I •

,

• r,

·.

.!

'··

-

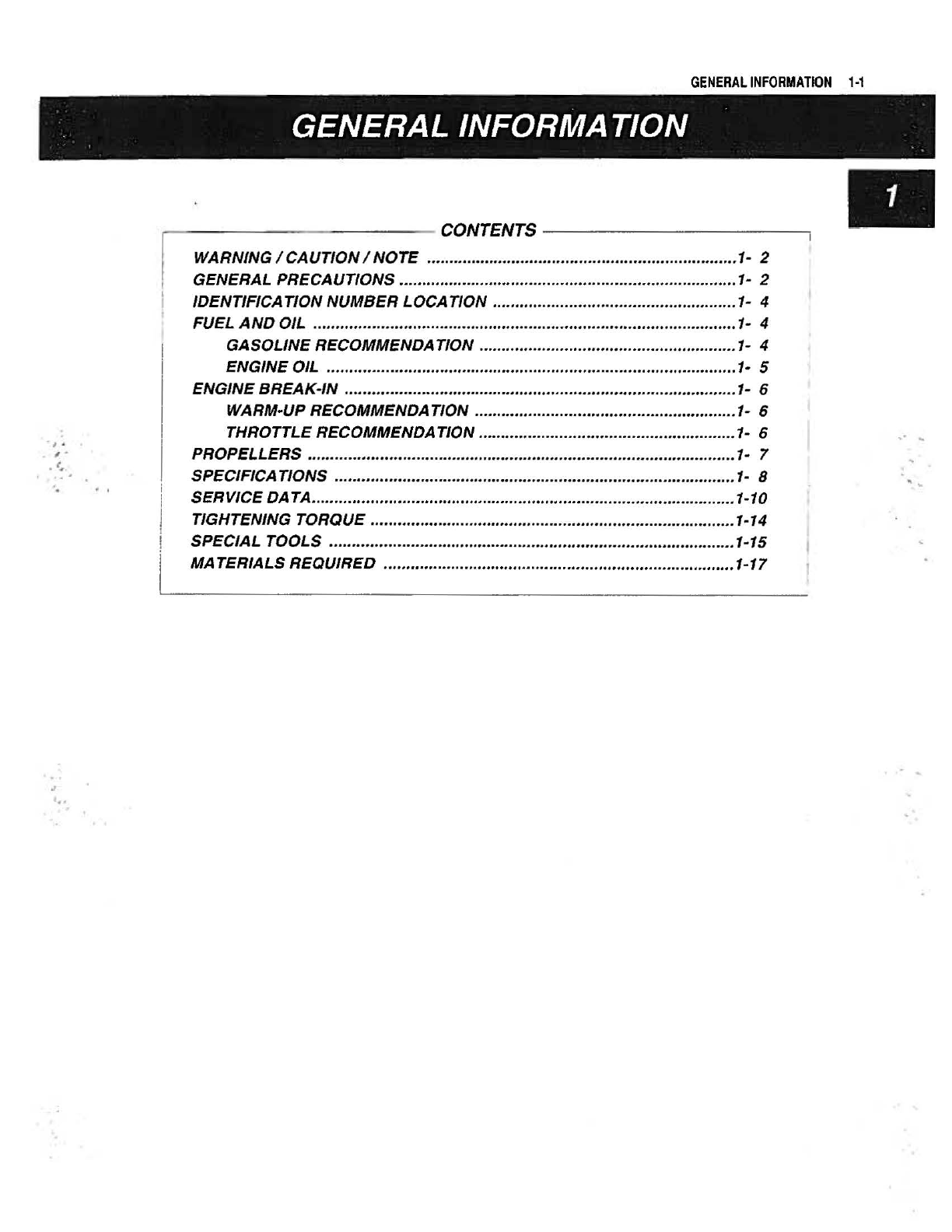

GENERAL

INFORMATION

1·1

GENERAL INFORMATION

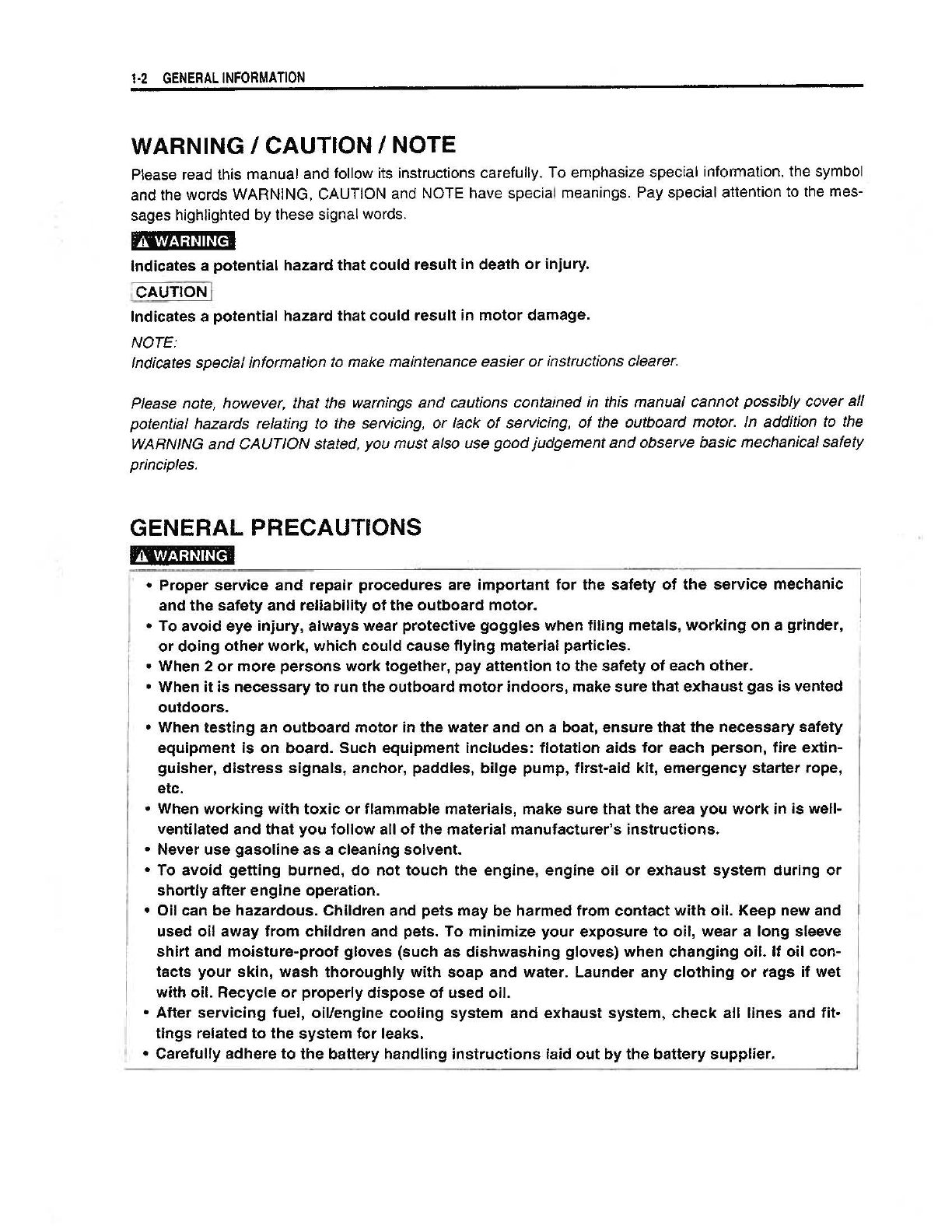

WARNING/CAUTION/NOTE

....................................... .............................. 1- 2

GENERAL PRECAUTIONS ............

..

.............

..

..............................

..

............

..

1-

2

IDENTIFICATION NUMBER LOCATION ......................................

..

............

..

1- 4

FUEL

AND

OIL .........

....

..

.......

..

.............

..

....

..

...................

..

............

..

.............. 1- 4

GASOLINE RECOMMENDATION ..........................................

..

............. 1- 4

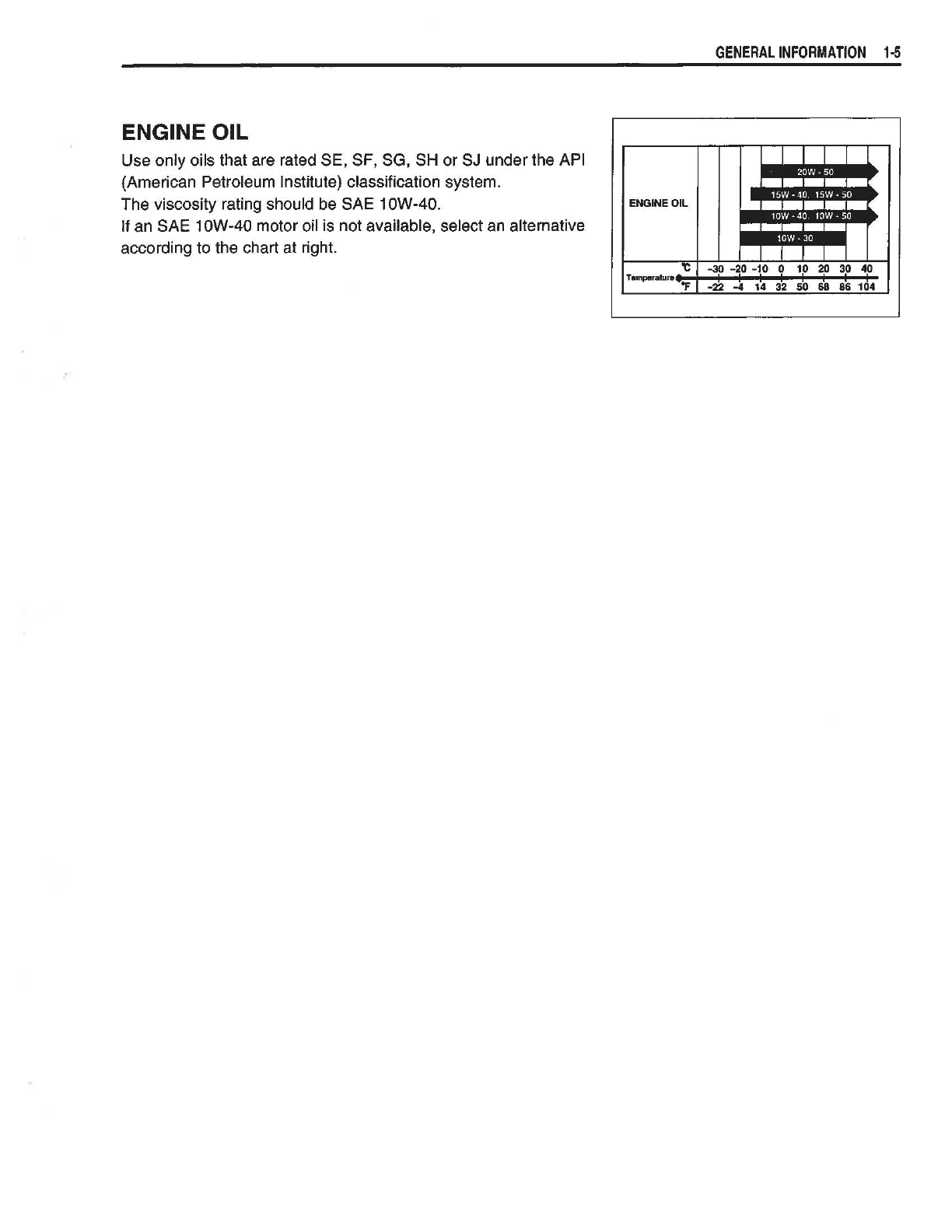

ENGINE OIL .............................................................

..

................ ............1· 5

ENGINE BREAK-IN .........................

..

............

..

................................

..

............ 1- 6

WARM-

UP

RECOMMENDATION ..........................................................

1-

6

THROTTLE RECOMMENDATION .........................................................1- 6

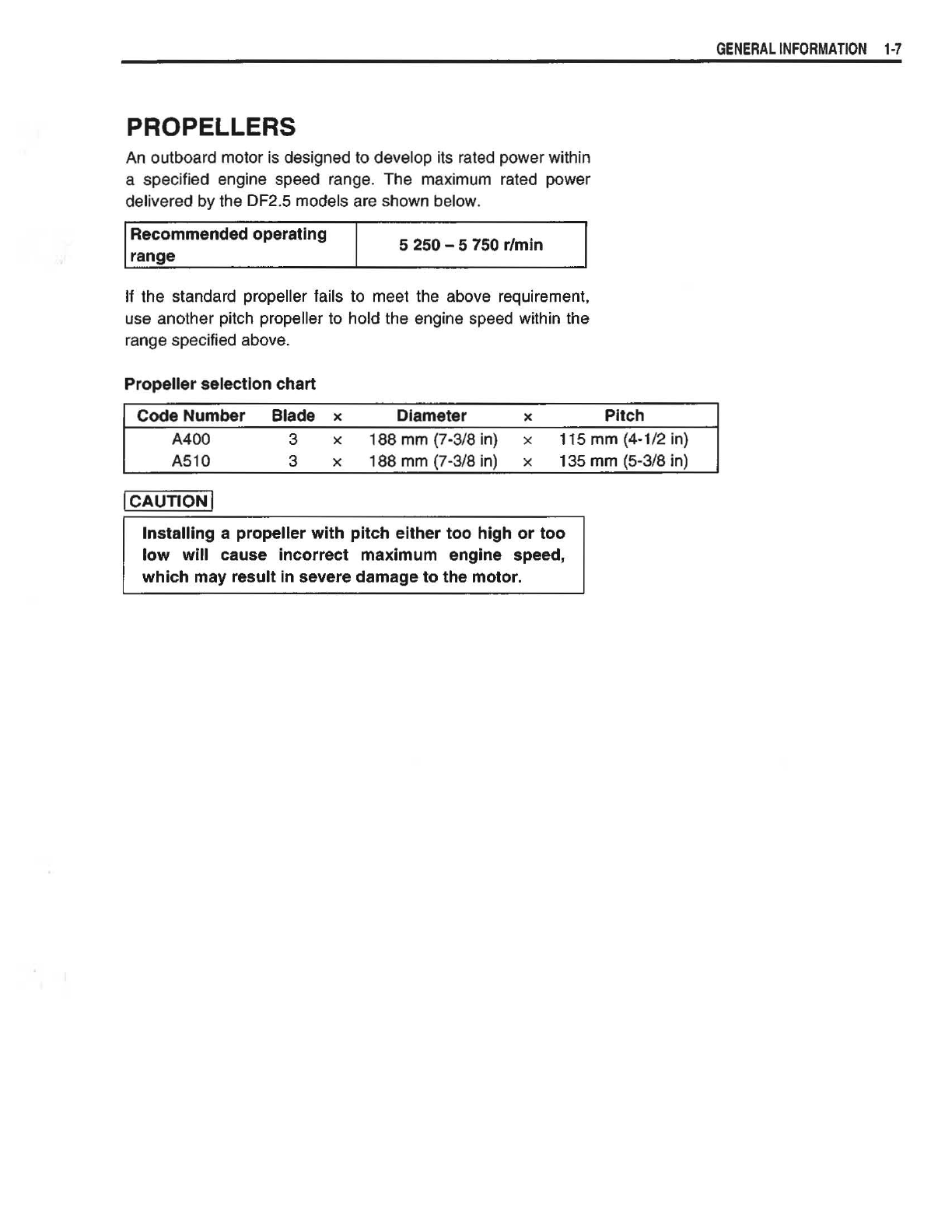

PROPELLERS

..

...........................

..

.................................................

..

............. 1- 7

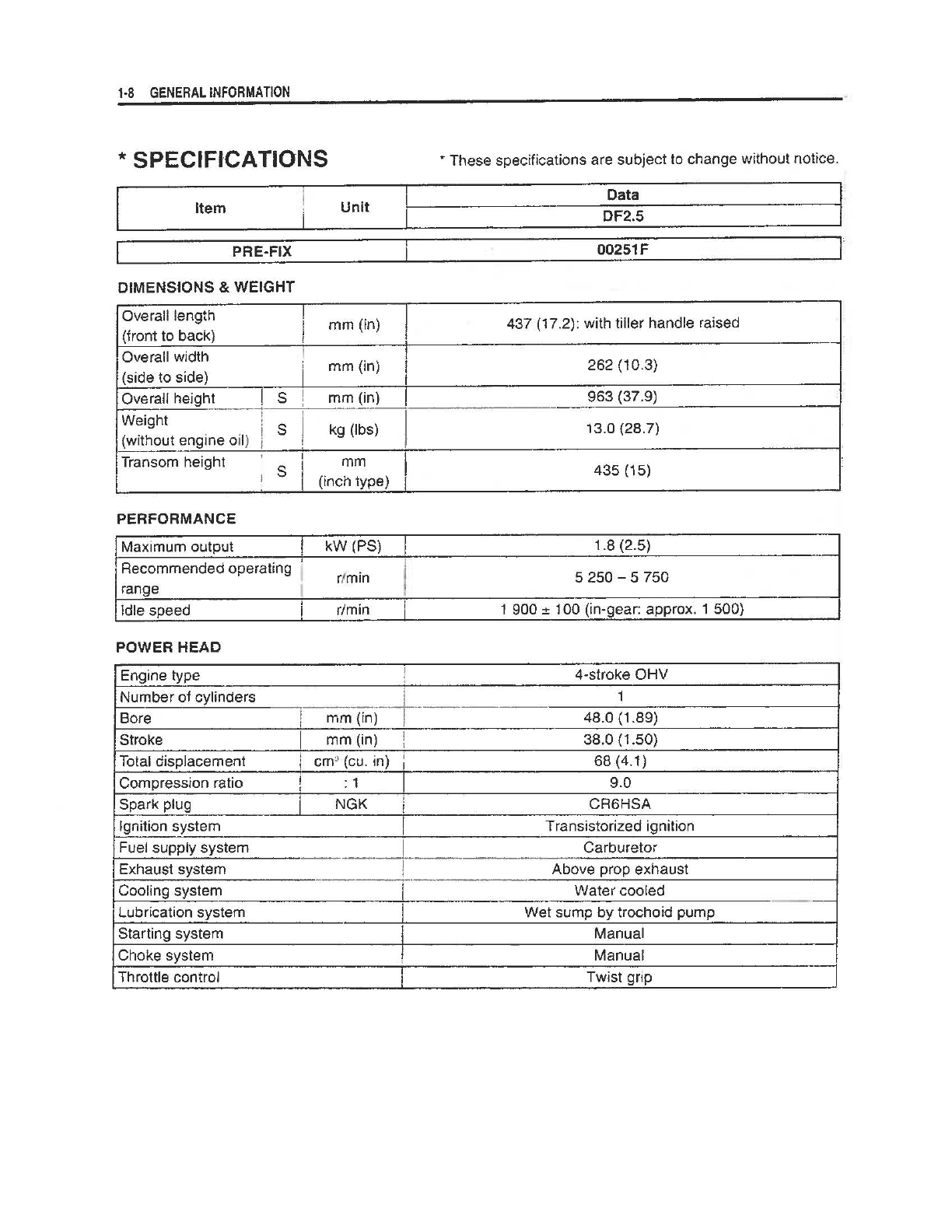

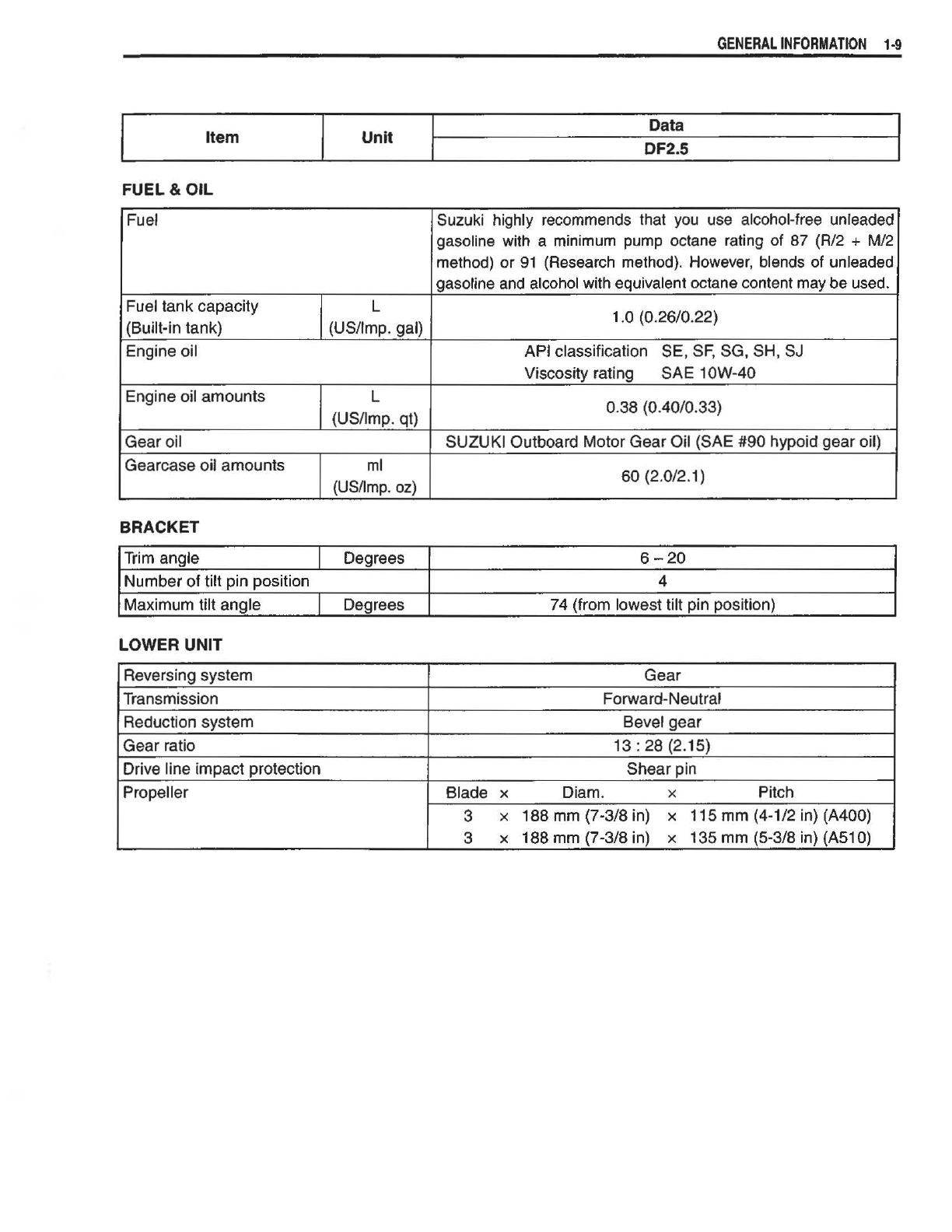

SPEC/FICA TIONS ........

..

................

..

..

..

......................................................... 1- 8

SERVICE DATA.............................................................................................. 1-10

TIGHTENING TORQUE

..

....................................................................

..

......... 1-14

SPECIAL TOOLS .............

..

...........................

...

...............................

..

....

..

..

..

..1-15

MATERIALS REQUIRED ...............

..

............................................

..

...............

1-17