Sunbeam Domestic 70 User manual

SMT081313

Domestic 70 Stitch Sewing Machine

Operating Instructions

Model No. SB700

Safety instructions

Component identication

Accessories

Fitting the snap-in sewing table

Connecting machine to the power source

Two-step presser foot lever

Attaching the presser foot holder

Winding the bobbin

Inserting bobbin

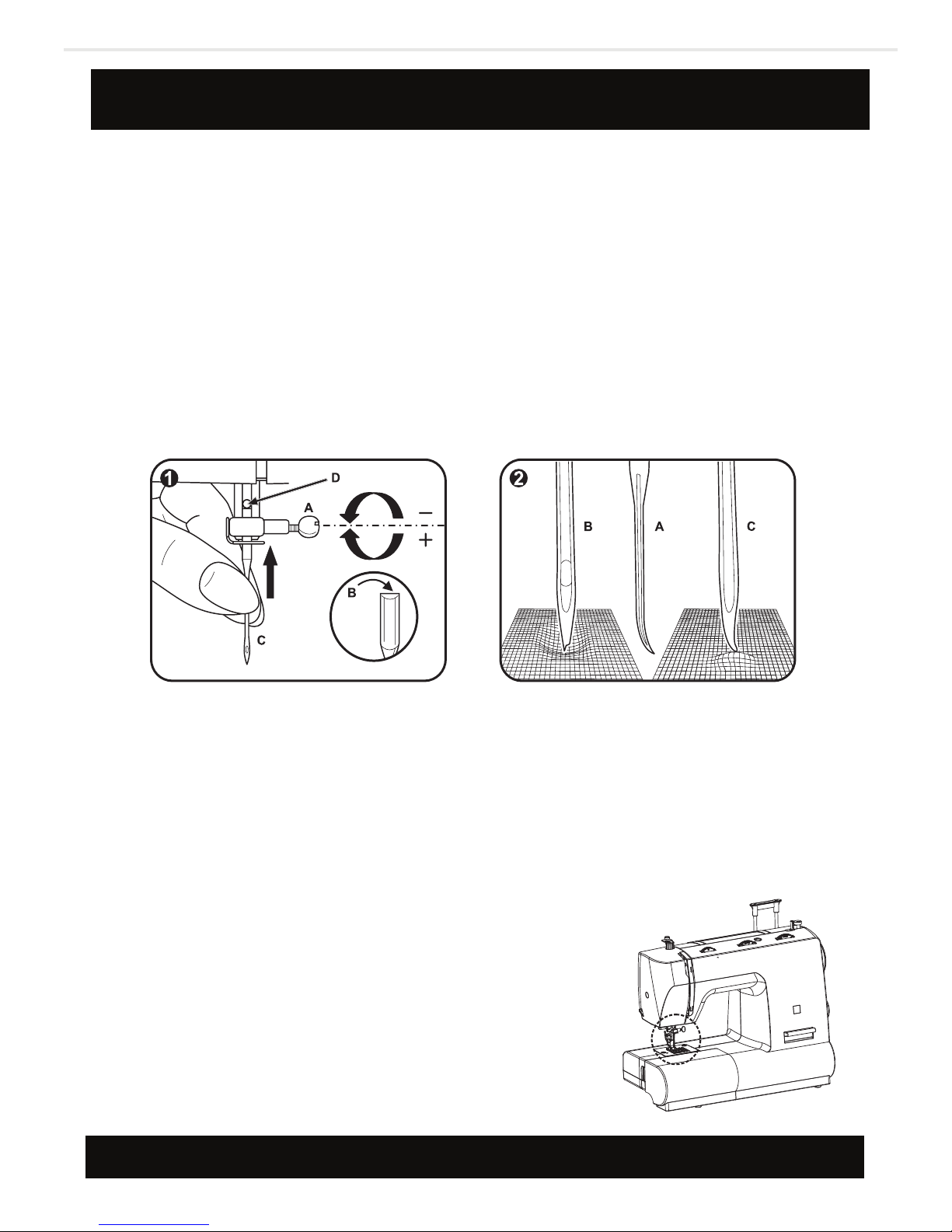

Changing the needle

Threading the upper thread

Automatic needle threader

Thread tension

Bringing up the lower thread

Finishing up

Matching needle / fabric / thread

How to choose your pattern

Straight stitching and needle position

Zig-zag sewing

Blind hem / lingerie stitch

Overlock stitches

Sewing on buttons

Utility sewing

Zippers and piping

Sewing with the hemmer foot

3 step zig-zag

Stitch selection

Smocking stitch

Sewing with the cording foot

Free motion darning

Practical stitches

Darning

Attaching lace

Applique

Twin needle

Quilting

Gathering x-foot

Patch work

Maintenance

Troubleshooting guide

03-04

05-06

07

08

09

10

11

12

13

14

15

16

17

18

19

20-21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

41

42

43

44

45-46

Contents

02

Safety instructions

When using an electrical appliance,

basic safety precautions should

always be followed, including the

following:

Read all instructions before using this

sewing machine.

1. An appliance should never be left

unattended when plugged in.

2. Always unplug this appliance from

the electric outlet inmediately after

using and before cleaning.

Always unplug before re-lamping.

Replace bulb with same type rated 10

watts.

DANGER - To reduce the risk of

electric shock:

1. Do not allow to be used as a toy.

Close attention is necessary when this

appliance is used by or near children.

2. Use this appliance only for its

intended use as described in this

manual.

3. Never operate this appliance if it

has a damaged plug or cord, if it is not

working properly, if it has been

WARNING - To reduce the risk of

burn, re, electric shock, or injury

to persons:

dropped or damaged or dropped into

water.

4. Never operate this appliance with

any air openings blocked. Keep

ventilation openings of the sewing

machine and foot controller free from

accumulation of lint, dust and loose

cloth.

5. Keep ngers away from all moving

parts. Special care is required around

the sewing machine needle.

6. Always use the proper needle plate.

The wrong plate can cause the needle

to break.

7. Do not use bent needles.

8. Do not pull or push fabric while

stitching. It may deect the needle

causing it to break.

9. Switch the sewing machine o (”O”)

when making any adjustments in the

needle area, such as threading needle,

changing needle, threading bobbin, or

changing presser foot, and the like.

10. Always unplug sewing machine

from the electrical outlet when

removing covers, lubricating, or when

making any other user servicing

adjustments mentioned in the

instruction manual.

11. Never drop or insert any object

into any opening.

12. Do not use outdoors.

13. Do not operate where aerosol

spray products are being used or

where oxygen is being administered.

14. To disconnect, turn all controls to

the o (”O”) position, then remove

plug from outlet.

15. Do not unplug by pulling on cord.

To unplug, grasp the plug, not the

cord.

This sewing machine is intended for

household use only.

03

SAVE THESE INSTRUCTIONS

1. Do not allow to be used as a toy.

Close attention is necessary when this

appliance is used by or near children.

2. Use this appliance only for its

intended use as described in this

manual.

3. Never operate this appliance if it

has a damaged plug or cord, if it is not

working properly, if it has been

dropped or damaged or dropped into

water.

4. Never operate this appliance with

any air openings blocked. Keep

ventilation openings of the sewing

machine and foot controller free from

accumulation of lint, dust and loose

cloth.

5. Keep ngers away from all moving

parts. Special care is required around

the sewing machine needle.

6. Always use the proper needle plate.

The wrong plate can cause the needle

to break.

7. Do not use bent needles.

8. Do not pull or push fabric while

stitching. It may deect the needle

causing it to break.

9. Switch the sewing machine o (”O”)

when making any adjustments in the

needle area, such as threading needle,

changing needle, threading bobbin, or

changing presser foot, and the like.

10. Always unplug sewing machine

from the electrical outlet when

removing covers, lubricating, or when

making any other user servicing

adjustments mentioned in the

instruction manual.

Safety instructions

11. Never drop or insert any object

into any opening.

12. Do not use outdoors.

13. Do not operate where aerosol

spray products are being used or

where oxygen is being administered.

14. To disconnect, turn all controls to

the o (”O”) position, then remove

plug from outlet.

15. Do not unplug by pulling on cord.

To unplug, grasp the plug, not the

cord.

This sewing machine is intended for

household use only.

04 04

Component identication (Part 1)

1.

2.

3.

4.

5.

6.

7.

1

2

Thread tension dial

Presser foot pressure

Thread take-up lever

Thread cutting

Presser foot

Needle plate

Sewing table and accessory box

Bobbin stopper

Stitch length dial

Stitch width dial

Stitch display

Reverse sewing lever

Automatic threader (optional)

8.

9.

10.

11.

12.

13.

8

9

5

3

4

6

7

13

10

11

12

05

14.

15.

16.

17.

18.

19.

20.

16

23

Upper thread guide

Presser foot lever

Handle

Bobbin winder

Spool pin

Handwheel

Pattern selector dial

Power switch

Main plug socket

Bobbin thread guide

21.

22.

23.

17

20

21

22

18

19

Component identication (Part 2)

06

a.

b.

c.

d.

e.

f.

g.

h.

i.

j.

k.

l.

m.

Standard Accessories (1)

4 step buttonhole foot

L shape screwdriver

Seam ripper/brush

Lubricate oil

#14 needle x 3pcs (ORGAN brand)

Bobbins x 3pcs in total

Twin needle

Screw driver (small)

Screw driver (large)

Edge/quilting guide

Emboidering plate

Spool holder

All purpose foot

n.

o.

q.

r.

s.

t.

u.

v.

w.

x.

Optional Quilting Package (2)

Zipper foot with double edge

Button sewing foot

Blind hem foot

Hemmer foot

Quilting foot

Stain stitch foot

Overcasting foot

Darning/embroidering foot

Gathering foot

Cording foot

Accessories

07

(To order optional accessories, please

call us at: 1- 877-678-6232).

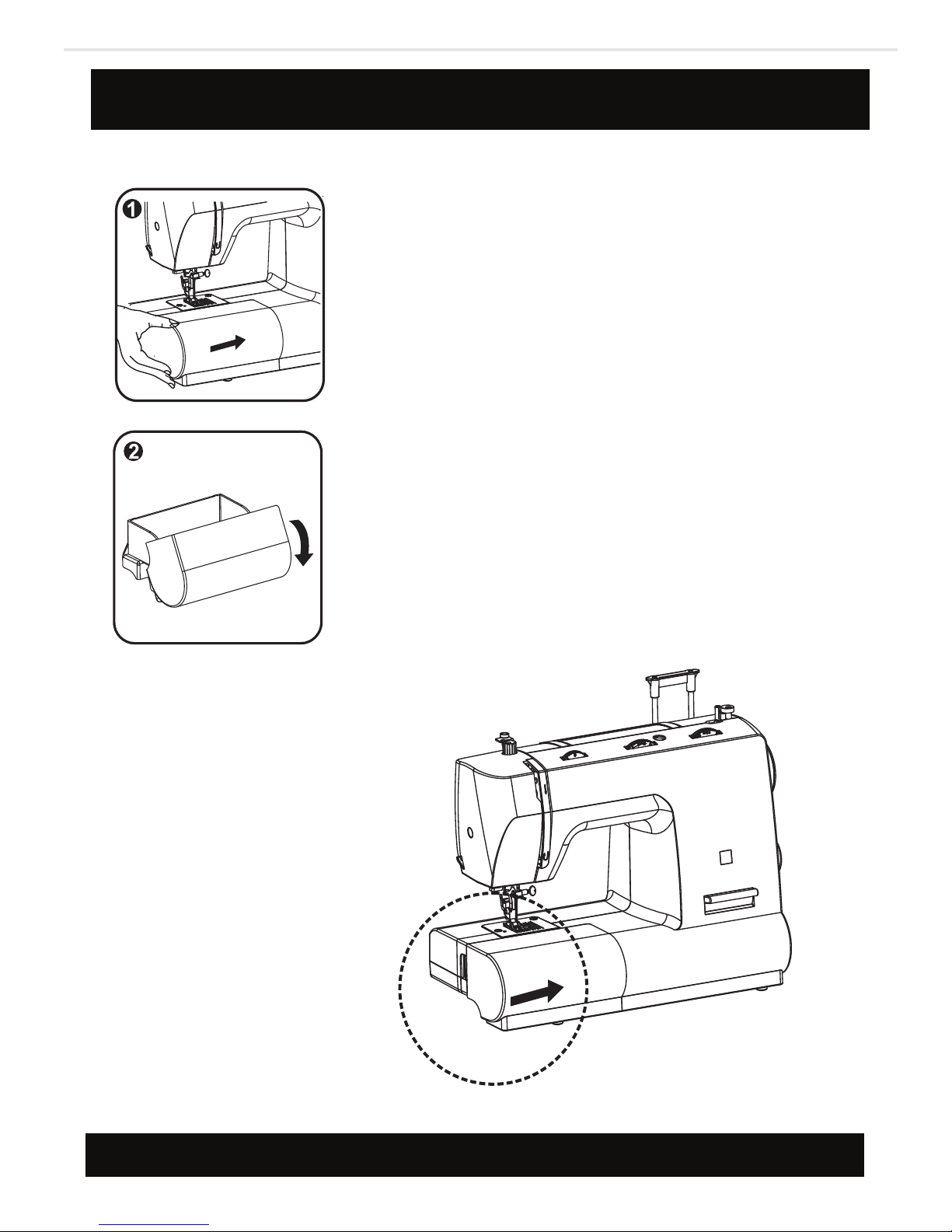

Fitting the snap-in sewing table

Hold the snap-in sewing table horizontal, and

push it in the direction of the arrow. (Fig.1)

The inside of the snap-in sewing table can be

utilized as an accessory box. To open, lift up at

the point of the arrow. (Fig.2)

08

Connecting machine to power source

Always make sure that the machine is unplugged from

power source and the main switch is on (O ) “0” when

the machine is not in use and before inserting or

removing parts.

- This machine is equipped with polarized plug which

must be used with an appropriate electrical outlet.

- Connect the machine to a power source as illustrated

(1/2).

-The power switch is located above the terminal box.

Your machine will not operate unless the switch is on

”I”. (1)

-Sewing light turns on automatically when the main

switch is on “I”.

-To start the machine, press the foot control (3). The

speed of the machine is regulated by the amount of

pressure exerted on the foot control.

CAUTION:

Consult a qualied electrician if in doubt as to connect

the machine to power source. Unplug power cord

when machine is not in use.

ATTENTION:

09

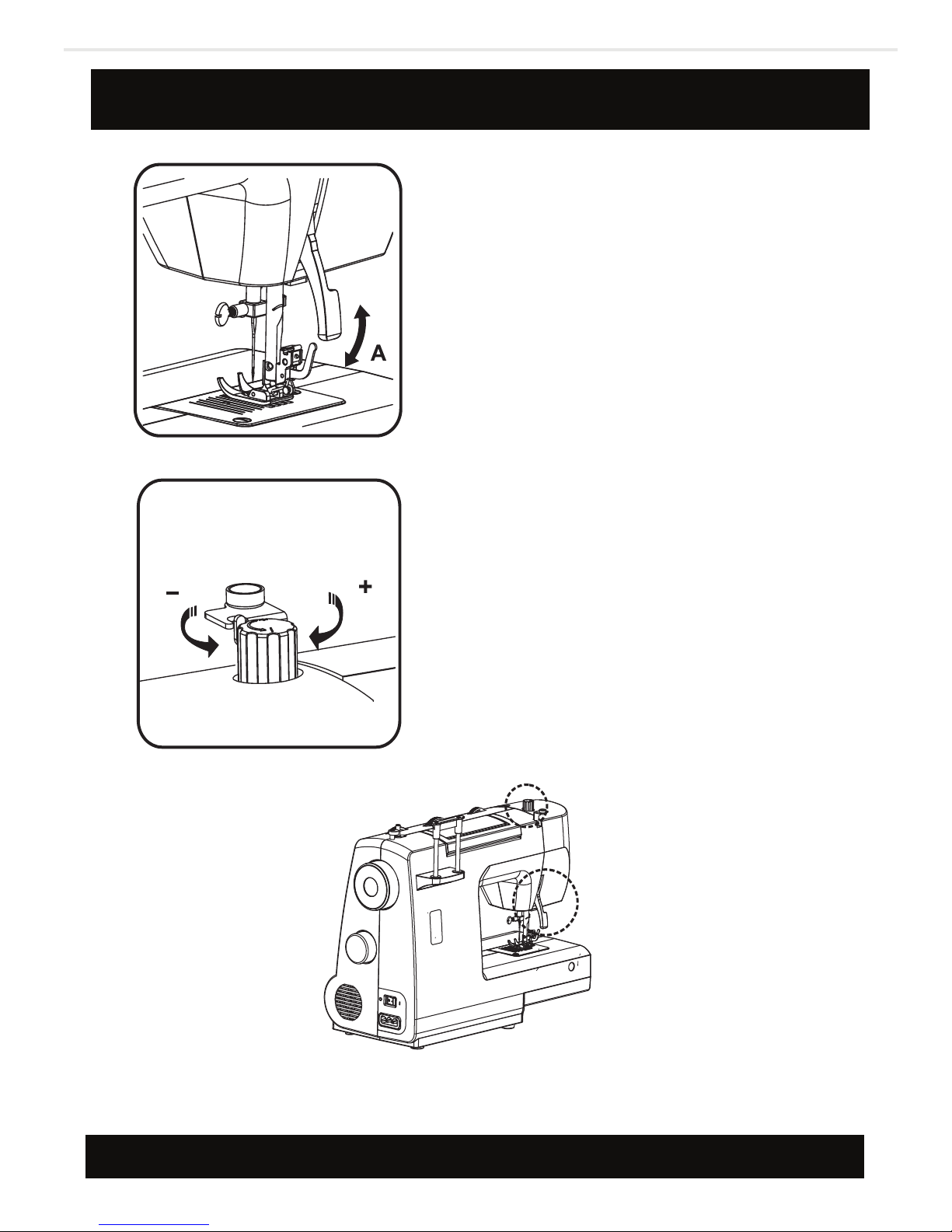

When sewing several layers or thick

fabrics, the presser foot can be raised a

second stage for easy positioning of

the work. (A)

The presser foot pressure of the

machine has been pre-set and requires

no particular readjustment according

to the type of fabric (light or heavy

weight).

However, if you need to adjust the

presser foot pressure, turn the presser

foot pressure dial as shown above.

For sewing very thin fabric, loosen the

pressure by turning the dial counter

clockwise, and for heavy fabric, tighten

by turning it clockwise.

Two-step presser foot lever

10

Attaching the presser foot holder

Turn power switch to “0” before carrying out

any of the operations below.

Raise the needle to its highest position and

raise the presser foot lever. Attach the presser

foot holder (b) to the presser foot bar (a). (1)

ATTENTION:

Lower the presser foot holder (b) until the

cut-out (c) is directly above the pin (d). (2)

Lower the presser foot holder (b) and the

presser foot (f) will engage automatically.

Attaching the presser foot:

Raise the presser foot.

Release the pressure foot by raising lever (e)

located at the back of the foot holder. (3)

Removing the presser foot:

Attach the seam guide (g) in the slot as

illustrated. Adjust the distance as required for

hems, pleats, etc.... (4)

Attaching the seam guide:

11

Place an empty bobbin winder spindle.

Take the thread from the spool through the

bobbin winder tension disc. (1)

Wind the thread a few times by hand around

the empty bobbin in a clockwise direction. Push

the bobbin to the right towards the bobbin

winding position. (2)

Press the foot control gently. The bobbin will

stop winding when it is full. Push the bobbin to

the left to “sewing position” and remove it.

Winding the bobbin

When the bobbin winder spindle is in “bobbin

winding” position, the machine will not sew and

the hand wheel will not turn. To start sewing,

push the bobbin winder spindle to the left

(sewing position).

NOTE:

a. Spool pin

12

- Open the hinged cover. (1)

- Hold the bobbin case with one hand. Insert

the bobbin so that the thread runs in a

clockwise direction (arrow). (2)

- Pull the thread through the slot, down and to the

left until it enters the delivery eyelet (rectangular

opening) under the tension spring. (3)

- Hold the bobbin case by the hinged latch. (4)

- Insert the bobbin case fully into the shuttle

race and release the latch. Make sure that the

metal nger ts into the notch at the top of the

race cover. (5)

Inserting bobbin

Turn power switch to (O) “0” before inserting

or removing the bobbin.

When inserting or removing the bobbin, the

needle must be fully raised.

ATTENTION:

13

Changing the needle

Turn power switch to (O) “0” before inserting or removing the needle.

Replace the needle at the rst sign of thread breakage or skipped

stitches. Select the correct type and size of needle for the fabric to be

sewn. Turn the balance wheel towards you until the needle is at

highest position. Loosen the needle clamp screw (A) and tighten again

after inserting the new needle. (1)

The at side of the needle shaft should be facing away from you (B).

Push the needle up (C) into the needle clamp as far as it will go (D).

Tighten the needle clamp screw rmly. The sewing needle must always

be straight and sharp for smooth sewing. Replace the needle (2) if it is

bent (A), blunt (B) or the point is damaged (C).

CAUTION:

14

Before threading, turn power

switch to (O) “0”.

Raise the needle bar to its

highest position. Follow exactly

the numbered threading

sequence illustrated below. If you

skip a step or fail to properly

engage the thread in any of the

thread guides, the machine will

not sew properly. (1-5)

Continue to draw the thread

down and into the needle bar

thread guide. Insert the thread

through the eye of the needle

from front to back. Leave about

10cm (4”) of thread loose behind

the needle. (6)

a. Spool pin

b. Spool holder

CAUTION:

Threading the upper thread

15

- Raise the needle to its highest position.

- Press lever (A) right down.

- The threader automatically swings to the threading position (B).

- Take the thread around the hook (C).

- Take the thread in front of the needle round the hook (D) from bottom

to top.

- Release lever (A).

- Pull the thread through the needle eye.

Automatic needle threader

Turn power switch to (O) “0” before carrying out any of the following:

*The automatic needle threader is an optional accessory not supplied

with your machine (to purchase call: 877-678-6232).

ATTENTION:

16

Thread tension

The bobbin thread tension has been adjusted at

the factory and readjustment is usually not

required.

NOTE:

To test the bobbin thread tension, remove the

bobbin case and bobbin from the machine and

hold the bobbin case suspended by the thread.

Shake it once or twice. If the tension is correct,

the thread will unwind by about an inch or two.

If the tension is too tight, it will not unwind. If

the tension is too loose, the thread will unwind

for more than two inches. To adjust, turn the

small screw on the side of the bobbin case. (1)

Lower thread tension

Basic thread tension setting: “4”. (2)

To increase the tension, turn the dial up to a

higher number. To reduce the tension, turn the

dial to a lower number.

A. Normal thread tension.

B. Thread tension too loose.

C. Thread tension too tight.

Upper thread tension

17

Hold the upper thread with the left hand. Turn the handwheel towards

you with your right hand until the needle goes down and comes up

again to its highest position. (1)

- Lightly draw the needle thread forming a loop with the bobbin thread.

The upper thread should have caught the lower thread in a loop.

- Pull the needle thread toward you and the lower thread will come up

from the bobbin in a large loop. (2) Pull about 15cm (6”) of both threads

away from you under the presser foot.

Bringing up the lower thread

18

Turn the handwheel towards you to bring

the thread take up lever to its highest

position. Raise the presser foot and draw the

fabric away from you.

Removing the fabric

Hold the threads behind the presser foot.

Using both hands, guide them to the slit (B)

at the rear of the presser bar and press down

to cut the thread. You can also use the thread

cutter on the side of the machine.

Cutting the thread

Reverse sewing is used for locking the end of

seams and where reinforcement is needed.

At the end of seam, press down the reverse

sewing lever and touch the foot control

lightly. Sew a few reverse stitches. Release

the lever and the machine will sew forwards

again. (A)

Finishing up

19

Reverse sewing

IMPORTANT: Match needle size to thread size and weight of fabric.

Matching needle / fabric / thread

9-11 (65-75)

NEEDLE

SIZE

FABRICS THREAD

Lightweight fabrics-thin cottons, voile,

serge, silk, muslin, Qiana, interlocks,

cotton knits, tricots, jerseys, drapes,

woven polyester, shirt & blouse fabrics.

Light-duty thread in cotton, nylon or

polyester.

12 (80) Medium weight fabrics-cotton, satin,

kettleclote, sailcloth, double knits,

lightweight woolens.

14 (90) Medium weight fabrics-cotton duck,

woolen, heavier knits, terrycloth,

denims.

16 (100) Heavyweight fabrics-canvas, woolens,

outdoor tent and quilted fabrics,

denims, upholstery material (light to

medium).

18 (110) Heavy woolens, overcoat fabrics,

upholstery fabrics, some leathers and

vinyls.

Heavy duty thread, carpet thread.

(Use heavy foot pressure-large

numbers.)

Most threads sold are medium size

and suitable for these fabrics and

needle sizes. Use polyester threads

on synthetic materials and cotton

on natural woven fabrics for best

results. Always use the same thread

on top and bottom.

20

This manual suits for next models

1

Table of contents

Other Sunbeam Sewing Machine manuals