6

Mechanical Stationary

Operator’s Manual

300-0804 © 05/2020

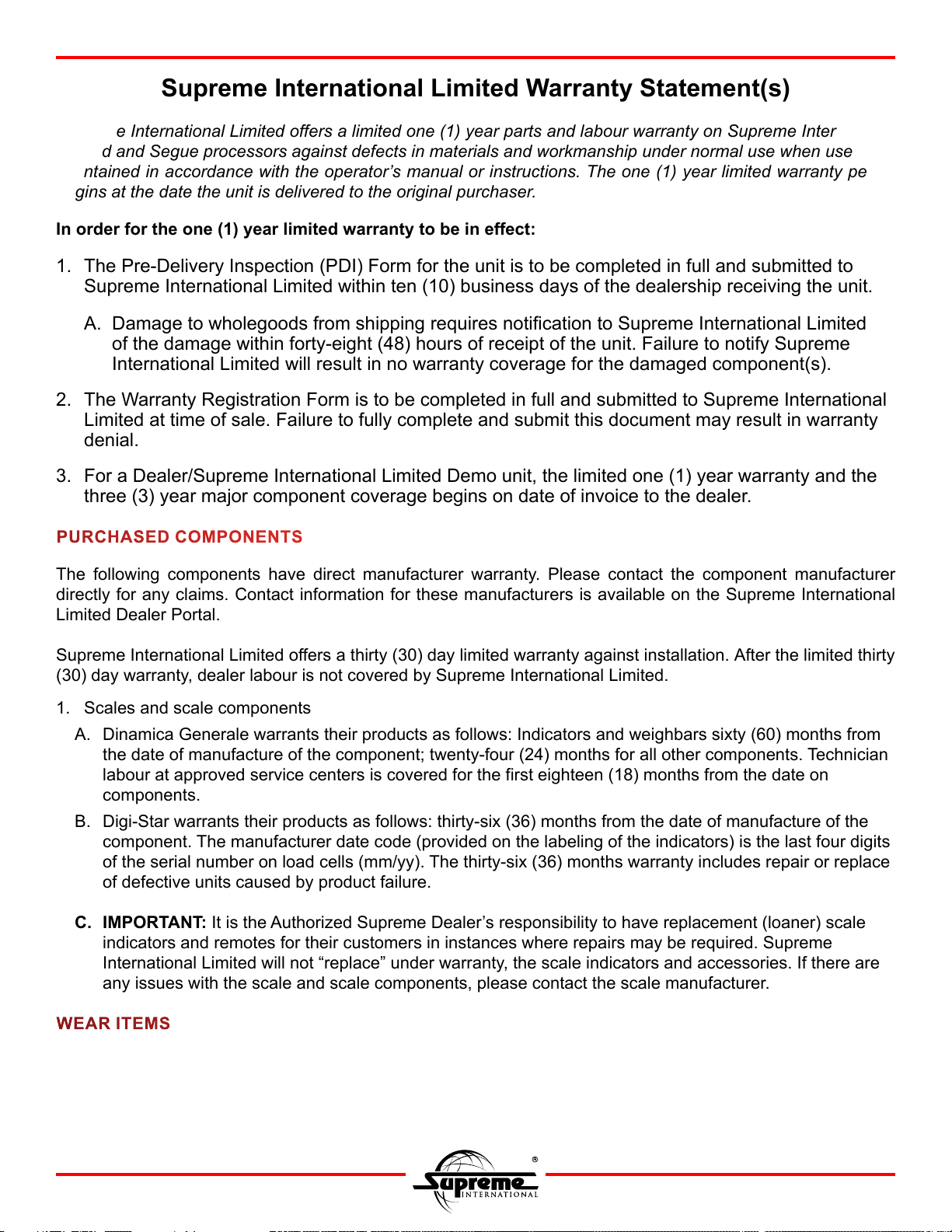

Supreme International Limited Warranty Statement(s)

Supreme International Limited offers a limited one (1) year parts and labour warranty on Supreme International

Limited and Segue processors against defects in materials and workmanship under normal use when used and

maintained in accordance with the operator’s manual or instructions. The one (1) year limited warranty period

begins at the date the unit is delivered to the original purchaser.

In order for the one (1) year limited warranty to be in effect:

1. The Pre-Delivery Inspection (PDI) Form for the unit is to be completed in full and submitted to

Supreme International Limited within ten (10) business days of the dealership receiving the unit.

A. Damage to wholegoods from shipping requires notification to Supreme International Limited

of the damage within forty-eight (48) hours of receipt of the unit. Failure to notify Supreme

International Limited will result in no warranty coverage for the damaged component(s).

2. The Warranty Registration Form is to be completed in full and submitted to Supreme International

Limited at time of sale. Failure to fully complete and submit this document may result in warranty

denial.

3. For a Dealer/Supreme International Limited Demo unit, the limited one (1) year warranty and the

three (3) year major component coverage begins on date of invoice to the dealer.

PURCHASEDCOMPONENTS

The following components have direct manufacturer warranty. Please contact the component manufacturer

directly for any claims. Contact information for these manufacturers is available on the Supreme International

Limited Dealer Portal.

Supreme International Limited offers a thirty (30) day limited warranty against installation. After the limited thirty

(30) day warranty, dealer labour is not covered by Supreme International Limited.

1. Scales and scale components

A. Dinamica Generale warrants their products as follows: Indicators and weighbars sixty (60) months from

the date of manufacture of the component; twenty-four (24) months for all other components. Technician

labour at approved service centers is covered for the first eighteen (18) months from the date on

components.

B. Digi-Star warrants their products as follows: thirty-six (36) months from the date of manufacture of the

component. The manufacturer date code (provided on the labeling of the indicators) is the last four digits

of the serial number on load cells (mm/yy). The thirty-six (36) months warranty includes repair or replace

of defective units caused by product failure.

C. IMPORTANT: It is the Authorized Supreme Dealer’s responsibility to have replacement (loaner) scale

indicators and remotes for their customers in instances where repairs may be required. Supreme

International Limited will not “replace” under warranty, the scale indicators and accessories. If there are

any issues with the scale and scale components, please contact the scale manufacturer.

WEARITEMS

Items under normal wear and tear, such as exterior finish, replacement parts – cutting knives, chains, belts, brake

pads, drums (rotors), conveyors, shields/guards, liners, walls, u-joints, or other wear items – have a thirty (30)

day warranty against installation defects. Continuous use of damaged items will not be covered under warranty.

WARRANTY