• LIQUID LEVEL / LWCO CONTROLLER

The electronic controller automatically maintains proper

water level, and shuts off the generator when water

supply in the boiler drops below a safe operating level.

• WATER LEVEL SIGHT GLASS

Allows constant observation of water level while

boiler is in operation.

• ON-OFF SWITCH

Complete with pilot light, for switching on the

generator.

• INTEGRAL ELECTRICAL CONTROL

Magnetic contactor energizes the element and is

integrally mounted in the control unit.

• BLOWDOWN/DRAIN VALVE

Facilitates emptying the pressure vessel during blowdown/drain sequence.

• J-BOX

for motor/pump connection.

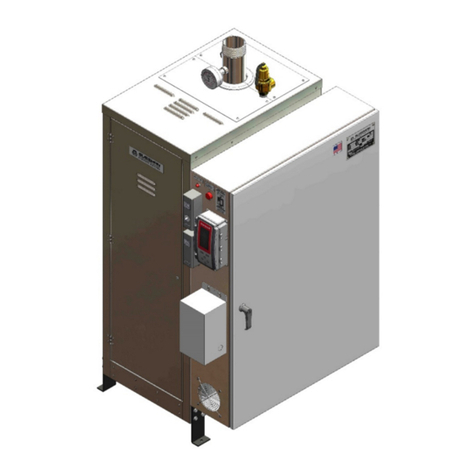

• LONG LIFE HEATING ELEMENTS

Industrial grade, heavy duty stainless steel heating elements equipped with one

piece resistance welded terminations for added strength and safety.

• OPERATING PRESSURE CONTROL

Operates automatically to maintain steam pressure within generator.

• MANUAL RESET PRESSURE CONTROL

Provides high limit pressure cut-out with manual reset.

• STEAM SAFETY VALVE

ASME Code valve, automatically opens to reduce pressure should excessive

steam cause pressure build-up.

• STEAM PRESSURE GAUGE

Allows visual observation of steam pressure over full range.

• ENERGY SAVING AND MINIMUM MAINTENANCE

Fully insulated pressure vessel minimizes heat loss and maximizes energy savings.

• EASY CONTROL MAINTENANCE

All controls and components are easily accessible. Fully-louvered openings avoid

component heat build-up.

• RUGGED CONSTRUCTION

Performance is insured for all typical industrial applications.

•

Pressure vessel rated at 100PSIG to ASME Section I, Code M and

National Board registered.

•

UL listed, CSA certified, built to NEC.

•

All units are physically identical and have a packed shipping weight of 125 lbs.

•

Units are trimmed at 100PSIG as standard. 15PSIG trim also available.

•

Incoming water line pressure must be 10 PSIG greater than generator

operating pressure. If not, a motor/pump must be used. Specify Sussman

MBA38002A high pressure water feed motor/pump system.

•

When ordering specify Model No., KW, Volts/PH and motor/pump if required.

•

Water Connection is 1/4 NPT. Steam outlet is 1/2 NPT.

MBA Electric Steam Generator Installation, Operation and Maintenance Manual

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _______________________

2

Standard Features

Meeting Code Requirements

Component Identification Dimensional Information

201⁄2”

171⁄2”

177⁄8”

153⁄4”

Symbol Description

_____________________________

1Strainer

_____________________________

2 Water Solenoid

_____________________________

3Check Valve

_____________________________

4Drain Valve

_____________________________

5Steam Outlet

_____________________________

6Gauge Glass Assembly

_____________________________

7Safety Valve

_____________________________

8 Pressure Gauge

_____________________________

9Hi-Limit Pressure Control

_____________________________

10 Operating Pressure Control

_____________________________

11 Access Panel

_____________________________

12 On/Off Switch

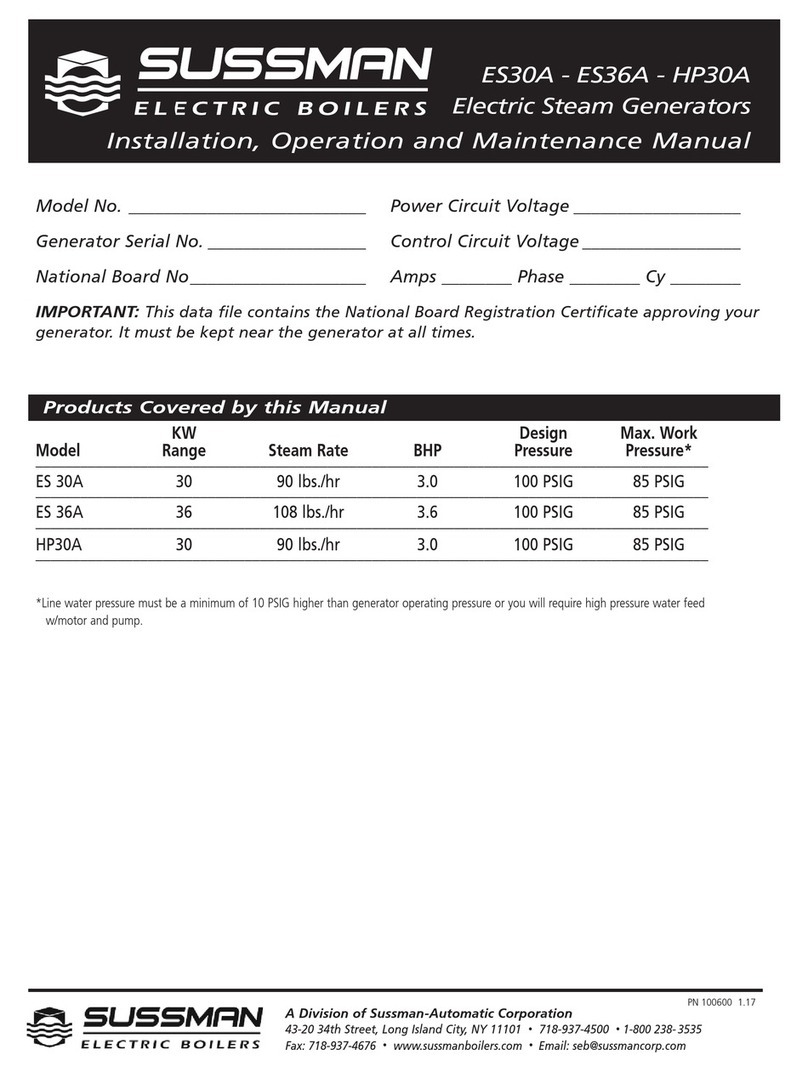

Model KW Volts PH Amps PPH

MBA3 3120,208,240 125, 15, 13 9

MBA6 6208,240,480 317, 15, 8 18

MBA9 9208,240,480 325, 22, 11 27

MBA12 12 208,240,480 334, 29, 15 36

MBA18 18 208,240,480 350, 44, 22 54

MBA20 20 208,240,480 356, 49, 25 60