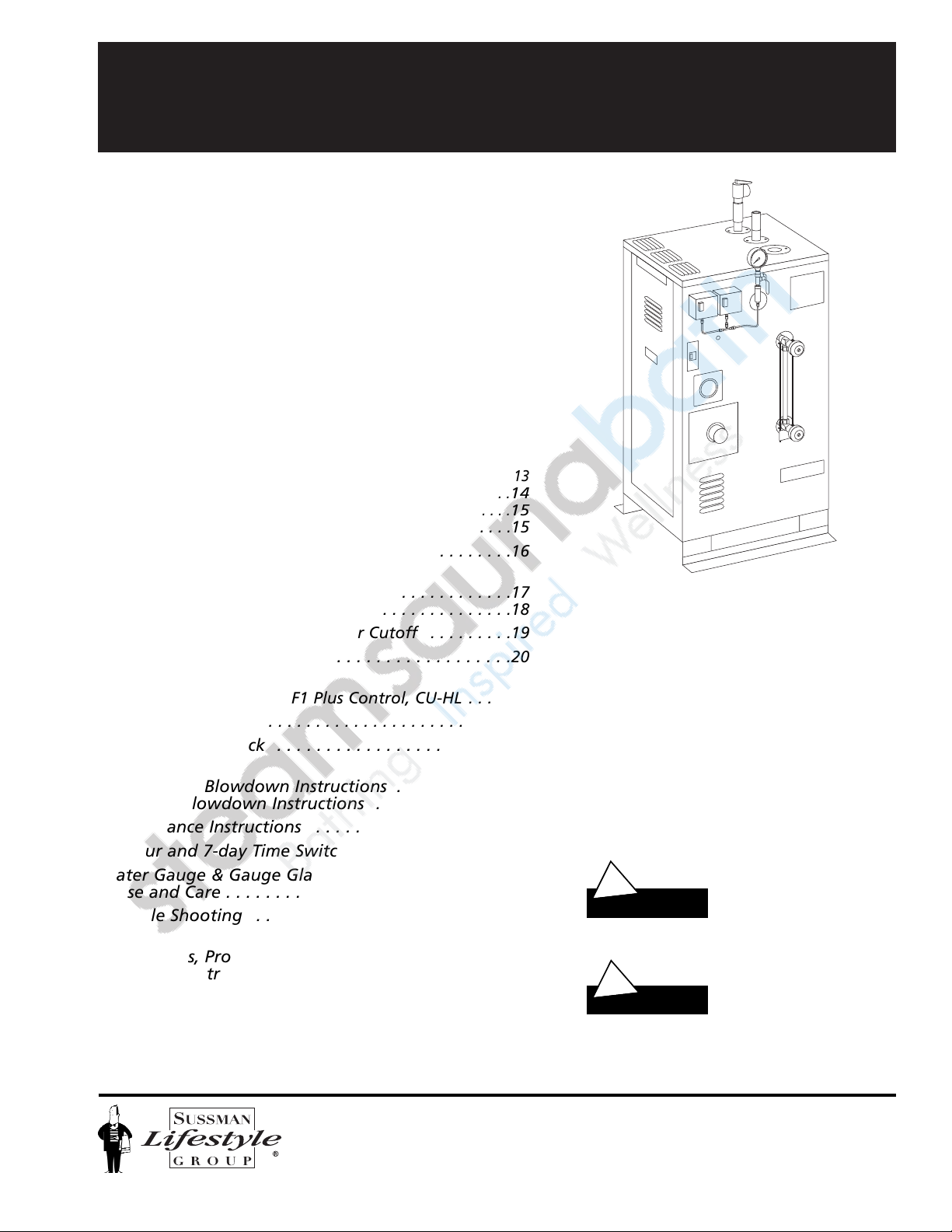

MrSteam CU Series

Installation, Operating & Maintenance Manual

5

Selecting a

MrSteam

CU Series Generator

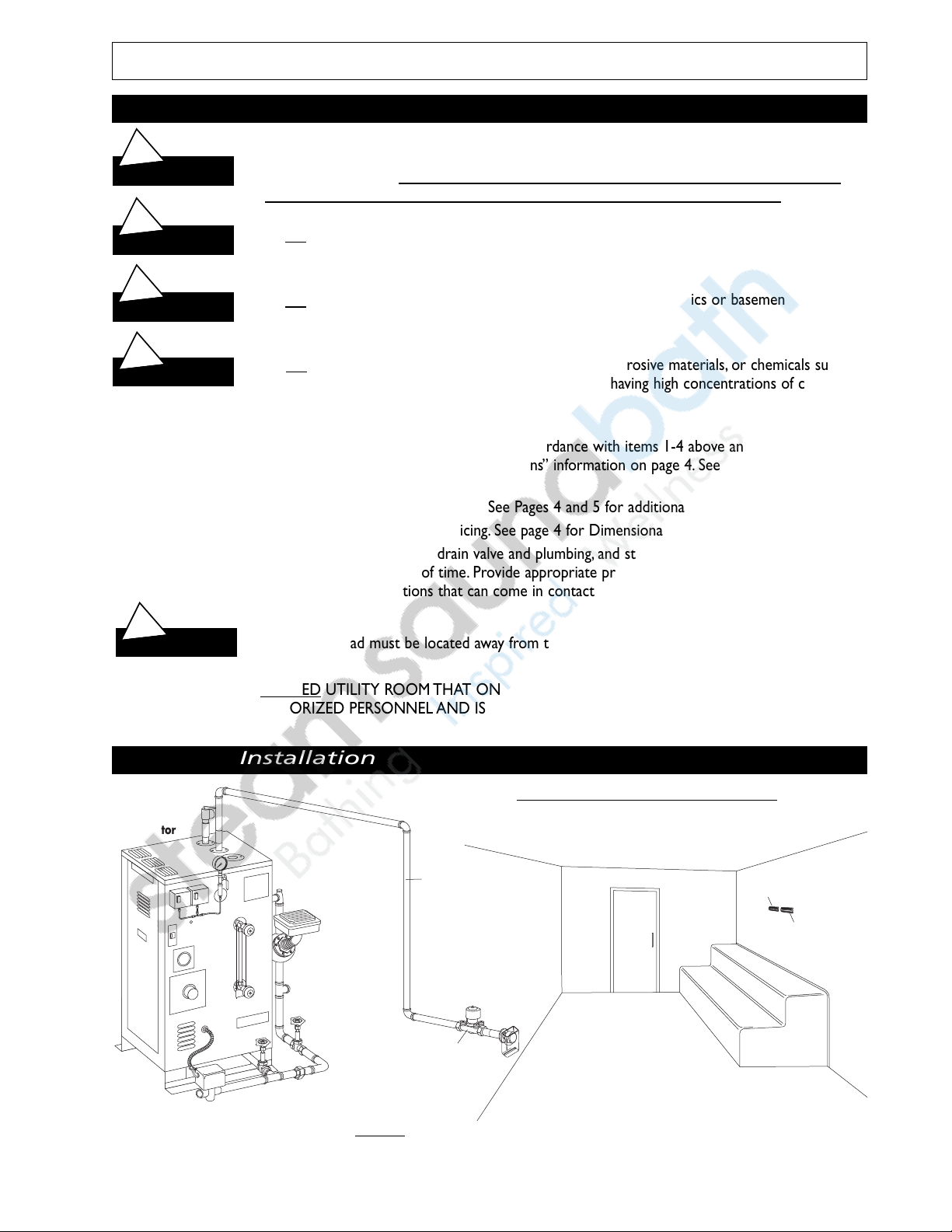

The resultant calculated volume of the steam room determines the Model CU steambath generator required. Steam

room size and additional constructional factors affect model selected.

A.

To determine the steam room volume first multiply Length x Width x Height of the steam room.

_______________________________________________________________________________________________

Example:

A steam room 8' x 9' x 8' = 576 Cu.Ft. (volume).

Select the MrSteam Model which is the next larger volume. In this example, Model CU-750 is the correct selection.

Example:

2 Steam rooms each 6' x 10' x 7' x 2 rooms = 840 Cu. Ft. (volume).

In this example, Model CU-1000 is the correct selection.

NOTE:

Insure adequate consideration is given to assure that the CU unit selected is not undersized for the room.

_______________________________________________________________________________________________

B. NOTE:

Certain additional factors effect the correct sizing of the steambath generator:

1.

Construction materials such as glass or glass block, natural marble or other stones: Increase volume.

2.

Piping runs longer than 25 feet from the steambath generator to the steam room: Increase volume.

3.

Exterior walls and outside windows: Increase volume.

4.

Steam room with interior height in excess of 8 feet: Increase volume

_______________________________________________________________________________________________

C.

IMPORTANT:

The above selection guidelines are recommendations only. Always consult with contractor

designer or architect. For general information, contact East Coast: 1-800-767-8326 or West Coast: 1-800-727-8326.

_______________________________________________________________________________________________

D.

IMPORTANT:

When specifying a CU Commercial Steambath generator the following is strongly recommend-

ed for best performance and user satisfaction.

1.

One CU steambath generator should service no more that two (2) steam rooms, each relatively similar in size and

construction.

2.

If two (2) steamrooms are serviced by one (1) CU generator, the combined resultant room volume of the two

rooms should not exceed 1000 cubic feet.

3.

Each room must be operated with the appropriate F1 Plus temperature control system inclusive of the room oper-

ating temperature control and the high-limit temperature control.

4.

In any case, the purchase and/or owner/operator must consult with a designer, architect, and/or consultant to

assure the proper specification of the steam generator.

Model No. KW Maximum* Water Inlet Steam Generator Dimensions (inches) Shipping

Room Volume Size NPT Outlet Size, NPT Width Length Height Wt.Lbs.

Cubic Feet

_______________________________

CU-360 9 400 1/2" 1" 20 20 38 250

____________________________________________________________________________________________________

CU-500 12 500 1/2" 1" 20 20 38 250

____________________________________________________________________________________________________

CU-750 18 750 1/2" 1" 20 20 38 250

____________________________________________________________________________________________________

CU-1000 24 1000 1/2" 1" 20 30 38 270

____________________________________________________________________________________________________

CU-1250 30 1250 1/2" 1" 20 30 38 290

____________________________________________________________________________________________________

CU-1400 36 1400 1/2" 1" 20 30 38 300

____________________________________________________________________________________________________

CU-2000 48 2000 1/2" 1" 24 33 44 330

____________________________________________________________________________________________________

CU-2500 60 2500 1/2" 1" 24 33 44 380

____________________________________________________________________________________________________

CU-3000 72 3000 1/2" 1" 24 33 44 390

____________________________________________________________________________________________________

CU-4500 108 4500 3/4" 1-1/2" 28 34 59 625

* After taking into consideration all factors affecting resultant steam room volume, including materials of construction, dis-

tance from generator to steam room, interior height of steam room ceiling, outside/exterior walls and windows etc., select

proper Model CU generator. Consult with architect, designer and contractor before making final selection.