2

Table of Contents

1General Safety Precautions............................................................................... 4

2Preface.............................................................................................................. 5

2.1 Intended Use............................................................................................... 5

2.2 Safety Precautions...................................................................................... 5

3Overview ........................................................................................................... 6

3.1 Features...................................................................................................... 6

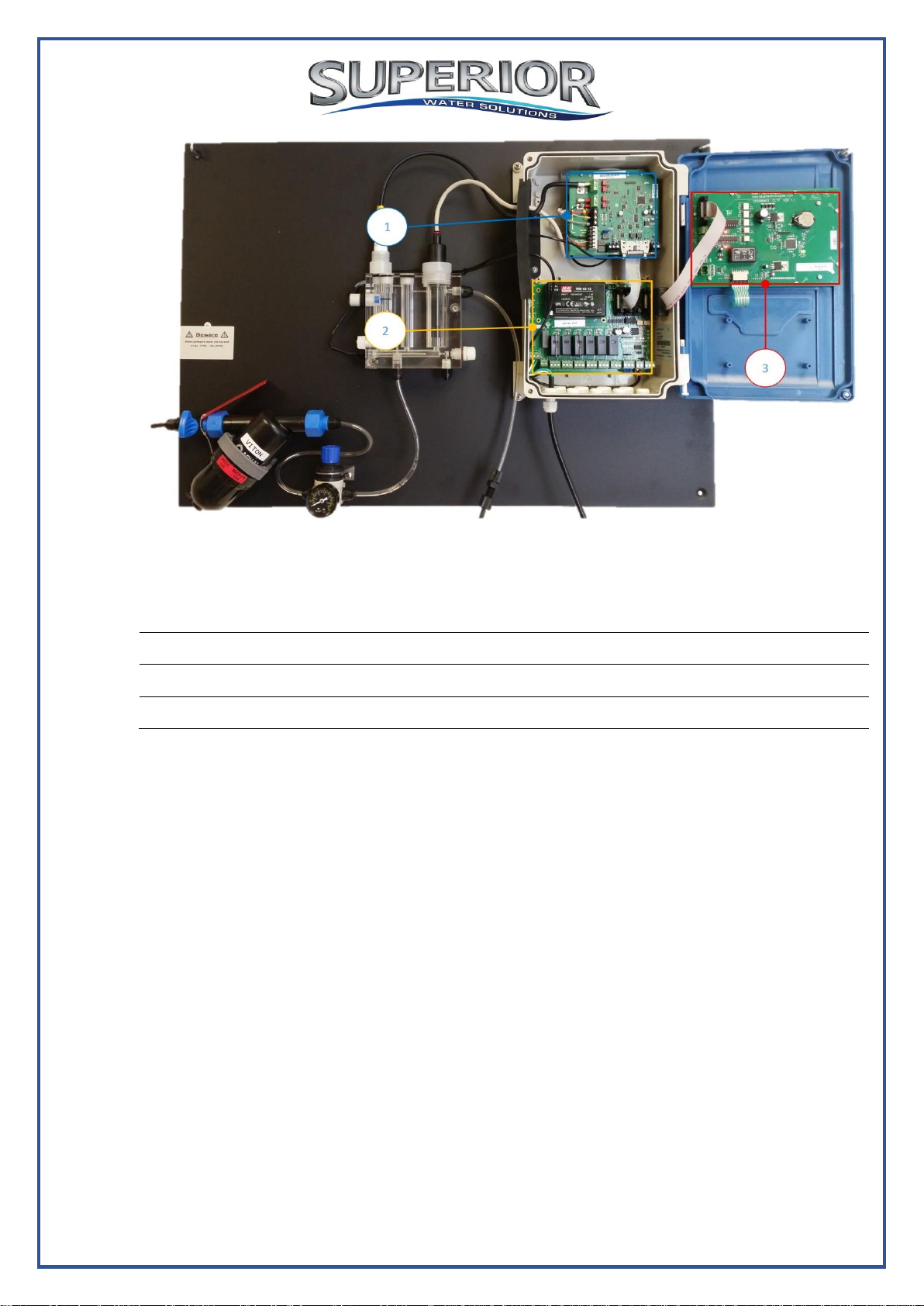

3.2 System Components................................................................................... 6

4Installation....................................................................................................... 13

4.1 Location Considerations............................................................................ 13

4.2 Site Requirements and Installation............................................................ 13

4.2.1 Mechanical Installation....................................................................... 13

4.3 Plumbing Requirements and Installation................................................... 14

4.3.1 Water supply and drain ...................................................................... 14

4.4 Electrical Requirements and Installation.................................................... 15

4.4.1 Connecting the Main Electrical Power................................................ 16

4.4.2 Input Switches.................................................................................... 16

4.5 Installing electrodes .................................................................................. 17

4.5.1 Free Chlorine electrode OCS140....................................................... 17

4.5.2 pH electrode....................................................................................... 19

4.5.3 Temperature sensor........................................................................... 19

5First Time Operation and Calibration............................................................... 20

5.1 Menu Setup............................................................................................... 20

5.2 Operator Menu.......................................................................................... 21

5.3 Technician Menu....................................................................................... 24

5.4 Calibration.................................................... Error! Bookmark not defined.

5.4.1 Temperature Calibration..................................................................... 27

5.4.2 pH Calibration.................................................................................... 28

5.4.3 Chlorine Electrode Calibration............................................................ 29

5.5 4 to 20 mA Output configuration................................................................ 30

6Routine Operation and Maintenance ............................................................... 31

6.1 Filter Cleaning........................................................................................... 31

6.2 Shut-down and Winterizing ....................................................................... 31

6.3 Start-up and Preventive Maintenance ....................................................... 31

6.4 Chlorine Electrode Maintenance ............................................................... 31

6.4.1 Cleaning the electrode....................................................................... 31

6.4.2 Electrolyte Change............................................................................. 32

6.4.3 Membrane Cap Change..................................................................... 32

6.4.4 Storage.............................................................................................. 33

7Technical Specification.................................................................................... 33