stud welding products STUDPRO Series User manual

OPERATOR’S MANUAL

STUDPRO SERIES

Capacitor Discharge Stud Welder

MODELS:

StudPro 2500XI

StudPro 2500XIP

StudPro 3125XI

StudPro 3750XI

CONTENTS

Descripon Pages

Safety 2

Specicaons and Features 3

Product Components 4-5

Screen Operaon 6-8

Setup and Welding 9-11

CD Stud Gun Exploded View 12

CD Accessories 13-15

Read the safety noces before operang welder

Electrical

•Due to potenal dangerous electrical input and output the

equipment must be disconnected from all incoming power

when servicing. Do not operate the equipment with the outer

cover removed or with the case open.

•Capacitors store electrical energy, completely discharge before performing any maintenance.

•Do not use uids to clean electrical components as these may penetrate the electrical system

and cause shorts.

•Connecon of the unit into service must be in accordance with the setup procedures as de-

tailed in this manual. Operaon of this equipment must be in accordance with all local, region-

al, and naonal safety codes.

Fire

•During welding, small parcles of hot metal can be expelled. Ensure

that no combusble materials are near the welding area.

Personal Safety

•Arc rays can burn eyes and skin. Wear protecve clothing and eye pro-

tecon when welding.

•Loud noises from welding can damage hearing. Wear earplugs or oth-

er protecve gear, if applicable.

•Fumes and gases expelled during welding can be health hazards. Make sure welding is done in

a well-venlated area.

•Hot metal splaer can cause res and burns. Wear protecve clothing, work in an area free of

combusble materials, and have a re exnguisher nearby.

Maintenance

•All cables must be inspected regularly to ensure that no danger exists from damaged insula-

on or unsafe electrical connecons. Take special note of the cables near the stud gun, this is

where maximum wear occurs.

Training

•Use of this equipment must be limited to authorized personnel only. They must be adequately

trained, and have read and understood everything in this manual.

•The manual must be available to operators at all mes.

Installaon

•Select a site which is capable of supporng the weight of the equipment.

•Select a site which is clear from heavy foot trac areas to avoid tripping hazards.

•Select a site that prevents cable damage from equipment and vehicles.

•Do not hang connecng cables over sharp edges or place near heat sources.

SAFETY

FIRE HAZARD

FROM SPARKS

2

SPECIFICATIONS AND FEATURES

StudPro XI- Capacitor Discharge Stud Welder Series

The StudPro XI series of capacitor discharge stud welders incorporates the latest solid state

technology into a compact, lightweight, and rugged CD stud welder. This full line of equipment is

capable of welding pins, cup head pins, and CD studs ranging from 14-gauge up to 3/8” full-flanged

stainless steel studs.

Specifications

Features

•Intuive Touchscreen Interface with preset values for fast, accurate, and repeatable weld sengs

•Set-Point Discharge: Unit discharges directly to a new set point without needing to discharge com-

pletely

•Universal Input Voltage: Plug and play, no need to re-tap the machine for 110V or 220V input volt-

ages

•Low input voltage capability enables operaon with long extension cords

•Contact and Trigger indicators for fast troubleshoong of hand tool and weld cable maintenance

issues

•Thermal and Voltage protecon indicators to protect the unit from damage due to overheang or

poor input power

•Rigid internal construcon minimizes the possibility of components coming loose during rough han-

dling or operaon

•Hand tool has been ergonomically designed to reduce operator fague for increased welding e-

ciency

•Hand tool has an adjustable internal spring to apply the correct spring pressure for every welding

applicaon

•Hand tool can be congured for B collets, CI (Collet Inserts), Euro collets, or standard tapered

chucks

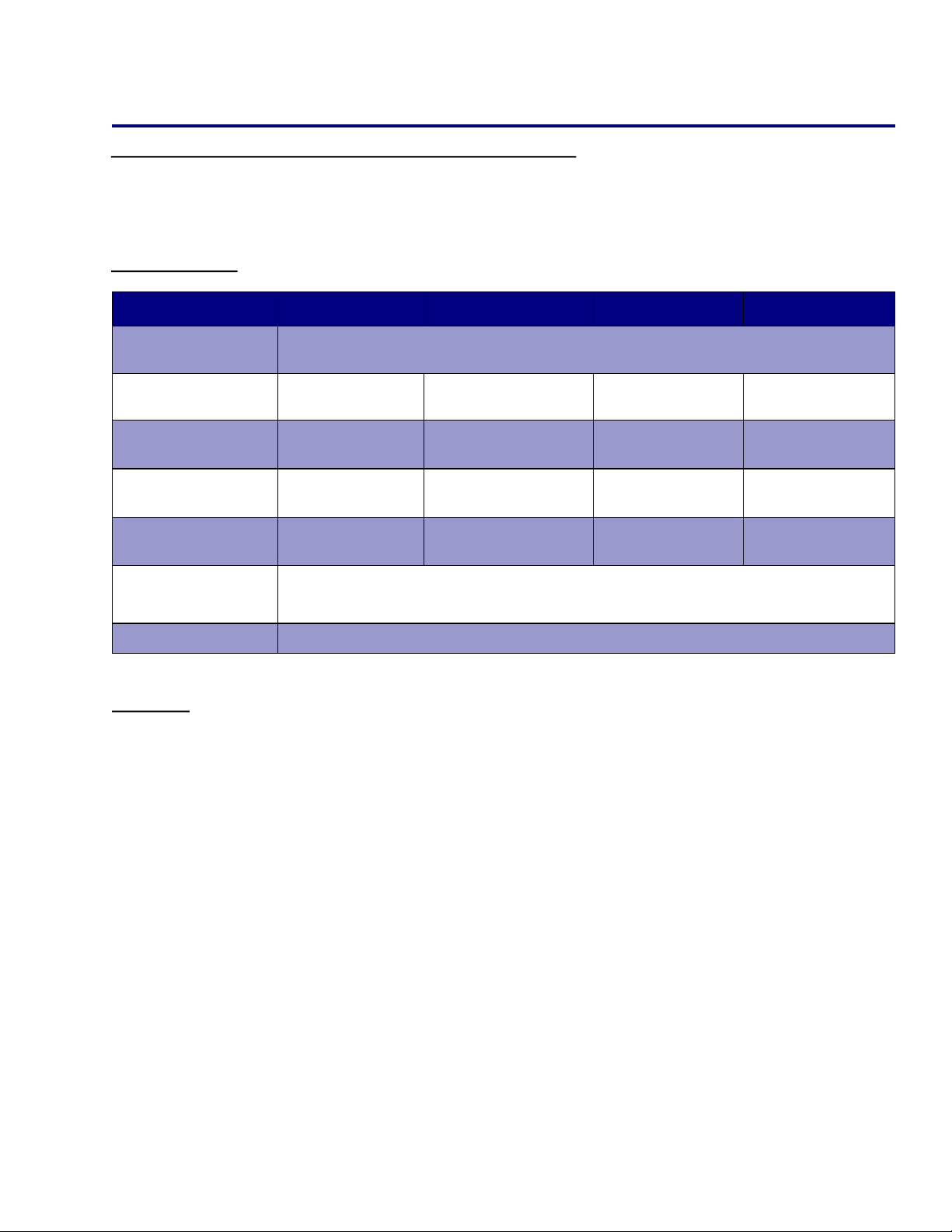

SPECS StudPro 2500XI StudPro 2500XIP StudPro 3125XI StudPro 3750XI

SIZE 14” L, 10.5” W, 11.5” H

356mm x 267mm x 292mm

WEIGHT

(Power Supply Only) 18 lbs. (8.1Kg) 18 lbs. (8.1Kg) 20.8 lbs. (9.4Kg) 23.4 lbs. (10.6Kg)

CAPACITANCE/ENERGY 76,000µF/1520Ws 76,000µF/1520Ws 114,000µF/2280Ws 152,000µF/3040Ws

WELD RANGE 14Ga - 1/4” Stainless 14Ga - 1/4” Stainless

(including cup head pins) 14Ga - 5/16” Stainless 14Ga - 3/8” Stainless

DUTY CYCLE 18 studs per minute

(1/4” sengs)

18 studs per minute

(1/4” sengs)

14 studs per minute

(5/16” sengs)

10 studs per minute

(3/8” sengs)

PRIMARY POWER

(Universal Input) 85-250 VAC, 6.0-2.0A, 50/60Hz

CHARGE VOLTAGE 35-200 VDC

3

* Specicaons are subject to change without prior nocaon

Front View Back View

Components

1. Touch Screen Interface

2. Weld Ground Connector

3. Cup Pin Weld Ground Connector (Model 250CP only, on all other TW-i models this connector is a

secondary Weld Ground Connector)

4. Stud Gun Control Cable Connector

5. Stud Gun Weld Cable Connector

6. ON/OFF Switch

7. 10A Fuse

8. Manufacturer Model Number and Serial Number Plate

9. Power Cord Socket

PRODUCT COMPONENTS

1

4

25

7

3

6

9

8

4

Internal View

Components

1. Venlaon Fan

2. ON/OFF Switch

3. 10A Fuse

4. AC Inline Filter/Power Cord Socket

5. Capacitor Bank

6. Freewheeling Diodes

7. SCR/Clamp

8. Discharge Resistor

9. Control Board

PRODUCT COMPONENTS

4

3

1

2

5

9

876

5

SCREEN OPERATION

Trigger Indicator

Stud Presets

Metric Stud Mode

Contact Indicator

Stud Preset Screen

Voltage Preset Screen

Charge Indicator

Welding Voltage

Stud Counter

Voltage

Adjustment

Adjustment

Voltage

Presets

Mode Selecon

Voltage

Mode Selecon

6

SCREEN OPERATION

Stud Counter Screen

Reseng the Stud Counter

Stud Counter Reset

•While on the stud counter screen, press the RESET tab located at the boom of the screen.

•The screen will then prompt the user for a conrmaon to clear the stud counter.

•To cancel the reseng of the stud counter, simply press NO on the screen.

•To conrm the reseng of the stud counter, simply press YES on the screen.

Stud Count

7

Screen Status Indicators

SCREEN OPERATION

Status Indicator

8

Status

Indicator Descripon Soluon

OVERTEMP Unit Has Exceeded

Temperature Threshold

Unit needs to cool down before more welds can be

made. Please allow the unit to cool down and clear

the overtemp warning.

UNDER

VOLTAGE

Insucient Input

Power

Unit has detected insucient supply power. Connect

the unit to a more stable power supply.

DC LIMIT ON Duty Cycle Limiter

Acvated

Protects capacitor from overheang by liming the

user to a maximum average duty cycle. This protec-

on only acvates when the set point of the welder

is above 85V. Below 85V there is no limitaon to the

duty cycle of the unit.

ERR: CHRG TIME Max Charge Time

Exceeded

Unit has taken too long to charge and there may be an

issue with the capacitor. With unit powered down en-

sure that all connectors and connecons are ght.

ERR: OUTPUT Capacitor Short

Detecon

Capacitor is not charging properly and the outputs

may be shorted. Check the unit for damage as well as

Connecng the Welding Leads

1. Connect the stud gun weld cable into the gun terminal socket on the front of the welding unit. The

cable end plug has a flat which aligns with a dot on the panel mount socket. Secure the connector

into the panel mount socket, and then turn it clockwise until it locks into proper position. Failure

to properly make these connections could result in damage to the connectors.

2. Connect the weld gun control cable into the center socket connector. The control cable plug has a

large pin and a small pin that match the socket on the unit. Push the plug firmly into the socket

and twist clockwise to secure the plug into the correct position.

3. Connect the ground clamp into the ground terminal socket on the front of the unit, this connec-

tion is identical to step 1.

Connecng the Ground Clamp

1. Prior to securing the clamp, make certain that

the contact area is free of rust, paint, grease, or

any other impuries to ensure a good ground

connecon.

2. Aach the clamp of the welding ground lead to

the work piece.

3. Most applicaons will require only one ground

clamp, but certain applicaons will require an

addional dual clamp.

SETUP AND WELDING

9

Stud Gun Weld

Cable Connecon

Ground Cable Connecon

Stud Gun Control

Cable Connecon

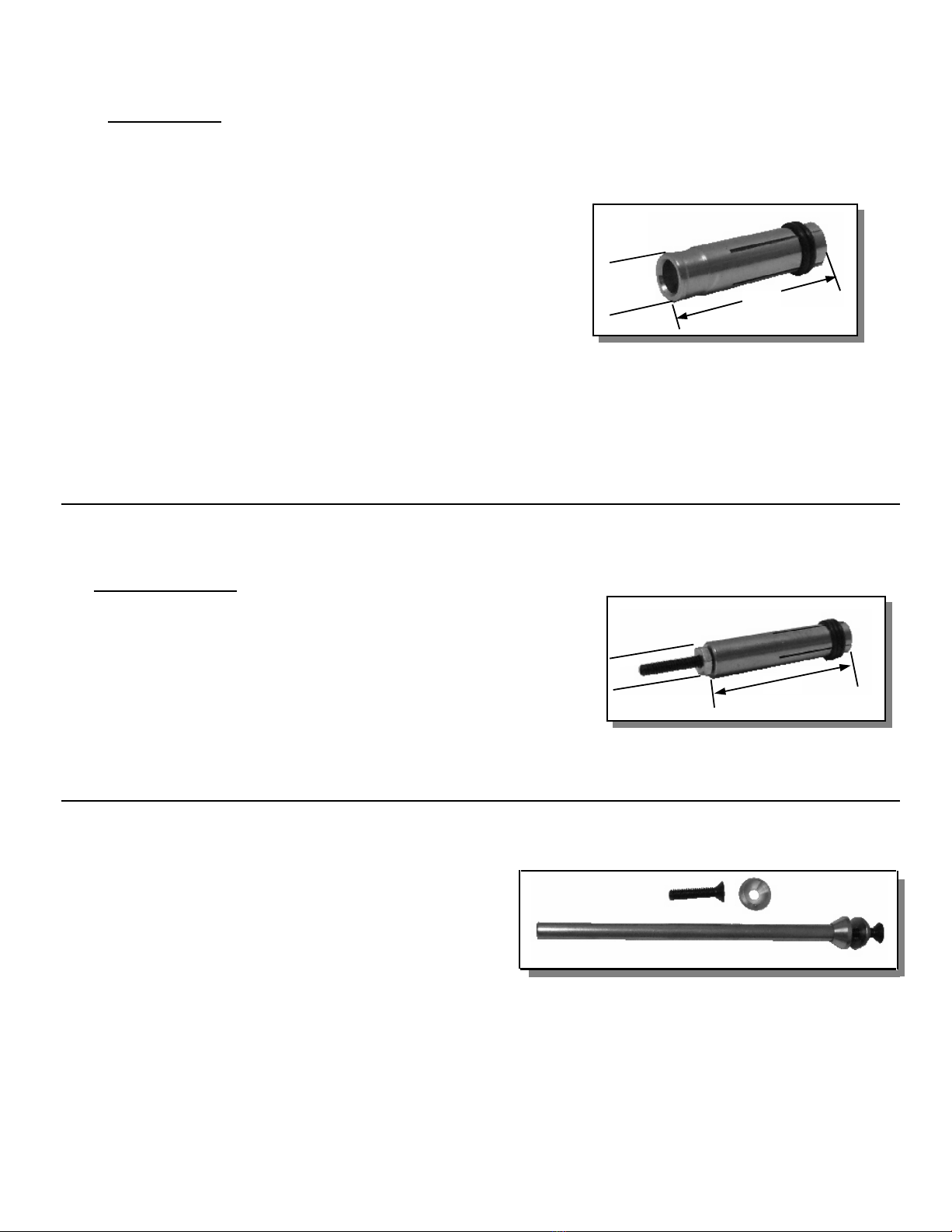

Selecng the Proper Stud Collet (Stud Holder)

Listed below are the common collet styles, the choice between these setups is usually a maer of per-

sonal preference

1. The B collet which is a two-piece assembly (collet and insert). The insert determines how much of

the stud is engaged in the collet.

2. The CI (Collet Insert) which is a single part and the amount of the stud that is engaged is predeter-

mined.

3. Standard Adjustable Chucks have an adjustable internal screw to manually adjust for the engage-

ment of the stud.

The collet sizes are based on the diameter of the stud to be welded.

CD Stud Gun Setup

1. Place the collet into the collet

adapter of the stud gun and set the

locking screws to hold the collet in

place.

2. Mount the two legs and foot piece

onto the stud gun. The collet

should be centered through the

opening of the foot piece.

3. Insert the stud to be welded into

the collet.

4. Adjust the leg and foot piece by sliding it into posion unl approximately 1/8” of the stud pro-

trudes from beyond the foot piece. Lock legs in place with the set screws.

5. The tension seng is adjusted by turning the adjustment cap on the back of the stud gun. On the

side of the stud gun is the tension seng indicator, this displays the tension seng of the internal

spring.

6. The spring tension seng of the stud gun will vary depending on the applicaon. Generally, mild

steel and stainless steel should be set in the 1 to 2 range. Aluminum and other nonferrous metals

will require sengs in the 3 to 5 range.

SETUP AND WELDING

Collet Adapter

Collet

Leg Piece

Adjustment Cap

Tension Indicator

10

Foot Piece

Powering On the Welder

When all of the previous setup steps in this manual are complete the welder can be powered on.

1. Ensure that the power cord is connected to the power cord socket and the supply power.

2. Check the 10A fuse below the ON/OFF switch located on the back of the unit.

3. Use the ON/OFF switch to power the unit on.

Voltage Selecon

•The voltage is determined by the diameter of the stud and the base material thickness. The unit is

programmed with the recommended voltage sengs for various stud sizes. Fine tuning the volt-

age for each applicaon from this starng point is recommended.

•Seng the required weld voltage is achieved by selecng the desired stud size on the screen or

manually seng the voltage by using the + or - arrows.

•Fast voltage selecon can be done from the voltage mode screen. This will replace the preset val-

ues on the screen with voltages in increments of 10V and can be manually adjusted by using the

arrows.

Tesng the Weld Sengs

1. Aer performing all of the setup steps listed in this manual, it is recommended that several test

welds be performed with the same diameter stud and base material used for the applicaon. This

will verify that all of the sengs are correct to achieve the desired results.

2. Welding is done by placing the stud into the collet and pressing the stud gun to the work piece.

3. Hold the gun perpendicular to the work piece, align the stud to the desired locaon, press down

so that the foot piece is ush with the base material, and squeeze the trigger.

4. Spreading the collet nes when liing the stud gun from the welded stud will shorten the life of

the collet and will eventually create an undesirable weld. For maximum collet life remove the

stud gun from the welded stud by pulling the stud gun straight o of the welded stud.

5. Properly welded studs are tested by either torqueing or bending the stud. Using either method

the threaded poron of the stud may break. However, the welded ange of the stud should stay

in place. Addionally, if the base material is very thin, a full slug the diameter of the ange will

pull from the base metal.

Inspecng the Weld

1. Visually inspect the weld. If there is a signicant amount of splaer then the weld is too hot, lower

the voltage. If there is no splaer then the weld is too cold, increase the voltage.

2. A good weld will result in a small, visible, and 360° ashing surrounding the ange of the stud. If

there is weld ash on only one side of the base of the ange, this is called “arc blow,” and can be

solved by reposioning the ground clamp or using a dual ground clamp.

SETUP AND WELDING

11

CD GUN EXPLODED VIEW

12

“B” COLLETS

STUD DIA

PART NO.

3 MM

CDB

-

003M

14 GA

CDB

-

008

12 GA & #4

CDB

-

010

1/8 GA & #5

CDB

-

012

10 GA & #6

CDB

-

013

4 MM

CDB

-

004M

#8

CDB

-

015

#10

CDB

-

018

5 MM

CDB

-

005M

6 MM

CDB

-

006M

.215

CDB

-

021

1/4

CDB

-

025

5/16

CDB

-

031

8 MM

CDB

-

008M

3/8

CDB

-

037

10 MM

CDB

-

010M

SOYER COLLETS

STUD DIA.

PART NO.

#6

CDBS

-

013

4 MM

CDBS

-

004M

#8

CDBS

-

015

#10

CDBS

-

018

5 MM

CDB

S-

005M

6 MM

CDBS

-

006M

1/4

CDBS

-

025

5/16

CDBS

-

031

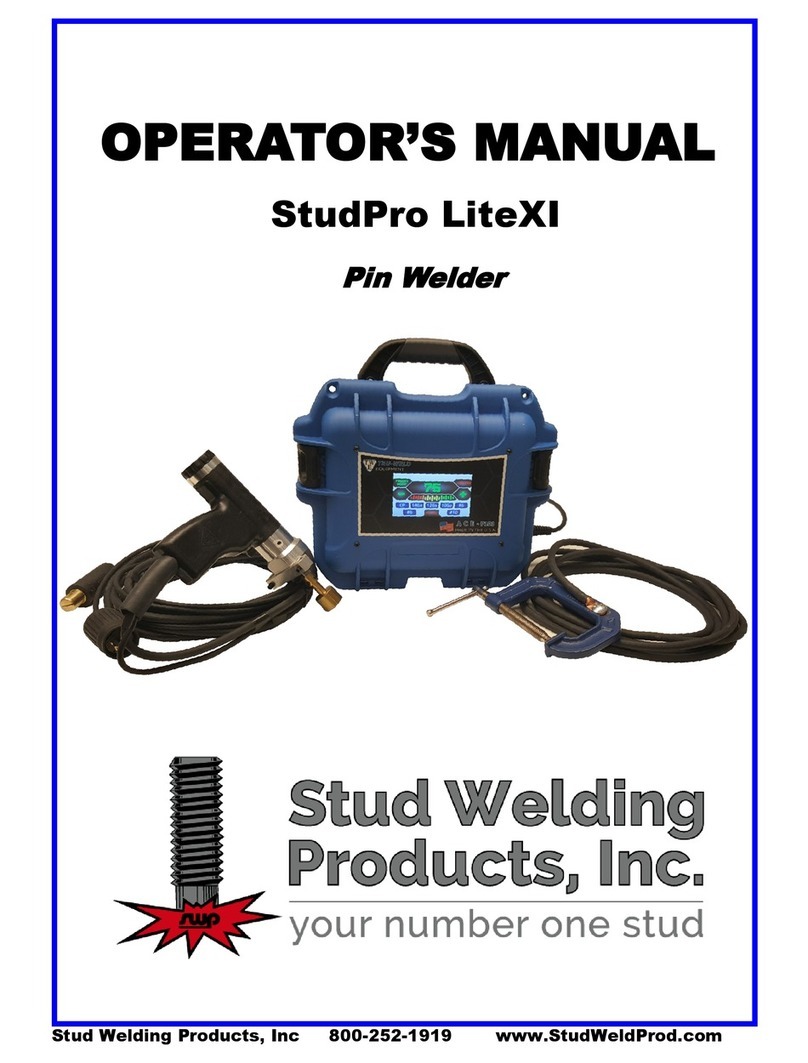

CAPACITOR DISCHARGE ACCESSORIES

3/8 DIA

1-

3/8

1.781

.390

LENGTH

DIA.

PART NO.

7”

5/16

L-

03107

9”

5/16

L-

03109

14”

5/16

L-

03114

18”

5/16

L-

03118

CD WELDING LEGS

5/16 LEG WASHER

5/16 LEG SCREW

3/8 LEG WASHER

3/8 LEG SCREW

L-

031

-2

L-

037

-1

L-

037

-2

L-

031

-1

13

CAPACITOR DISCHARGE ACCESSORIES

ONE PIECE CONTACT/MAGNETIC CHUCK

PART NO.

039

-

613

“B” COLLETS PROTECTOR

STUD SIZE

PART NO.

14 GA X 12 GA

028

-

837

10 GA

028

-

838

BODY ONLY

028

-

836

12 GA INSER

T

028

-

834

10 GA INSERT

028

-

835

“B” STOP

STUD

STOP

LENGTH LENGTH

PART NO.

1/4

1-

1/4

033

-

781

3/8

1-

1/8

033

-

782

1/2

1”

033

-

783

5/8 7/8 033

-

784

3/4 3/4 033

-

785

7/8 5/8 033

-

775

1”

1/2 033

-

776

1-

1/8

3/8 033

-

777

1-

1/4

1/4 033

-

778

1-

3/8

(BUTTON STOP)

1/8 033

-

779

UNIVERSAL

033

-

780

SHORT BUTTON STOP

UNIVERSAL “B” STOP

MAGNETIC CHUCK

PART NO.

DESCRIPTION

035

-

301

COMPLETE ASSY

017

-

633

MAGNET ONLY

029

-

615

CONDUCTOR PLATE

039

-

609

INSU

L. TUBE

039

-

610

INSUL. DISC

SCREW

10

-

32 X 7/8

14

TEMPLATE TUBE ADAPTOR

STUD RANGE

PART NO.

14 GA

–

#6

033

-

764

#8

–

3/8

033

-

765

STANDARD SPARK SHIELD

STUD DIA.

X DEPTH

PART NO.

#4 X 1/4

CI

-

010

-

025

#4 X 3/8

CI

-

010

-

037

#4 X 1/2

CI

-

010

-

050

#4 X 1”

CI

-

010

-

100

#6X 1/4

CI

-

013

-

025

#6 X 3/8

CI

-

013

-

037

#6 X 1/2

CI

-

013

-

050

#6 X 5/8

CI

-

013

-

062

#6 X 3/4

CI

-

013

-

075

#6X 1”

CI

-

013

-

10

0

10GA X 1/2

CI

-

014

-

050

10GA X 3/4

CI

-

014

-

075

10GA X 1

CI

-

014

-

100

#8X 1/4

CI

-

015

-

025

#8 X 3/8

CI

-

015

-

037

#8 X 1/2

CI

-

015

-

050

#8 X 5/8

CI

-

015

-

062

#8 X 3/4

CI

-

015

-

075

#8X 1”

CI

-

015

-

100

#10 X 1/4

CI

-

018

-

025

#10 X 3/8

CI

-

018

-

037

#10 X 1/2

CI

-

018

-

050

#10 X 5/8

CI

-

018

-

062

#10 X 3/4

CI

-

018

-

075

#10X 1”

CI

-

018

-

100

1/4 X 1/4

CI

-

025

-

025

1/4 X 3/8

CI

-

025

-

037

1/4 X 1/2

CI

-

025

-

050

1/4 X 5/8

CI

-

025

-

062

1/4 X 3/4

CI

-

025

-

075

1/4 X 1”

CI

-

025

-

100

5/16 X 3/8

CI

-

031

-

037

5/16 X 1/2

CI

-

031

-

050

5/16 X 5/8

CI

-

031

-

062

5/16 X 3/4

CI

-

031

-

075

5/16 X 1”

CI

-

031

-

100

3/8 X 1/2

CI

-

037

-

050

3/8 X

3/4

CI

-

037

-

075

3/8 X 1”

CI

-

037

-

100

COLLETS INSERTS

FOR WELD STUDS

CAPACITOR DISCHARGE ACCESSORIES

STUD RANGE

PART NO.

14 GA

–

10 GA

033

-

769

#6

–

3/8

033

-

769L

VENTED SPARK SHIELD

PART NO.

039

-

481

TEMPLATE I.D.

1” DIA.

30MM

80-40-513

1-

3/4”

1/4 DIA

028-

833

CD FOOT PIECE

PART NO.

028-833

15

This manual suits for next models

4

Table of contents

Other stud welding products Welding System manuals

stud welding products

stud welding products StudPro LiteXI User manual

stud welding products

stud welding products StudPro LiteXI User manual

stud welding products

stud welding products StudPro 2500 User manual

stud welding products

stud welding products StudPro 2500XI User manual

stud welding products

stud welding products StudPro 2500i User manual

Popular Welding System manuals by other brands

schweisskraft

schweisskraft EASY-MIG 201 i MULTI operating instructions

EWM

EWM Picomig 180 puls TGE operating instructions

Simadre

Simadre CT5200D owner's manual

MAGNUM WELDERS

MAGNUM WELDERS TIG200L AC/DC PRO Operation manual

Hot Max

Hot Max PL-25 Operator's manual

Red-D-Arc

Red-D-Arc SuitCase 12VS owner's manual