AERA EVO-R User manual

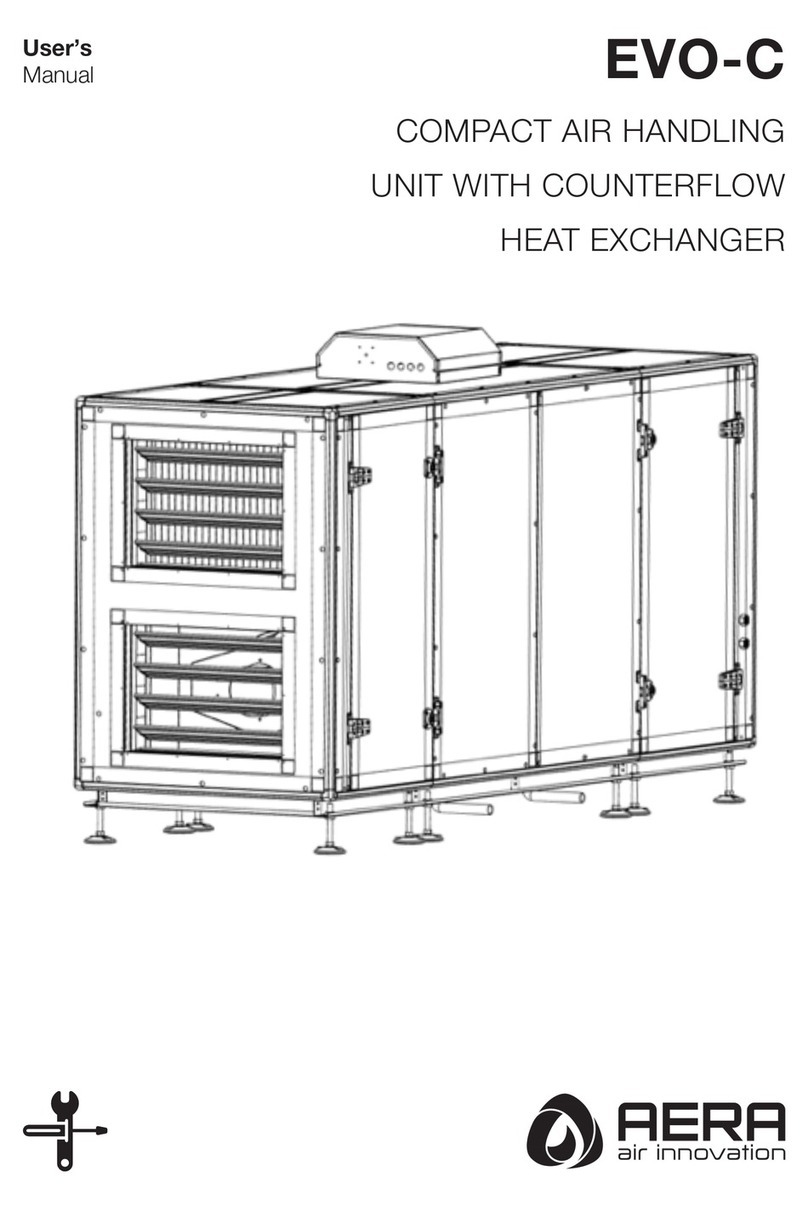

User’s

Manual EVO-R

COMPACT AIR HANDLING

UNIT WITH ROTARY

HEAT RECOVERY

2

Table of Contents

CHAPTER 1 GENERAL INSTALLATION AND OPERATING INSTRIUCTIONS

1.0 Important information………………………………………………………………………………………………………….……Page 4

1.1 Warning and safety instructions………………………………………………………………………...…………………………Page 4

1.2 Warranty claims – Exclusion of liability…………………………………………………………………...………………………Page 4

1.3 Regulations – Guidelines…………………………………………………………………...……………………………………...Page 5

1.4 Receipt…………………………………………………...…………………………………………………………………………..Page 5

1.5 Storage………………………………………………………………………………………………………………..………….….Page 5

1.6 Transport…..……………………………………………………………………………………………………………..……….…Page 5

1.7 Intended use..…………………………………………………………..…………………………………………………………...Page 6

1.8 Performance data…………………………………………………………………………………………………………………...Page 7

1.9 Guideline series VDI 6022….………………………………………………………………………………………..…………….Page 7

1.10 Heat systems….……………………………………………………………………….…………………………………………..Page 7

1.11 Technical data……………………………………………………………………..………………………………………………Page 7

CHAPTER 2 INSTALLATION

2.0 Assembly…………………..……………………………………………………………………………………………....….….....Page 9

2.1 Unit insulation………………………………………………………………………………………………………………………Page 10

2.2 Installation………………………………………………………………………………………………………………………….Page 10

2.3 Flange connection / adapter pieces. ……………………………………………………………………………………………Page 10

2.4 Air ducting, Ventilation circuit…………………………………………………………………………………………………….Page 12

2.5 Electrical Connection…………………………………………………………………………………………………………...…Page 12

CHAPTER 3 FUNCTIONAL DESCRIPTION

3.0 Unit overview…..…………………………………………………………………………………………………….….…………Page 13

CHAPTER 4 DIMENSIONS – PERFORMANCE CURVE

4.0 Dimensions…….……………………………………………………………………………………………………..……………Page 16

4.1 Performance curve….……………………………………………………………………………………………….……………Page 18

CHAPTER 5 SERVICE AND MAINTENANCE

5.0 Service and maintenance…………………………………………………………………………………………………………Page 20

5.1 Service and maintenance of rotary heat exchanger…………..….……………………………………………………………Page 20

5.2 Filter change……………………………………………………………………………………………………………………….Page 23

5.3 Service and maintenance of fan…………………..……………………………………………………………………………. Page 24

5.4 Module assembly…..……………..……………………………………………………………………………………………….Page 26

5.5 Terminal box with isolator/main switch………………………………………………………………………………………….Page 26

CHAPTER 6 Installation, service and maintenance of accessories

6.1 Accessory list………………………………………………………………………………………………………………………Page 27

6.2 Installation of accessories………………………………………………………………………………………………………...Page 34

6.2.1 Installation of electrical after heater……………………….……………………………………………….……….…………Page 34

6.2.2 Installation of outdoor air filter ePM10 50%……………………………..……………………………………………...……Page 35

6.2.3 Installation of recirculation damper...……………………………………………………………………..…………………..Page 36

6.2.4 Installation of outdoor damper…………………………………………………………………………………………………Page 37

6.2.5 Installation of condensate pump………………………………………………………………………………………………Page 39

6.2.6 Installation of water after heater ...……………………………………………………………………………………………...Page -

Page 4

Page 4

Page 4

Page 5

Page 5

Page 5

Page 5

Page 6

Page 7

Page 7

Page 7

Page 7

Page 9

Page 10

Page 10

Page 10

Page 11

Page 11

Page 12

Page 14

Page 18

Page 19

Page 19

Page 21

Page 22

Page 24

Page 25

Page 26

Page 27

Page 27

Page 28

Page 29

Page 30

Page 32

Page 32

3

CHAPTER 7 WIRING DIAGRAM OVERVIEW

7.1 EVO-15R Wiring Diagrams………………………………………………………………………………………………………

7.2 EVO-20R Wiring Diagrams………………………………………………………………………………………………………

7.3 EVO-30R Wiring Diagrams………………………………………………………………………………………………………

7.4 EVO-50R Wiring Diagrams………………………………………………………………………………………………………

7.5 EVO-60R Wiring Diagrams………………………………………………………………………………………………………

7.6 EVO-80R Wiring Diagrams………………………………………………………………………………………………………

7.7 EVO-95R Wiring Diagrams………………………………………………………………………………………………………

7.8 EVO-120R Wiring Diagrams………………………………………………………………………………………………………

7.9 EVO-150R Wiring Diagrams………………………………………………………………………………………………………

CHAPTER 8 SPARE PART LIST

8.1 Spare part list……………………………………………..………………………………….…………………………..………Page 41

Page 33

Page 37

Page 41

Page 45

Page 49

Page 53

Page 57

Page 61

Page 65

Page 69

4

CHAPTER 1

GENERAL INSTALLATION AND OPERATING INSTRIUCTIONS

1.0 Important information

To ensure safety and correct operation please read and observe the following instructions carefully before proceeding.

Important information is specified in the maintenance section on filter changes and necessary cleaning and maintenance

activities. The user usually carries out maintenance work. The chapter “Installation” with important installation

tips and basic unit adjustments is intended for the specialised installer.

The electrical connection must be fully isolated from the supply up to the final assembly!

This appliance is not intended for use by persons (including children) with reduced physical, sensory or mental capabilities,

or lack of experience and knowledge, unless they have been given supervision or instruction concerning use of the appliance by

a person responsible for their safety.

Children should be supervised to ensure that they do not play with the appliance.

The planning office provides the planning documents necessary for system calculations. Additional information can be

requested ex works. Keep the installation and operating instructions as a reference at the device. After the final assembly,

the document must be handed out to the operator (tenant/owner).

1.1 Warning and safety instructions

The adjacent symbol is a safety-relevant prominent warning symbol. All safety regulations and/or symbols must

be absolutely adhered to, so that any dangerous situation is avoided.

1.2 Warranty claims – Exclusion of liability

This device is designed to operate efficiently and safely in the event that they are installed in accordance with the instructions in

the operating instructions, and the operating and maintenance requirements are fully. All maintenance procedures required for

the device must be carried out by experts and authorized persons.

Warranty Conditions

- The devices are warranted against defects in material and workmanship for two (2) years.

- During the warranty period of the device, due to material and manufacturing mistakes in the event of a malfunction, the following

conditions will not be charged;

a. Labor costs

b. Change value of the parts

- The user should report within 8 days of production defects or defects, in terms of the validity of the warranty, immediately upon

the detection of defects, device will be stopped

- As explained in the instruction for use and maintenance, the warranty is valid as long as the devices are periodically maintained.

- Consumables that are periodically changed during the warranty period must be originally supplied from AERA.

- Warranty does not apply to consumables, eg filters.

Issues to be Considered by Customers Related to Warranty

The AERA service personnel or the services authorized by AERA should intervene for the devices covered by the warranty.

Damage caused by installation mistakes or by unauthorized persons is not covered by the warranty.

The following conditions are not covered by warranty:

- Damage due to transportation and improper placement.

- Damage caused by operating the device outside the operating conditions.

- Damage caused by the use of spare parts not approved by the manufacturer.

- Damage due to improper electrical connections, connection other than that specified on the electrical diagram label.

- Damage and failures due to factors such as impact, breaking, scratching and freezing.

5

- Faults that may arise from irregularities in the electrical supply where the device is installed.

- Damage caused by failure to make drainage pipe and to be corrosion inside the device.

- Damage that may be caused by the corrosive and acidic effect of the environment in which the device will operate.

- Damages caused by foreign materials forgotten in the device or fan motor.

- Damage caused by not using flexible connection in channel connections.

- Damages caused by failure to observe the points specified in this user manual.

AERA heat recovery devices do not have any parts replacement or repair work to be performed by the user other than cleaning

and eye inspection. Users should contact the AERA company for faults detected during operation or maintenance.

1.3 Regulations – Guidelines

If the product is installed correctly and used to its intended purpose, it conforms to all applicable CE standards at its date of

manufacture. The AERA EVO-R ventilation units in this series are compliant with Eco-Design 2018.

1.4 Receipt

The delivery contains one of the following unit types:

Please check delivery immediately on receipt for accuracy and damage. If damaged, please notify carrier immediately.

In case of delayed notification, any possible claim may be void.

1.5 Storage

When storing for a prolonged time the following steps are to be taken to avoid damaging influences:

Protection by dry, air- dustproof packing (plastic bags with drying agent and moisture indicators). The storage place must be

water-protected, vibration-free and free of temperature variations. (Ambient temperature limit, min/max, 0°C/ +40°C) Damages

due to improper transportation, storage or putting into operation are not covered by warranty.

1.6 Transport

The transport of the devices must be done with carefully. All manufactured devices are shipped from the factory after all tests and

controls have been made before shipment.

The transport must be carried out by trained and experienced personnel and the necessary safety precautions should be taken

to prevent overturning and slipping of the device. During transport of the devices it should be ensured that the weight is evenly

distributed over the four corners.

Danger due to overhead loads – risk of grave injuries or death!

- Never stand beneath suspended loads, since there is always a risk that the lifting gear, tackle, ropes or slings are faulty or

damaged.

Unit

EVO-15R

EVO-20R

EVO-30R

EVO-50R

EVO-60R

EVO-80R

EVO-95R

EVO-120R

EVO-150R

Unit

EVO-15R/SO

EVO-20R/SO

EVO-30R/SO

EVO-50R/SO

EVO-60R/SO

EVO-80R/SO

EVO-95R/SO

EVO-120R/SO

EVO-150R/SO

6

- Make sure that equipment is firmly seated before lifting it.

Warning! Risk of personal injury and equipment damage!

Due to a high center of gravity, some equipment can tend to tip over and cause damage to persons and property.

- When transporting the unit, carefully observe its behavior and do not get near any possible hazardous areas.

1.7 Intended use

EVO-R devices are designed in 9 different models to correspond the need of up to 15000 m3/ h air flow. There is an ePM1 55%

class filter on the outdoor air side and an ePM10 50% class filter on the exhaust side as standard. The units are produced

according to European Union energy criteria and have EcoDesign label.

EVO-R devices are designed with energy efficient, low sound pressure radiating and low power consumption plug fans. Plug fans

with EC motors can be driven with 3 fixed speeds or steplessly with the help of an air quality sensor thanks to build in smart control

system.

The EVO-R units are equipped with rotary heat exchanger. More than 80 % of the extract air heat is transferred to the outdoor air.

The supply air is led by the duct system to the primary (supply air needing) areas. The used air is extracted from the secondary

areas (like e.g. social rooms, toilets, showers etc.). It flows back through the ducting to the ventilation unit, transfers the heat and

is discharged by the exhaust air duct to the atmosphere.

The heat recovery efficiency depends on several factors, which include, among other things, air humidity and the temperature

variation of outside air and exhaust air. The fan performance can be adjusted by the controller in scope of delivery. Various

sensors e.g. CO2 or humidity sensors (accessory) are available on request, with which automatic fan control is possible

If the device is used at < + 5 °C, it is necessary to use a heater in the device electronic box. (not included scope of delivery,

optional)

The standard equipment permits the installation and the application in frost-free rooms > + 5 °C.

If the unit is to be used in outdoor, it is necessary to use a weather roof and outdoor spigot. (not included scope of delivery,

optional)

If the unit is to be used in other applications where high humidity, excessive dust, temperature in excess of 40 °C or long periods

at standstill (not running), please contact AERA sales representative. This also applies for special technical and electrical

applications.

The EVO-R units are equipped with an electrical pre-heater (accessory- not included in scope of delivery); this prevents the heat

exchanger from freezing at extremely cold outdoor temperatures.

Electrical after heater (accessory) used in EVO-R devices can be installed in the unit (EVO-15R, EVO-20R, EVO-30R) and module

(EVO-50R, EVO-60R, EVO-80R, EVO-95R, EVO-120, EVO-150R). The after heater is controlled by the desired supply air

temperature. The temperature is chosen by the user.

Water after heater (accessory) are used for increasing the supply air temperature and for bringing the supply air to the desired

temperature. Hot water coils can be driven by proportional control via 2 or 3-way valves. Frost protection mechanism is available

as standard to prevent the temperature of the supply water from reaching freezing conditions in extreme cold climates.

Externally module water cooling coils and DX coils (accessory) are used for such purposes as lowering the blowing temperature

and dehumidifying the air in the units. It can be driven either proportionally or by on / off method.

7

1.8 Performance data

Mechanical connections must be made correctly in order to obtain maximum efficiency from the device. The device's thermal

efficiency, sound level and electrical performance may vary depending on the ambient conditions the device is operating. These

conditions may affect the measurement result on site and vary from the catalogue data.

1.9 Guideline series VDI 6022

The AERA EVO-R ventilation units in this series are produced compliant with VDI 6022. The guidelines range from operating

regulations and material requirements through to construction regulations, which ensure high air quality. It must be ensured that

only original AERA accessories are used for operation compliant with VDI 6022.

1.10 Heat systems

The relevant applicable regulations on the combined use of heat systems, domestic ventilation and extractor hoods (Federal

Association of Chimney Sweeps (ZIV) information) must be observed!

General construction-law requirements

The EVO-R units with heat recovery must only be installed and operated in rooms with heat systems which depend on room air,

if their flue gas venting is monitored by specific (on-site) safety devices, which shut down the EVO-R unit when activated. We

recommend speaking with the competent chimney sweep to take account of possible wishes before procuring a negative pressure

monitoring system for heat systems.

1.11 Technical data

MODEL

EVO-R

15

20

30

50

60

80

95

120

150

Air flow (m3/h)

1500

2000

3000

5000

6000

8000

9500

12000

15000

Rated current – ventilation (A)

2,17

3,39

2,28

3,8

3,65

5,47

5,32

7,6

9,12

Max. total rated current (A)

8,3x8,3x7,2

11,8x11,8x9,5

17,7x17,7x18,8

7,6x7,6x8,7

7,3x7,3x8,4

11x11x12,1

10,7x10,7x12,3

15,2x15,2x16,9

18,3x18,3x19,9

Power consumption – ventilation (kW)

0,5

0,78

1,5

2,5

2,4

3,6

3,5

5

6

Max. power consumption (kW)

5,4

7,6

12,3

5,2

5

7,4

7,4

10,4

12,4

Voltage/Frequency

3~400V 50Hz

3~400V 50Hz

3~400V 50Hz

3~400V 50Hz

3~400V 50Hz

3~400V 50Hz

3~400V 50Hz

3~400V 50Hz

3~400V 50Hz

Filter class (extract/ outdoor air)

ePM10 50% -M5 /

ePM1 55% - F7

ePM10 50% -M5 /

ePM1 55% - F7

ePM10 50% -M5 /

ePM1 55% - F7

ePM10 50% -M5 /

ePM1 55% - F7

ePM10 50% -M5 /

ePM1 55% - F7

ePM10 50% -M5 /

ePM1 55% - F7

ePM10 50% -M5 /

ePM1 55% - F7

ePM10 50% -M5 /

ePM1 55% - F7

ePM10 50% -M5 /

ePM1 55% - F7

Weight (kg)

Sound pressure (dB)

56

54

57

53

58

60

59

59

59

Standby losses

IP Class with weather roof

IP54

IP54

IP54

IP54

IP54

IP54

IP54

IP54

IP54

IP Class without weather roof

IP20

IP20

IP20

IP20

IP20

IP20

IP20

IP20

IP20

Wiring diagram

MODEL

EVO-R/SO

15

20

30

50

60

80

95

120

150

Air flow (m3/h)

1500

2000

3000

5000

6000

8000

9500

12000

15000

Rated current – ventilation (A)

2,17

3,39

2,28

3,8

3,65

5,47

5,32

7,6

9,12

Max. total rated current (A)

8,3x8,3x7,2

11,8x11,8x9,5

17,7x17,7x18,8

7,6x7,6x9,3

7,3x7,3x9

11x11x13,8

10,7x10,7x13,4

15,2x15,2x18

18,3x18,3x21

Power consumption – ventilation

(kW)

0,5

0,78

1,5

2,5

2,4

3,6

3,5

5

6

Max. power consumption (kW)

5,4

7,6

12,3

5,2

5

7,4

7,4

10,4

12,4

Voltage/Frequency

3~400V 50Hz

3~400V 50Hz

3~400V 50Hz

3~400V 50Hz

3~400V 50Hz

3~400V 50Hz

3~400V 50Hz

3~400V 50Hz

3~400V 50Hz

Filter class (extract/ outdoor air)

ePM10 50% -M5 /

ePM1 55% - F7

ePM10 50% -M5 /

ePM1 55% - F7

ePM10 50% -M5 /

ePM1 55% - F7

ePM10 50% -M5 /

ePM1 55% - F7

ePM10 50% -M5 /

ePM1 55% - F7

ePM10 50% -M5 /

ePM1 55% - F7

ePM10 50% -M5 /

ePM1 55% - F7

ePM10 50% -M5 / ePM1

55% - F7

ePM10 50% -M5 / ePM1

55% - F7

Weight (kg)

Sound pressure (dB)

56

54

57

53

58

60

59

59

59

Standby losses

IP Class with weather roof

IP54

IP54

IP54

IP54

IP54

IP54

IP54

IP54

IP54

IP Class without weather roof

IP20

IP20

IP20

IP20

IP20

IP20

IP20

IP20

IP20

Wiring diagram

8

EcoDesign Points

15

20

30

50

60

80

95

120

150

Declared typology

Bidirectional

Bidirectional

Bidirectional

Bidirectional

Bidirectional

Bidirectional

Bidirectional

Bidirectional

Bidirectional

Type of drive

Variable

Variable

Variable

Variable

Variable

Variable

Variable

Variable

Variable

Type of HRS

Recuperative

Recuperative

Recuperative

Recuperative

Recuperative

Recuperative

Recuperative

Recuperative

Recuperative

Nominal NRVU flow rate [ m3/h ]

1400

2200

2900

4400

5500

8000

9500

12500

15000

Thermal efficiency of heat recovery

[ % ]

81

79

79

81

81

81

81

79

82

Static efficiency of fans [ % ]

58,2

61,4

52,8

63,6

63,6

62,4

64,1

67,2

63,5

Effective electric power input [kW ]

0,48

0,77

1,12

2,46

2,34

3,27

3,25

4,88

5,57

Face velocity [ m/s ]

1,4

2,03

1,76

1,71

1,75

1,85

1,89

2,07

1,94

Normal external pressure [ Pa ]

250

250

300

350

350

350

350

350

350

Internal pressure drop of

ventilation components [ Pa ]

274

368

310

274

280

288

298

334

302

SFPint [ W/(m3/s) ]

926

1183

1157

847

867

908

914

976

936

Declared maximum external

leakage [ % ]

<1

<1

<1

<1

<1

<1

<1

<1

<1

Declared maximum internal

leakage [ % ]

<3

<3

<3

<3

<3

<3

<3

<3

<3

Description of visual filter warning

Pressure

controled

Pressure

controled

Pressure

controled

Pressure

controled

Pressure

controled

Pressure

controled

Pressure

controled

Pressure

controled

Pressure

controled

Casing sound power level (Lwa) [

dB(A) ]

ErP Compliance

2018

2018

2018

2018

2018

2018

2018

2018

2018

9

CHAPTER 2

INSTALLATION

2.0 Assembly

EVO-R compact devices must be mounted in a vertical position. Due to noise level which change according to working conditions,

it is recommended to install the EVO-R units in the infrequently used rooms like that storage rooms, washing rooms etc. If the

device to be used has a cooling coil, ensure that there is a waste water connection in the installation area. Assembly should take

place in such a way to enable preferably short ventilation ducts and their trouble-free connection to the unit. Tight bends can lead

to increased pressure loss and flow noise. The unit can be turned 180° for optimal installation, so that the outdoor/exhaust air and

extract/supply air inlets and outlets can be on the left or right side. There is no need for bends and long stretches of pipeline due

to these features. They reduce losses and increase the degree of efficiency of the system.

Important notes:

1. The ventilation ducts must not become kinked.

2. Any kind of connections (valves, flanges etc.) which associated with fluids like that air or water, must be tight and leakproof.

3. If necessary, vibration isolators can be used between unit and floor.

4. In order to prevents sound transmission, appropriate acoustic decoupling must be provided on site depending on the building

material.

The outdoor spigot should be placed on the exhaust air side in case of no duct connection.

Make sure that the device is placed on a flat surface before any assembly work.

Assembly area

Observe the following criteria during installation to ensure that the device service is comfortable. (Fig. 1)

A is the minimum distance for servicing the terminal box.

C is the minimum distance for opening service cover.

MODEL

A (mm)

B (mm)

C (mm)

D (mm)

EVO-15R

600

910

1360

1145

EVO-20R

600

1010

1460

1245

EVO-30R

600

1120

1570

1355

EVO-50R

600

1390

1840

1625

EVO-60R

600

1510

1960

1745

EVO-80R

600

1760

-

1995

EVO-95R

600

1860

2310

2095

EVO-120R

600

2010

2460

2245

EVO-150R

600

2260

2710

2495

Fig. 1

10

2.1 Unit insulation

The outside and exhaust air ductwork should be insulated sufficiently.

If the unit is to be used in outdoor, make sure that the necessary equipment is installed. (weather roof and outdoor spigot, optional)

2.2 Installation

EVO-R has easily adjustable stays. (Fig. 2) First of all, make sure that there is enough space for the device servicing. Therefore,

the device must be assembled after the dimensions have been identified.

Make sure that the device is placed on a flat surface before any assembly work.

2.3 Flange connection / adapter pieces

EVO-R flange connection diameters are shown below (Fig.3)

Fig. 2

Fig. 3

11

Model

Dimensions (mm)

A

B

C

n

D

m

E

F

K

L

EVO-15R

350

310

14,14

0

-

0

-

-

378,28

338,28

EVO-20R

470

310

14,14

0

-

0

-

-

498,28

338,28

EVO-30R

580

410

14,14

1

304,1

0

-

30

608,28

438,28

EVO-50R

855

410

14,14

1

441,6

0

-

30

883,28

438,28

EVO-60R

855

410

14,14

1

441,6

0

-

30

883,28

438,28

EVO-80R

1055

410

14,14

2

361,1

0

-

30

1083,28

438,28

EVO-95R

1200

410

14,14

2

409,4

0

-

30

1228,28

438,28

EVO-120R

1475

510

14,14

2

501,1

1

269,1

30

1503,28

538,28

EVO-150R

1600

710

14,14

3

407,1

1

369,1

30

1628,28

738,28

n : number of drill hole (horizontal) (Except corner holes)

m : number of drill hole (vertical) (Except corner holes)

Hole/Bolt dimension : M8X20

2.5 Air ducting, Ventilation circuit

When designing the ductwork, use the shortest possible runs. Airtight connections and changeovers must be ensured for the best

possible heat recovery. To avoid pressure losses, dirt build-up and noise, use smooth ducts (plastic or rigid ducting). If supply and

extract air ductworks run through unheated rooms, insulation must be provided to reduce heat losses. Fresh air should be supplied

to living and bedrooms and extraction should take place in bathrooms, toilets and kitchens. The installation of extractor hoods to

the system is not permitted (reasons: dirt, fire danger, hygiene).

All fire and building regulations must be observed!

2.6 Electrical Connection

The unit must be fully isolated from the mains power supply before any maintenance and

installation work or before opening the enclosure! The electrical connection must only be carried out by an authorised

qualified electrician in accordance with the following wiring diagrams. The electrical connection must be fully isolated

from the mains power supply until the assembly is complete!

The unit is equipped with a main switch and an isolator which can be secured against unauthorized switching with a U-lock. The

relevant standards, safety regulations (e.g. DIN VDE 0100) and the technical connection conditions of the local electricity supply

companies must be observed. An all-pole mains switch / isolator, with a contact opening of at least 3 mm (VDE 0700 T1 7.12.2 /

EN 60335-1) must be provided. The main switch and/or isolator can be secured against unauthorized switching with a U-lock.

The surface-mounted controller with touchscreen is connected to the unit by means of a 5 m connecting cable (also available in

10 or 20 m length). The electrical connection of the EVO-R takes place directly in the terminal box. If any electronic accessory is

added the unit, the electrical connections must be made in the terminal box.

12

CHAPTER 3

FUNCTIONAL DESCRIPTION

3.0 Unit overview

-Non-dividable unit (EVO-15R, EVO-20R, EVO-30R) (Fig. 4)

1

10

4

5

8

8

2

7

9

6

3

11

1. Terminal box

2. Exhaust air fan

3. Supply air fan

4. Outdoor air pre-filter (ePM10 50%) (optional)

5. Extract air filter (ePM10 50%)

6. Outdoor air main filter (ePM1 55%)

7. Rotary heat exchanger

8. Outdoor damper (optional)

9. Water heater coil or electrical after heater (optional)

10. Main switch

11. Casing

Fig. 4

13

-Dividable unit (EVO-50R, EVO-60R, EVO-80R, EVO-95R, EVO-120R, EVO-150R) (Fig. 5)

1. Terminal box

2. Exhaust air fan

3. Supply air fan

4. Outdoor air pre-filter (ePM10 50%) (optional)

5. Extract air filter (ePM10 50%)

6. Outdoor air main filter (ePM1 55%)

7. Rotary heat exchanger

8. Outdoor damper (optional)

9. Recirculation damper (optional)

10. Main switch

11. Casing

8

10

1

6

2

8

7

4

5

9

3

11

Fig. 5

14

CHAPTER 4

DIMENSIONS

PERFORMANCE CURVE

4.0 Dimensions

-Non-dividable unit (EVO-15R, EVO-20R, EVO-30R) (Fig. 6)

MODEL

A

B

C

D

E

F

K

L

M

N

X

Y

Dimensions (mm) (Fig. 6)

EVO-15R

1295

990

155

1700

760

910

205

360

415

520

350

310

EVO-20R

1400

1090

155

1700

860

1010

205

360

415

520

470

310

EVO-30R

1500

1200

155

1700

970

1120

205

360

415

520

580

410

Fig. 6

15

MODEL

AA

BB

CC

DD

EE

FF

GG

HH

Dimensions (mm) (Fig. 7)

EVO 15-R

680

568

472

93,5

150

463,2

263,4

380

EVO 20-R

670

568

472

143,5

150

514,2

286,4

430

EVO 30-R

680

568

472

193,5

150

573,2

313,4

485

Fig.7

16

-Dividable unit (EVO-50R, EVO-60R, EVO-80R, EVO-95R, EVO-120R, EVO-150R) (Fig. 8)

MODEL

A

B

C

D

E

F

K

M

P

R

S

X

Y

Dimensions (mm)

EVO-50R

1775

1470

155

1845

1240

1390

610

1230

555

440

690

855

410

EVO-60R

1895

1590

155

2015

1360

1510

680

1330

625

480

748

855

410

EVO-80R

2145

1840

155

2100

1610

1760

750

1350

-

-

-

1055

410

EVO-95R

2245

1940

155

2315

1710

1860

830

1480

775

605

775

1200

410

EVO-120R

2400

2090

155

2450

1860

2010

895

1550

840

605

845

1475

510

EVO-150R

2645

2340

155

2535

2110

2260

940

1590

890

620

870

1600

710

Fig. 8

17

MODEL

AA

BB

CC

DD

EE

FF

GG

HH

JJ

KK

LL

MM

Dimensions (mm) (Fig. 9)

EVO 50-R

150

45

568

615

472

366,5

620

725

372,5

59,6

130,4

106

EVO 60-R

150

125

568

690

472

446,5

680

785

402,5

179,6

130,4

106

EVO 80-R

150

---

568

---

472

---

805

---

---

429,6

130,4

106

EVO 95-R

150

125

568

840

472

616,5

855

960

490,5

529,6

130,4

106

EVO 120-R

150

125

568

910

472

696,5

930

1035

527,5

679,6

130,4

106

EVO 150-R

150

125

568

950

472

816,5

1055

1160

589,5

929,6

130,4

106

Fig. 9

18

4.1 Performance curve

19

CHAPTER 5

SERVICE AND MAINTENANCE

5.0 Service and maintenance

The filter change is usually carried out by the user. Additional cleaning and maintenance work must only be carried out

by qualified electricians.

The EVO-R unit must be fully isolated from the power supply and secured against reactivation with the main

isolator switch located on top of the unit before any cleaning and maintenance work.

Danger of electric shock, moving parts (fan) and hot surfaces.

5.1 Service and maintenance of rotary heat exchanger

Make sure that the power connection is disconnected before doing any work on the device. Danger of electric

shock; moving parts (fan) and hot surfaces.

Maintenance is restricted to regular visual inspections. Inspections should be initially carried out about every 3 months and then

after trouble-free operation can be extended to 12 months. The following must be checked:

- Tension of drive belt

- Quality of bearings (assess by bearing noise)

- Function of slide seal

- Condition of casing

RISK OF INJURY! High weight! Two people are required for dismantling! (EVO-15R, EVO-20R)

Use forklift to transport the heat exchanger on the EVO-30R, EVO-50R, EVO-60R, EVO-80R, EVO-95R, EVO-120R,

EVO-150R models

1. Unscrew the screws of the device service cover and open (Fig. 10)

Unit

Rotary heat

exchanger weight

(kg)

EVO-15R

38

EVO-20R

45

EVO-30R

51

EVO-50R

76

EVO-60R

104

EVO-80R

136

EVO-95R

152

EVO-120R

177

EVO-150R

218

Fig. 10

20

2. Remove the exhaust fan to disconnected the electrical connections easily. (6.3 Service and maintenance of the fan)

3. Unplug the electrical connections on the varimax drive unit (Fig. 11)

3. Pull lock-bars for unlock heat exchanger (Fig. 12)

4. Pull the heat exchanger to remove (Fig. 13)

Fig. 11

Fig. 12

Fig. 13

Table of contents

Other AERA Air Handler manuals

Popular Air Handler manuals by other brands

McQuay

McQuay IM 777-3 Installation and maintenance manual

Kampmann

Kampmann KaCool HY 600x600 Installation, operation & maintenance manual

Verano

Verano freshAIR+ VWT Installer manual

Lennox

Lennox LGH Series Unit information

Hoval

Hoval RoofVent RH Series Original operating manual

Trane

Trane BAYWACC11SC1AA Installer's guide

Armstrong Air

Armstrong Air BCE3M 18 installation instructions

Frico

Frico PA2500 Original instructions

Magic Aire

Magic Aire HCA Series Installation, operation and maintenance manual

Armstrong Air

Armstrong Air BCE7E Series installation instructions

TemperZone

TemperZone IJD 2000 Installation & maintenance

Dantherm

Dantherm VA-M40 MKII Service manual