SurfPrep LP ROS User manual

DOC 0004-SP

1 Revision 06/18/14

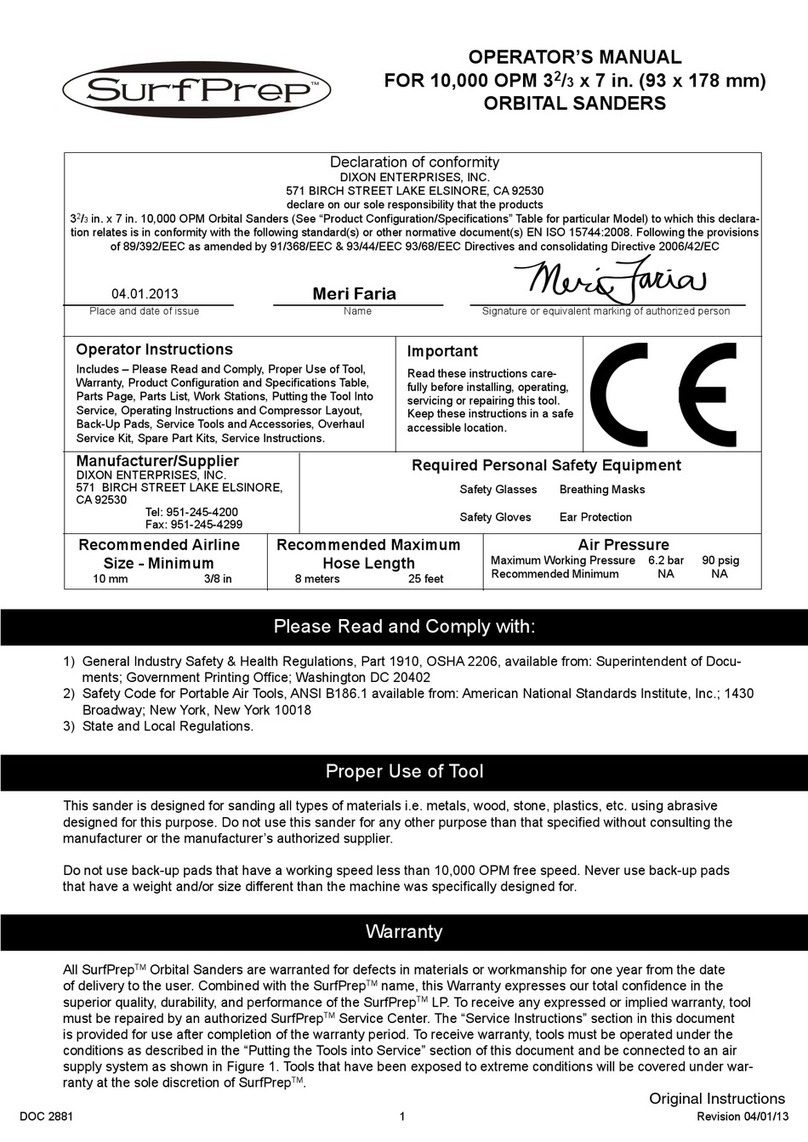

OPERATOR’S MANUAL

FOR LOW PROFILE

12,000 RPM 5 in. (127 mm) and 6 in. (150 mm)

RANDOM ORBITAL SANDERS

Manufacturer/Supplier

DIXON ENTERPRISES, INC.

571 BIRCH STREET LAKE ELSINORE,

CA 92530

Tel: 951-245-4200

Fax: 951-245-4299

All SurfPrepTM Random Orbital Sanders are warranted for defects in materials or workmanship for one year from the

date of delivery to the user. Combined with the SurfPrepTM

superior quality, durability, and performance of the SurfPrepTM LP. To receive any expressed or implied warranty, tool

must be repaired by an authorized SurfPrepTM Service Center. The “Service Instructions” section in this document

is provided for use after completion of the warranty period. To receive warranty, tools must be operated under the

conditions as described in the “Putting the Tools into Service” section of this document and be connected to an air

supply system as shown in Figure 1. Tools that have been exposed to extreme conditions will be covered under war-

ranty at the sole discretion of SurfPrepTM

Warranty

Please Read and Comply with:

Proper Use of Tool

1) General Industry Safety & Health Regulations, Part 1910, OSHA 2206, available from: Superintendent of Docu-

2) Safety Code for Portable Air Tools, ANSI B186.1 available from: American National Standards Institute, Inc.; 1430

Broadway; New York, New York 10018

3) State and Local Regulations.

This sander is designed for sanding all types of materials i.e. metals, wood, stone, plastics, etc. using abrasive

manufacturer or the manufacturer’s authorized supplier.

Do not use back-up pads that have a working speed less than 12,000 RPM free speed. Never use back-up pads

Required Personal Safety Equipment

Safety Glasses Breathing Masks

Safety Gloves Ear Protection

Recommended Airline

Size - Minimum

10 mm 3/8 in

Recommended Maximum

Hose Length

8 meters 25 feet

Air Pressure

Maximum Working Pressure 6.2 bar 90 psig

Recommended Minimum NA NA

Declaration of conformity

DIXON ENTERPRISES, INC.

571 BIRCH STREET LAKE ELSINORE, CA 92530

declare on our sole responsibility that the products

Table for particular Model) to which this declaration

relates is in conformity with the following standard(s) or other normative document(s) EN ISO 15744:2008. Following the provisions of

89/392/EEC as amended by 91/368/EEC & 93/44/EEC 93/68/EEC Directives and consolidating Directive 2006/42/EC

Place and date of issue Name Signature or equivalent marking of authorized person

Important

Read these instructions care-

fully before installing, operating,

servicing or repairing this tool.

Keep these instructions in a safe

accessible location.

03.20.2013 Meri Faria

Operator Instructions

Includes – Please Read and Comply, Proper Use of Tool,

Parts Page, Parts List, Work Stations, Putting the Tool Into

Service, Operating Instructions and Compressor Layout,

Back-Up Pads, Service Tools and Accessories, Overhaul

Service Kit, Spare Part Kits, Service Instructions.

Original Instructions

Parts Page

ITEM

TORQUE SETTING

in.-lbs. (Nm)

12

55 - 65 (6.2 - 7.3)

57

16 - 20 (1.8 - 2.3)

51

8.7 (1.0)

42

26.0 (2.9)

16

30 - 35 (3.4 - 3.9)

DOC 0004-SP

2 Revision 06/18/14

66

5

1

2

3

4

61

67

8

9

10

11

12

13

15

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

34

35

36

37

38

39

27

40

25

41

42

43

44

45

46

47

27

52

54

55

56

57

58

49

50

51

59

14

53

48

32

33

65

64

16

60

62

TO VACUUM

SYSTEM FOR

CENTRAL VAC

67

63

Parts List

Item No. Part No. Description Qty.

1 SPA0040 EXTERNAL RETAINING RING 1

2 SPA0021 10X26X8 BEARING -2 SHIELDS 1

3 SPB0017 REAR ENDPLATE 1

4 SPA0005 20 mm CYLINDER ASSEMBLY 1

5 SPA0042 5 mm X 2.0mm O-RING 1

6 SPB0005 MACHINED ROTOR 1

7 SPA0010 VANE 5

8 SPA0041 3mm X 13mm WOODRUFF KEY 1

9 SPG0001 FRONT ENDPLATE 1

10 SP50059 15 X 32 X 9 BEARING - 2 SHIELDS 1

11 SPA0045 39.4 mm X 3.1 mm O-RING 1

12 SPF0002 LOCK RING 1

13 SPG0002 COOLING FAN 1

14 SP50012 SMALL SPACER-COOLING FAN 1

15 SP50013 LARGE SPACER-COOLING FAN 1

16 SPF0020 FRONT BEARING DUST SHIELD 1

17 SPG0004 5 X 3/32 in. ORBIT NON-AirSHIELD Plus TM SHAFT BALANCER 1

17 SPG0003 5 X 3/16 in. ORBIT NON-AirSHIELD Plus TM SHAFT BALANCER 1

17 SPG0006 6 X 3/32 in. ORBIT NON-AirSHIELD Plus TM SHAFT BALANCER 1

17 SPG0005 6 X 3/16 in. ORBIT NON-AirSHIELD Plus TM SHAFT BALANCER 1

18 SPA0938 12 X 28 16 DOUBLE ROW ANGULAR CONTACT BEARING - 1 SEAL 1

19 SPA0016 SPACER 12.1 ID X 18.0 OD X0.2 THK 1

20 SPA2542 SPINDLE BEARING DUST SHIELD 1

21 SPA0017 BELLEVILLE WASFER 1

22 SPA0018 RETAINING RING 1

23 SPB0018 SPINDLE 1

24 SPG0024 GRIP (3in. 75mm) 1

25 SPA0039 INTERNAL RETAINING RING 2

26 SPF0001 SPEED CONTROL (PRESET) 1

27 SPA0043 9 mm X 1.5 mm O-RING 3

28 SPF0024 THROTTLE LEVER FOR AIRVANTAGE 12,000 RPM 2.5 mm (3/32 in.) ORBIT SANDER 1

SPF0022 THROTTLE LEVER FOR AIRVANTAGE 12,000 RPM 5.0 mm (3/16 in.) ORBIT SANDER 1

29 SPA0031 LEVER SPRING PIN 1

30 SPG0031 MACHINED HOUSING 1

31 SPH0004 5in. / 6in. NON-VACUUM SHROUD 1

32 SPH0005 5 in. CV.SGV SHROUD 1

33 SPH0006 6 in. CV.SGV SHROUD 1

34 SPA0022 24 mm PAD WRENCH 1

35 NA 1 PAD SUPPLIED WITH EACH TOOL 1

36 SPA0008 VALVE STEM ASSEMBLY 1

37 SPA0015 VALVE SLEEVE 1

38 HN2-04CA M4 NUT 1

39 S6-0430A HEX.SOCKET BUTTON HEAD SCREW (M4x30L) 1

40 SPF0003 SPEED CONTROL 1

41 PW1-050D PLAIN WASHER (M5 X10) 1

42 S6-0520A HEX. SOCKET BUTTON HEAD SCREW (M5X20L) 1

43 SPF0008 MUFFLER CAP 1

44 SPF0011 MUFFLER INSERT 1

DOC 0004-SP

3 Revision 06/18/14

Parts List

Item No. Part No. Description Qty.

45 SPF0012 O-RING (20 mm X 1 mm NBR70) 1

46 SPF0009 SGV EXHAUST CAP 1

47 SPF0010 VARIABLE EXHAUST 1

48 SPF0021 LOGO INSERT - END CAP 1

49 SPG0023 END CAP 1

50 SPA2474 INLET BUSHING ASSEMBLY 1

51 S6-0410 HEX.SOCKET BUTTON HEAD SCREW (M4X10L) 3

52 SPG0030 EXHSUST CHAMBER 1

53 SPA2204 9.5 mm X 1.0 mm O-RING 1

54 SPA2484 24 mm X 1.0 mm O-RING 1

55 SPF0013 INTERNAL MUFFLER 1

56 SPA0009 VALVE SEAT 1

57 SPA0007 VALVE 1

58 SPA0014 VALVE SPRING 1

59 SPF0015 NON-VACUUM COVER 1

60 SPG0021 5 in. SGV SWIVEL EXHAUST FITTING - 3/4 in./19mm HOST OPT

SPG0023 6 in. SGV SWIVEL EXHAUST FITTING - 3/4 in./19mm HOST OPT

61 SPG0022 5 in. CV SWIVEL EXHAUST FITTING - 3/4 in./19mm HOST OPT

SPG0024 6 in. CV SWIVEL EXHAUST FITTING - 3/4 in./19mm HOST OPT

62 SPG0013 5 in. SGV SWIVEL EXHAUST FITTING - 1 in./28mm HOST 1

SPG0015 6 in. SGV SWIVEL EXHAUST FITTING - 1 in./28mm HOST 1

63 SPG0014 5 in. CV SWIVEL EXHAUST FITTING - 1 in./28mm HOST 1

SPG0016 6 in. CV SWIVEL EXHAUST FITTING - 1 in./28mm HOST 1

64 SPA0300 Ø 3/4 in. VAC HOSE TO Ø 3/4 in. x 1 in./28 mm ADAPTER COUPLING AND AIRLINE ASSEMBLY OPT

SPA0392 Ø 1 in. VAC HOSE TO Ø 1 in./28 mm x 1 1/2 in. ADAPTER COUPLING AND AIRLINE ASSEMBLY OPT

65 SPA0412 Ø 1 in. VAC HOSE TO DOUBLE BAG FITTING AND AIRLINE ASSEMBLY 1

66 SPA0468 VACUUM BAG 1

67 SPA0470 VACUUM BAG INSERT 1

DOC 0004-SP

4 Revision 06/18/14

and the physical condition of the user. SurfPrep

Orbit Pad

Face

Vacuum

Type Pad Type Pad Size

in. (mm)

Model

Number.

Product

Net Weight

Pound (kg)

Height in.

(mm)

Length in.

(mm)

Power HP

(watts)

Air

Consump-

tion scfm

(LPM)

*Noise

Level

dBA

*Vibration

Level

m/s2

*Uncer-

tainty

K

m/s2

3/32 in.

(2.5 mm)

Vinyl

Non-

Vacuum

5 in. (127) SP051200 1.84 (0.83) 3.9 (100.6)

3.9 (100.6)

3.9 (100.6)

3.9 (100.6)

3.9 (100.6)

3.9 (100.6)

3.9 (100.6)

3.9 (100.6)

3.9 (100.6)

3.9 (100.6)

3.9 (100.6)

3.9 (100.6)

3.9 (100.6)

3.9 (100.6)

3.9 (100.6)

3.9 (100.6)

3.9 (100.6)

3.9 (100.6)

3.9 (100.6)

3.9 (100.6)

3.9 (100.6)

3.9 (100.6)

3.9 (100.6)

3.9 (100.6)

7.0 (178) .28 (209) 17 (481)

17 (481)

17 (481)

17 (481)

17 (481)

17 (481)

17 (481)

17 (481)

17 (481)

17 (481)

17 (481)

17 (481)

17 (481)

17 (481)

17 (481)

17 (481)

17 (481)

17 (481)

17 (481)

17 (481)

17 (481)

17 (481)

17 (481)

17 (481)

77.5 1.91 0.68

6 in. (150) SP061200 1.91 (0.86) 7.4 (189) .28 (209) 77.0 2.19 0.71

Central

Vacuum

5 in. (127) SP051234 1.96 (0.89) 9.0 (231) .28 (209) 76.5 1.79 0.67

6 in. (150) SP061234 2.06 (0.93) 9.5 (242) .28 (209) 75.0 2.40 0.73

Self-Gen

Vacuum

5 in. (127) SP051267 1.98 (0.90) 9.4 (239) .28 (209) 83.5 2.15 0.71

6 in. (150) SP061267 2.08 (0.94) 9.8 (250)

7.0 (178)

7.4 (189)

9.0 (231)

9.5 (242)

9.4 (239)

9.8 (250)

7.0 (178)

7.4 (189)

9.0 (231)

9.5 (242)

9.4 (239)

9.8 (250)

7.0 (178)

7.4 (189)

9.0 (231)

9.5 (242)

9.4 (239)

9.8 (250)

.28 (209) 82.5 2.20 0.71

Hook

Non-

Vacuum

5 in. (127) SP051202 .28 (209)

6 in. (150) SP061202 .28 (209)

Central

Vacuum

5 in. (127) SP051236 .28 (209)

6 in. (150) SP061236 .28 (209)

Self-Gen

Vacuum

5 in. (127) SP051269 .28 (209)

6 in. (150) SP061269 .28 (209)

3/16 in.

(5.0 mm)

Vinyl

Non-

Vacuum

5 in. (127) SP051300 1.88 (0.85) .28 (209) 76.0 2.79 0.77

6 in. (150) SP061300 1.97 (0.89) .28 (209) 76.0 2.92 0.78

Central

Vacuum

5 in. (127) SP051334 2.00 (0.90) .28 (209) 77.0 2.64 0.76

6 in. (150) SP061334 2.12 (0.96) .28 (209) 76.0 1.99 0.69

Self-Gen

Vacuum

5 in. (127) SP051367 2.02 (0.91) .28 (209) 84.0 2.51 0.74

6 in. (150) SP061367 2.14 (0.97)

1.84 (0.83)

1.91 (0.86)

1.96 (0.89)

2.06 (0.93)

1.98 (0.90)

2.08 (0.94)

1.88 (0.85)

1.97 (0.89)

2.00 (0.90)

2.12 (0.96)

2.02 (0.91)

2.14 (0.97)

.28 (209) 82.5 2.08 0.70

77.5 1.91 0.68

77.0 2.19 0.71

76.5 1.79 0.67

75.0 2.40 0.73

83.5 2.15 0.71

82.5 2.20 0.71

76.0 2.79 0.77

76.0 2.92 0.78

77.0 2.64 0.76

76.0 1.99 0.69

84.0 2.51 0.74

82.5 2.08 0.70

Hook

Non-

Vacuum

5 in. (127) SP051302 .28 (209)

6 in. (150) SP061302 .28 (209)

Central

Vacuum

5 in. (127) SP051336 .28 (209)

6 in. (150) SP061336 .28 (209)

Self-Gen

Vacuum

5 in. (127) SP051369 .28 (209)

6 in. (150) SP061369 .28 (209)

The noise test is carried out in accordance with EN ISO 15744:2008 Measurement of noise emission from hand-held non-electric power tools.

The vibration test is carried out in accordance with EN 28662-1. Hand-held portable power tools – Measurement of vibration at the handle. Part 1:

General and EN 8662-8, 1997. Hand-held portable power tools – Measurement of vibration at the handle. Part 8: Polishers and rotary

, orbital and

random orbital sanders

risk evaluation. Values measured in a particular work place may be higher than the declared values. The actual exposure values

and amount of risk or harm experienced to an individual is unique to each situation and depends upon the surrounding environment,

the way in which the individual works, the particular material being worked, work station design as well as upon the exposure time

TM cannot be held responsible for the consequences of using declared values

instead of actual exposure values for any individual risk assessment.

Further occupational health and safety information can be obtained from the following websites:

http://europe.osha.eu.int (Europe)

http://www.osha.gov (USA)

DOC 0004-SP

5 Revision 06/18/14

Work Stations

Putting the Tool into Service

Operating Instructions

1) Read all instructions before using this tool. All operators

must be fully trained in its use and aware of these safety

rules. All service and repair must be carried out by

trained personnel.

2) Make sure the tool is disconnected from the air supply.

Select a suitable abrasive and secure it to the back-up

pad. Be careful and center the abrasive on the back-up

pad.

3) Always wear required safety equipment when using this

tool.

4) When sanding always place the tool on the work then

start the tool. Always remove the tool from the work

before stopping. This will prevent gouging of the work

due to excess speed of the abrasive.

5)

adjusting or removing the abrasive or back-up pad.

6)

of torque reaction developed by the sander.

7) Use only correct spare parts.

8)

9)

the tool by its hose; always be careful to prevent the tool

from being started when carrying the tool with the air

supply connected.

10) Dust can be highly combustible. Vacuum dust collection

bag should be cleaned or replaced daily. Cleaning or

replacing of bag also assures optimum performance.

11) Do not exceed maximum recommended air pressure.

Use safety equipment as recommended.

12) The tool is not electrically insulated. Do not use where

there is a possibility of coming into contact with live

electricity, gas pipes, water pipes, etc. Check the area of

operation before operation.

The tool is intended to be operated as a hand held tool. It is

always recommended that the tool be used when standing

grip and footing and be aware that the sander can develop a

torque reaction. See the section “Operating Instructions”.

Use a clean lubricated air supply that will give a measured

air pressure at the tool of 90 psig (6.2 bar) when the tool is

running with the lever fully depressed. It is recommended

to use an approved 3/8 in. (10 mm) x 25 ft (8 m) maximum

length airline. It is recommended that the tool be connected

to the air supply as shown in Figure 1.

Do not connect the tool to the airline system without incorpo-

rating an easy to reach and operate air shut off valve. The air

supply should be lubricated. It is strongly recommended that

in Figure 1 as this will supply clean, lubricated air at the

correct pressure to the tool. Details of such equipment can

be obtained from your supplier. If such equipment is not used

then the tool should be manually lubricated

To manually lubricate the tool, disconnect the airline and put

2 to 3 drops of suitable pneumatic motor lubricating oil such

as Fuji Kosan FK-20, Mobil ALMO 525 or Shell TORCULA®

32 into the hose end (inlet) of the machine. Reconnect tool to

the air supply and run tool slowly for a few seconds to allow

air to circulate the oil. If the tool is used frequently, lubricate

it on a daily basis or lubricate it if the tool starts to slow or

lose power.

It is recommended that the air pressure at the tool be 90 PSI

(6.2 Bar) while the tool is running so the maximum RPM is not

exceeded. The tool can be run at lower pressures but should

never be run higher than 90 PSI (6.2 Bar). If run at lower pres-

sure the performance of the tool is reduced.

13) Take care to avoid entanglement with the moving parts

of the tool with clothing, ties, hair, cleaning rags, etc. If

entangled, it will cause the body to be pulled towards the

work and moving parts of the machine and can be very

dangerous.

14) Keep hands clear of the spinning pad during use.

15) If the tool appears to malfunction, remove from use im-

mediately and arrange for service and repair.

16) Do not allow the tool to free speed without taking precau-

tions to protect any persons or objects from the loss of

the abrasive or pad.

Closed Loop Pipe System

Sloped in the direction

of air flow

Drain Leg

Ball Valve

To Tool Station

Filter

Drain Valve

Regulator

Lubricator

Ball

Valve

Ball Valve

Air Flow

Air Dryer

Air Compressor

and Tank

Air Hose

To Coupler

at or near Tool

Figure 1

DOC 0004-SP

6 Revision 06/18/14

SPF0033 Overhaul Service Kit for 12,000 RPM 5 & 6 in. ROS Contents

Part No. Description Qty.

SPA0040 External Retaining Ring 1

SPA0021 Bearing 1

SPA0042 O-Ring 1

SPB0005 Rotor 1

SPA0010 Vanes 5

SPA0041 Key 1

SP50059 Bearing 1

SPA0937 Shim 1

SPA0938 Bearing 1

SPA0016 Spacer 1

SPA0008 Valve Stem Assembly 1

SPA0043 O-Ring 1

SPA0039 Internal Retaining Ring 1

SPF0013

SPG0030

SPA2204

SPA2484

SPF0008

1

SPF0011

1

1

SPA0009 Valve Seat

Muffler Cap

Exhsust Chamber

9.5 mm X 1.0 mm O-Ring

24 mm X 1.0 mm O-Ring

1

SPA0007 Valve

1

1

SPA0014 Valve Spring

1

1

1

Overhaul Service Kit

The SPF0033 Overhaul Service Kit contains all the replacement parts that naturally wear over time and a straightforward

manual to make servicing an SurfPrepTM sander simple. Overhauling the Random Orbital Sander can be made even easier with

the use of the above Service Tools. The Service Tools also reduce the chance of improper assembly.

Service Tools and Accessories

When an SurfPrepTM LP ROS needs to be serviced, we offer a tool kit to make the disassembly/assembly fast and easy. The

Service Tools are highly recommended for use with the Overhaul Service Kit. NOTICE: To receive any expressed or implied

warranty, the tool must be repaired by an authorized SurfPrepTM Service Center. The 5 in. and 6 in. Random Orbital Sanders

Service Instructions section provided are for use after completion of the warranty period.

T-6 MOTOR LOCK RING

WRENCH/SPINDLE PULLER T-7 SOFT COLLAR T-8 MOTOR FACE PLATE

BEARING REMOVAL TOOL

T-13 BEARING

PRESS TOOL

T-9 12 mm ID

BEARING PULLER

T-1 ROS SPINDLE

BEARING PRESS TOOLS

T-6 MOTOR LOCK RING

WRENCH/SPINDLE PULLER T-7 SOFT COLLAR T-8 MOTOR FACE PLATE

BEARING REMOVAL TOOL

T-13 BEARING

PRESS TOOL

T-9 12 mm ID

BEARING PULLER

T-1 ROS SPINDLE

BEARING PRESS TOOLS

SERVICE INSTRUCTIONS

FOR LOW PROFILE 12,000 RPM

5 in. (127 mm) and 6 in. (150 mm)

RANDOM ORBITAL SANDERS

SPA0479 UNIVERSAL SERVICE TOOL KIT

DOC 0004-SP

7 Revision 06/18/14

1/4-18 NPT Air Inlet Kit

Reorder P/N SPF0029Reorder P/N SPF0028

ROS Spindle Bearing Kit

Reorder P/N SPA1164

Sander Spare Parts Kits

Endplate Bearing Kit

Reorder P/N SPF0032

Speed Valve Kit

Reorder P/N SPF0030

Rotor, Vanes and Key Kit

Reorder P/N SPA0063

Scaled 50%

DOC 0004-SP

8 Revision 06/18/14

DISASSEMBLY INSTRUCTIONS

Changing Grips:

1. The Grip has two “tabs” that wrap around the body of

the sander under the inlet and exhaust. Use a small

screwdriver to pick out one of the “tabs” of the Grip,

and then continue to go underneath the Grip with the

screwdriver and pry the Grip off of sander. To install a

new Grip, hold the Grip by the tabs making them face

outward, align the Grip and slide it under the Throttle

Lever then press the Grip down until it seats onto the

top of the sander. Make sure the two “tabs” seat under

the inlet and exhaust.

Motor Disassembly:

1. Lightly secure the tool in a vise using the T-7 Soft Collar

or padded jaw vice and remove the pad with the 24 mm

Pad Wrench then remove the Shroud.

2. Remove the Lock Ring with the T-6 Motor Lock Ring

Wrench/Spindle Puller Tool. The motor assembly can

now be lifted out of the Housing.

3. Secure the motor assembly by clamping the 5 in. or 6

in. (125 or 150 mm) Shaft Balancer in a padded jaw vise

and remove the Retaining Ring and the O-Ring from the

Cylinder.

4. Remove the Rear Endplate. This may require support-

ing the Rear Endplate with a Bearing Separator and

lightly pressing the shaft through the Bearing and Rear

Endplate. Remove Cylinder and the Vanes and Rotor

Set from the shaft of the Shaft Balancer. Remove the

Key then press off the Front Endplate (with Bearing), O-

Ring and the Lock Ring. It may be necessary to remove

the Bearing with a Bearing Separator if it came out of

the Front Endplate and stuck to the shaft of the Shaft

Balancer.

5. Remove and discard Dust Shield from the Shaft Bal-

ancer.

6. Remove the Bearing(s) from the Endplates by using the

T-8 Bearing Removal Tool to press out the Bearings.

Shaft Balancer and Spindle Disassembly:

1. Grip the shaft end of the Shaft Balancer in a padded

vise. With a thin screwdriver pick out the slotted end of

the Retaining Ring and peel out.

2. Screw the threaded end of the T-6 Motor Lock Ring

Wrench/Spindle Puller Tool into the Spindle until hand

tight. Apply a gentle heat from a propane torch or hot

air gun to the large end of the Balancer Shaft until it is

about 212° F (100° C) to soften the adhesive. Do not

over heat. Remove the Spindle assembly by using the

slider to give sharp outward blows to the Spindle. Allow

the parts to cool so they are safe to handle. Follow one

of the appropriate directions below:

• If the Bearing come out with the spindle, use a small

Bearing Separator to remove it. Move onto step 3.

• If the Bearing stays in the Shaft Balancer. Follow

steps A - D below.

Procedure for removal of the Bearings from the Shaft

Balancer:

A. Position the Set Screw in the top of the T-9 12 mm ID

Bearing Puller.

B. Make sure the Retaining Ring is removed, then press

the Bearing Puller into the I.D. of Bearing until the Bear-

ing Puller hits the bottom of the Shaft Balancer.

C. Thread the Set Screw down until it hits the bottom of the

Shaft Balancer or becomes very tight. Grip the shaft end

of the Shaft Balancer in a padded vise.

D. Screw the threaded end of the T-6 Motor Lock Ring

Wrench/Spindle Puller Tool into the Bearing Puller until

hand tight. Apply a gentle heat from a propane torch

or hot air gun to the large end of the Shaft Balancer to

re-heat it until it is about 212° F (100° C) to soften the

adhesive. Do not over heat. Remove the Bearing by

using the slider to give sharp outward blows to the Bear-

ing Puller. Allow the Bearing Puller, Bearing and Shaft

Balancer to cool. After cooling, unthread the T-6 Motor

Lock Ring Wrench/Spindle Puller Tool from the Bearing

Puller. Back off the set screw. Secure the Bearing Puller

and Bearings in a Bearing Separator and press out the

Bearing Puller.

3. Remove the bearing from the Spindle. Remove the

Spacer, Dust Shield and Washer from the Spindle.

Discard Dust Shield.

Housing Disassembly:

1. For Non-Vacuum (NV) and Central Vacuum (CV)

machines follow the steps outlined in Section I below.

For Self Generated Vacuum (SGV) machines follow the

steps outlined in Section III.

I. This section is for NV and CV machines.

Remove the Muffler Housing from the Housing.

Remove the Muffler insert from the cavity of the Muffler

Housing and remove the Bronze Muffler from the Muff-

ler Housing.

A)

B)

C) For NV machines move onto D. For CV machines move

onto Section II.

D) Remove the NV Shroud. Move onto Step 2.

II. This section continued from Section I for CV Exhaust

machines:

A) Remove the Screw, and Nut.

B) Remove the Ø 1 in. (28 mm) CV Swivel Exhaust

Assembly or the Ø 3/4 in. (19 mm) CV Swivel Exhaust

Assembly from the Shroud.

C) Remove the Shroud from the Housing. Move onto step 2.

NOTICE: To receive any expressed or implied warranty, the tool must be repaired by an authorized Service Center.

The 5 in (127 mm.) and 6 in. (150 mm) Random Orbital Sander Service Instructions section provided is for use after completion of

the warranty period.

12,000 RPM – 5 in. (127 mm) and 6 in. (150 mm)

LOW PROFILE RANDOM ORBITAL SANDERS SERVICE INSTRUCTIONS

DOC 0004-SP

9 Revision 06/18/14

3. Install the Valve Seat, the Valve and the Valve Spring.

Coat the threads of the Bushing Assembly with 1 or 2

drops of Loctite® 222 or equivalent non-permanent pipe

thread sealant. Screw the assembly into the Housing.

Torque to 60 in/lbs (6.77 Nm.)

Press Tool Top

Press Tool Base

Dust Shield

Bearing

Washer

Spindle

T-1B

T-1A

Spacer

III. This section is for SGV Exhaust machines:

A) Remove the Screw, and Nut.

B) Remove the Ø 1 in. (28 mm) Hose SGV Swivel Exhaust

Assembly from the Housing and SGV Shroud Adapter.

C) Remove the Vacuum Shroud from the Housing. Move

onto step 2.

2. Place the Speed Control to the midway position and

remove the Retaining Ring. NOTE: If the machine is a

vacuum model, the vacuum exhaust must be removed

(see Section 1 above for removal) before the Retaining

Ring can be removed with lock ring pliers. The Speed

Control will now pull straight out. Remove the O-ring.

3. Unscrew the Inlet Bushing Assembly from the Housing.

Remove the Valve Spring, Valve, Valve Seat, Valve

Stem and O-Ring.

4. Press out the Spring Pin from the Housing and remove

the Throttle Lever.

ASSEMBLY INSTRUCTIONS

NOTE: All assembly must be done with clean dry parts and

all bearings are to be pressed in place by the correct tools

and procedures as outlined by the bearing manufacturers.

Housing Assembly:

1. Install Throttle Lever into Housing with the Spring Pin.

2. Lightly grease the O-ring and place it on the Speed

Control. Install Valve Stem, O-ring (cleaned and lightly

greased) and insert the Speed control into the Hous-

ing in the midway position. Install the Retaining Ring.

CAUTION: Make sure the Retaining Ring is completely

snapped into groove in the Housing.

DOC 0004-SP

10 Revision 06/18/14

Spindle, and Shaft Balancer Assembly:

1. Place the Washer on the Spindle shaft with the curve of

the Washer facing up so that the outside diameter of the

Washer will contact the outer diameter of the Bearing.

Place the Dust Shield onto the Spindle shaft. Place

the Spacer onto the shoulder of the Spindle. Note: Be

sure that the Dust Shield is past the shoulder where

Spacer rests. Place the Bearing on the Spindle with the

seal side toward the Washer. Press onto Spindle using

seated at bottom.

2. When the Spindle Assembly is done correctly, the Bear-

ing will rotate freely but not loosely.

3. Take the new Filter and center it on the small bore that

the original Filter was in before removal. With a small

Place the Valve into the bore so it is oriented correctly,

the bottom of the Bearing bore.

4. Apply a pin head size drop of #271 Loctite® or equiva-

lent to the outside diameter of each of the bearings on

the spindle assembly. Spread the drop of bearing locker

around the bearing until distributed evenly. CAUTION:

Only a very small amount of bearing locker is needed

to prevent rotation of the bearing OD. Any excess will

-

sembly into the bore of the Shaft Balancer and secure

with the Retaining Ring. CAUTION: Make sure that the

Retaining Ring is completely snapped into the groove in

the Balancer Shaft. Allow the adhesive to cure.

Motor Assembly:

1. Place the Dust Shield onto the shaft of the Shaft Bal-

ancer.

2. Use the larger end of the T-13 Bearing Press Sleeve to

press the front Bearing (with 2 Shields) onto the shaft of

the Shaft Balancer.

3. Slide the Front Endplate with the bearing pocket facing

down onto the Motor Shaft. Gently press the Front End-

plate onto the Bearing using the larger end of the T-13

Bearing Press Sleeve until the Front Bearing is seated

in the bearing pocket of the Endplate. CAUTION: Only

press just enough to seat the bearing into the pocket.

Over-pressing can damage the bearing.

4. Place the Key into the groove on the Shaft Balancer.

Place the Rotor on the Shaft Balancer, making sure that

5.

place them in the slots of the Rotor. Place the Cylinder

Assembly over the Rotor with the short end of the

Spring Pin engaging the blind hole in the Front End-

plate. NOTE: The Spring Pin must project .060 in. (1.5

6.

Endplate with the T-1B Bearing Press Tool. Make sure

the T-1B Press Tool is centered on the O.D. of the outer

Assembly over the Shaft Balancer using the small end

of the T-13 Bearing Press Sleeve. The sleeve should

press only the inner race of the bearing. IMPORTANT:

The Rear Endplate and Bearing Assembly is pressed

correctly when the Cylinder is squeezed just enough

between the Endplates to stop it from moving freely

under its own weight when the shaft is held horizontal,

but be able to slide between the Endplates with a very

light force. If the assembly is pressed to tightly the

motor will not run freely. If the pressed assembly is to

loose, the motor will not turn freely after assembly in the

Housing. Secure the assembly by placing the Retaining

Ring in the groove of the Shaft Balancer. CAUTION: The

Retaining Ring must be placed so that the middle and

center portions must be securely “snapped” into the

groove in the Shaft Balancer by pushing on the curved

portions with a small screwdriver.

7. Lightly grease the O-Ring and place in the air inlet of the

Cylinder Assembly.

8. Lightly grease or oil the inside diameter of the Housing,

line up the Spring Pin with the marking on the Housing

and slide the Motor Assembly into the Housing. Make

sure the Spring Pin engages the pocket in Housing.

9. Carefully screw the Lock Ring into the Housing with the

T-6 Motor Lock Ring Wrench/Spindle Puller Tool. Torque

to 60 in/lbs (6.77 Nm.) NOTE: A simple technique to

counter clockwise with the T-6 Motor Lock Ring Wrench/

Spindle Puller while applying light pressure. You will

hear and feel a click when the lead thread of the lock

ring drops into the lead thread of the housing.

10. Spin on a new Pad and hand tighten it using a 24 mm

Pad Wrench.

Testing:

Place 3 drops of quality pneumatic air tool oil directly into

the motor inlet and connect it to a 90 psig (6.2 bar) air

supply. A 12,000 RPM tool should run between 11,500 to

12,500 RPM when the air pressure is 90 psig (6.2 bar) at

the inlet of the tool while the tool is running at free speed.

This free speed will be about 500 RPM to 1,000 RPM less

when a Vacuum or Hook Face Pad is used because of wind

resistance. This will not affect performance when sanding.

Loctite® is a registered trademark of the Loctite Corp.

DOC 0004-SP

11 Revision 06/18/14

Symptom Possible Cause Solution

Low Power and/or Low Free Speed

Check air line pressure at the Inlet of

the Sander while the tool is running at

free speed. It must be 90 psig (6.2 Bar).

See the “Housing Disassembly” section

cleaning solution until all contaminates

and obstructions have been removed. If

(See the “Housing Assembly” Section).

Plugged Inlet Screen

Clean the Inlet Screen with a clean,

suitable cleaning solution. If Screen

does not come clean replace it.

One or more Worn or Broken Vanes

Install a complete set of new Vanes

(all vanes must be replaced for proper

operation). Coat all vanes with quality

pneumatic tool oil. See “Motor Disas-

sembly” and “Motor Assembly”.

Internal air leakage in the Motor Housing

indicated by higher than normal air con-

sumption and lower than normal speed.

Check for proper Motor alignment and

Lock Ring engagement. Check for

damaged O-Ring in Lock Ring groove.

Remove Motor Assembly and Re-Install

the Motor Assembly. See “Motor Disas-

sembly” and “Motor Assembly”.

Motor Parts Worn Overhaul Motor. Contact authorized

SurfPrepTM Service Center.

Worn or broken Spindle Bearings

Replace the worn or broken Bear-

ings. See “Shaft Balancer and Spindle

Disassembly” and “Spindle Bearings,

AirSHIELD™ and Shaft Balancer As-

sembly”.

Air leakage through the Speed

Control and/or Valve Stem.

Dirty, broken or bent Valve Spring, Valve

or Valve Seat.

Disassemble, inspect and replace worn

or damaged parts. See Steps 2 and 3

in “Housing Disassembly” and Steps 2

and 3 in “Housing Assembly”.

Vibration/Rough Operation

Incorrect Pad Only use Pad Sizes and Weights

designed for the machine.

Addition of interface pad or other material

Only use abrasive and/or interface

designed for the machine. Do not at-

tach anything to the Sanders Pad face

used with the Pad and Sander.

Improper lubrication or buildup of foreign

debris.

Disassemble the Sander and clean in

a suitable cleaning solution. Assemble

the Sander.

Worn or broken Rear or Front Motor

Bearing(s)

Replace the worn or broken Bearings.

See “Motor Disassembly” and “Motor

Assembly”.

For vacuum machines it is possible to

have too much vacuum while sanding on

the sanding surface.

For SGV machines add extra washer(s)

to the pad spindle to increase the gap

between the pad and shroud. For CV

machines reduce vacuum through

the vacuum system and/or add extra

washer(s) to the pad.

Troubleshooting Guide

DOC 0004-SP

12 Revision 06/18/14

SurfPrepTM Tools

571 BIRCH STREET LAKE ELSINORE, CA 92530

Tel : 951-245-4200

Fax: 951-245-4299

Table of contents

Other SurfPrep Sander manuals

Popular Sander manuals by other brands

Hilti

Hilti WFO 280 Original operating instructions

Grizzly

Grizzly G0634X owner's manual

Rupes

Rupes Scorpio III Translation of the original instructions

Alpha Professional Tools

Alpha Professional Tools AEP-458 Instructional guide

EINHELL Bavaria

EINHELL Bavaria BSS 105 operating instructions

AGP

AGP Intex Giraffe GHOST Operation manual