MORTEX PRODUCTS INC. 501 TERMINAL RD FORT WORTH, TX 76106 Page 1

INSTALLATION MANUAL

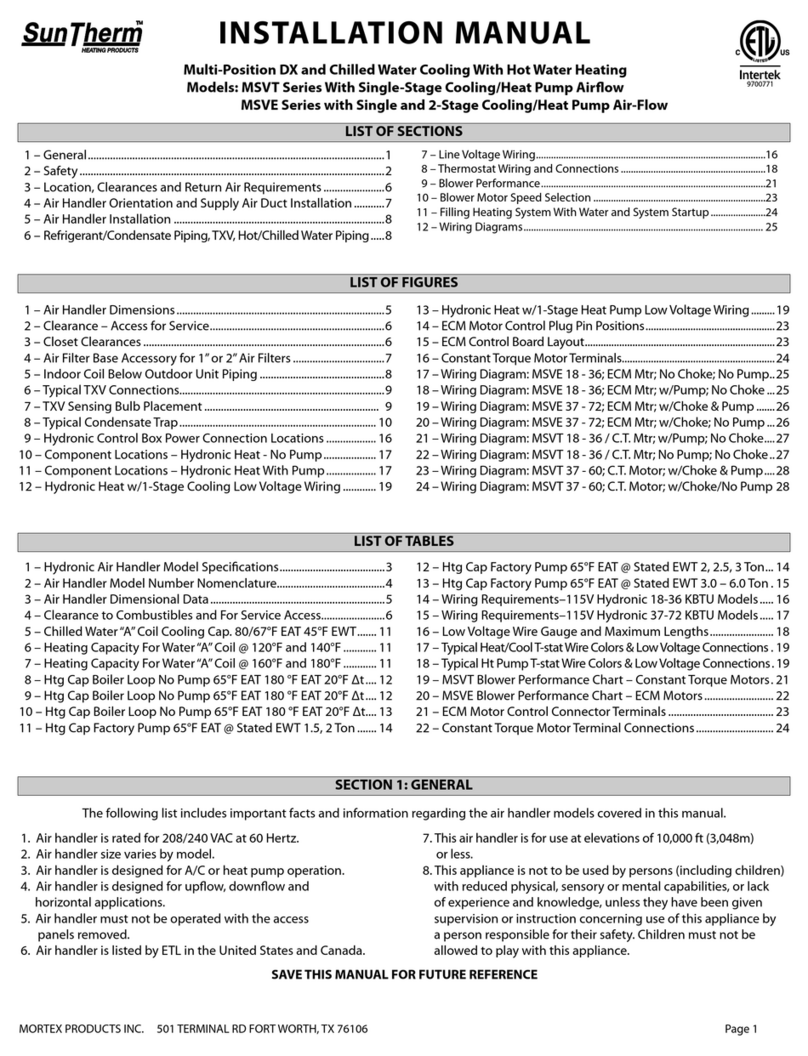

LIST OF SECTIONS

LIST OF FIGURES

LIST OF TABLES

SECTION 1: GENERAL

8 – Line Voltage Wiring................................................................................................21

9 – Thermostat Wiring and Connections ..............................................................23

10 – Blower Performance .............................................................................................28

11 – Blower Motor Speed Selection .........................................................................30

12 – Final System Checkout and Startup................................................................31

13 – Wiring Diagrams.....................................................................................................30

17 – Components and Water Connections ............................................................15

18 – Proper Wiring of the SHL Temperature Switch............................................23

19 – Component Locations – No Heat Control Box ........................................... 23

20 – Component Locations - Hydronic Heat Control Box................................ 23

21 – Heat/Cool Tstat Connections - Separate Tstats & Single Tfmr................24

22 – Heat/Cool Tstat Connections-Separate Tstats & Separate Tfmrs...........24

23 – Heat/Cool Tstat Connections - Single Tstat & Separate Tfmrs................25

24 – Heat/Cool Tstat Connections - Single Tstat & Single Tfmr.......................25

25 – Heat Pump Tstat Connections - Single Tstat & Single Tfmr.....................25

26 – Constant Torque Motor Control Module Terminals ..................................30

27 – Constant Torque Blower Assembly .................................................................30

28 – Wiring Diagram - No Heat; C.T. Motor ............................................................30

29 – Wiring Diagram 3kW-10kW Electric Ht; C.T. Motor w/ Lockout.............32

30 – Wiring Diagram Hydronic Heat; C.T. Motor; No Water Pump.................33

31 – Wiring Diagram Hydronic Heat; C.T. Motor and Water Pump ................33

12 – Electrical Data – Electric and Hot Water Heat ............................................ 22

13 – Electric Heater Heating Capacity .................................................................... 22

14 – Low Voltage Wire Gauge and Maximum Lengths..................................... 23

15 – Thermostat Terminal Designations................................................................. 25

16 – Air Handler Low Voltage Pigtail Wire Colors & Connections ................. 26

17 – Typical Heating/Cooling Tstat Wire Colors & Connections..................... 26

18 – Typical Heat Pump Tstat Wire Colors & Connections ............................... 26

19 – 28 – Blower Performance..............................................................................28-29

29 – Constant Torque Motor Terminals - Electric Heat Models...................... 30

30 – Constant Torque Motor Terminals - Hydronic Heat Models .................. 30

1 – General............................................................................................................................1

2 – Safety, General, Dimensional & Model Number Nomenclature ................2

3 – Location and Clearances...........................................................................................6

4 – Return and Supply Air Requirements ..................................................................7

5 – Air Handler Installation..............................................................................................8

6 – Refrigerant Piping, TXV, Flowrator & Condensate Drain ........................... 10

7 – Hot Water and Chilled Water........................................................................................ 14

1. This air handler is rated at 208/240 VAC (electric heat) or 115 VAC

(hydronic heat), 60 Hertz, Single-Phase

2. This air handler is not designed to operate at 50 Hertz.

3. Air handler size varies by model.

4. This air handler is designed for both A/C and heat pump applications

5. Use 4-wire thermostat cable for heating/cooling

applications and 7-wire thermostat cable for heat pump applications.

6. This air handler is designed for horizontal applications only.

7. This air handler must not be operated without the access

panels installed.

8. This air handler and its components listed are listed by ETL for the

United States and Canada.

9. This air handler is for use at elevations of 10,000 ft (3,048m) or less.

10. This appliance is not to be used by persons (including children) with

reduced physical, sensory or mental capabilities, or lack of experience

and knowledge, unless they have been given supervision or instruction

concerning use of this appliance by a person responsible for their safety.

1 – CEHX/CCWE Dimensions........................................................................................4

2 – SEHX/SCWE Dimensions.........................................................................................5

3 – Clearance For Service Access ................................................................................7

5 – Return & Supply Duct Transitions........................................................................8

6 – Cased Air Handler Mounting ................................................................................9

7 – Piping for Air Handler Below Outdoor Unit ................................................. 10

8 – TXV Sensing Bulb Placement ............................................................................. 10

9 – TXV Sensing Bulb Location................................................................................. 10

10 – Typical TXV Connections ................................................................................... 12

11 – Flowrator Distributor Assembly....................................................................... 13

12 – SHL Temperature Sensor Location ................................................................. 13

13 – SHL Temperature Sensor Mounting............................................................... 13

14 – SHL Temperature Switch Wiring ...................................................................... 13

15 – Typical Condensate Trap..................................................................................... 14

16 – Condensate Drain Pan......................................................................................... 14

1 – CEHX/CCWE/CDXW/CCWW Dimensional Data..............................................4

2 – SEHX/SCWE/SDXW/SCWW Dimensional Data................................................5

3 – SEHX/CEHX/SCWE/CCWE Model Nomenclature ...........................................6

4 – Clearance to Combustibles....................................................................................6

5 – Optional Ceiling Access Panels.............................................................................8

6 – SCWW/CCWW Chilled Water Capacity 4&5 Row Coil – C.T .................... 16

7 – SCWE/CCWE Hot Water Capacity 4&5 Row Coil – C.T............................... 17

8 – SCWW/CCWW Chilled Water Capacity 4&5 Row Coil – C.T .................... 18

9 – SCWW/CCWW Hot Water Capacity 4 & 5 Row Coil – C.T......................... 19

10 – SCWW/CCWW Hot Water Capacity 2 Row HW Coil – C.T........................ 20

11 – SDXW/CDXW Hot Water Capacity 2 Row HW Coil – C.T.......................... 20

The following list includes important facts and information regarding this air handler.

Horizontal Air Handler Models:

SEHX - DX Cooling w/ Electric Heat, Uncased SDXW - DX Cooling w/ Hot Water Heat, Uncased

CEHX – DX Cooling w/ Electric Heat, Cased CDXW – DX Cooling w/ Hot Water Heat, Cased

SCWE – Chilled Water Cooling w/Electric Heat, Uncased-2P SCWW – Chilled Water Cooling w/Hot Water Heat, Uncased-4P

CCWE – Chilled Water Cooling w/Electric Heat, Cased-2P CCWW – Chilled Water Cooling w/Hot Water Heat, Cased-4P