2

Contents

1. SAFETYPRECAUTION.................................................................................................................3

2. TECHNICAL SPECIFICATIONS..................................................................................................4

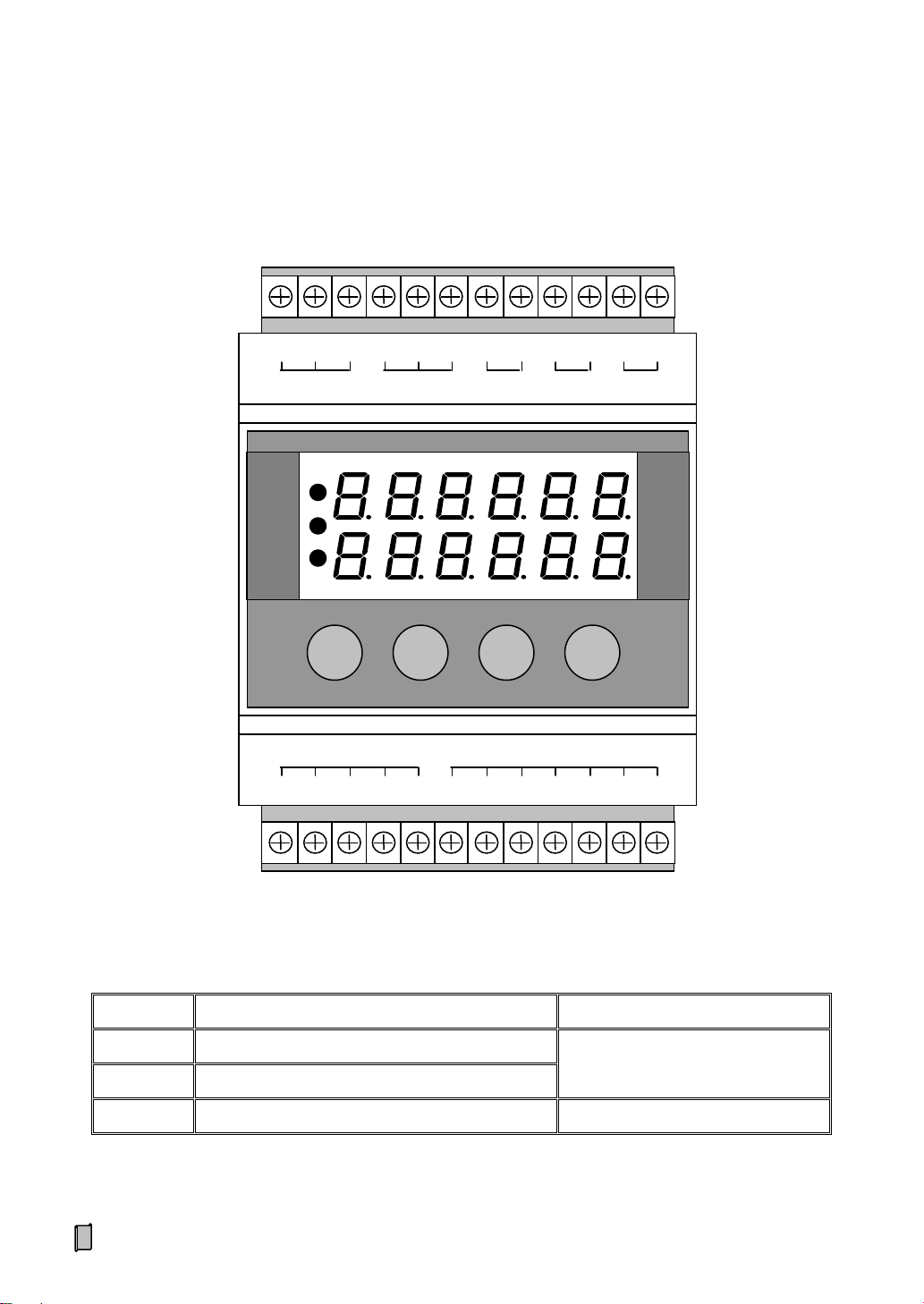

3. USER INTERFACE..........................................................................................................................6

3.1 USER INTERFACE DIAGRAM .................................................................................................................. 6

3.2 STATE INDICATION................................................................................................................................. 6

3.3 KEYPAD OPERATION.............................................................................................................................. 7

3.4ALARM SIGNS ....................................................................................................................................... 7

4. INSTALLATION&CONNECTION................................................................................................8

4.1 INSTALLATION....................................................................................................................................... 8

4.2 TERMINAL............................................................................................................................................. 9

5. OPERATION PROCEDURE ........................................................................................................11

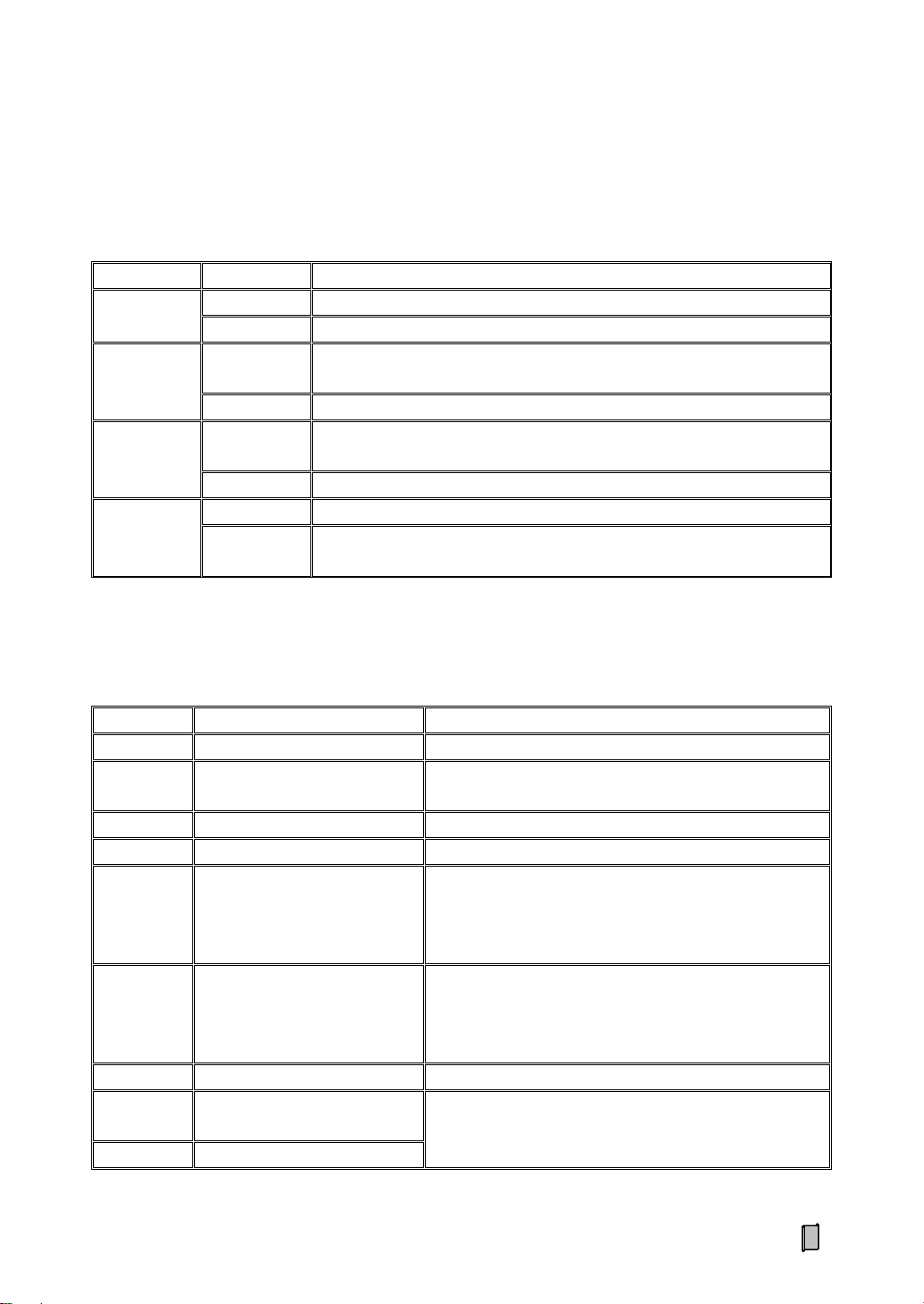

6. FUNCTIONS&OPERATION........................................................................................................12

6.1 MAIN DISPLAY INTERFACES................................................................................................................ 12

6.1.1 Real-time Weight Value and Percent [L] ................................................................................... 12

6.1.2 Real-time Weight, Peak Hold Value or Checking-weight Value [P].......................................... 12

6.1.3 Real-time Weight, AO Output Value [Ao]................................................................................. 12

6.1.4 Real-time Weight, VO Output Value [Vo] ................................................................................. 13

6.1.5 Real-time Weight, Communication State [Co].......................................................................... 13

6.2 MAIN MENU........................................................................................................................................ 14

6.3 F1-SET PARAMETER SETTING............................................................................................................. 16

6.3.1 Weighing Parameters (SCAL) ................................................................................................... 16

6.3.2 Calibration Parameters (CALP)................................................................................................. 18

6.3.3 Setpoint Parameters (SEtP) ....................................................................................................... 20

6.3.4 Communication Parameters (SErP)........................................................................................... 23

6.3.5 Display Parameters (dISP) ........................................................................................................ 24

6.3.6 A Sample of Parameter Setting.................................................................................................. 25

6.4 F2-CALSYSTEM CALIBRATION .......................................................................................................... 26

6.4.1 Zero Calibration (ZEro)............................................................................................................. 26

6.4.2 Data Calibration (dAtA)............................................................................................................ 27

6.4.3 Load Calibration (LoAd)........................................................................................................... 29

6.4.4 Segmenting Span Correction (SEgC)........................................................................................ 30

6.5 F5-LOC KEY-LOCKER......................................................................................................................... 31

6.5.1 Key-unlocking (oPEn)............................................................................................................... 31

6.5.2 Key-locking (Locc) ................................................................................................................... 31

6.5.3 Password Set (PASS)................................................................................................................. 32

APPENDIXA. REGISTER TABLE OF HOST-SLAVE MODBUS[ASCII/RTU]........................33

APPENDIX B. DATA FRAME FORMAT OFCONTINUOUS SENDING [ASCII]....................36