Before Installing your new elements be sure the

McDonnell Miller low water cut-off an aux. low

water cutoff (if supplie ) is operating properly. The float chamber an

lower equalizer column of the MM control must be completely clear of

slu ge or other foreign matter. Failure to o this may cause the imme-

iate burn-out of the new elements. If the unit is probe equippe ,

check con ition of the probes an isolator.

All elements are thoroughly checke before shipment The manufactur-

er cannot be responsible for burn-outs cause by a faulty low water

cut-off.

The lower equalizer column can best be examine by breaking the

unions on either si e an then visually an manually examining the

piping with your finger or probes to see if it is clear an clean.

1.

Disconnect boiler from electric power supply at main safety switch or

fuse panel. Then turn boiler switch to “OFF" position.

2.

Close water supply valve on incoming water supply line.

Drain boiler completely of water.

3.

Open boiler oor to access heating element.

4.

Disconnect wire (electric) lea s connecting element to main power system of boiler.

Again, note wire connections to facilitate re-assembly. Procee to remove

an iscar (6) bolts from flange.

IMPORTANT:

Note the wire connections to facilitate re-assembly (see wiring schematic).

Remove an iscar six (5/16"-18) bolts from flange. Do not reuse these bolts.

5.

Thoroughly clean boiler flange of all foreign material. Be certain no part of ol gasket

remains on flange.

6.

Apply "Slic-Tite" Gasket Compoun (or equal) to both surfaces of new gasket supplie

with replacement element. Procee to install element flange assembly with gasket

between boiler flange an element flange. In oing this, be careful to align flange holes

so element wire connection terminals on element assembly are in line with previously

isconnecte wire lea s to facilitate easy connections.

NOTE:

Observe markings on element flange. Install element marking “TOP” on top.

7.

Use only new element flange bolts. Tighten all (6) element flange bolts to a torque value

of 22 lb-ft each (see illustration).

.

Connect all wires to the terminals. Tighten all element terminals to a torque value of

20 lb-in each (see illustration). Make sure all wires are clean an bright to assure goo

electrical contact.

9.

Check that the wires are correctly connecte to the contactor terminals an are tight-

ene to a torque value of 45 lb-in. (see illustration). Make sure all wires are clean an

bright to assure goo electrical contact.

10.

Open water valve to allow water supply to reach boiler fee mechanism.

11.

As boiler automatically refills, observe the new flange assembly for possible leaks.

If water is notice , the bolts must be re-tightene . Before oing this, turn the boiler

off at the main fuse safety switch.

12.

When boiler reaches working pressure, check flange assembly again for leaks.

Follow maintenance instructions provi e with the boiler.

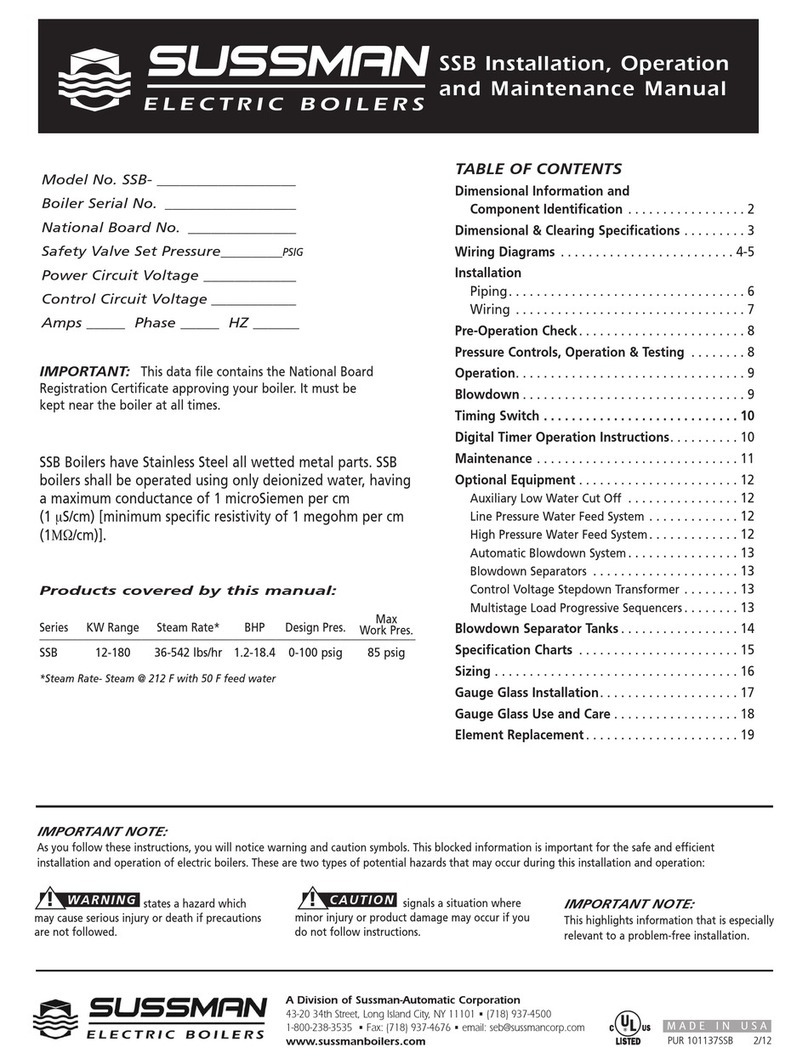

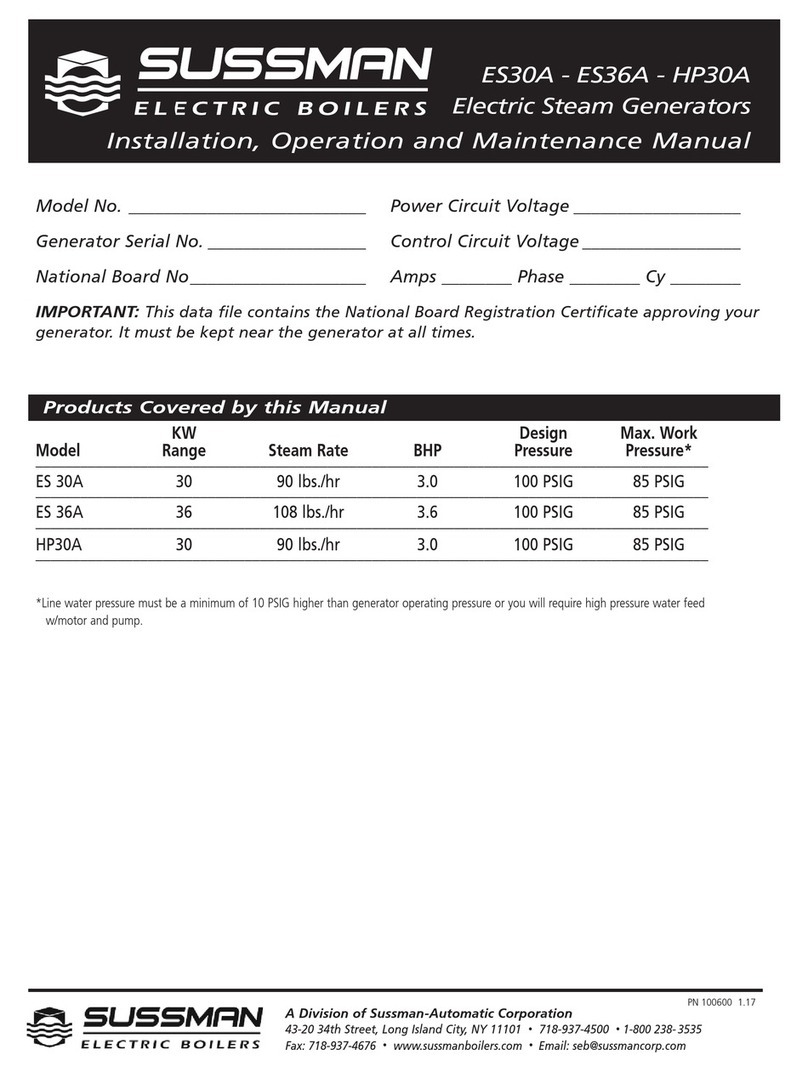

ES 24A Electric Steam Generator Installation, Operation and Maintenance Manual

_____________________________________________________________________________

6

Element Replacement

Torque Values:

Element Flange Bolts: 22 lb-ft

Element Terminals: 20 lb-in

Contactor Terminals: see Torque chart

For Illustrative Purposes Only.

Power wiring shown in approximate

factory-installed location

TORQUE VALUES

________________________________________

Element Flange Bolts 22 lb-ft

________________________________________

Element Terminals 20 lb-in

________________________________________

Contactor Terminals 45 lb-in

Torque

Wrench

Torque

Wrench

Torque

Wrench

READ INSTRUCTIONS COMPLETELY BEFORE STARTING WORK

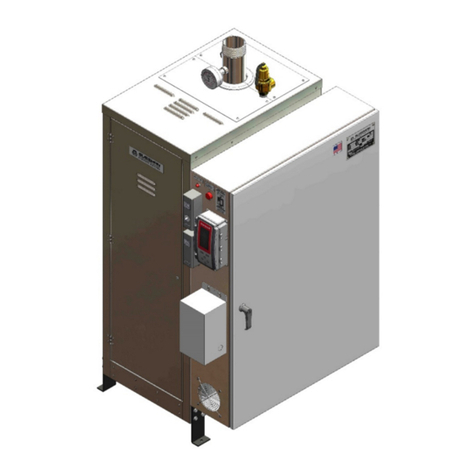

Boiler with

McDonnell Miller

11⁄2

1 Steam Equalizing Pipe

Pump and Low Water Control

Normal Boiler Water Line

Cut-Off Level is Arrow Mark

Blowdown Valve

1 Water Equalizing Pipe

!CAUTION

!CAUTION