SAFETY RULES FOR AIR TOOLS

1. Always wear approved eye protection.

2. Have throttle (trigger) in "on" position when connecting to

air supply.

3. Disconnect tool before performing service or when not in

use.

4. Always use tool a safe distance from other people in work

area

5. Maintain tools with care. Keep tools clean and oiled for best

and safest performance. Follow instructions for lubricating

and changing accessories. Wiping or cleaning rags and

other flammable waste materials must be placed in a lightly

closed metal container and disposed of later in the proper

fashion

6. Do not wear loose or ill-fitting clothing. remove matches and

rings

7 Never use quick change couplings at toot They add weight

and could fail due to vibration. Instead add a hose whip and

connect coupling between air supply and hose whip, or

between hose whip and leader hose

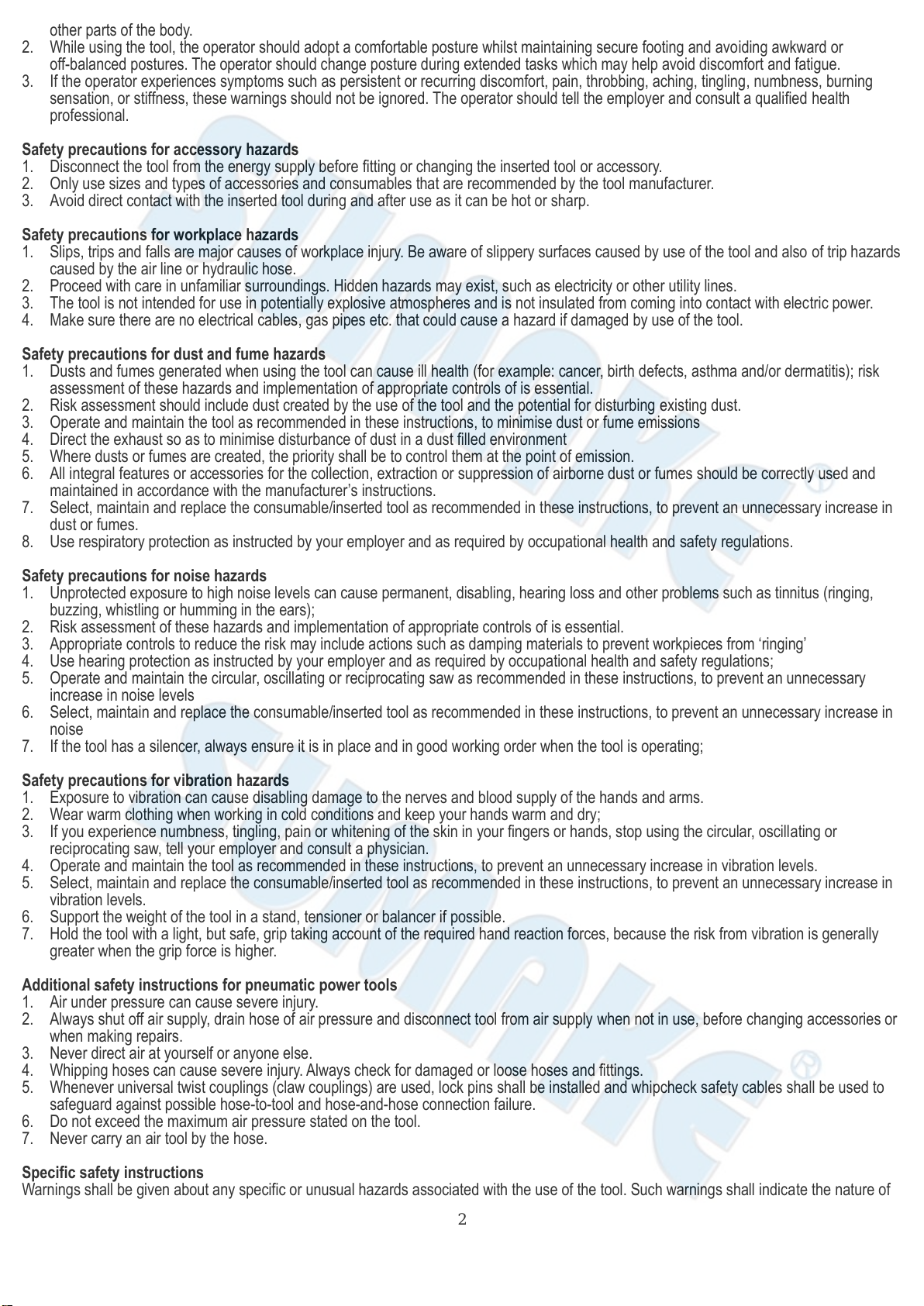

AIR SUPPLY

Toots of this class operate on a wide range of air pres-

sure. It is recommended that air pressure to these tools

do not exceed 90 PSI at the tool while running. Higher

pressure and unclean air will shorten the tool’s life be-

cause of faster wear and could create an unsafe condi-

tion.

Water in the air line will cause damage to the tool. Drain

the air tank daily. Clean the air inlet filler screen on at

least a weekly schedule. The recommended hook-up

procedure can be viewed in Figure l

The air inlet (A) Figure 2. used for connecting air supply

has standard 1/4 NPT Thread

Line pressure or hose inside diameter should be increased to compensate for unusually long air hoses (over 25 feet) Minimum

hose diameter should be 1/4” l.D. But 3/8” I.D. is recommended

OPERATING

On tools with regulators the air regulator (A) Figure 2. can be

used as an air throttle. If there are no other means of regulating

air.

Turn the air regulator (A}all the way in and adjust outward

until desired speed

Daily before using and before putting tool into operation, discon-

nect air hose and pour about one tablespoonful of recommended

oil (see “Lubrication and Maintenance”) into tool air inlet Blow out

air line to clear it of accumulated dirt and moisture, connect tool

and operate on low throttle to allow oil to be carried to the interior

of tool.

Let the tool do the work. Do not put extreme pressure on the

machine. This will only slow down the speed of the cutting

wheel, reduce cutting efficiency, and put additional burden on

the motor. Start the tool off the work. set it down on the work

evenly and move in the direction desired to make the cut. When

finished cutting, lift off the work before stopping the motor.

NOTE:PURING OPERATION SAFETY GOGGLES SHOULD

ALWAYS BE WORN TO GUARD AGAINST FLYING RUST

AND CHIPS.

USE ONLY WHEELS RATED AT 15,000 RPM OR HIGHER

LUBRICATION AND MAINTENANCE

Lubricate the air motor daily with a good grade of air motor oil. If

no air line oil is used run a teaspoon of oil through the tool The

oil can be squirted into the tool air inlet (A) Figure 2. or into the

hose at the nearest connection to the air supply, then run the

tool A rust inhibitive oil such as “Marvel Mystery” oil. available

from

auto supply stores etc.. is acceptable for air motor

Other factors outside the tool may cause loss of power or erratic

action Reduced compressor output, excessive drain on the air

line. moisture or restrictions in air pipes or the use of hose

connection of improper size or poor

OPERATING INSTRUCTIONS

8. Don’t overreach keep proper tooting and balance at all

times.

9. Don’t force tool. It will do the job better and safer at the

rate for which it was designed

10. Don't abuse hoses or connectors Never carry tool by the

hose or yank it to disconnect from power supply keep

hoses from heat oil and sharp edges. Check hoses for

weak or worn condition before each use making certain

that all connections are secure

11. When possible secure work with clamps or vise so both

hands are free to operate tool

12. Accessory retainers should be used to prevent discard or

ejection of the accessory which might injure persons in the

general area

EXCEPTION Retainers not be used it in compliance

with applicable safety codes In such cases, to avoid injury

the trigger should never be depressed unless the

accessory is held firmly against the work piece Accessory

should be removed when tool is not in use

condition may reduce air supply Grit or gum deposits in the tool

may cut power and may be corrected by cleaning the air

strainer and flushing out the tool with gum solvent oil or an

equal mixture or SAE #10 oil and kerosene If outside

conditions are in order, disconnect tool from hose. disassemble

tool. replace worn or damaged parts, clean, reassemble

and relubricate, or take tool to your nearest authorized service

center

FIGURE 1

FIGURE 2

Do Not Install

Quick Coupler

Here Nipple

Hose Whip Nipple Filter

Air Supply

Drain Daily

RegulatorOiler

Quick Coupler

Leader Hose

Air Inlet

(A) Regulator Knob

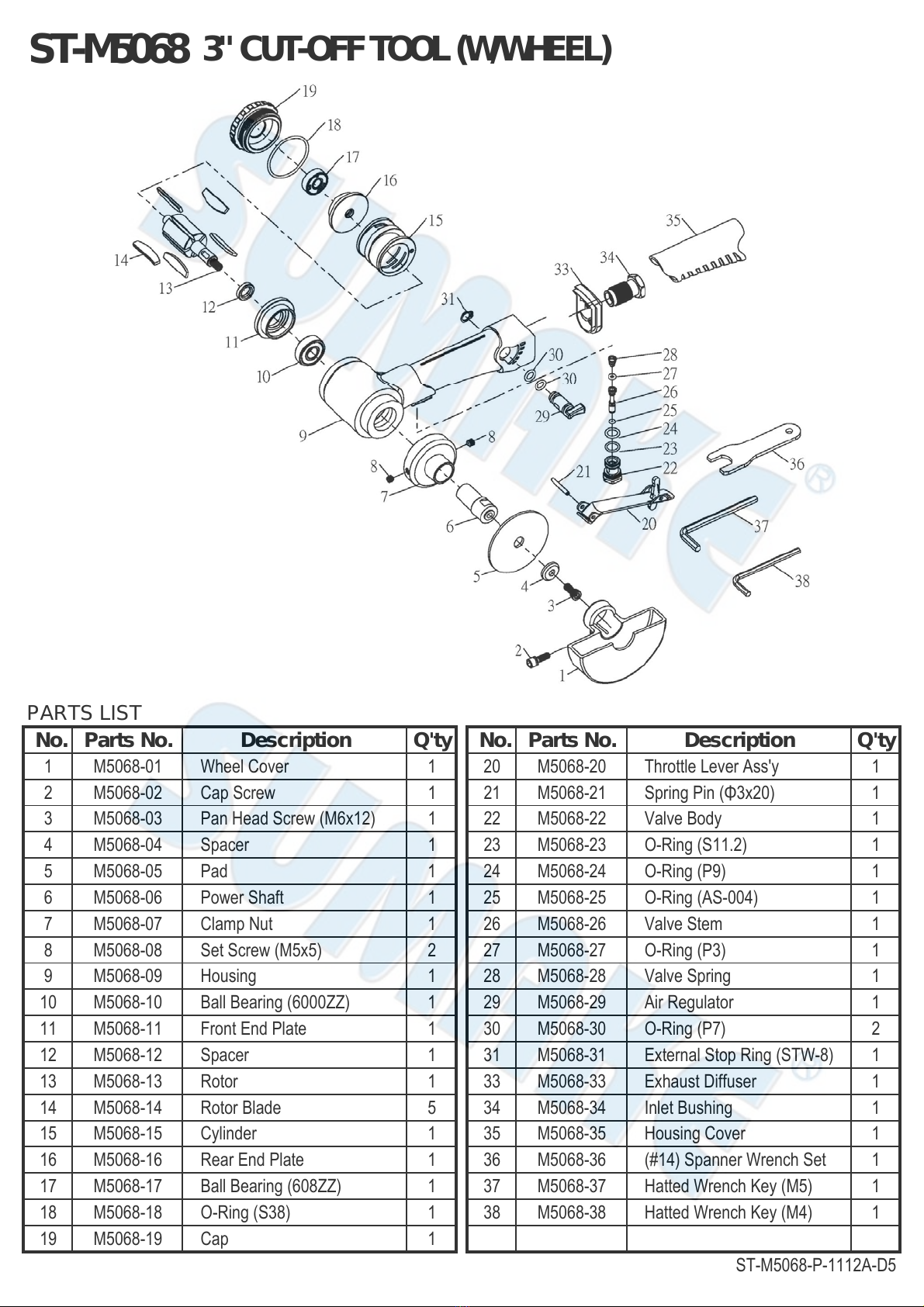

ST-M5068-I-1112A-D5