Superabrasive Owner’s Manual Original Language –Lavina ®32RE /32REHV 5/2020

4

WARRANTY AND RETURNS ......................................................................3

1. GENERAL INFORMATION......................................................................5

MANUFACTURER......................................................................................5

GENERAL DESCRIPTION............................................................................5

MACHINE CHARACTERISTICS....................................................................5

LAVINA®32RE/32REHV MAIN DESIGN......................................................5

ENVIRONMENTAL CONDITIONS...............................................................5

ELECTRICAL CONNECTION........................................................................6

VACUUM CONNECTION ...........................................................................6

TECHNICAL DATA .....................................................................................6

VIBRATIONS .............................................................................................6

NOISE EMISSIONS.....................................................................................6

LABEL DATA..............................................................................................6

CUSTOMER SERVICE.................................................................................6

2. SAFETY ISTRUCTIONS ...........................................................................7

RECOMMENDED USE ...............................................................................7

PROHIBITED USE ......................................................................................7

PREPARATION FOR WORK........................................................................7

PROTECTION DEVICES..............................................................................7

ARREST FUNCTIONS .................................................................................7

SAFE USE..................................................................................................7

RESIDUAL RISKS........................................................................................7

BEFORE YOU BEGIN..................................................................................7

OPERATING MACHINE..............................................................................7

AFTER WORK IS COMPLETED ...................................................................7

THE WORK AREA......................................................................................7

PERSONAL PROTECTIVE EQUIPMENT (PPE)..............................................7

OPERATOR ...............................................................................................8

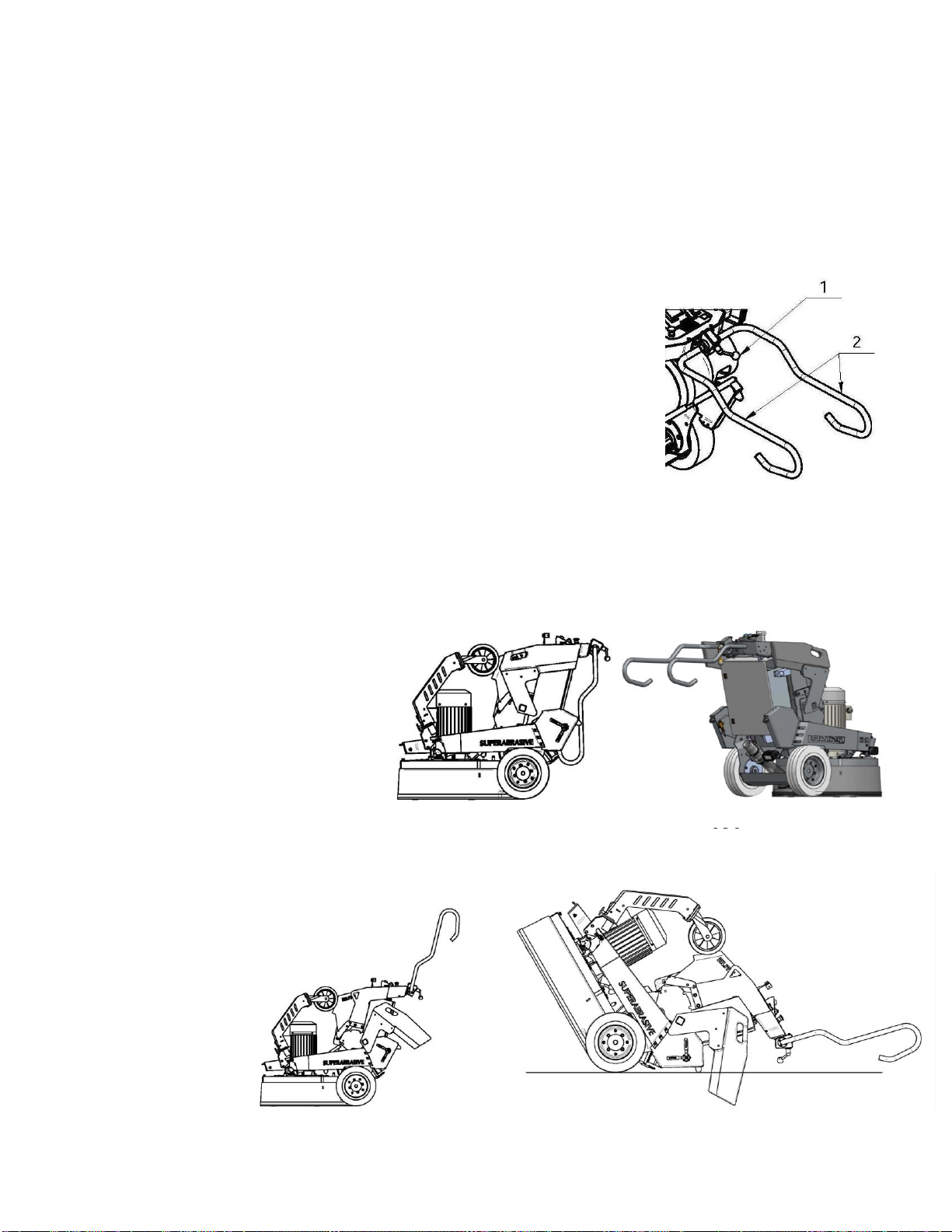

3. HANDLING AND TRANSPORTATION .....................................................8

3.1 POSITIONING THE HANDLE ................................................................8

3.2 USING THE STEERING BRACKET..........................................................8

3.3 FLIPPING THE MACHINE UP................................................................8

3.4 HANDLING WEIGHTS..........................................................................9

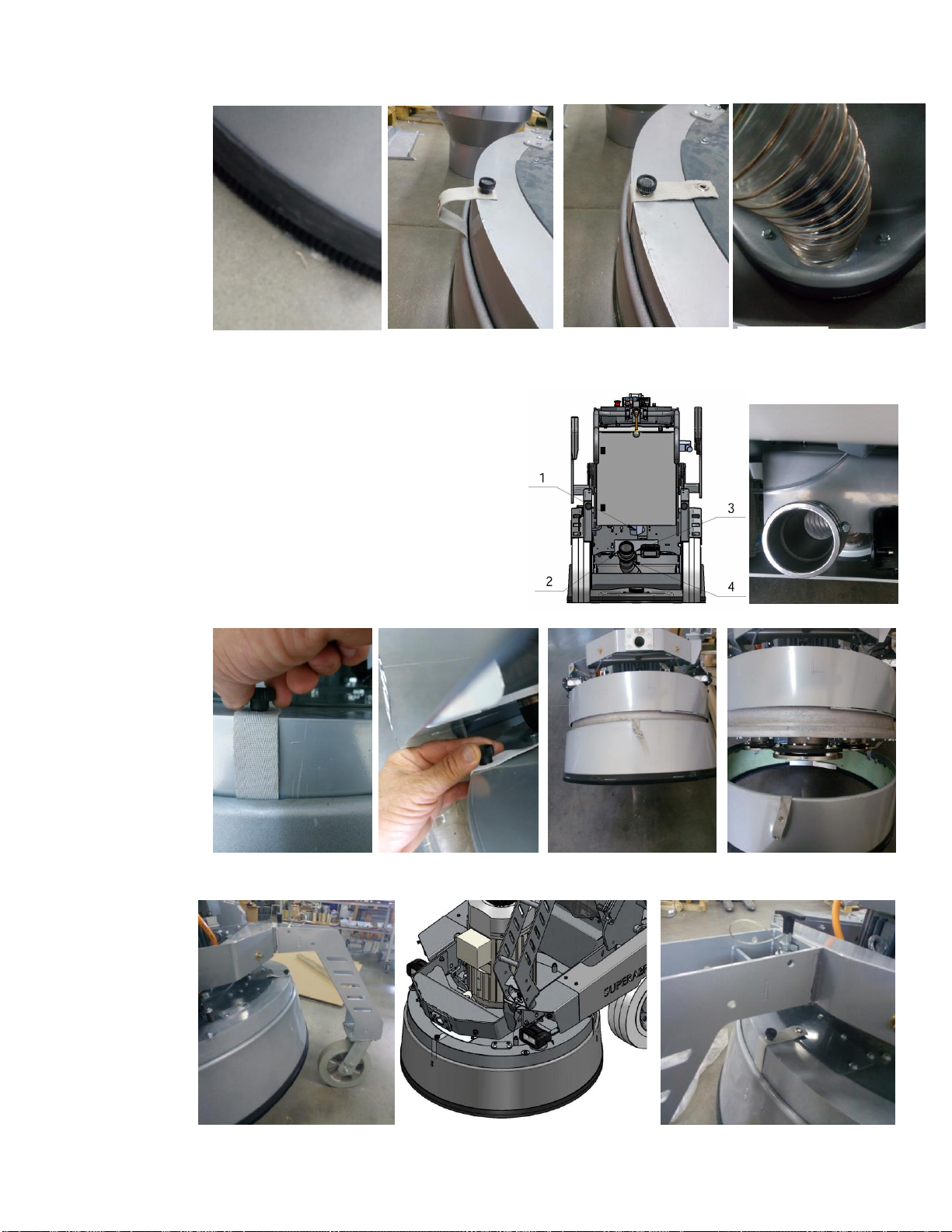

3.5 HANDLING THE GUARD ....................................................................10

3.5.1 DISMOUNTING THE GUARD ..........................................................10

3.6THIRD WHEEL....................................................................................10

3.7 LIFTING.............................................................................................11

3.8 STORAGE..........................................................................................11

3.9 POWER CABLE MANAGEMENT.........................................................11

3.10 LOCKING THE WHEEL .....................................................................11

4. OPERATION ........................................................................................12

4.1 PRELIMINARY CONTROLS.................................................................12

4.2 CONTROL OF THE WATERFLOW.......................................................12

4.3 ADJUSTING AND MOUNTING TOOLS................................................12

4.4 VACUUM CONNECTION....................................................................13

4.5 CONTROL BOARD .............................................................................14

4.5.1 MAIN SCREEN................................................................................14

4.5.2 LOCAL SETTINGS............................................................................15

4.5.3 MAINTENANCE..............................................................................15

4.5.4 OPERATION TIME ..........................................................................15

4.5.5 TOOL DEPENDENT SCALE SETTINGS ..............................................15

4.5.6 ALARM HISTORY............................................................................15

4.6 PORTABLE DEVICE............................................................................16

4.7 STARTING THE MACHINE .................................................................17

4.8 OPERATING THE MACHINE...............................................................17

4.9 STOPPING THE MACHINE .................................................................17

5. TOOLS AND ACCESSORIES ..................................................................17

TOOL HOLDER KEY .................................................................................17

SECURITY PLATE FOR QUICKCHANGE PADS ...........................................17

7. MAINTENANCE AND INSPECTION ......................................................19

CHECK DAILY ..........................................................................................19

CHECK EVERY 200 WORKING HOURS.....................................................19

CHECK EVERY 400 WORKING HOURS.....................................................19

VACUUM................................................................................................19

WATER LEAKS.........................................................................................19

ELECTRICAL SYSTEM...............................................................................19

MECHANICAL PARTS ..............................................................................19

LAVINA®32RE ELECTRICAL SCHEMES WITH YASKAWA INVERTER 200-240

VOLT.......................................................................................................20

8. TROUBLESHOOTING...........................................................................26

INDEX OF PROBLEMS AND SOLUTIONS ..................................................26

8.1 REPLACING POWER CORD AND PLUGS.............................................26

8.2 MOTOR CONNECTION ......................................................................26

8.3 DISMOUTING TOOL HOLDERS TO CHANGING V-RINGS AND FELT

RINGS .....................................................................................................26

8.4 DISASSEMBLING AND MOUNTING TOOL HOLDERS TO CHANGING

BUFFERS AND ELASTIC ELEMENT............................................................27

8.5 SEPARATING THE HEAD FROM THE CARRAGE..................................28

8.6 REPLACING THE MOTOR...................................................................29

8.7 FAULT DIAGNOSIS INVERTER YASKAWA V1000................................30

8.8 CORRECTING SAG OF USED PLANETARY CHAIN................................32

8.9 MOUNTING NEW PLANETARY CHAIN...............................................32

8.10 REPLAING THE FRONT KEY JOINT OF THE PLANETARY PULLEY.......33

8.12 REPLACING THE PULLEYS................................................................35

8.13 REPLACING THE PLANETARY DRIVING CHAIN WHEEL AND CENTRAL

CHAIN WHEEL AND PLANETARY TENSIONER..........................................35

9. DISPOSAL............................................................................................36

10. MANUFACTURER’S CONTACTS.........................................................36

11. SPARE PARTS ....................................................................................37

11.1 LAVINA®32RE GENERAL PARTS.......................................................37

11.2 LAVINA®32RE MISTING NOZZLE SUPPORT L32RE ........................37

11.3 LAVINA®32E MISTING NOZZLE LEFT SUPPORT.............................37

11.4 LAVINA®32E THIRD WHEEL..........................................................38

11.5 LAVINA®32E FRONT FRAME PARTS ................................................38

11.6 LAVINA®32RE CARRIAGE...............................................................40

11.7 LAVINA®32RE FRAME AND STEERING BRACKET PARTS................41

11.8 LAVINA® 32RE WATER TANK........................................................41

11.9 LAVINA® 32RE WATER INSTALLATION .........................................42

11.10 LAVINA® 32RE WATER BALL VALVE ..............................................42

11.11 LAVINA®32RE WATER PUMP PARTS .............................................42

11.12 LAVINA® 32RE TOP COVER PARTS ................................................43

11.13 LAVINA® 32E GUARD ASSEMBLY ..................................................43

11.14 LAVINA® 32RE PLANETARY CHAIN PARTS.....................................43

11.15 LAVINA® 32E TOP COVER..............................................................44

11.16 LAVINA® 32RE BOTTOM COVER PARTS ........................................44

11.17 LAVINA®32RE TOOL HOLDER PARTS /see also fig.8.4.13/.............44

11.18 LAVINA® 32RE TRANSMISSION BELT PARTS..................................45

11.19 LAVINA® 32RE CENTRAL SHAFT BEARNING PARTS .......................45

11.20 LAVINA® 32RE DRIVING PULLEY UNIT PARTS................................46

11.21 LAVINA® 32RE PLANETARY TENSIONING UNIT .............................46

11.22 LAVINA®32E MOTOR FAN PARTS................................................46

11.23 LAVINA®32RE AND LAVINA®32REHV CONTROL BOARD ASSEMBLY

...............................................................................................................47

11.24 LAVINA® 32RE MODULE DRIVE RIGHT..........................................48

11.25 LAVINA® 32RE MODULE DRIVE LEFT.............................................49