Sussman Boilers

Installation, Op ration & Maint nanc Manual

8. Start-Up and Op ration

The following procedures should be performed in sequence

to eliminate problems on start-up.

8.1 Start-up

It is presumed that all electrical wiring and plumbing has

been checked prior to this start-up procedure.

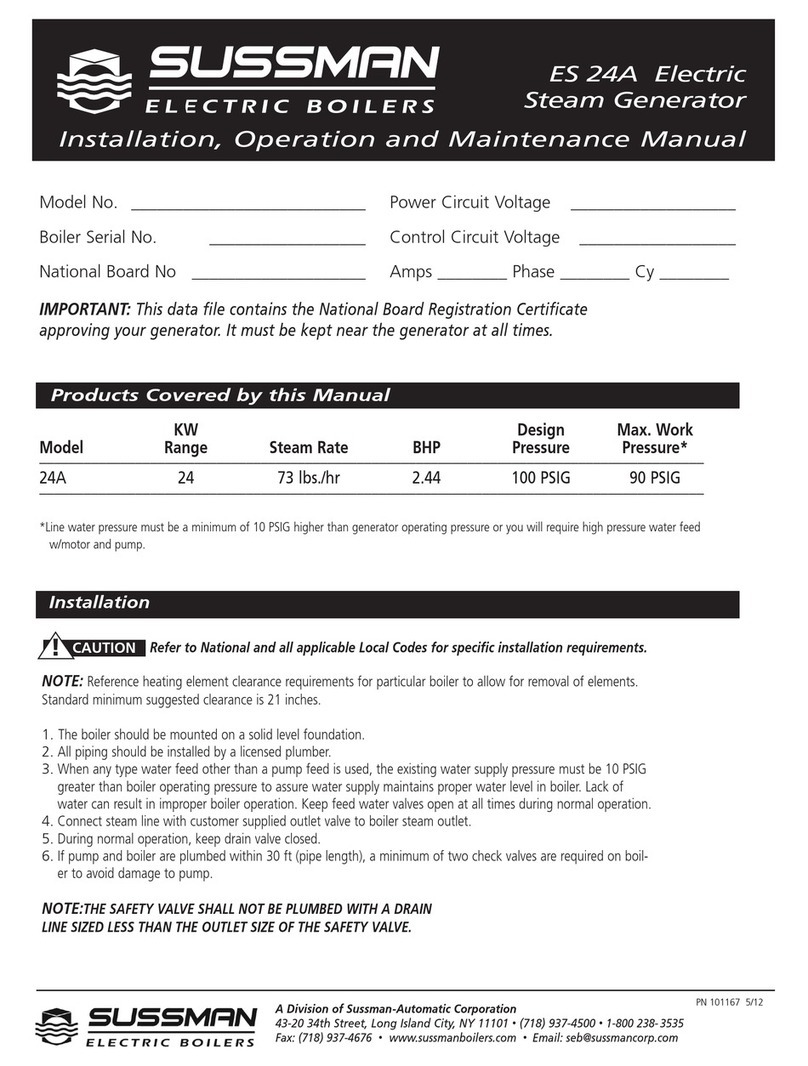

8.1.1 Make sure that the steam boiler valves are in the fol-

lowing positions:

Steam Outlet Open Drain Valve(s) Closed

Water Inlet(s) Open Blowdown Valve(s) Closed

8.1.2 Adjust the pressure controller to its lowest setting by

turning the large screw on the top of the controller.

8.1.3 Make sure that the electrical panel door is closed.

8.1.4 Switch to the “On” position. The green power light and

red low level light should then be illuminated indicating

that the system has power and a low water level condi-

tion exists. If the boiler was previously started, sufficient

water may be present and the red low level light will not

illuminate. The boiler solenoid valve will activate and the

water will enter the boiler until the high water level

control closes the valve. Just prior to this, the low level

indictor will de-energize the red low level light and

energize the heating element. At this point, close the

steam valve. The elements will heat the water and begin

to generate steam within a few minutes.

8.1.5 Do a first check on the piping system for leaks at con-

nection points and tighten connections as necessary.

8.1.6 Simulate a low water condition by depressing the

“push-to-test” button. The boiler contactors should open

and the red “low level light” should illuminate. The

noise indicates that the elements have been turned off

and the light indicates the control is working. You

should begin to notice a small pressure requirement. This

is not cause for concern. If the boiler has a step con-

troller it may not have had enough time at this low

demand situation to activate all the heating stages

before satisfying the pressure requirement. This is not

cause for concern.

8.1.7 Set the pressure controller (by turning the large

screw on top of the controller) to the desired pressure

setting. NOTE: The pressure control setting should not

be set at more than 90% of the relief valve setting.

For example: If relief valve setting is 100 PSI, set the

pres-sure control at 90 PSI and the differential at 8

PSI. This will allow the boiler to control the pressure

to between 82 PSI and 90 PSI.

8.1.8 Set the differential (by turning the small screw on

the top of the controller) to the minimum setting.

8.1.9 The pressure will rise on the gauge until the boiler

pressure has reached the pressure control setpoint.

Do a final check for leaks.

8.1.10 Ensure that the system (external to the boiler) is

fully prepared for operation and that personnel are

aware that the system is being started up.

8.1.11 Next, slowly open the steam outlet valve, while

maintaining pressure, until the valve is fully opened.

8.1.12 Inspect the heating system for leaks and functionali-

ty. NOTE: Initially, as the system is being heated up,

the boiler may not be able to maintain the setpoint

pressure. However, if the boiler has been properly

sized, after a short period of time the desired operat-

ing pressure will be reached and maintained automat-

ically. Undersized steam heating systems will prime

i.e. discharge excessive amounts of water through the

outlet nozzle. Boilers should not be operated under

this condition. You may wish to check factory for

assistance. The system should now be operational. It is

not normally necessary to pre-boil water to clean the

heating elements or the interior of the vessel. They

have already been semi-cleaned prior to installation

and there is no excessive grease or oil inside the boil-

er. However, if super-clean conditions make pre-boil-

ing necessary, ensure that the detergents used are not

harmful to brass, copper, silver, steel or stainless steel.

8.2 Op ration

With main disconn ct “OFF” tight n all l ctrical conn ctions b for n rgizing

boil r to pr v nt arcing, carbonizing of contact and/or ov rh ating

8.2.1 If a proper maintenance schedule is followed, all that is

required is to turn the boiler on for it to function normally.

Before restarting the boiler, ensure that:

Steam outlet valve is open

Water inlet valve(s) is open

Drain valve(s) are closed

Pressure control is set to the desired system pressure

8.2.2 Although the boiler can operate safely unattended, it

is best to shut the boiler down when it is not required

over evenings, weekends or other prolonged periods.

8.2.3 Water treatment may be necessary in some hard

water areas since excessive scale build up on internal

boiler components will result in heating element

failure and costly repairs. Refer to section 9.6 for a

discussion on this subject.

8

CAUTION

!