Superabrasive User Manual Original Language Lavina®30GEB 1/2021

4

LAVINA ELITE L30GEB .............................................. 1

1. GENERAL INFORMATION .................................................. 6

MANUFACTURER .................................................................. 6

GENERAL DESCRIPTION........................................................... 6

MACHINE CHARACTERISTICS..................................................... 6

LAVINA® 30GEB MAIN DESIGN............................................. 6

ENVIRONMENTAL CONDITIONS ........................................ 6

VACUUM CONNECTION .................................................... 6

TECHNICAL DATA.............................................................. 7

2. SAFETY INSTRUCTIONS ..................................................... 8

PREPARATION FOR WORK........................................................ 8

PROTECTION DEVICES............................................................. 8

ARREST FUNCTIONS.......................................................... 8

SAFE USE............................................................................ 8

FIRE SAFETY...................................................................... 8

EMISSIONS .......................................................................... 8

HAZARD COMMUNICATION ..................................................... 8

LOCAL AGENCIES AND REGULATIONS ................................ 9

RESIDUAL RISKS.................................................................... 9

BEFORE YOU BEGIN............................................................... 9

OPERATING MACHINE ............................................................ 9

AFTER WORK IS COMPLETED ...................................................10

THE WORK AREA.................................................................10

PERSONAL PROTECTIVE EQUIPMENT (PPE) ..........................10

TESTING ............................................................................10

OPERATOR .........................................................................10

PROPANE CYLINDERS.............................................................10

REFUELLING CYLINDERS ......................................................11

STORAGE CYLINDERS.............................................................11

TRANSPORTING CYLINDERS.....................................................11

3. HANDLING AND TRANSPORTATION ................................ 12

ADJUSTING THE HANDLE ........................................................12

LIFTING THE MACHINE FROM WORKING TO TOOL

MOUNTING POSITION .....................................................13

LIFTING .............................................................................13

STORAGE ...........................................................................13

4. OPERATION .................................................................... 14

PRELIMINARY CONTROLS .......................................................14

FUEL-MINDER USER MANUAL ..........................................14

SYSTEM COMPONENTS ..........................................................14

OVERVIEW OF FEATURES........................................................14

FAULTY O2 SENSOR DETECTION ..............................................14

BUILT-IN FUEL LOCKOFF CONTROLLER .......................................14

EMISSIONS WARNINGS AND SHUTDOWN ...................................14

DUAL HOUR METERS............................................................14

BATTERY VOLTMETER ...........................................................14

ENGINE TACHOMETER ...........................................................15

JOB TIMER .........................................................................15

PASSWORD PROTECTION .......................................................15

SERVICE ALERTS...................................................................15

SLEEP MODE ......................................................................15

MAIN MENU NAVIGATION AND USE.........................................15

MAIN MENU ......................................................................15

LED ALERTS &RESETTING SERVICE INTERVALS ............................15

OPTIONS MENU NAVIGATION AND USE.....................................16

OPTIONS MENU ..................................................................16

SAFETY INFORMATION .......................................................... 16

WATER FLOW CONTROL SYSTEM ............................................. 17

ADJUSTING AND MOUNTING TOOLS......................................... 18

VACUUM CONNECTION................................................... 18

USE HORIZONTAL PROPANE TANK................................... 18

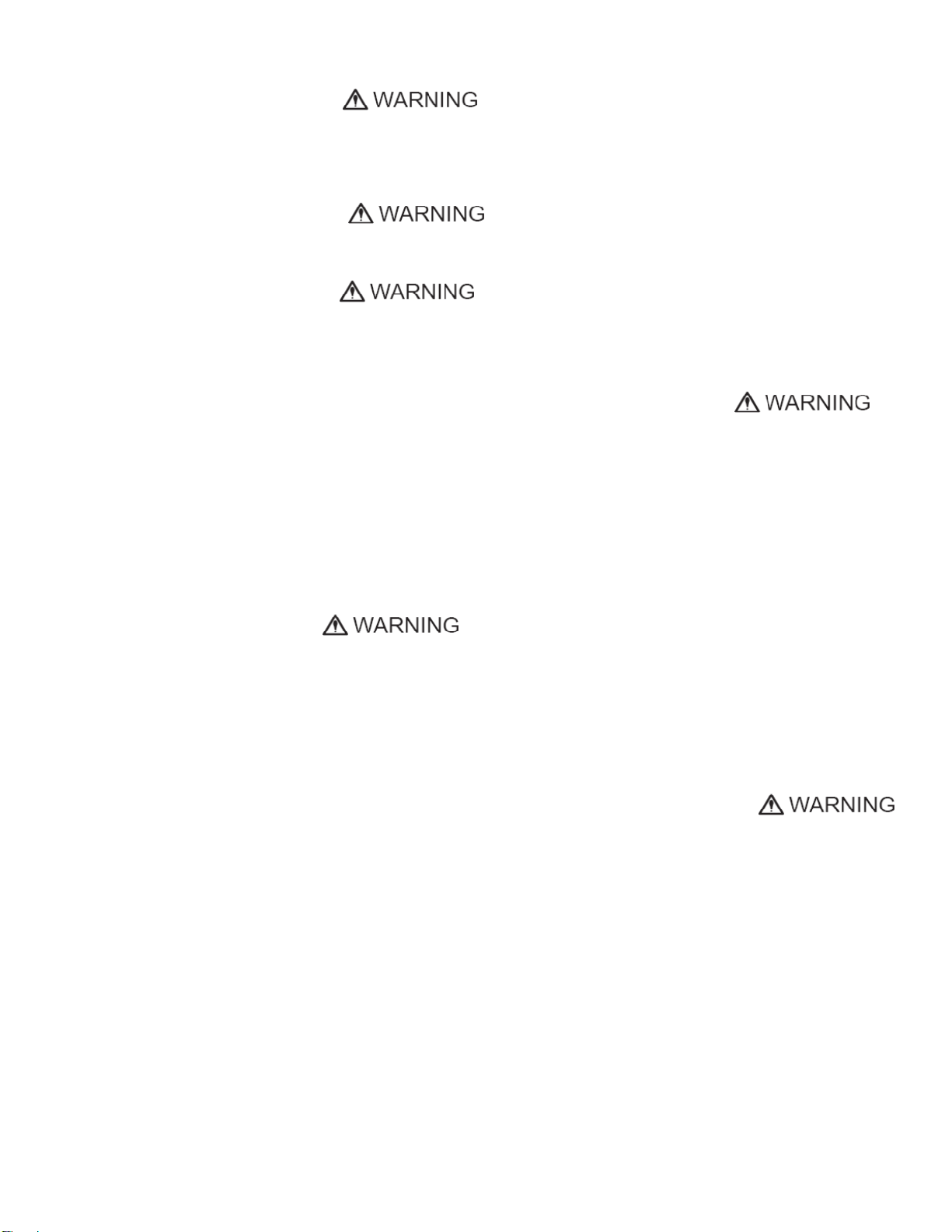

CONTROL BOARD ................................................................ 19

THE CONTROL BOARD........................................................... 19

STARTING THE MACHINE ....................................................... 19

OPERATING THE MACHINE..................................................... 19

STOPPING THE MACHINE....................................................... 19

5. TOOLS AND ACCESSORIES ...............................................20

TOOL HOLDER KEY ............................................................... 20

SECURITY PLATE FOR QUICKCHANGE PADS.................................. 20

SECURITY PLATE FOR RING TOOLS ......................................... 20

6. POPULAR TOOLS .............................................................21

7.MAINTENANCE AND INSPECTION..................................... 22

REMARK ......................................................................... 22

MECHANICAL PARTS ............................................................ 22

CLEANING ......................................................................... 22

CHECK HOURLY ................................................................... 22

CHECK DAILY................................................................... 22

CHECK AND REPLACE AFTER THE FIRST 8WORKING HOURS............. 22

CHECK AND REPLACE EVERY 50 WORKING HOURS ....................... 22

CHECK AND REPLACE EVERY 200 WORKING HOURS ..................... 23

CHECK AND REPLACE EVERY 400 WORKING HOURS ..................... 23

VACUUM........................................................................... 23

MECHANICAL PARTS ............................................................ 23

8. TROUBLESHOOTING........................................................ 24

8.1 ENGINE ..................................................................... 24

8.2 CHECKING AND CHANGING OILCHECK THE ENGINE OIL LEVEL,

SCREW THE DIPSTICK IN TO GET READING.WHILE CHANGING ENGINE

OIL,CHECK FOR LEAKAGE OF ENGINE OIL AT

THE

VARIOUS SEALS...... 25

....................................................................................... 25

8.4 SEPARATING THE HEAD FROM THE CARRIAGE ............ 25

8.5 DISMOUNTING/MOUNTING THE ENGINE................... 28

8.6 REPLACING THE CLUTCH ............................................ 29

8.7DISMOUNTING TOOL HOLDER TO CHANGING V-RINGS

AND FELT-RINGS ............................................................. 29

8.8 DISASSEMBLING AND MOUNTING TOOL HOLDER TO CHANGE

BUFFERS AND ELASTIC ELEMENT............................................... 30

8.9 CORRECTING DEFLECTION OF THE USED PLANETARY

CHAIN............................................................................. 31

8.10 MOUNTING NEW PLANETARY CHAIN....................... 31

8.11 REPLACING THE PLANETARY DRIVING CHAIN WHEEL

AND PLANETARY TENSIONER .......................................... 32

8.12 TENSIONING AND REPLACING THE BELTS.................. 33

8.13 REPLACING THE PLANETARY DRIVEN CHAIN WHEEL.. 35

8.14 REPLACING THE PULLEY UNITS ................................. 35

8.15 REPLACING THE PLANETARY UNIT ............................ 36

9. DISPOSAL........................................................................36

10. MANUFACTURER’S CONTACTS ......................................36

11.EMISSION CONTROL WARRANTY STATEMEN..................37

ASSEMBLY AND PARTS SPECIFICATIONS.......................... 39

12.1 GENERAL PARTS........................................................... 39

12.2 BUMPER .................................................................... 39