to be pumped.

The motor for single phase alternating current is protected against overload by an integrated

motor protection switch.

Description

8 RE3011C

3 Description

3.1 Design

The diaphragm pump consists of a pump

casing and a drive motor.

The pump casing contains the drive unit and

two pump heads.

Both pump head contains a diaphragm and

the work valves. Two pair of pump heads are

arranged opposite each other.

The pump heads are driven via an eccentric

shaft with a connecting rod.

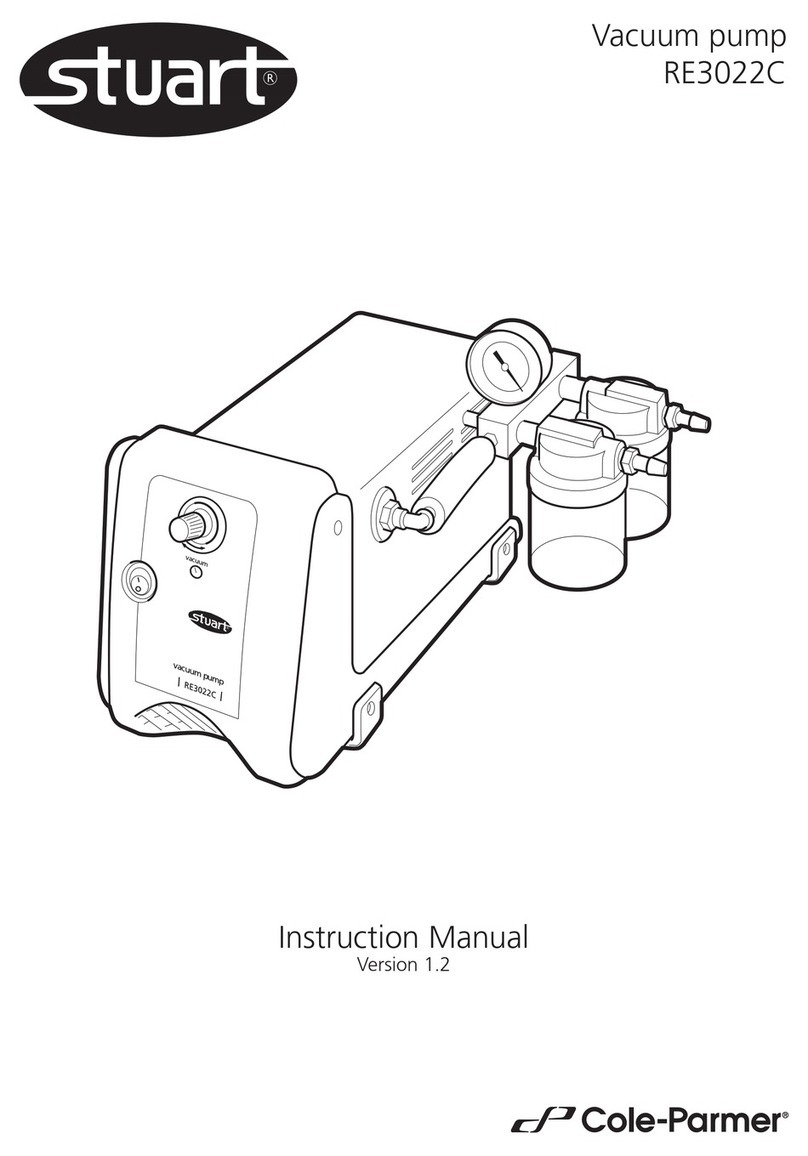

Fig. 1 Diaphragm pump RE3011C

3.2 Principle of Operation

Motor, eccentric shaft and connecting rod set the diaphragms in stroke movement. This

changes the size of the space between the diaphragms and pump head (pump chamber).

Increasing the size of the pump chamber opens the inlet valve while the outlet valve is

closed (intake process).

Decreasing the size of the pump chamber ejects the gas through the outlet valve.

The valves are actuated by the gas being pumped. A large proportion of fluid in the dia-

phragm pump minimizes the pumping efficiency.

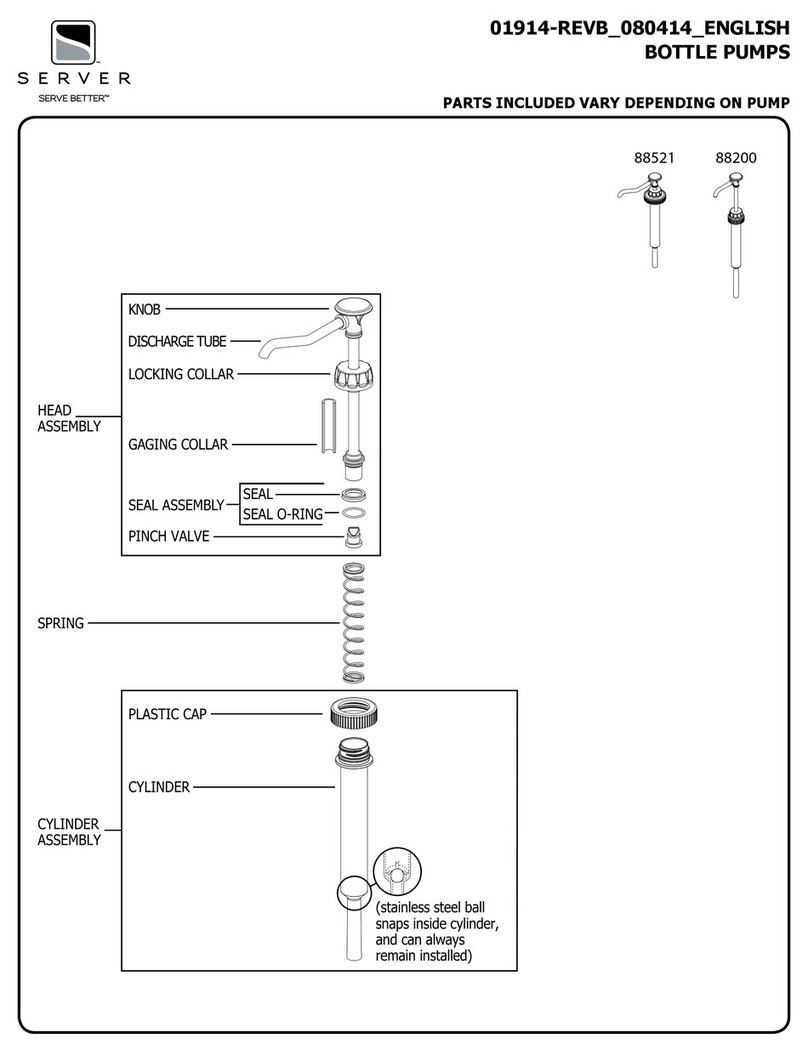

3.3 Gas ballast

When condensable vapours are pumped, they

may be compressed above the saturated vapour

pressure and condense.

Opening the gas ballast valve (A) in the suction

line of the last pump stage allows air to flow into

the pump chamber. This prevents condensation

and flushes the pump clear.

Operation leads to increasing the ultimate pres-

sure and the operating temperature.

Fig. 2 Gas ballast valve

(A)

Description

RE3011C 9

3.4 Areas of Application

The Diaphragm Pump is intended for:

Pumping and compressing neutral and aggressive gases and vapours.

Generating a vacuum down to an ultimate pressure < 8 mbar.

Use in physical and chemical laboratories in trade and industry.

Use for vacuum filtration, vacuum distillation and vacuum drying, and other vacuum tech-

nology applications.

3.5 Pump head circuitry

Two-stage:

Both pump heads are connected in series.

3.6 Materials of the medium-affecting pump parts

Component

Chemical model - RE3011C

(resistant to aggressive gases)

Seal

EPDM

Screw fitting / Connecting elements

PVDF, PP

Valve

PEEK

Diaphragm

Elastomer + PTFE Layer

Vacuum hose

PTFE

Connection head / Pump head

PTFE with carbon-fibre reinforcing *)

*) electrically conductive (with manufacturer's certificate of electrical conductivity)

Material resistance to aggressive media see: Publisher Hoppenstedt Publishing (18. September 2007)

3.7 Scope of Delivery

The scope of delivery is specified in the supply contract.

Technical Data

10 RE3011C

4 Technical Data

4.1 Dimensions

1

Gas ballast valve

2

Intake port

(Hose nozzle DN 8 for hose inside diameter 8 mm)

3

Pressure port

(Hose nozzle DN 8 for hose inside diameter 8 mm)

Fig. 3 Dimensions

4.2 Intake Pressure / Pumping Speed –Diagram

Fig. 4 Intake Pressure / Pumping Speed –Diagram

Technical Data

RE3011C 11

4.3 Device Data

Parameter

Unit

Data

Pumping performance 50/60 Hz

DIN 28432

at speed of 1500 rpm

m3/ h

1.0 / 1.1

l / min

16.7 / 18

Ultimate pressure

at speed of 1500 rpm

mbar

8

Ultimate pressure with

gas ballast

at speed of 1500 rpm

18

Max. inlet pressure

bar

1

Max. outlet pressure

1

Pump stages

-

2

Intake and pressure ports

-

Hose nozzle DN 8

for hose inside diameter 8 mm

Ambient temperature

°C

+ 10 to + 40

Max. Operating gas temperature

+ 60

Bearing

-

maintenance-free

Reference surface sound pressure level

DIN EN ISO 2151

dB (A)

44

Voltage / Frequency

(with motor protection switch, switch

and cable)

V, Hz

230, 50/60

Power

kW

0.06

Operating mode

-

S 1

Type of protection DIN EN 60529

IP 54

Class of insulation DIN EN 600034-1

F (160°C)

Weight

kg

6.5

Dimensions (W/D/H)

mm

195 / 235 / 145

Order no.

-

RE3011C

The information presented in this material is based on technical data and test results of nominal units. It is believed

to be accurate and reliable and is offered as and aid to help in the selection of products.

It is the responsibility of the user to determine the suitability of the product for the intended use and the user as-

sumes all risk and liability whatsoever in connection therewith.

Bibby Scientific Limited does not warrant, guarantee or assume any obligation or liability in connection with this in-

formation.

Installation and Operation

12 RE3011C

5 Installation and Operation

5.1 Unpacking

Carefully unpack the diaphragm pump.

Check the pump for:

Transport damage,

Conformity with the specifications of the supply contract (type, electrical supply data),

Completeness of the delivery.

Please inform us without delay if there are discrepancies between the delivery and the con-

tractually agreed scope of delivery, or if damage is detected.

Please take note of the general terms of business of the manufacturing firm.

In case of a claim under warranty, the device must be returned in packaging that is

suitable for protecting it during transport.

5.2 Installation and Connection

1. Set the diaphragm pump on a flat and horizontal surface.

2. Remove the protective caps on the suction and pressure ports.

3. Prepare the connections.

4. Connect the DN 8 vacuum connector to the suction port.

5. Connect the exhaust pipe to the pressure connection.

6. Connect the diaphragm pump to the electrical supply.

5.3 Operation

Observe the basic safety instructions when using the pump.

The diaphragm pump is switched on and off at the operating switch.

5.4 Storage

The pumps are to be stored in a low-dust, interior room within the temperature range from

+ 5 to + 40 °C and at a relative air humidity < 90%.

Leave the protective elements on the suction and pressure ports. Another equally good pro-

tection may be used.

5.5 Scrap Disposal

CAUTION !

The Diaphragm pump must be disposed of in accordance with the 2012/19/EC

guideline and the specific national regulations.

Contaminated Diaphragm pumps must be decontaminated according to the laws.

Maintenance and Servicing

RE3011C 13

6 Maintenance and Servicing

6.1 General Requirements

Check the pump daily for unusual running noises and heat building up on the surface of

the pump.

We recommend changing the diaphragm after 10,000 operating hours. The user may

specify that the exchange be made earlier, depending upon the application process.

Check the electrical and vacuum connections daily.

6.2 Maintenance Performed by the User

WARNING !

Only perform the work that is described here, and that which is permitted to be done

by the user.

All other maintenance and service work may only be performed by the manufacturer

or a dealer authorized by him.

Beware of the pump parts being possibly contaminated by hazardous substances.

Wear protective clothing if there is contamination.

Scope of permissible work:

Loosen and remove the hoses

Open and remove the pump heads

Inspect the pump chambers, diaphragms and valves

Deposits in the inside of the pump must be cleaned out

Change the diaphragms, valves and seals

Tools required:

Tool kit: Order no. RE3011C/1

consists of:

Pin type face wrench, adjustable, size 3

Allan key, size 4

Open spanner, size 17

Maintenance and Servicing

14 RE3011C

6.2.1 Disassembly

1. Disconnect the power supply and ensure that it cannot be switched on again.

2. Open the screw clamps of the hoses on the pump body with the SW 17 open spanner.

3. Remove four machine screws (1) from each connection head with an Allan key, size 4.

4. Lift off the pressure plate (2), the connection head (3) and the pump head (6). The valve

gasket (5) and diaphragm (8) are now freely exposed.

5. Loosen the diaphragm (8) at the strain washer (7) by turning the size 3 pin type face

wrench anticlockwise.

6. Clean the valve gasket (5) the pump head (6) and the diaphragm (8) with a soft cloth and

acetone.

7. Check that the drive is in good working order.

Fig. 5 Disassembly, Assembly

WARNING !

Renew defective parts, if necessary! Wear protective gloves!

Parts must be renewed at the intervals stated in this Operating Manual or as speci-

fied by the user internally! Do not clean with compressed air!

6.2.2 Assembly (see Fig. 5)

1. Place the pump so that the diaphragm is lying in a horizontal position.

2. Use the size 3 pin-type face wrench to tighten the pressure disc (9), the diaphragm (8)

and the strain washer (7) with the correct torque of 2 - 4 Nm.

3. Bring the connecting rod (5) (see Fig. 6) and the diaphragm (8) into the central position.

4. Replace the pump head (6).

5. Insert the valve (5) and the O-ring (4).

Ensure that they are lying completely flat. Do not insert the burred side facing the sealing

surface. Align the connection head flush with the pin.

6. Replace the pressure plate (2) and insert and tighten the 4 machine screws with a torque

of 3 - 4 Nm.

7. Reattach the hose connections with clamping ring screw fittings.

Maintenance and Servicing

RE3011C 15

6.2.3 Test

Connect a vacuum measuring device to the suction connector and measure the ultimate

pressure.

If the device is working properly, then the figure stated in the technical data must be at-

tained within a maximum of one minute.

The pump must not make any abnormal noises.

Moving parts must not touch each other.

6.3 Maintenance by the Manufacturer

Repairs and maintenance going beyond the extent of the work described in chapter 6.2 or

reconditioning or modification may only be performed by the manufacturer or authorized

workshops.

WARNING !

The user shall be liable for the consequences of an incorrect damage report or a

contaminated pump. The statements in the damage report are legally binding.

6.4 Damage Report

You find the form of the damage report to the appendix of this manual.

WARNING !

Incomplete or incorrectly completed damage reports may endanger the service

personnel!

Give full information in the damage report, in particular regarding a possible con-

taminating of the sensor.

Troubleshooting

16 RE3011C

7 Troubleshooting

Only manufacturing firm and authorized service workshops may work on the diaphragm

pump and their accessories during the warranty period.

Trouble

Cause

Remedy

by:

with:

Vacuum pump

does not start

No power supply

Qualified

electrician

Check electrical installation

Motor defective

Service

workshop

Exchange

Pump body defective

Repair and/or exchange

Vacuum pump

does not

generate a

vacuum or

only an

inadequate

one

Connected apparatus

and/or

connecting elements

leaking

User or

Service

workshop

Identify and seal the leak,

replace the seals and/or

hoses if necessary.

Vacuum pump leaking

Check the hose

connections between the

pump heads, replace the

hoses and/or fittings if

necessary.

Pump head leaking

Service

workshop

Repair and/or exchange

Diaphragm defective

User or

Service

workshop

Exchange of the diaphragm

(see chapter 6.2)

Valve defective

Exchange of the valve

(see chapter 6.2)

Vacuum pump dirty

General maintenance /

cleaning

Valves dirty

Cleaning condensates and

foreign objects out of the

valves.

Running noise

Vacuum pump dirty

User or

Service

workshop

General maintenance /

cleaning

Cable(s)

defective and/or brittle

Qualified

electrician

Exchange of the cable(s)

Spare Parts Overview

RE3011C 17

8 Spare Parts Overview

The spare parts lists contain all the spare parts and all the information necessary for order-

ing. When ordering, please quote the description, quantity and serial number!

CAUTION !

We are not liable for any damage caused by the installation of any parts not sup-

plied by the manufacturer.

8.1 Service kit

Designation

Order no.

Service kit

RE3011C/2

The Service kit consists of:

Designation

Piece

O-Ring ø 28 x 2

4

O-Ring ø 12 x 2

3

Valve

4

Diaphragm

2

8.2 Spare parts view

Fig. 6 Exploded view

Spare Parts Overview

18 RE3011C

8.2.1 Spare parts list

Item

no.

Designation

Piece

-

Basic pump complete (consisting of position: 1 –5)

1

1

- Pump casing

1

-

- Drive complete (consisting of position: 2 –4)

1

2

- Eccentric

1

3

- Piston rod with ball bearing

2

4

- Close tolerance spacer 25x35x1

3

5

- Alternating-current motor

1

- IEC power cable extension

1

-

Mains connection cable IEC with plug CEE (D)

1

Mains connection cable IEC with plug BS (UK)

1

6

Pressure washer

2

7

Diaphragm

2

8

Tightening washer

2

9

Pump head 1

2

10

Valve

4

11

O-Ring EPDM ø 28 x 2

4

12

Connecting head 1

2

13

Pressure plate

2

14

O-Ring EPDM ø 12 x 2

3

15

Hose nozzle PP, DN 8 - 1/4"

2

16

Gas ballast valve

1

17

Straight threaded joint with seal edge PVDF, 8 - 1/4"

1

18

Vacuum hose PTFE, 8 / 6x1 mm

0.2 m

19

Threaded elbow joint PVDF, 8 - 1/4"

1

20

Handle

1

21

Rubber-metal pad 20 x 24

2

22

Rubber-metal pad 15 x 6

2

Damage Report

(EN)

RE3011C E Damage Report 2015-08-19

Bibby Scientific Limited

Beacon Road, Stone

Staffordshire

ST15 0SA, UK

Tel: +44 (0)1785 812121

Fax: +44 (0)1785 810405

Email: [email protected]

www.bibby-scientific.com

Order No.:

Date of Purchase:

Company

/

Facility

Typ

e No.:

Seri

al No.:

Str

eet

Typ

e

:

P

ost Code

/

Town

1. Description of the fault: (Which fault occurred?)

2. Conditions of use:

a) Were the pumps / components in use?

yes

no

b) Which oil was used? * _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

c) Field of application (load, process, use): _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

3. Type of contamination of pumps / components:

a) toxic **

1)

yes

no

b) corrosive **

1)

yes

no

c) microbiological **

1)

yes

no

d) explosive

1)

yes

no

e) radioactive **

1)

yes

no

f) other harmful substances

1)

yes

no

* In the case of rotary vane pumps

and roots pumps (Important!) **

Pumps / components will only be accepted if proof is provided that they have been properly cleaned.

By arrangement, cleaning can be done by Bibby Scientific Limited.

Type(s) of substances or process-related reaction products which came into contact with the pumps/ components:

1)

Commercial name /

Product name / Manufacturer

1)

Chemical name

(possibly formula) 1) Danger class

1)

Actions to be taken if

harmful substances escape

1)

First aid in case

of accidents

1.

2.

3.

4.

Are the pumps / components free of harmful substances?

yes

no

4. Legally binding declaration:

I/ We declare that the statements here are correct and complete.

The pumps / components are shipped in accordance with the legal requirements. Hereby we order the repair.

Contact: _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ Phone: _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

Department: _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

Fax: _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

Date: _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

Legally binding signature: _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ Company Stamp:

The repair can only be made if a completely filled out damage report is received. Otherwise the work may be delayed. Our general terms of delivery

and payment apply.

1) Answer all questions or mark with

yes or

no. If a box is not filled out, we automatically suppose that there was a contamination and

the required measures are charged to you.

Return Authorization No.

RNA:

Table of contents

Languages:

Other Stuart Water Pump manuals

Popular Water Pump manuals by other brands

Sunlight Supply

Sunlight Supply Eco 185 instruction manual

GORMAN-RUPP

GORMAN-RUPP AMT 3993-96 Specifications information and repair parts manual

Circoflo PRO

Circoflo PRO CFM-MXVP0111 installation guide

KSB

KSB moviBOOST Vt manual

AL-KO

AL-KO JET 4000 manual

Wilden

Wilden Original Series operation & maintenance

Grundfos

Grundfos CH Series Installation and operating instructions

Graco

Graco Husky 2150e repair parts

MULTIQUIP

MULTIQUIP QP303H Operation and parts manual

Edwards

Edwards nXR30i instruction manual

Grundfos

Grundfos CRN 95 Service instructions

Ingersoll-Rand

Ingersoll-Rand ARO PD10P Series Operator's manual