stud welding products StudPro 2500i User manual

OPERATION MANUAL

MODELS

TWE-250

TWE-321

TWE-375

TRU‐WELDEQUIPMENTCOMPANY

6400N.HONEYTOWNROAD

SMITHVILLE,OHIO44677

(330)669‐2773

Downey, CA

9459 Washburn Rd.

Downey, CA 90242

Phone- 800.252.1919

Fax- 562.862.3022

Hayward, CA

2391 American Ave.

Hayward, CA 94545

Phone- 510.782.7883

Fax- 510.782.7918

Renton, WA

927 Thomas Ave. SW

Renton, WA 98057

Phone- 425.656.9787

Fax- 425.656.9786

Phoenix, AZ

3535 East Wier Ave., Ste. #4

Phoenix, AZ 85040

Phone- 602.305.9350

Fax- 602.305.4890

Toll free customer support: 1.800.252.1919

MODEL

StudPro 2500i

2

22

CONTENTS

SectionDescriptionPages

1Introduction3

2ExternalFeatures4‐5

3Safety6‐8

4SetupandWelding9‐15

5TestingWeldSettings16

6InspectingTheWeld17

7CDStudGunViews18

8CDStudGunExplodedView19

9CDStudGunPartsList20

10CDControllerExplodedView21

11CDControllerPartsList22

1 Introducon 3

2 External Features 4-5

3 Safety 6-8

4 SetupandWelding 9-15

5 TesngWeldSengs 16-19

6 TypesofFractures 20

7 ArcBlowEect 21

8 CDStudGunExplodedView 22

9 InternalComponents 23-25

10 CDAccessoreis 26-30

11 TorqueBendingTest 31-32

12 CDGunSetUp’s 33-34

1 Introducon 3

2 External Features 4-5

3 Safety 6-8

4 SetupandWelding 9-15

5 CupHeadWelding 16-17

6 TesngWeldSengs 18-21

7 TypesofFractures 22

8 ArcBlowEect 23

9 CDStudGunExplodedView 24

10 InternalComponents 25-27

11 CDAccessoreis 28-32

12 TorqueBendingTest 33-34

13 CDGunSetUp’s 35-36

3

33

Thecompleterangeofthecapacitordischargeequipmentiscompact,portablestud

weldingequipment.Theunitsarespecificallydesignedtoenableasmalldiameter

rangeofferrousandnonferrousweldstudstobeweldedtolightgaugemetalmateri‐

alswithlittleornoreverse‐sidemarking.

Theequipmentconsistsofacontrolunit,aweldinghandgun,andallnecessaryinter‐

connectingcables.

THEPROCESS

CapacitorDischarge(CD)studweldingisaformofweldinginwhichtheenergyre‐

quiredfortheweldingprocessisderivedfromabankofchargedcapacitors.This

storedenergyisdischargedatthebaseofthespeciallydesignedCDstudanditfuses

thestudtothebasematerial.Thetimeoftheweldisdeterminedinsuchashortdu‐

rationthatnoburnthroughmarkingismadeonthefinishsideofthematerial.

CONTACT

IncontactCDwelding,thestudisplacedunderspringpressureonthematerialtobe

welded.Whenthecapacitorsaredischarged,thespecialtipoftheCDstudmeltsand

thespringpressureforcesthestudtofusewiththebasematerial.

GAP

IngapCDwelding,thestudisplacedontothematerialtobewelded.Asthestudgun

isengaged,thestudliftsfromthebasematerialandthenreturnstothepointofcon‐

tactatthetimeofthedischargeofthecapacitors.Asthecapacitorsdischarge,melt‐

ingthetipoftheweldstud,thepressurecreatedbythemovementofthestudtothe

basematerialbythestudgunfusesthestudtothebasematerial.

INTRODUCTION

4

4

4

FRONTPANEL

1.WeldVoltageSelector‐rotatetochangetorequiredvoltage.

2.WeldingVoltageDigitalDisplay‐displaysselectedvoltage.

3.LEDLights‐Charging(capacitorsarebeingchargingtodesiredvoltage),Ready

(unitisreadytoweld),Reset(indicatesanerrorandunitshouldbeturnedoff).

4.WeldingGroundCableConnector(+)

5.StudGunControlConnector

6.WeldingStudGunCableConnector(‐)

EXTERNAL FEATURES

1

4

2

56

3

1

2

3

654

7. GroundCupHead

7

5

55

REARPANEL

1.On/OffSwitch

2.FuseHolder(10amp)

3.ACPowerCord

4.ManufacturerModelNumberandSerialNumberPlate

WARNING!

Thisunitoperatesfroma110VAC60Hertz@10ampcircuit.

Donotobstructtheventilationfan,asthismaycauseunittooverheat.

Donotremoveanyportionoftheunithousingwithoutfirstdisconnectingtheunit

fromthepowersupply.

EXTERNAL FEATURES

ON/OFFSwitch

15AmpFuse

PowerSupplyFan

ACCord

ON/OFF Switch

15Amp Fuse

Power Supply Fan

AC Cord

6

6

6

PROTECTYOURSELFANDOTHERS!

Readthesafetynoticesbeforeusingwelder.

ELECTRICAL

Noportionoftheoutercoveroftheweldingcontrollershouldberemovedbyany‐

oneotherthanqualifiedpersonnel.Alwaysdisconnecttheunitfromthemainpower

priortoremovingcover.

• Thisequipmentcontainsatransformerpowersupplysystem,whichisenergized

byACcurrentandtransformstheACtoDCcurrent.Duetopotentialdangerous

electricalinputandoutputtheequipmentmustbedisconnectedfromallincom‐

ingpowerwhenservicing.

• Capacitorsstoreelectricalenergy.Checkforresidualchargebeforeperforming

anymaintenance.

• Donotusefluidstocleanelectricalcomponentsasthesemaypenetratetheelec‐

tricalsystemandcauseshorts.

Connectionoftheunitintoservicemustbeinaccordancewiththesetupprocedures

asdetailedinthismanual.Operationofthisequipmentmustbeinaccordancewith

alllocal,regional,andnationalsafetycodes.

SAFETY

7

77

FIRE

Duringwelding,smallparticlesofhotmetalcanbeexpelled.Ensurethatnocombus‐

tiblematerialsareneartheweldingarea.

PERSONALSAFETY

Arcrayscanburnyoureyesandskin.Wearprotectiveclothingandeyeprotection

whenwelding.

Loudnoisesfromweldingcandamagehearing.Wearearplugsorotherprotective

gear,ifapplicable.

Fumesandgasesexpelledduringweldingcanbehazardoustoyourhealth.Make

sureweldingisdoneinawell‐ventilatedarea.

Hotmetalsplattercancausefiresandburns.Wearprotectiveclothing,freeofcom‐

bustiblematerials.Haveafireextinguishernearbyandknowhowtouseit.

MAINTENANCE

Allcablesmustbeinspectedregularlytoensurethatnodangerexistsfromwornor

damagedinsulationorunsafeelectricalconnections.Takespecialnotetothecables

nearthestudgun‐thisiswheremaximumwearoccurs.

Worncablesnotonlyproduceinconsistentwelds,butcanoverheatorspark.

SAFETY

FIRE HAZARD

FROM SPARKS

8

8

8

TRAINING

Useofthisequipmentmustbelimitedtoauthorizedpersonnelonly.Theymustbe

adequatelytrained,andhavereadandunderstoodeverythinginthismanual.The

manualmustbeavailabletooperatorsatalltimes.

INSTALLATION

Selectasitefortheequipmentwhichiscapableofsupportingtheweightofthe

equipment,whichisclearfromtrafficrouteswherepeoplemaytripovercables,or

theymaybedamagedbyotherequipmentorvehicles.

Donothangconnectingcablesoversharpedgesorhavenearheatsources.

DISPOSAL

Theequipment,initsentiretyorascomponents/partsmaybedisposedofasgeneral

industrialwasteorscrap.Noneofthecomponentsusedinthemanufacturingofthe

CDWeldersaretoxic,carcinogenic,orotherwiseharmfultoyourhealth.

SAFETY

AUTHORIZED

PERSONNEL ONLY

9

99

POWERINGUPTHEEQUIPMENT

Setuptheequipmentpowersupply(ControlUnit)andconnecttothemainpower,

makingcertainofthepropervoltagerequirementoftheparticularunit.

CapacitorDischarge(CD)unitsgenerallyrequire110VAC@60Hzincomingpower.

Refertothesafetyrecommendationsbeforepluggingthisunitin.

ON/OFFSwitch

Fuse

PowerCord(110VAC)

CONNECTINGTHEWELDINGLEADS

Connecttheweldinggroundcableintothe(+)terminalmountsocketonthefrontof

theweldingunit.

***NOTE‐thecableendplughasaflatwhichalignswithadotonthepanelmount

socket.Securetheconnectorintothepanelmountsocket,andthenturnitclockwise

untilitlocksintoproperposition.Failuretodosocouldresultindamagetothecon‐

nector.

GroundCableSocket

SET-UP AND WELDING

ON/OFF Switch

Fuse

Power Cord (110 VAC)

For Cup Head to

Ground Cable Socket

10

10

10

CONNECTINGTHEWELDINGLEADS

Connecttheweldingstudgunpowercableintothe(‐)terminalpanelmountsocket

(designatedbythegunsymbol)onthefrontoftheweldingunit.

***NOTE‐thecableendplughasaflatwhichalignswithadotonthepanelmount

socket.Securetheconnectorintothepanelmountsocket,andthenturnitclockwise

untilitlocksintoproperposition.Failuretodosocouldresultindamagetothecon‐

nector.

WeldingGunPowerConnector

WeldingGunControlCableConnector

Connecttheweldguncontrolcableintothecenterpanel2‐pinsocket.

**NOTE‐theplughasalargepinandasmallpinthatmatchthesocketontheunit.

Thisistopreventincorrectconnections.Pushtheplugfirmlyintothesocketand

twistclockwisetosecuretheplugintothecorrectposition.

SET-UP AND WELDING

Welding Gun Control Cable Connector

Welding Gun Power Connector

11

1111

CONNECTINGTHEGROUNDCLAMP

Attachtheclampoftheweldinggroundleadtotheworkpiece.Priortosecuringthe

clamp,makecertainthatthecontactareaisfreeofrust,paint,grease,oranyother

impuritiestoensureagoodgroundconnection.

NOTE***Mostapplicationswillrequireonlyonegroundclamp,butcertainapplica‐

tionswillrequireanadditionaldualclamp.

SET-UP AND WELDING

13

CONNECTINGTHEGROUNDCLAMP

Attachtheclampoftheweldinggroundleadtotheworkpiece.Priortosecuringthe

clamp,makecertainthatthecontactareaisfreeofrust,paint,grease,oranyother

impuritiestoensureagoodgroundconnection.

NOTE***Mostapplicationswillrequireonlyonegroundclamp,butcertainapplica‐

tionswillrequireanadditionaldualclamp.

SET-UP AND WELDING

12

12

14

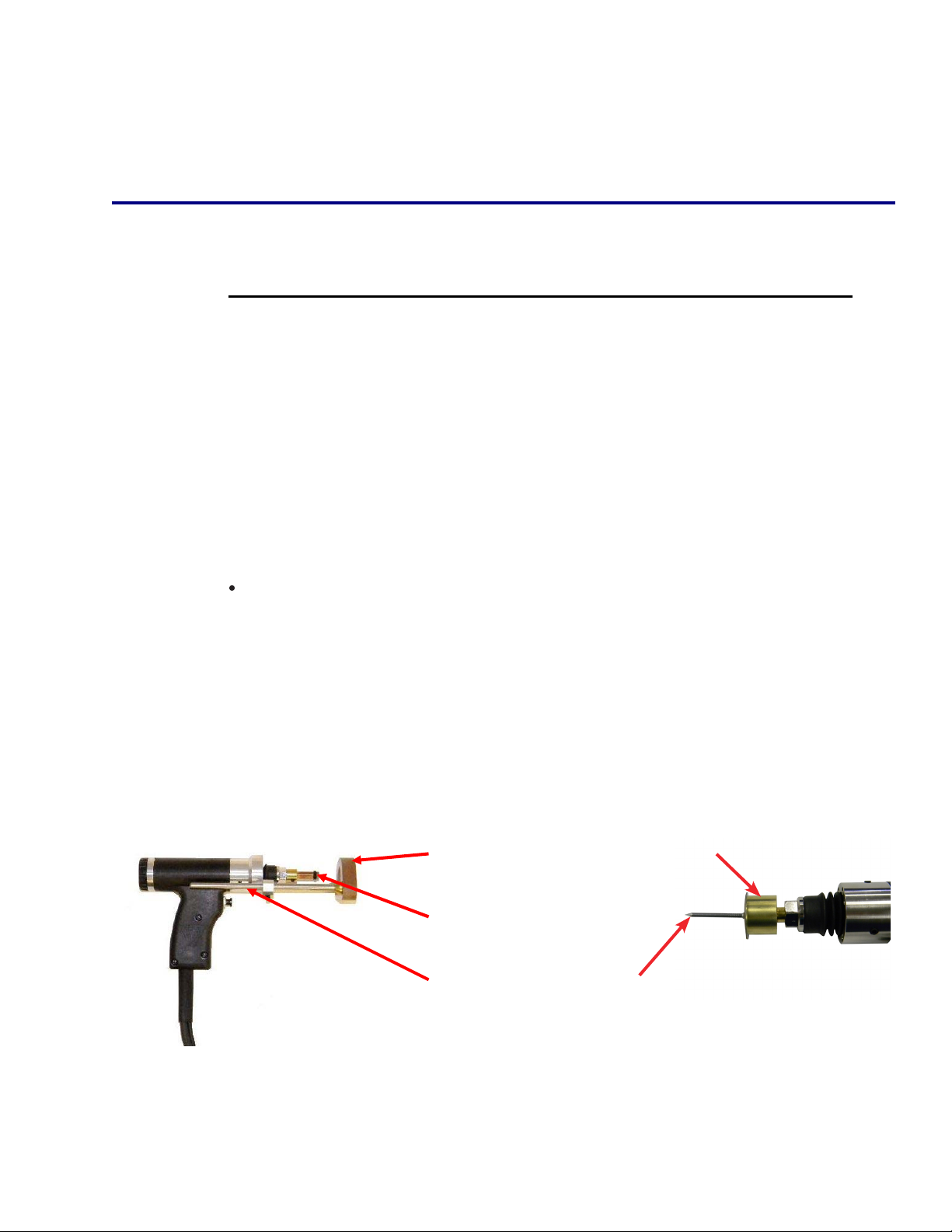

SELECTINGTHEPROPERSTUDCOLLET(STUDHOLDER)

Thecolletisselectedtotheproperdiameterthatyouarewelding.

Therearethreestylesofcollets;

• The“B”colletwhichisatwo‐pieceassembly(colletandinsert).Theinsertdeter‐

mineshowmuchofthestudisengagedinthecollet.

• TheCI(ColletInsert)whichisasinglepartandtheamountofthestudthatisen‐

gagedispredetermined.

• EuroColletshaveanadjustableinternalscrewtomanuallyadjust

fortheengagementofthestud.

Thechoicebetweenthesesystemsisusuallyamatterofpersonalpreference.

Insertingtheselectedcolletintothestudgunisasimpletask.Placethecolletinto

thefrontholderofthestudgunandsetthelockingscrewstoholditinplace.

Afterinsertingthecollet,mountthetwolegsandfootpieceontothestudgun.The

colletshouldbecenteredthroughtheopeningofthefootpiece.

Whenthelegsandfootpieceareinplace,insertthestudtobeweldedintothecol‐

let.Adjustthelegandfootpiecebyslidingitintopositionuntilapproximately1/8”

ofthestudprotrudesfrombeyondthefootpiece.Locklegsinplacewiththeset

screws.

SET-UP AND WELDING

FootPiece

Collet

LegPiece

12

SELECTINGTHEPROPERSTUDCOLLET(STUDHOLDER)

Thecolletisselectedtotheproperdiameterthatyouarewelding.

Therearethreestylesofcollets;

• The“B”colletwhichisatwo‐pieceassembly(colletandinsert).Theinsertdeter‐

mineshowmuchofthestudisengagedinthecollet.

• TheCI(ColletInsert)whichisasinglepartandtheamountofthestudthatisen‐

gagedispredetermined.

• StandardAdjustableChuckshaveanadjustableinternalscrewtomanuallyadjust

fortheengagementofthestud.

Thechoicebetweenthesesystemsisusuallyamatterofpersonalpreference.

Insertingtheselectedcolletintothestudgunisasimpletask.Placethecolletinto

thefrontholderofthestudgunandsetthelockingscrewstoholditinplace.

Afterinsertingthecollet,mountthetwolegsandfootpieceontothestudgun.The

colletshouldbecenteredthroughtheopeningofthefootpiece.

Whenthelegsandfootpieceareinplace,insertthestudtobeweldedintothecol‐

let.Adjustthelegandfootpiecebyslidingitintopositionuntilapproximately1/8”

ofthestudprotrudesfrombeyondthefootpiece.Locklegsinplacewiththeset

screws.

SET-UP AND WELDING

FootPiece

Collet

LegPiece

Adapterisrequired.

Adapterisrequired.

Nofootpieceorlegsrequiredwhenweldingcupheadpins.

Forcupheadpinsusecupheadpincollet

Thechoicebetweenthesesystemsisusuallyamaerofpersonalpreference.

12

14

SELECTINGTHEPROPERSTUDCOLLET(STUDHOLDER)

Thecolletisselectedtotheproperdiameterthatyouarewelding.

Therearethreestylesofcollets;

• The“B”colletwhichisatwo‐pieceassembly(colletandinsert).Theinsertdeter‐

mineshowmuchofthestudisengagedinthecollet.

• TheCI(ColletInsert)whichisasinglepartandtheamountofthestudthatisen‐

gagedispredetermined.

• EuroColletshaveanadjustableinternalscrewtomanuallyadjust

fortheengagementofthestud.

Thechoicebetweenthesesystemsisusuallyamatterofpersonalpreference.

Insertingtheselectedcolletintothestudgunisasimpletask.Placethecolletinto

thefrontholderofthestudgunandsetthelockingscrewstoholditinplace.

Afterinsertingthecollet,mountthetwolegsandfootpieceontothestudgun.The

colletshouldbecenteredthroughtheopeningofthefootpiece.

Whenthelegsandfootpieceareinplace,insertthestudtobeweldedintothecol‐

let.Adjustthelegandfootpiecebyslidingitintopositionuntilapproximately1/8”

ofthestudprotrudesfrombeyondthefootpiece.Locklegsinplacewiththeset

screws.

SET-UP AND WELDING

FootPiece

Collet

LegPiece

12

SELECTINGTHEPROPERSTUDCOLLET(STUDHOLDER)

Thecolletisselectedtotheproperdiameterthatyouarewelding.

Therearethreestylesofcollets;

• The“B”colletwhichisatwo‐pieceassembly(colletandinsert).Theinsertdeter‐

mineshowmuchofthestudisengagedinthecollet.

• TheCI(ColletInsert)whichisasinglepartandtheamountofthestudthatisen‐

gagedispredetermined.

• StandardAdjustableChuckshaveanadjustableinternalscrewtomanuallyadjust

fortheengagementofthestud.

Thechoicebetweenthesesystemsisusuallyamatterofpersonalpreference.

Insertingtheselectedcolletintothestudgunisasimpletask.Placethecolletinto

thefrontholderofthestudgunandsetthelockingscrewstoholditinplace.

Afterinsertingthecollet,mountthetwolegsandfootpieceontothestudgun.The

colletshouldbecenteredthroughtheopeningofthefootpiece.

Whenthelegsandfootpieceareinplace,insertthestudtobeweldedintothecol‐

let.Adjustthelegandfootpiecebyslidingitintopositionuntilapproximately1/8”

ofthestudprotrudesfrombeyondthefootpiece.Locklegsinplacewiththeset

screws.

SET-UP AND WELDING

FootPiece

Collet

LegPiece

12

14

SELECTINGTHEPROPERSTUDCOLLET(STUDHOLDER)

Thecolletisselectedtotheproperdiameterthatyouarewelding.

Therearethreestylesofcollets;

• The“B”colletwhichisatwo‐pieceassembly(colletandinsert).Theinsertdeter‐

mineshowmuchofthestudisengagedinthecollet.

• TheCI(ColletInsert)whichisasinglepartandtheamountofthestudthatisen‐

gagedispredetermined.

• EuroColletshaveanadjustableinternalscrewtomanuallyadjust

fortheengagementofthestud.

Thechoicebetweenthesesystemsisusuallyamatterofpersonalpreference.

Insertingtheselectedcolletintothestudgunisasimpletask.Placethecolletinto

thefrontholderofthestudgunandsetthelockingscrewstoholditinplace.

Afterinsertingthecollet,mountthetwolegsandfootpieceontothestudgun.The

colletshouldbecenteredthroughtheopeningofthefootpiece.

Whenthelegsandfootpieceareinplace,insertthestudtobeweldedintothecol‐

let.Adjustthelegandfootpiecebyslidingitintopositionuntilapproximately1/8”

ofthestudprotrudesfrombeyondthefootpiece.Locklegsinplacewiththeset

screws.

SET-UP AND WELDING

FootPiece

Collet

LegPiece

12

SELECTINGTHEPROPERSTUDCOLLET(STUDHOLDER)

Thecolletisselectedtotheproperdiameterthatyouarewelding.

Therearethreestylesofcollets;

• The“B”colletwhichisatwo‐pieceassembly(colletandinsert).Theinsertdeter‐

mineshowmuchofthestudisengagedinthecollet.

• TheCI(ColletInsert)whichisasinglepartandtheamountofthestudthatisen‐

gagedispredetermined.

• StandardAdjustableChuckshaveanadjustableinternalscrewtomanuallyadjust

fortheengagementofthestud.

Thechoicebetweenthesesystemsisusuallyamatterofpersonalpreference.

Insertingtheselectedcolletintothestudgunisasimpletask.Placethecolletinto

thefrontholderofthestudgunandsetthelockingscrewstoholditinplace.

Afterinsertingthecollet,mountthetwolegsandfootpieceontothestudgun.The

colletshouldbecenteredthroughtheopeningofthefootpiece.

Whenthelegsandfootpieceareinplace,insertthestudtobeweldedintothecol‐

let.Adjustthelegandfootpiecebyslidingitintopositionuntilapproximately1/8”

ofthestudprotrudesfrombeyondthefootpiece.Locklegsinplacewiththeset

screws.

SET-UP AND WELDING

FootPiece

Collet

LegPiece

12

14

SELECTINGTHEPROPERSTUDCOLLET(STUDHOLDER)

Thecolletisselectedtotheproperdiameterthatyouarewelding.

Therearethreestylesofcollets;

• The“B”colletwhichisatwo‐pieceassembly(colletandinsert).Theinsertdeter‐

mineshowmuchofthestudisengagedinthecollet.

• TheCI(ColletInsert)whichisasinglepartandtheamountofthestudthatisen‐

gagedispredetermined.

• EuroColletshaveanadjustableinternalscrewtomanuallyadjust

fortheengagementofthestud.

Thechoicebetweenthesesystemsisusuallyamatterofpersonalpreference.

Insertingtheselectedcolletintothestudgunisasimpletask.Placethecolletinto

thefrontholderofthestudgunandsetthelockingscrewstoholditinplace.

Afterinsertingthecollet,mountthetwolegsandfootpieceontothestudgun.The

colletshouldbecenteredthroughtheopeningofthefootpiece.

Whenthelegsandfootpieceareinplace,insertthestudtobeweldedintothecol‐

let.Adjustthelegandfootpiecebyslidingitintopositionuntilapproximately1/8”

ofthestudprotrudesfrombeyondthefootpiece.Locklegsinplacewiththeset

screws.

SET-UP AND WELDING

FootPiece

Collet

LegPiece

12

SELECTINGTHEPROPERSTUDCOLLET(STUDHOLDER)

Thecolletisselectedtotheproperdiameterthatyouarewelding.

Therearethreestylesofcollets;

• The“B”colletwhichisatwo‐pieceassembly(colletandinsert).Theinsertdeter‐

mineshowmuchofthestudisengagedinthecollet.

• TheCI(ColletInsert)whichisasinglepartandtheamountofthestudthatisen‐

gagedispredetermined.

• StandardAdjustableChuckshaveanadjustableinternalscrewtomanuallyadjust

fortheengagementofthestud.

Thechoicebetweenthesesystemsisusuallyamatterofpersonalpreference.

Insertingtheselectedcolletintothestudgunisasimpletask.Placethecolletinto

thefrontholderofthestudgunandsetthelockingscrewstoholditinplace.

Afterinsertingthecollet,mountthetwolegsandfootpieceontothestudgun.The

colletshouldbecenteredthroughtheopeningofthefootpiece.

Whenthelegsandfootpieceareinplace,insertthestudtobeweldedintothecol‐

let.Adjustthelegandfootpiecebyslidingitintopositionuntilapproximately1/8”

ofthestudprotrudesfrombeyondthefootpiece.Locklegsinplacewiththeset

screws.

SET-UP AND WELDING

FootPiece

Collet

LegPiece

MagnecChuck

CupheadPins

13

13

13

SELECTINGTHESPRINGLOAD

Theproperspringpre‐loadsettingonthestudgunwillvarydependingonthese‐

lectedapplication.Generalsrulesofapplicationwouldbe;mildsteelorstainless

steelusuallyinthe1to2range,dependingonthestuddiameterandthethicknessof

thebasematerial.Aluminumandothernonferrousmetalswouldrequiresettings

from3to5dependingonthediameterofthestudandbasematerialthickness.

Thisspringpre‐loadadjustmentismadebyturningthescrewinsertinthebackofthe

studgunwithascrewdriver.Onthebottomofthebackcapofthestudgunisthe

indicatornumbered1thru5,whichwillshowyouthetensionsettingduringthead‐

justment.

SET-UP AND WELDING

AdjustmentScrew

TensionIndicator

15

SELECTINGTHESPRINGLOAD

Theproperspringpre‐loadsettingonthestudgunwillvarydependingonthese‐

lectedapplication.Generalsrulesofapplicationwouldbe;mildsteelorstainless

steelusuallyinthe1to2range,dependingonthestuddiameterandthethicknessof

thebasematerial.Aluminumandothernonferrousmetalswouldrequiresettings

from3to5dependingonthediameterofthestudandbasematerialthickness.

Thisspringpre‐loadadjustmentismadebyturningthebackcapofthestudgun.On

thesideofthestudgunistheindicatornumbered1thru5,whichwillshowyouthe

tensionsettingduringtheadjustment.

SET-UP AND WELDING

AdjustmentCap

TensionIndicator

Locationofadjustment

onbackofthegun.

14

1414

READYFORWELDING

Whenyouhavecompletedallofthepreviousstepstoprepareforwelding,including

connectingthestudgunandgroundcablestotheunit,attachingthegroundcable(s)

totheworkarea,settingupandadjustingthestudgunfortheselectedstuddiame‐

terandmaterial,youcannowpoweronthewelder.

ThecontrollerON/OFFswitchislocatedontherearoftheunitintheupperright

handcorner.Belowthisswitchisthe15ampfuseholderforthesystem.

SET-UP AND WELDING

ON/OFFSWITCH

FUSE

ON/OFF Switch

FUSE

15

1515

VOLTAGESELECTION

Selectingtherequiredweldvoltageisachievedbyturningtheselectorknob.The

voltagerangeisfrom35VDCto200VDC.

Thevoltageisdeterminedbythediameterofthestudandthebasematerial.

Approximatevoltagestaringpointsarelistedbelow.Finetuningthevoltagetomeet

yourrequirementforyourspecificapplicationisrecommended.

NOTE***whenweldingcupped‐headinsulationpins,settheDCVoltageto35voltsto

beginandincreaseasnecessary.AdjustthespringpressureontheCDgunbetween

#1and#3asnecessary.

SET-UP AND WELDING

DiameterVoltage(DC)

14ga.50‐75

12ga.75‐110

#8110‐130

#10125‐160

1/4”160‐190

DiameterVoltage(DC)

14ga.35‐50

12ga.50‐75

#875‐100

#10100‐120

1/4”120‐140

MODELTWE‐321&375

3/8”(TWE‐375)160‐200

5/16”140‐160

VoltageAdjustmentKnob

VOLTAGESELECTION

Selectingtherequiredweldvoltageisachievedbyturningtheselectorknob.The

voltagerangeisfrom35VDCto200VDC.

Thevoltageisdeterminedbythediameterofthestudandthebasematerial.

Approximatevoltagestaringpointsarelistedbelow.Finetuningthevoltagetomeet

yourrequirementforyourspecificapplicationisrecommended.

NOTE***whenweldingcupped‐headinsulationpins,settheDCVoltageto35voltsto

beginandincreaseasnecessary.AdjustthespringpressureontheCDgunbetween

#1and#3asnecessary.

SET-UP AND WELDING

DiameterVoltage(DC)

14ga.50‐75

12ga.75‐110

#8110‐130

#10125‐160

1/4”160‐190

DiameterVoltage(DC)

14ga.35‐50

12ga.50‐75

#875‐100

#10100‐120

1/4”120‐140

MODELTWE‐321&375

3/8”(TWE‐375)160‐200

5/16”140‐160

VoltageAdjustmentKnob

MODEL 3125 & 3750

(3750)

Voltage Adjustment Knob

1515

VOLTAGESELECTION

Selectingtherequiredweldvoltageisachievedbyturningtheselectorknob.The

voltagerangeisfrom35VDCto200VDC.

Thevoltageisdeterminedbythediameterofthestudandthebasematerial.

Approximatevoltagestaringpointsarelistedbelow.Finetuningthevoltagetomeet

yourrequirementforyourspecificapplicationisrecommended.

NOTE***whenweldingcupped‐headinsulationpins,settheDCVoltageto35voltsto

beginandincreaseasnecessary.AdjustthespringpressureontheCDgunbetween

#1and#3asnecessary.

SET-UP AND WELDING

DiameterVoltage(DC)

14ga.50‐75

12ga.75‐110

#8110‐130

#10125‐160

1/4”160‐190

DiameterVoltage(DC)

14ga.35‐50

12ga.50‐75

#875‐100

#10100‐120

1/4”120‐140

MODELTWE‐321&375

3/8”(TWE‐375)160‐200

5/16”140‐160

VoltageAdjustmentKnob

VOLTAGESELECTION

Selectingtherequiredweldvoltageisachievedbyturningtheselectorknob.The

voltagerangeisfrom35VDCto200VDC.

Thevoltageisdeterminedbythediameterofthestudandthebasematerial.

Approximatevoltagestaringpointsarelistedbelow.Finetuningthevoltagetomeet

yourrequirementforyourspecificapplicationisrecommended.

NOTE***whenweldingcupped‐headinsulationpins,settheDCVoltageto35voltsto

beginandincreaseasnecessary.AdjustthespringpressureontheCDgunbetween

#1and#3asnecessary.

SET-UP AND WELDING

DiameterVoltage(DC)

14ga.50‐75

12ga.75‐110

#8110‐130

#10125‐160

1/4”160‐190

DiameterVoltage(DC)

14ga.35‐50

12ga.50‐75

#875‐100

#10100‐120

1/4”120‐140

MODELTWE‐321&375

3/8”(TWE‐375)160‐200

5/16”140‐160

VoltageAdjustmentKnob

MODEL 3125 & 3750

(3750)

Voltage Adjustment Knob

MODEL STUDPRO 2500i

1515

VOLTAGESELECTION

Selectingtherequiredweldvoltageisachievedbyturningtheselectorknob.The

voltagerangeisfrom35VDCto200VDC.

Thevoltageisdeterminedbythediameterofthestudandthebasematerial.

Approximatevoltagestaringpointsarelistedbelow.Finetuningthevoltagetomeet

yourrequirementforyourspecificapplicationisrecommended.

NOTE***whenweldingcupped‐headinsulationpins,settheDCVoltageto35voltsto

beginandincreaseasnecessary.AdjustthespringpressureontheCDgunbetween

#1and#3asnecessary.

SET-UP AND WELDING

DiameterVoltage(DC)

14ga.50‐75

12ga.75‐110

#8110‐130

#10125‐160

1/4”160‐190

DiameterVoltage(DC)

14ga.35‐50

12ga.50‐75

#875‐100

#10100‐120

1/4”120‐140

MODELTWE‐321&375

3/8”(TWE‐375)160‐200

5/16”140‐160

VoltageAdjustmentKnob

VOLTAGESELECTION

Selectingtherequiredweldvoltageisachievedbyturningtheselectorknob.The

voltagerangeisfrom35VDCto200VDC.

Thevoltageisdeterminedbythediameterofthestudandthebasematerial.

Approximatevoltagestaringpointsarelistedbelow.Finetuningthevoltagetomeet

yourrequirementforyourspecificapplicationisrecommended.

NOTE***whenweldingcupped‐headinsulationpins,settheDCVoltageto35voltsto

beginandincreaseasnecessary.AdjustthespringpressureontheCDgunbetween

#1and#3asnecessary.

SET-UP AND WELDING

DiameterVoltage(DC)

14ga.50‐75

12ga.75‐110

#8110‐130

#10125‐160

1/4”160‐190

DiameterVoltage(DC)

14ga.35‐50

12ga.50‐75

#875‐100

#10100‐120

1/4”120‐140

MODELTWE‐321&375

3/8”(TWE‐375)160‐200

5/16”140‐160

VoltageAdjustmentKnob

MODEL 3125 & 3750

(3750)

Voltage Adjustment Knob

CupheadPin 70-100

1515

VOLTAGESELECTION

Selectingtherequiredweldvoltageisachievedbyturningtheselectorknob.The

voltagerangeisfrom35VDCto200VDC.

Thevoltageisdeterminedbythediameterofthestudandthebasematerial.

Approximatevoltagestaringpointsarelistedbelow.Finetuningthevoltagetomeet

yourrequirementforyourspecificapplicationisrecommended.

NOTE***whenweldingcupped‐headinsulationpins,settheDCVoltageto35voltsto

beginandincreaseasnecessary.AdjustthespringpressureontheCDgunbetween

#1and#3asnecessary.

SET-UP AND WELDING

DiameterVoltage(DC)

14ga.50‐75

12ga.75‐110

#8110‐130

#10125‐160

1/4”160‐190

DiameterVoltage(DC)

14ga.35‐50

12ga.50‐75

#875‐100

#10100‐120

1/4”120‐140

MODELTWE‐321&375

3/8”(TWE‐375)160‐200

5/16”140‐160

VoltageAdjustmentKnob

VOLTAGESELECTION

Selectingtherequiredweldvoltageisachievedbyturningtheselectorknob.The

voltagerangeisfrom35VDCto200VDC.

Thevoltageisdeterminedbythediameterofthestudandthebasematerial.

Approximatevoltagestaringpointsarelistedbelow.Finetuningthevoltagetomeet

yourrequirementforyourspecificapplicationisrecommended.

NOTE***whenweldingcupped‐headinsulationpins,settheDCVoltageto35voltsto

beginandincreaseasnecessary.AdjustthespringpressureontheCDgunbetween

#1and#3asnecessary.

SET-UP AND WELDING

DiameterVoltage(DC)

14ga.50‐75

12ga.75‐110

#8110‐130

#10125‐160

1/4”160‐190

DiameterVoltage(DC)

14ga.35‐50

12ga.50‐75

#875‐100

#10100‐120

1/4”120‐140

MODELTWE‐321&375

3/8”(TWE‐375)160‐200

5/16”140‐160

VoltageAdjustmentKnob

MODEL 3125 & 3750

(3750)

Voltage Adjustment Knob

16

Cup Head Welding

(A) (B) (C)

Connect Male Ground Camlok To Cup Head Ground

Camlok Receptacle On Unit (See Location A)

Connect Male Gun Control To The Female Gun Control

Receptacle On Unit. (See Location B)

Connect Male Gun Camlok To The Female Gun Camlok

Receptacle On Unit. (See Location C)

17

Cup Head Welding

Insert Magnetic Chuck Into The Supplied “B” Adapter

And Tighten The Set Screws. (See Figure Above)

Set Spring Pressure Between #1 And #2 By Turning The

Back Cap. (See Figure Above)

Set The Voltage. Recommended Voltage Setting For

Cup Head Pins Is Between 70 And 100 Volts.

18

16

18

TESTINGYOURSETTINGS

Whenyouhaveperformedallofthepresetsasdiscussedinthismanual,itisrecom‐

mendedthatyouperformseveraltestweldswiththesamediameterstudandbase

materialthatyouwillbeusing.Thiswillverifythatallofthesettingsarecorrectto

theresultsyoudesire.Weldingisdonebyplacingthestudintothecollet,andpress‐

ingthestudguntotheworkpiece,compressingthespring.Thisiswhythestudmust

protrudebeyondthefootpieceatleast1/8”.

Holdingthegunperpendiculartotheworkpiece,andaligningthestudtothedesired

positionontheworkpiece,pressdownsothatthefootpieceisflushwiththework

piece(springcompressed),anddepressthetrigger.

Whenremovingthestudgunfromtheweldedstud,alwaysliftthestudgunvertically

fromtheweldedstudinordertomaintainthepropertensionofthecollet.Spreading

thecolletwhenliftingthestudgunfromtheweldedstudwillshortenthelifeofthe

colletandwilleventuallycreateanundesirableweld.

TESTING WELD SETTINGS

Cupheadpinwelding–Whenweldingcupheadpinstherewillnotbeafootpiece

toholdthegunperpendicularthismustbedonemanually.Pressdownonthework

piecesothegunshaisatapprox.½”ofit’smaxtravel(springswillbecompressed

properly)anddepressthetrigger.

16

18

TESTINGYOURSETTINGS

Whenyouhaveperformedallofthepresetsasdiscussedinthismanual,itisrecom‐

mendedthatyouperformseveraltestweldswiththesamediameterstudandbase

materialthatyouwillbeusing.Thiswillverifythatallofthesettingsarecorrectto

theresultsyoudesire.Weldingisdonebyplacingthestudintothecollet,andpress‐

ingthestudguntotheworkpiece,compressingthespring.Thisiswhythestudmust

protrudebeyondthefootpieceatleast1/8”.

Holdingthegunperpendiculartotheworkpiece,andaligningthestudtothedesired

positionontheworkpiece,pressdownsothatthefootpieceisflushwiththework

piece(springcompressed),anddepressthetrigger.

Whenremovingthestudgunfromtheweldedstud,alwaysliftthestudgunvertically

fromtheweldedstudinordertomaintainthepropertensionofthecollet.Spreading

thecolletwhenliftingthestudgunfromtheweldedstudwillshortenthelifeofthe

colletandwilleventuallycreateanundesirableweld.

TESTING WELD SETTINGS

16

18

TESTINGYOURSETTINGS

Whenyouhaveperformedallofthepresetsasdiscussedinthismanual,itisrecom‐

mendedthatyouperformseveraltestweldswiththesamediameterstudandbase

materialthatyouwillbeusing.Thiswillverifythatallofthesettingsarecorrectto

theresultsyoudesire.Weldingisdonebyplacingthestudintothecollet,andpress‐

ingthestudguntotheworkpiece,compressingthespring.Thisiswhythestudmust

protrudebeyondthefootpieceatleast1/8”.

Holdingthegunperpendiculartotheworkpiece,andaligningthestudtothedesired

positionontheworkpiece,pressdownsothatthefootpieceisflushwiththework

piece(springcompressed),anddepressthetrigger.

Whenremovingthestudgunfromtheweldedstud,alwaysliftthestudgunvertically

fromtheweldedstudinordertomaintainthepropertensionofthecollet.Spreading

thecolletwhenliftingthestudgunfromtheweldedstudwillshortenthelifeofthe

colletandwilleventuallycreateanundesirableweld.

TESTING WELD SETTINGS

19

17

17

INSPECTINGTHEWELD

Visuallyinspecttheweld.Agoodweldwillresultinanall‐aroundweld,withasmall

visibleamountofweldsurroundingtheflangeofthestud.Toomuchsplatterandthe

weldistoohot,lowerthevoltage.Nosplatterandtheweldistoocold,increasethe

voltage.

Ifyougetweldflashtoonesideofthestudasopposedtoanevenamountaround

thebaseoftheflange,thisiscalled“arcblow”,andcanbesolvedbyrepositioning

thegroundclamporusingadualgroundclamp.

Properweldedstudscanbetestedbyeithertorquingorbendingthestud.The

weldedflangeofthestudshouldstayinplaceusingeithermethod,eventhoughthe

threadedportionofthestudbreaks.Ifthebasematerialisverythin,thenafullslug,

thediameteroftheflangewillpullfromthebasemetalforaproperlyweldedstud.

CDStudWeldingSteps

SET-UP AND WELDING

TESTINGYOURSETTINGS

Whenyouhaveperformedallofthepresetsasdiscussedinthismanual,itisrecom‐

mendedthatyouperformseveraltestweldswiththesamediameterstudandbase

materialthatyouwillbeusing.Thiswillverifythatallofthesettingsarecorrectto

theresultsyoudesire.Weldingisdonebyplacingthestudintothecollet,andpress‐

ingthestudguntotheworkpiece,compressingthespring.Thisiswhythestudmust

protrudebeyondthefootpieceatleast1/8”.

Holdingthegunperpendiculartotheworkpiece,andaligningthestudtothedesired

positionontheworkpiece,pressdownsothatthefootpieceisflushwiththework

piece(springcompressed),anddepressthetrigger.

Whenremovingthestudgunfromtheweldedstud,alwaysliftthestudgunvertically

fromtheweldedstudinordertomaintainthepropertensionofthecollet.Spreading

thecolletwhenliftingthestudgunfromtheweldedstudwillshortenthelifeofthe

colletandwilleventuallycreateanundesirableweld.

TESTING WELD SETTINGS

20

18

18

CD 2301 Order No. BA 92-12-0231A Issue 05.01.10 31

5.8.1

Visual Inspection

A visual inspection must be carried out with each welding element.

Condition Possible cause Corrective actions

Good welded joint

Low spatters around the weld

without outer flaws

The weld pool forms a collar around

the flange of about 1 - 1,5 mm

- Correct parameters - None

Cold weld pool

Gap between flange and workpiece

- Heat input too low

- Plunging speed too low

- No sufficient backing of workpiece

- Increase charging voltage

- Adjust plunging speed correctly

- Provide sufficient backing

Hot weld pool

Many spatters around the weld

- Heat input too high

- Plunging speed too low

- Reduce charging voltage

- Increase plunging speed

One-sided weld pool

One-sided spatter collar

Weld pool came out on one side

- Arc blow effect

- Unsymmetric ground connection

- Welding gun put at an angle

- Take care for symmetrical ground

connection

- Put welding gun vertically to the workpiece

Visual Inspection

5 Stud Welding Procedure

5.8 Checking the Quality of the Weld

TESTINGYOURSETTINGS

Whenyouhaveperformedallofthepresetsasdiscussedinthismanual,itisrecom‐

mendedthatyouperformseveraltestweldswiththesamediameterstudandbase

materialthatyouwillbeusing.Thiswillverifythatallofthesettingsarecorrectto

theresultsyoudesire.Weldingisdonebyplacingthestudintothecollet,andpress‐

ingthestudguntotheworkpiece,compressingthespring.Thisiswhythestudmust

protrudebeyondthefootpieceatleast1/8”.

Holdingthegunperpendiculartotheworkpiece,andaligningthestudtothedesired

positionontheworkpiece,pressdownsothatthefootpieceisflushwiththework

piece(springcompressed),anddepressthetrigger.

Whenremovingthestudgunfromtheweldedstud,alwaysliftthestudgunvertically

fromtheweldedstudinordertomaintainthepropertensionofthecollet.Spreading

thecolletwhenliftingthestudgunfromtheweldedstudwillshortenthelifeofthe

colletandwilleventuallycreateanundesirableweld.

TESTING WELD SETTINGS

Other stud welding products Welding System manuals

stud welding products

stud welding products STUDPRO Series User manual

stud welding products

stud welding products StudPro LiteXI User manual

stud welding products

stud welding products StudPro 2500XI User manual

stud welding products

stud welding products StudPro LiteXI User manual

stud welding products

stud welding products StudPro 2500 User manual