Specications Information and Repair Parts Manual 3993-96, 3993-Z6, 3994-96 & 4210-96

3993-254-00 2 3/2017

MAINTENANCE

MECHANICAL SEAL REPLACEMENT

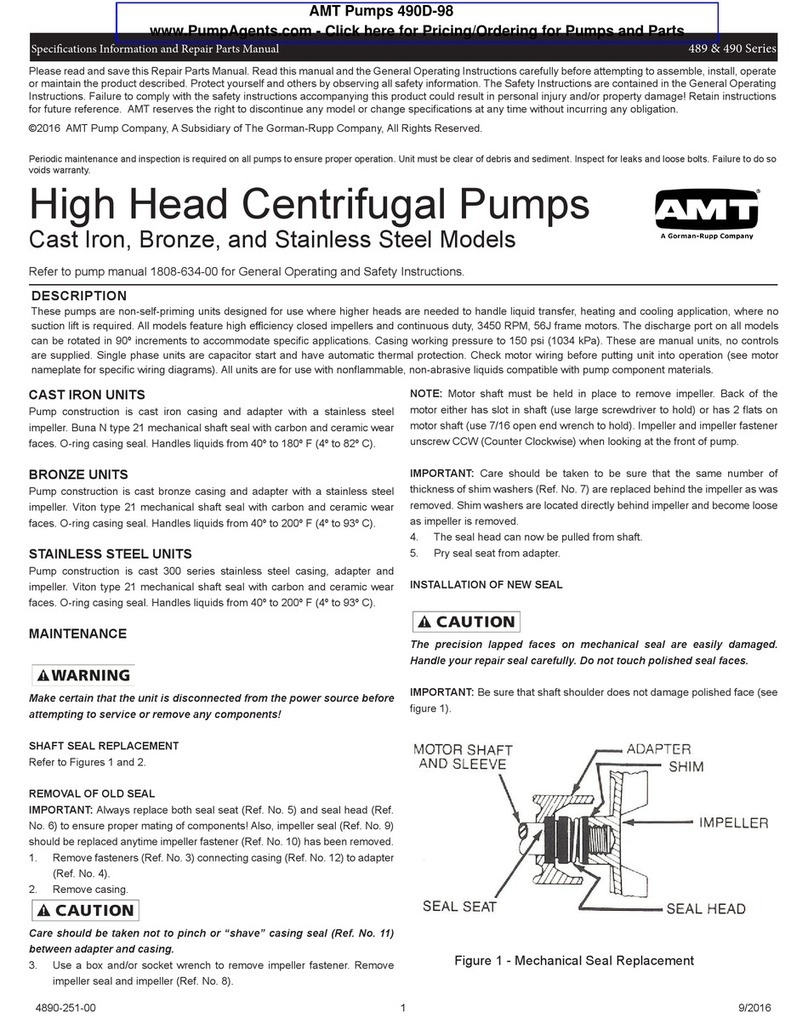

Refer to Figures 1 and 2

NOTE: Always replace the seal seat (Ref. No. 12), seal head

(Ref. No. 13) and shaft sleeve (Ref. No. 3) to ensure proper

mating of mechanical seal components!

See Figure 1

1. Unthread cap screws (Ref. No. 20) and remove casing

(Ref. No. 19) and casing seal (Ref. No. 37) from casing

cover (Ref. No. 6).

2. Unthread screws (Ref. No. 15) and remove volute (Ref. No.

14) from casing cover.

3. Unscrew impeller (Ref. No. 2) from the engine shaft.

Remove the impeller shim (Ref. No. 5), shaft sleeve and

seal head from engine shaft. Use a rubber mallet or soft

block of wood to loosen impeller. Turn it counterclockwise.

Disconnect spark plug wire and battery to prevent

accidental starting.

4. Unthread cap screws (Ref. No. 9) and remove the adapter

(Ref. No. 7) and casing cover from the engine mounting

face.

5. Push seal seat from the casing cover recess with a

screwdriver.

6. Clean the casing cover recess before inserting a new seal

seat.

7. Carefully wipe the polished surface of the new seal seat

with a clean cloth.

8. Wet the rubber portion of the seal seat with a light coating

of soapy water.

9. Press the new seal seat squarely into the cavity in the

casing cover. If the seal seat does not press squarely into

the cavity, it can be adjusted in place by pushing on it with

a piece of pipe. Always use a piece of cardboard between

the pipe and the seal seat to avoid scratching the seal

seat. (This is a lapped surface and must be handled very

carefully).

10. After the seal seat is in place, ensure that it is clean and

has not been marred.

11. Using a clean cloth, wipe the shaft and make certain that it

is perfectly clean.

12. Secure the adapter on the engine mounting face.

NOTE: Tighten cap screws EVENLY to avoid cocking rabbet on

engine mounting face.

13. Apply a light coating of soapy water to the inside rubber

portion of seal head and slide onto the shaft sleeve. Slip

the shaft sleeve with seal head onto the engine shaft.

IMPORTANT: Before installing new shaft sleeve, apply a bead

of non hardening, pliable sealant (such as Permatex® Form-A-

Gasket® No. 2) around motor shaft shoulder.

Do not touch or wipe the face of the polished part of the

seal head.

14. Replace any impeller shims removed in disassembly.

15. Screw the impeller back in place tightening until it is seated

against shims and shaft sleeve.

NOTE: Check to be sure that the shaft sleeve (Ref. No. 3) is in

place against engine shaft shoulder. Model 3993-96 requires a

shaft ange (Ref. No. 4).

16. Remount volute with fasteners.

17. Refer to section titled Shim Adjustment at this time if shaft

sleeve or any other parts listed therein have been replaced.

18. Inspect position of apper valve assembly (Ref. No. 16) to

ensure proper movement and sealing.

19. Replace o-ring seal on volute rabbet.

NOTE: Always inspect o-ring seals. Replace when cracked or

worn. Wet o-ring with soapy water for ease of assembly.

20. Remount casing.

21. Remount any other parts and reconnect spark plug wire

and battery (if so equipped). Pump should now run with

renewed original performance.

SHIM ADJUSTMENT

1. When installing a replacement impeller, engine, shaft

sleeve, adapter, or volute, it may be necessary to vary the

number of impeller shims (Ref. No. 5) that will be required.

This is easily done by adding one shim more than was

removed and reassembling the pump as described in

Mechanical Seal Replacement section.

2. Ensure that volute (Ref. No. 14) and casing cover (Ref. No.

6) are tted rmly (check fastener Ref. No. 15). Remove

spark plug wire from engine and turn engine over by pulling

the recoil starter. If engine does not turn freely, disassemble

pump and remove one shim.

NOTE: When adding or removing shims, it is best to proceed

with a 0.010” increment each time. If engine does turn freely,

add shims until it does strike, then remove a 0.010” shim. This

should allow proper clearance.

4-INCH TRASH PUMP

Figure 1 - Mechanical Seal

www.PumpAgents.com - Click here for Pricing/Ordering for Pumps and Parts

AMT Pumps 3993-Z6