Sunbeam SB1800 User manual

Compact Sewing Machine

Operating Instructions

Model Nos. SB1800/SB1818

Please read all instructions carefully before operating the

sewing machine.

Keep this manual for future reference.

SMT080811

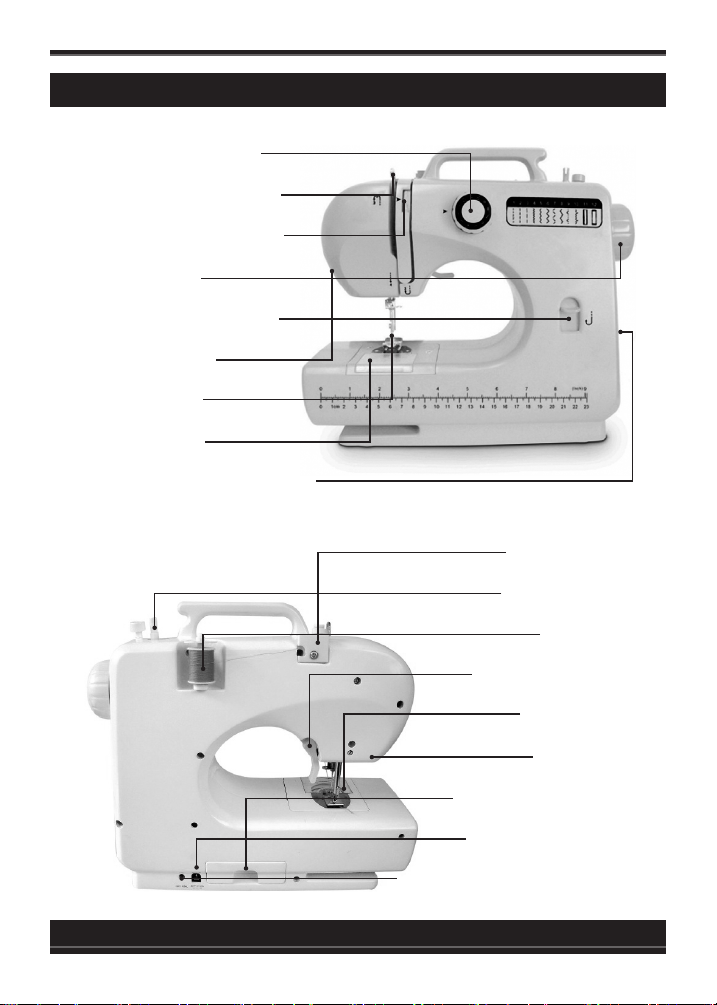

Sewing Machine InstructionsPage 2

Thread clamp

Bobbin winder

Spool pin

Presser foot lever

Presser foot

Work lamp

Accessories drawer

AC/DC receptacle

Foot controller receptacle

Stitch pattern knob

Thread take-up lever

Upper tension control

Hand wheel

Reverse stich button

Thread cutter

Needle feed

Bobbin case

Power and speed switch

Components

Sewing Machine Instructions Page 3

For Your Safety

Use this machine only as recommended in this manual.1.

Do not leave the unit unattended, especially near children.2.

To avoid electric shock, remove the adapter before cleaning or3.

after use.

Keep ngers away from all inside electrical parts, especially 4.

around the needle.

Never operate the machine if it has a damaged power cord or 5.

has been dropped into water.

Do not use the machine outdoors.6.

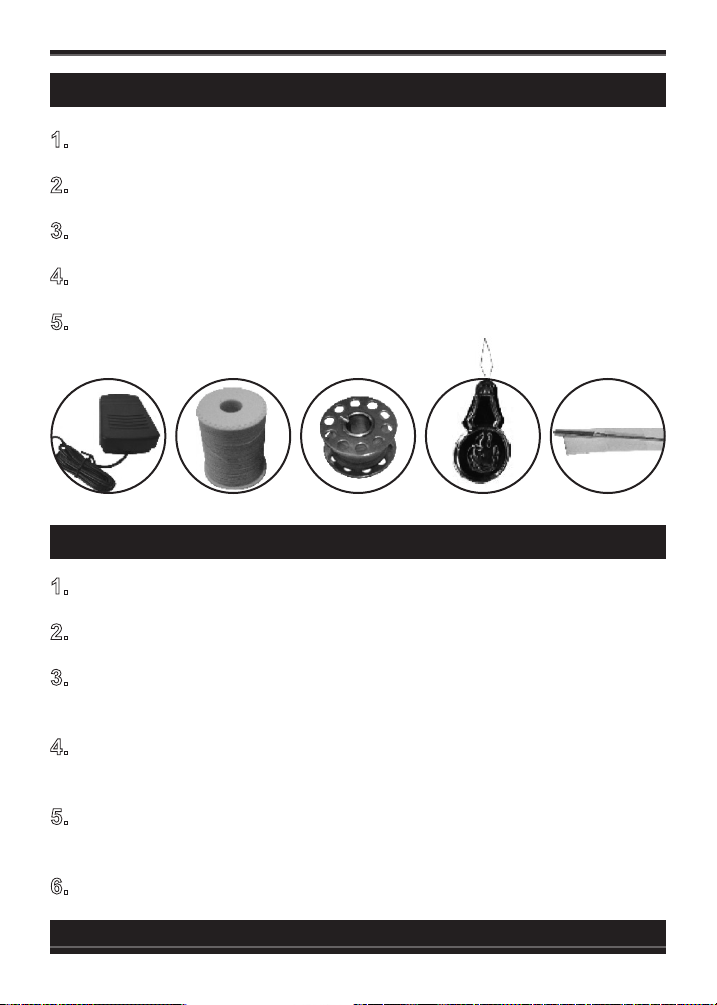

Accessories

Foot control1.

2 spools of thread2.

2 bobbins3.

Needle threader4.

Needle5.

Sewing Machine InstructionsPage 4

Preparations for Use

Plug one end of the adapter into the DC socket on the sewing •

machine, and the other end into an outlet.

Plug the foot control into its socket.•

Turn the power switch on.•

Caution: Always turn the switch on off before un-plugging the

machine.

Operating Instructions

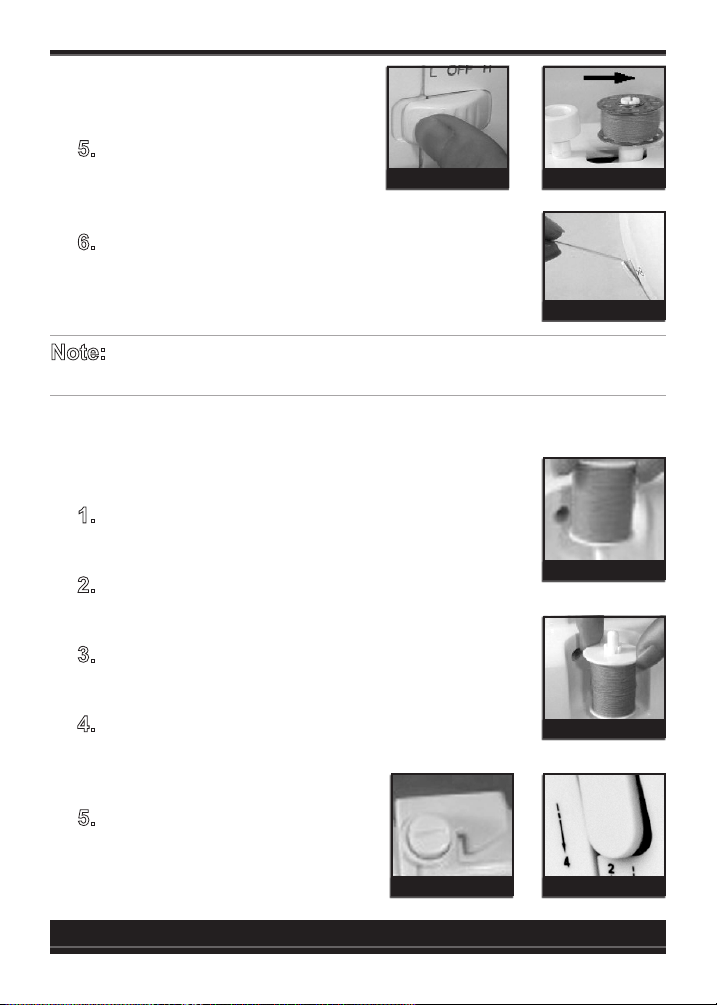

Winding the bobbin

Place a spool of thread on the Spool Pin.1.

(Figure 1) (Make sure that the machine’s

needle is not threaded at this time.)

Place the metal bobbin on the bobbin winder, 2.

making sure to insert it in the groove. (Figure

2) (Note: It is important to use metal bobbins

only. The Bobbin Case is magnetized and is

activated with metal.)

Guide the thread from the Spool Pin through3.

the thread clamp (Figure 3) and to the bobbin.

Wind a small piece of thread around the

bobbin

clockwise.

(Figure 4)

Move the4.

bobbin Figure 5

Figure 2

Figure 1

Figure 4Figure 3

Sewing Machine Instructions Page 5

to the right, clicking it into

place. (Figure 5)

Select a speed switch. This 5.

will start the bobbin winding.

(Figure 6)

When you have your desired amount of thread6.

on the bobbin, switch to OFF and move the

bobbin to the left (Figure 7) snip the thread.

(Figure 8)

Note: It is preferable to manually assist in the

winding of the bobbin. Use your hands to guide the thread.

Threading the machine

Make sure that the power switch is on OFF.

Place a spool of thread on the Spool Pin with 1.

the thread end facing rear. (Figure 9)

Clamp the reel cover over the Spool Pin so2.

that the thread remains in place. (Figure 10)

Loop the thread around the outside of thread3.

guide 1. (Figure 11)

Guide the thread into Groove 2, and pull4.

toward the chrome take-up

lever. (Figure 12)

Feed the thread through the5.

hole in the chrome take-up

lever and pull straight down

to the needle. (Figure 13) Figure 11 Figure 12

Figure 10

Figure 9

Preparations for Use

Plug one end of the adapter into the DC socket on the sewing •

machine, and the other end into an outlet.

Plug the foot control into its socket.•

Turn the power switch on.•

Caution: Always turn the switch on off before un-plugging the

machine.

Operating Instructions

Winding the bobbin

Place a spool of thread on the Spool Pin.1.

(Figure 1) (Make sure that the machine’s

needle is not threaded at this time.)

Place the metal bobbin on the bobbin winder, 2.

making sure to insert it in the groove. (Figure

2) (Note: It is important to use metal bobbins

only. The Bobbin Case is magnetized and is

activated with metal.)

Guide the thread from the Spool Pin through3.

the thread clamp (Figure 3) and to the bobbin.

Wind a small piece of thread around the

bobbin

clockwise.

(Figure 4)

Move the4.

bobbin

Figure 8

Figure 6 Figure 7

Sewing Machine InstructionsPage 6

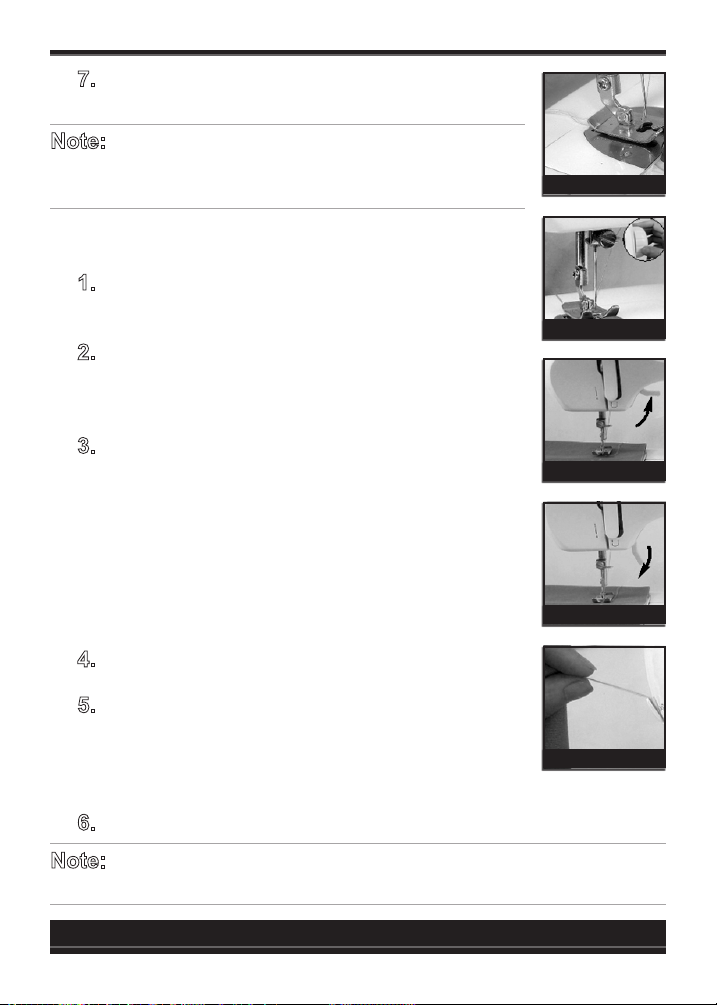

Feed the thread through the6.

hole in the needle holder

and then through the eye of

the needle. (Figure 14) The

threading is now complete,

except for the bobbin.

Connecting the bobbin

Remove the Bobbin Cover. (Figure 15)1.

Place the bobbin into the Bobbin Case,2.

(Figure 16) making sure that the thread

unwinds in a clockwise direction. Allow

approximately 4 inches of thread to extend

from the case.

Extend about 4 inches of thread from the3.

machine’s needle. (Figure 17)

Raise the presser foot. Hold the thread from4.

the needle with your left hand while turning

the hand wheel with your right hand counter-

clockwise (toward you). (Figure 18)

Keep rotating the wheel till the needle goes 5.

through the plate down to the Bobbin Case

and then back up again. When the needle

comes back up, it will pull a loop of bobbin

thread with it.

Pull at the loop to get the raw 6.

edge of the bobbin thread

farther out of the Bobbin

Case. (Figure 19) Figure 18 Figure 19

Figure 15

Figure 16

Figure 17

Figure 14Figure 13

Sewing Machine Instructions Page 7

Pull both the bobbin and top thread toward the 7.

back of your presser foot. (Figure 20)

Note: Try a practice stitch before beginning to sew

to make sure you’ve threaded the machine

correctly.

How to sew

Turn the hand wheel counter-clockwise till the 1.

needle is at its highest position. (Figure 21)

Lift the presser foot. Place the fabric beneath2.

the presser foot at exact spot where you want

to begin sewing. (Figure 22)

Lower the presser foot onto the fabric. (Figure 3.

23) Select a stitch pattern. Make sure the

power switch is ON. Lower the needle into

the fabric. Press down on the foot control and

begin sewing. The sewing speed depends on

the pressure applied to the paddle: the harder

you press, the faster the needle moves. Guide

the fabric gently with your hands.

When done, switch the power OFF.4.

Turn the hand wheel anti-clockwise till the 5.

needle is at its highest position. Lift the

presser foot. Gently ease the fabric away from

beneath the presser foot.

Snip the threads with the thread cutter. (Figure 24)6.

Note: Do not touch the pattern selection knob while the machine is

running.

Figure 24

Figure 23

Figure 22

Figure 21

Figure 20

Sewing Machine InstructionsPage 8

Note: Do not use this machine for stretchable or knitted fabrics, such

as towels, sweaters, etc., as this machine is not intended for

such use.

Adjusting tension

A good stitch is neither too tight nor too loose. Check

both the top and bottom threads to make sure they

are smooth and even. (Figure 25)

If the top thread on your sewing machine is too

loose, the bottom thread on your fabric will look like

a very straight line. To correct this, gradually turn the

thread clamp downward (numbers go up) to increase

tension, until the stitching is smooth and even. (Figure 26)

If the bottom thread on your sewing machine is too

loose, the top thread on your fabric will look like a

very straight line. To correct this, gradually turn the

thread clamp upward (numbers go down) to decrease

tension, until the stitches are smooth and even. (Figure 27)

Using the sewing arm

To sew sleeves, cuffs, or other narrow garments, use the sewing arm.

Lift the presser foot.1.

Position the narrow garment around the 2.

sewing arm. (Figure 28)

Lower the presser foot and follow the regular 3.

sewing instructions.

Replacing the needle

Caution: Make sure that the machine is on off before replacing the

needle.

Figure 27

Figure 26

Figure 25

Figure 28

Sewing Machine Instructions Page 9

Note: Do not use this machine for stretchable or knitted fabrics, such

as towels, sweaters, etc., as this machine is not intended for

such use.

Adjusting tension

A good stitch is neither too tight nor too loose. Check

both the top and bottom threads to make sure they

are smooth and even. (Figure 25)

If the top thread on your sewing machine is too

loose, the bottom thread on your fabric will look like

a very straight line. To correct this, gradually turn the

thread clamp downward (numbers go up) to increase

tension, until the stitching is smooth and even. (Figure 26)

If the bottom thread on your sewing machine is too

loose, the top thread on your fabric will look like a

very straight line. To correct this, gradually turn the

thread clamp upward (numbers go down) to decrease

tension, until the stitches are smooth and even. (Figure 27)

Using the sewing arm

To sew sleeves, cuffs, or other narrow garments, use the sewing arm.

Lift the presser foot.1.

Position the narrow garment around the 2.

sewing arm. (Figure 28)

Lower the presser foot and follow the regular 3.

sewing instructions.

Replacing the needle

Caution: Make sure that the machine is on off before replacing the

needle.

Figure 29

Make sure the power is OFF. Turn the hand 1.

wheel until the needle is at its highest position.

Hold the old needle with one hand while 2.

loosening the needle clamp screw with the

other. When the needle is loose, remove it

from its clamp. (Figure 29)

Insert a new needle in the clamp with the 3.

at side toward the right. When the needle

is rmly in place, tighten the needle clamp

screw. (Figure 30)

Features

Stitch patterns

This sewing machine offers a choice of 12 stitches: 3 straight, 7

zigzag, and 2 buttonhole stitches. The 12 stitches are

illustrated to the right of the stitch pattern knob.

(Figure 31) Turn the stitch pattern knob to the number

that corresponds to your desired stitch. (Figure 32)

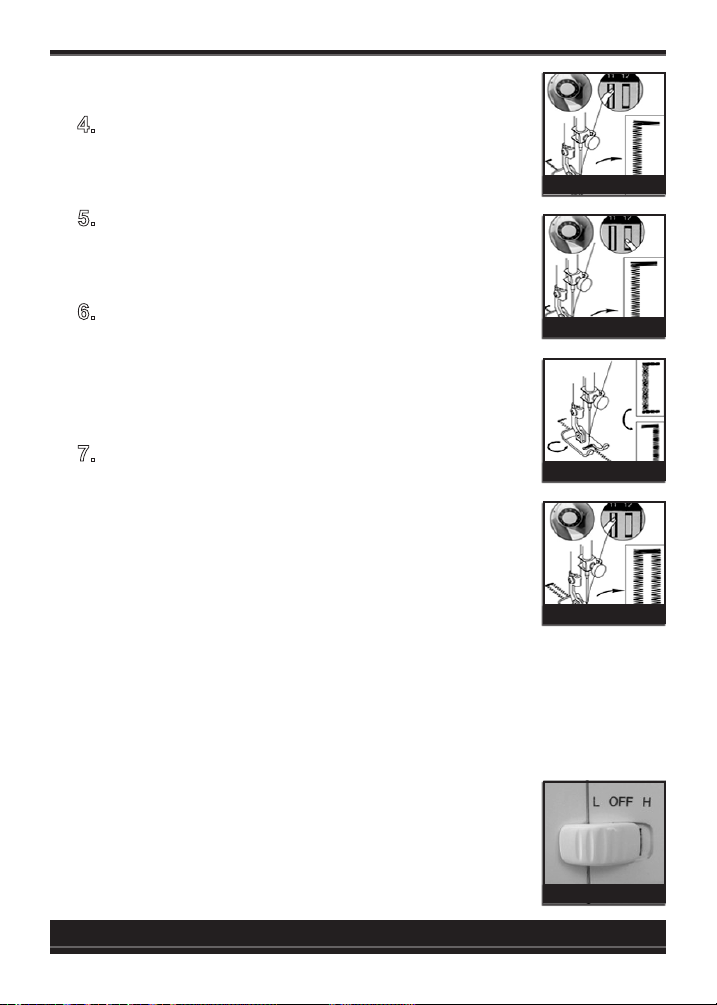

Buttonhole stitch

Select #12 on the stitch pattern knob. Place1.

fabric beneath the presser foot at the exact

spot of buttonhole.

Turn the switch ON. Sew about 3-4 stitches at 2.

low speed and turn switch OFF. (Figure 33)

Select #11 on the stitch pattern knob. Turn the3.

switch ON. Sew several stitches until you

reach the desired length of the buttonhole.

Make sure you sew in a straight line. Turn

Figure 30

Figure 31

Figure 32

Figure 33

Sewing Machine InstructionsPage 10

switch OFF. (Figure 34)

Lift the presser foot. Rotate the fabric so that4.

you will now sew in the opposite direction.

(Figure 35)

Select #12 on the pattern stitch knob. Turn5.

switch ON. Sew about 3-4 stitches at low speed. Turn switch

OFF. (Figure 36)

Select #11 on the pattern stitch knob. Turn6.

switch ON. Sew several stitches in the

opposite direction of Step 3, till you meet the

original stitches of Step 2. Turn switch OFF.

(Figure 37)

Use a seam ripper to cut the space between 7.

stitches.

Work lamp

The work lamp provides direct lighting to the sewing

area. Use the light switch to turn the lamp ON or

OFF.

Reverse stitch button

Reverse stitching is good for reinforcing the two edges of a seam,

so that the stitches will not unravel. Press and hold the reverse stitch

button to sew backwards; release to sew in regular direction.

Sewing speeds

The Sewing Machine offers two speed settings: low

(L) and high (H). Depending on the type of sewing

you’re doing, select the appropriate setting. (Figure

38)

Figure 34

Figure 36

Figure 35

Figure 37

Figure 38

Sewing Machine Instructions Page 11

Accessories drawer

The accessories drawer has a

designated space for bobbins,

threads, and needles. (Figure 39)

Thread cutter

Use the handy thread cutter at the left side of the sewing machine to

snip threads after threading or sewing. (Figure 40)

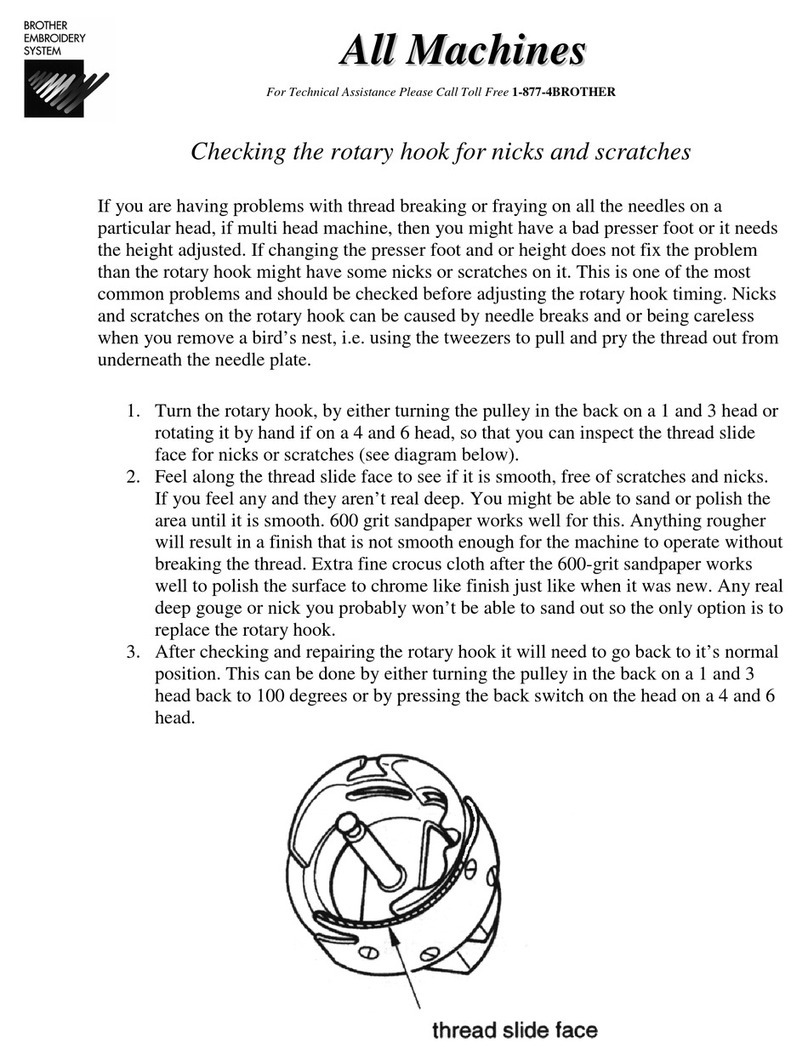

Troubleshooting Guide

PROBLEM CAUSE SOLUTION

Machine

runs slowly

or not at all

Adapter power inadequate or

inappropriate

Adapter not plugged in

Use a compatible adapter

and make sure it is plugged

in correctly to an outlet with

enough power

Machine

skips

stitches

Needle eye not in the center Remove and reinsert the

needle correctly

Needle bent Remove and insert a new

needle

Presser foot too loose Tighten the screw of the

presser foot

Bobbin

thread

cannot be

drawn up

Lower thread used up Wind thread onto bobbin

Machine incorrectly threaded

Follow the instructions listed

above on threading this

machine

Thread

keeps

breaking

Thread blocked by lower

bobbin

Thread the upper thread and

lower thread again

Needle scarf too rough Remove and reinsert a new

needle

Figure 39 Figure 40

Sewing Machine InstructionsPage 12

Thread

keeps

breaking

Needle shank not seated in

the upper end Insert the needle correctly

Thread tension dial, thread

guide or thread pulling bar

rough

Polish with ne sand paper

Stitches too

loose or

uneven

Upper thread is too loose or

incorrectly threaded

Remove the spool of thread

from the spool pin, wind any

loose thread around it, and

rethread the machine

Upper thread is too tight or

lower thread too loose

Adjust thread tension dial

according to the instructions

listed in “Adjusting Tension”

Needle

breaks

Needle bent or deformed Remove and insert a new

needle

Presser foot too loose

Insert a new needle and

tighten the screw of the

presser foot

Pulling fabric with force while

sewing

Remove and insert a new

needle, and guide fabric

along gently

Needle not lowered into fabric

when starting to sew

Remove and insert a new

needle turn hand wheel to

lower the needle into fabric,

and then start sewing

1 YEAR LIMITED WARRANTY

The SB1800 / SB1818 Compact Sewing Machine is warranted for 1 year from provable date of purchase against defects in

material and workmanship.

During this period such defects will be repaired, or the product will be replaced without charge.

This warranty does not cover damage caused by misuse, negligence or improper installation. Warranty is also invalid in any

case that the product is taken apart or serviced by an unauthorized service station.

Send your package postage prepaid with a copy of your proof of purchase. You will also need to enclose a letter explaining

the nature of your difculty in detail. Please allow 2-4 weeks for return shipping.

SmartekUSAInc.•49BartlettStreetBrooklyn,NY11206•1-877-678-6232

Sunbeam™ logo is a trademark of Sunbeam Products, Inc. used under license.

Other manuals for SB1800

1

This manual suits for next models

1

Table of contents

Other Sunbeam Sewing Machine manuals