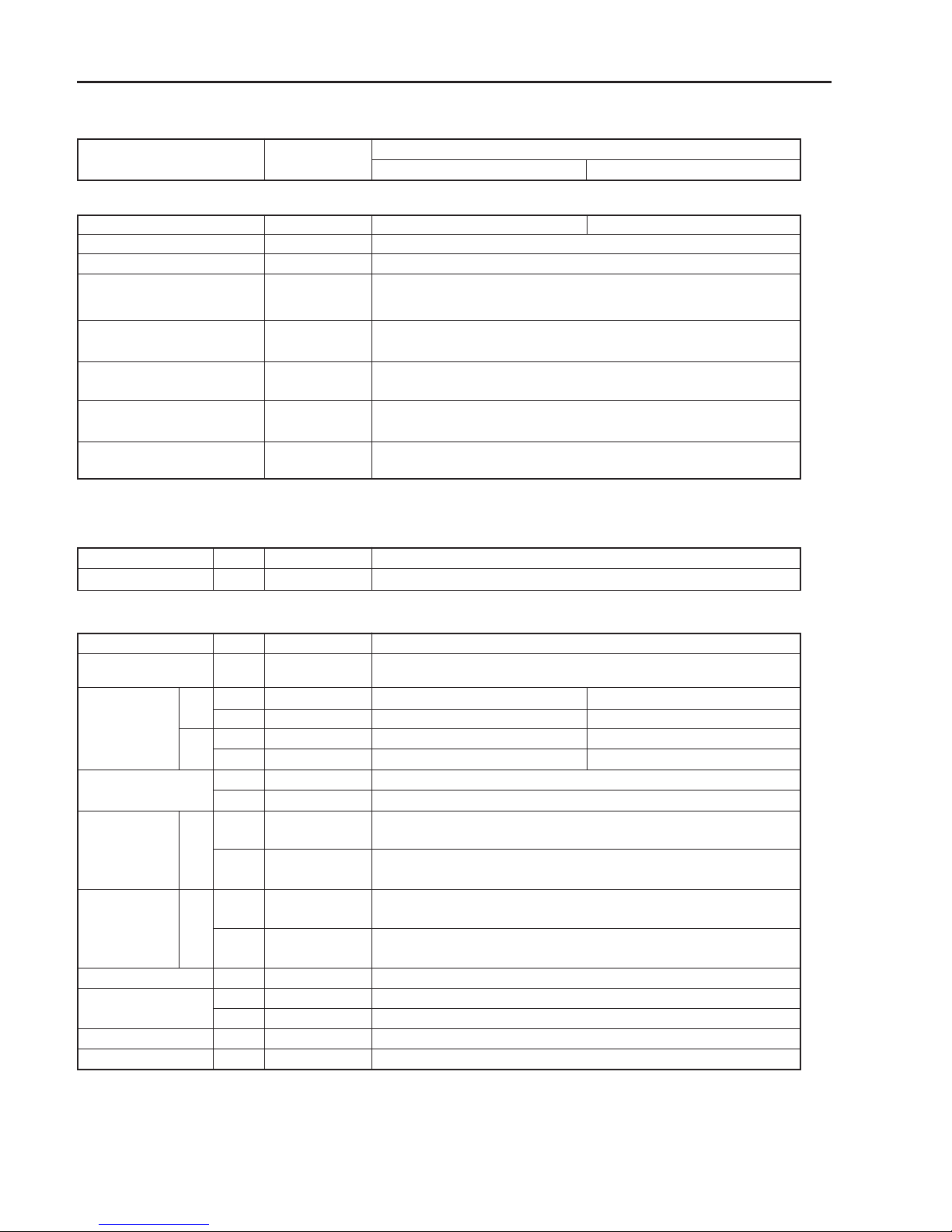

6 DF40/DF50 “K3”(‘03) model

CYLINDER/PISTON/PISTON RING

0.060 (0.0024)mm (in)

Limit

Piston ring

end gap

mm (in) 0.10 –0.25 (0.004 –0.010)

Cylinder distortion

Piston to cylinder

clearance

STD

Limit mm (in) 0.70 (0.028)

1st

mm (in) 0.25 –0.40 (0.010 –0.016)

STD

Limit mm (in) 1.00 (0.039)

2nd

Item Unit Data

DF40T/40QH DF50T/50WT/50WQH

mm (in) 0.020 –0.040 (0.0008 –0.0016)

STD

Limit mm (in) 0.100 (0.0039)

71.000 –71.020 (2.7953 –2.7961)mm (in)

STD

Cylinder bore

50 (2.0) from cylinder top surfacemm (in)

Cylinder measuring position

70.970 –70.990 (2.7941 –2.7949)mm (in)

STD

Piston skirt diameter

19 (0.7) from piston skirt endmm (in)

Piston measuring position

0.100 (0.0039)mm (in)

Limit

Cylinder bore wear

Piston ring

free end gap

mm (in) Approx. 7.5 (0.30)

STD

Limit mm (in) 6.0 (0.24)

1st

mm (in) Approx. 11.0 (0.43)

STD

Limit mm (in) 8.8 (0.35)

2nd

Piston ring

groove width

mm (in) 1.01 –1.03 (0.040 –0.041)

1st

mm (in) 1.01 –1.03 (0.040 –0.041)

mm (in) 2.01 –2.03 (0.079 –0.080)

2nd

Oil

Piston ring to

groove

clearance

mm (in) 0.02 –0.06 (0.001 –0.002)

STD

Limit mm (in) 0.10 (0.004)

1st

mm (in) 0.02 –0.06 (0.001 –0.002)

STD

Limit mm (in) 0.10 (0.004)

2nd

Piston ring

thickness

mm (in) 0.97 –0.99 (0.038 –0.039)

STD

STD mm (in) 0.97 –0.99 (0.038 –0.039)

1st

2nd

Pin clearance in

piston pin hole

mm (in) 0.006 –0.018 (0.0002 –0.0007)

STD

Limit mm (in) 0.040 (0.0016)

Piston pin outside

diameter

mm (in) 17.996 –18.000 (0.7085 –0.7087)

STD

Limit mm (in) 17.980 (0.7079)

Piston pin hole

diameter

mm (in) 18.006 –18.014 (0.7089 –0.7092)

STD

Limit mm (in) 18.040 (0.7102)

Pin clearance in

conrod small end

mm (in) 0.003 –0.015 (0.0001 –0.0006)

STD

Limit mm (in) 0.050 (0.0020)

Conrod small end

bore mm (in) 18.003 –18.011 (0.7088 –0.7091)STD

STD

STD

STD