6

V. Description

1. Assembly:

There are five individual boxs after opening, please follow the steps below to

assemble.

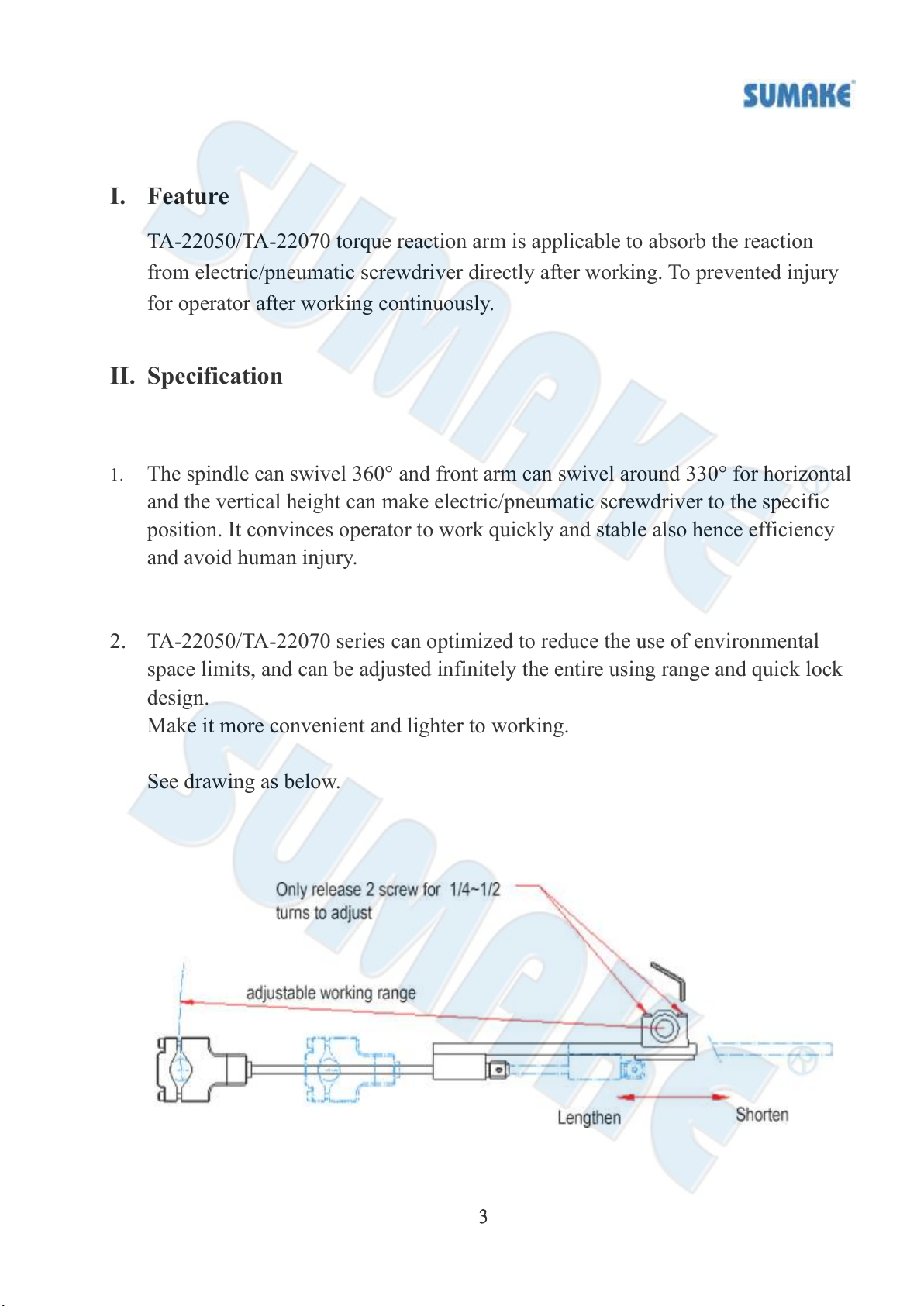

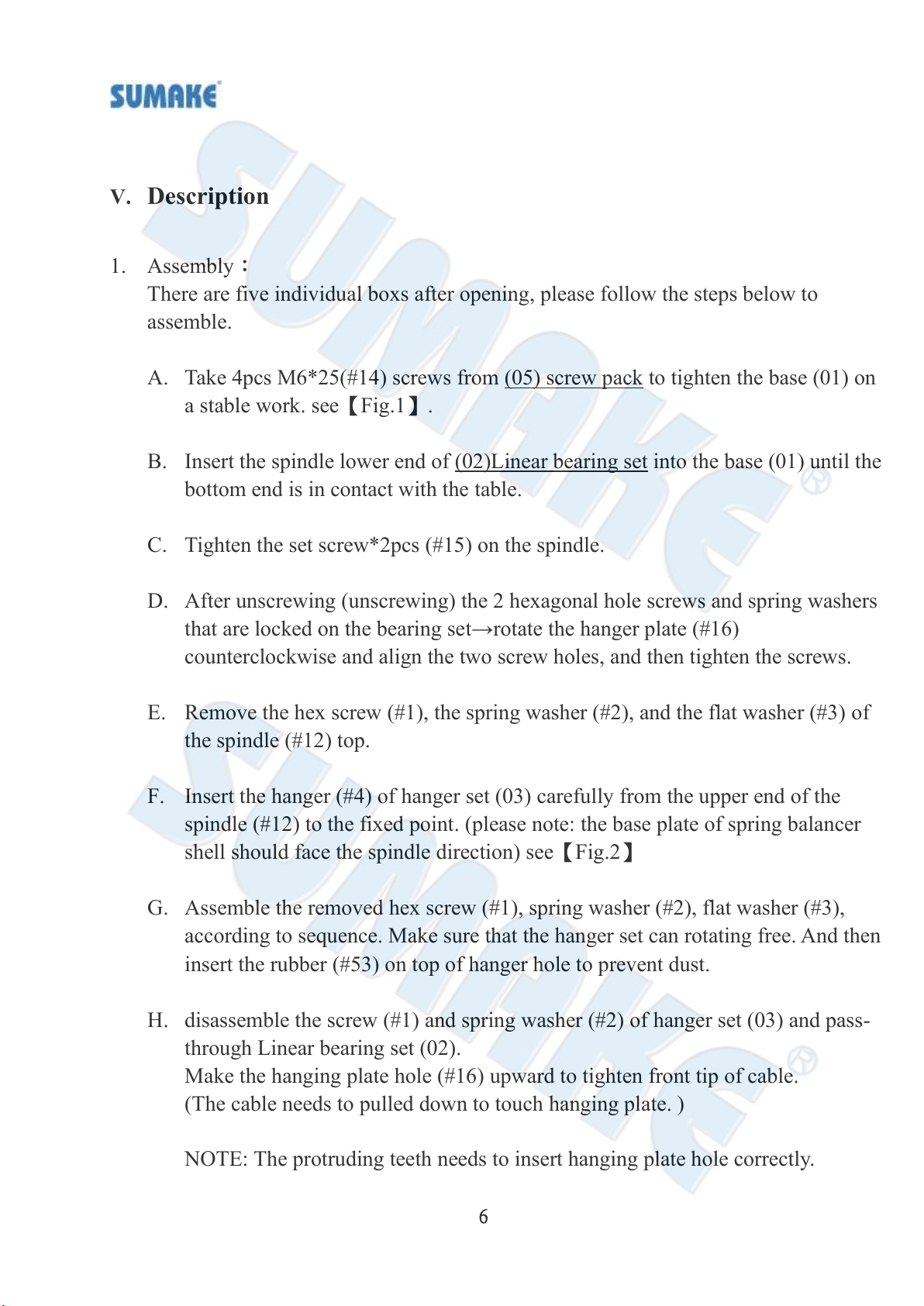

A. Take 4pcs M6*25(#14) screws from (05) screw pack to tighten the base (01) on

a stable work. see【Fig.1】.

B. Insert the spindle lower end of (02)Linear bearing set into the base (01) until the

bottom end is in contact with the table.

C. Tighten the set screw*2pcs (#15) on the spindle.

D. After unscrewing (unscrewing) the 2 hexagonal hole screws and spring washers

that are locked on the bearing set→rotate the hanger plate (#16)

counterclockwise and align the two screw holes, and then tighten the screws.

E. Remove the hex screw (#1), the spring washer (#2), and the flat washer (#3) of

the spindle (#12) top.

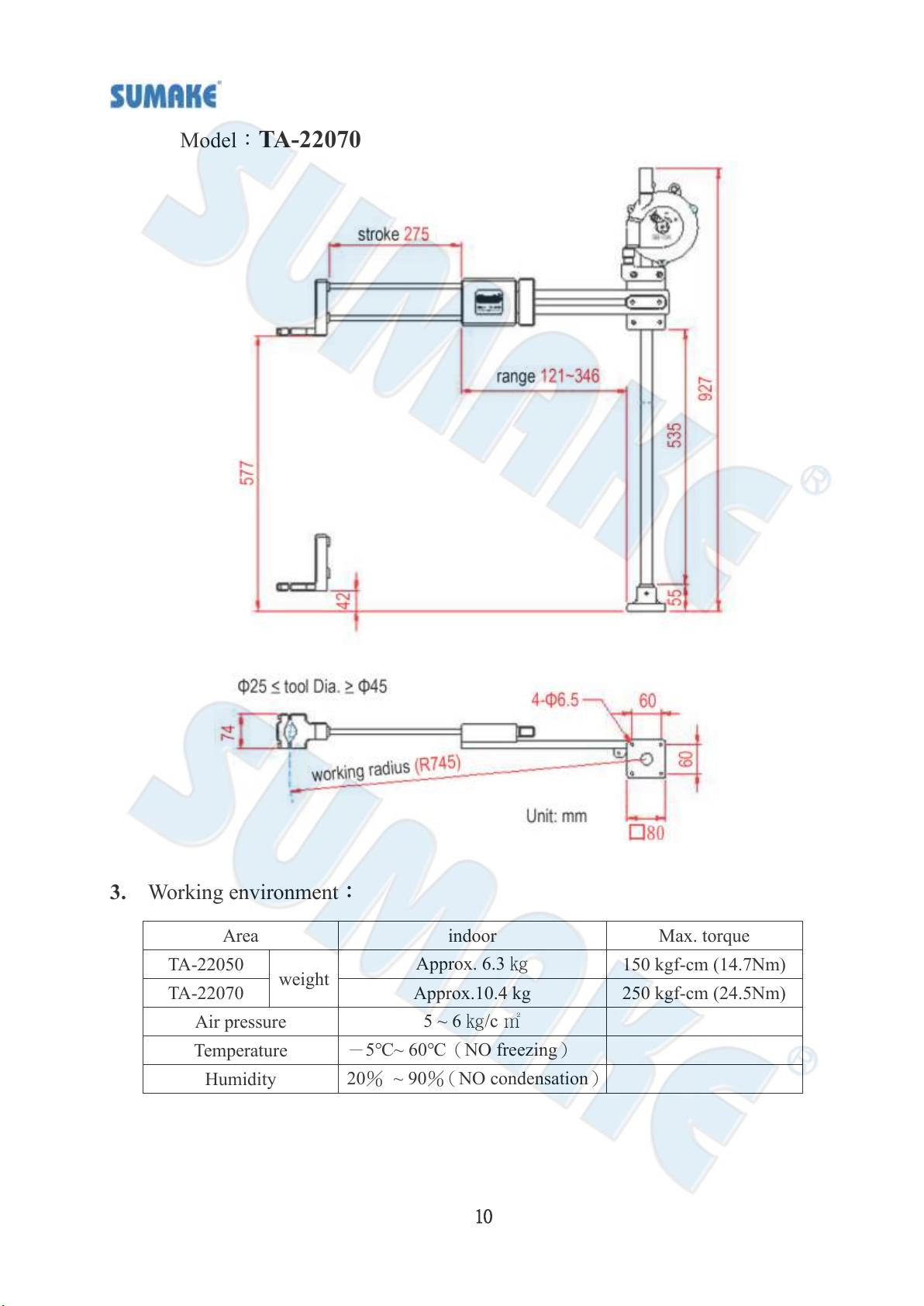

F. Insert the hanger (#4) of hanger set (03) carefully from the upper end of the

spindle (#12) to the fixed point. (please note: the base plate of spring balancer

shell should face the spindle direction) see【Fig.2】

G. Assemble the removed hex screw (#1), spring washer (#2), flat washer (#3),

according to sequence. Make sure that the hanger set can rotating free. And then

insert the rubber (#53) on top of hanger hole to prevent dust.

H. disassemble the screw (#1) and spring washer (#2) of hanger set (03) and pass-

through Linear bearing set (02).

Make the hanging plate hole (#16) upward to tighten front tip of cable.

(The cable needs to pulled down to touch hanging plate. )

NOTE: The protruding teeth needs to insert hanging plate hole correctly.