- V -

©Sveaverken All rights reserved.

Sveaverken F100 Auto Steer System Hardware Installation Manual

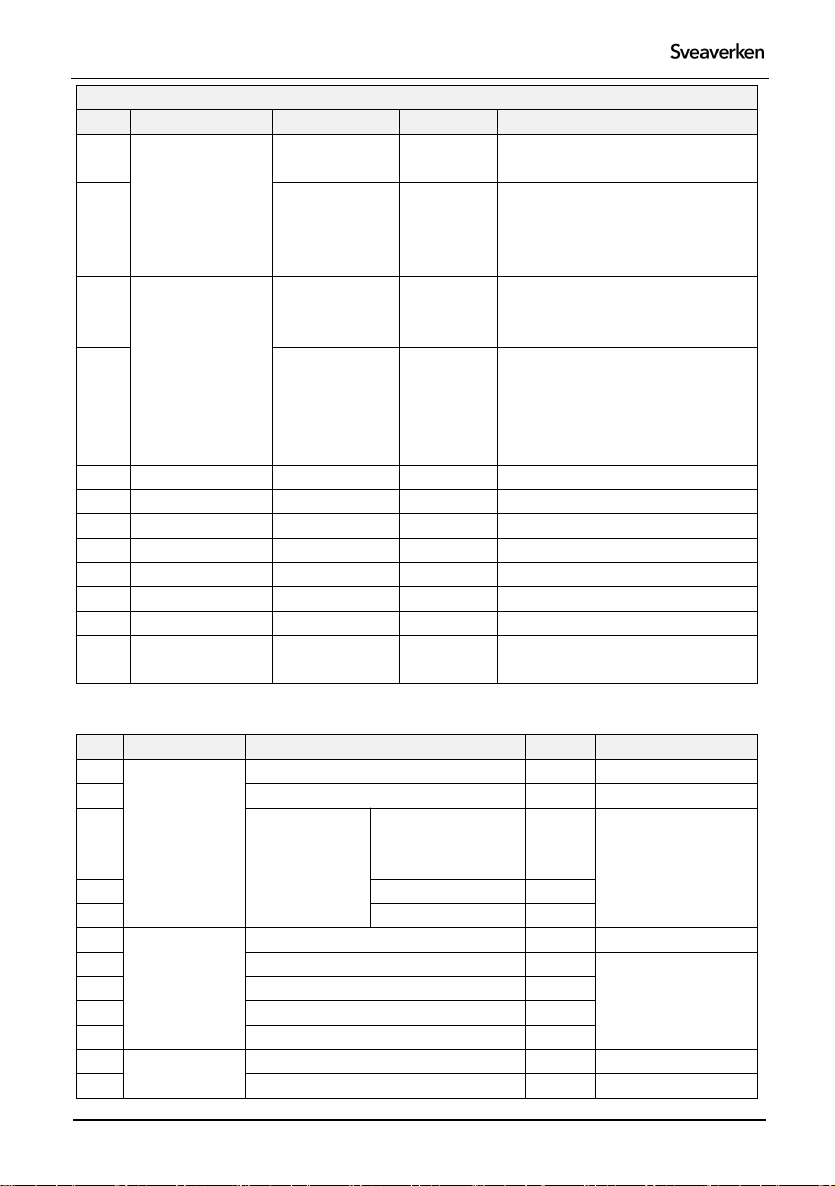

Contents

1 Product Introduction............................................................................................................................ 1

2 Preparation Before Installation......................................................................................................2

2.1 Safety Instructions.................................................................................................................2

2.1.1 Installation...................................................................................................................... 2

2.1.2 Disassembly........................................................................................................................ 2

2.1.3 Electrical Operations.................................................................................................... 2

2.2 Installation Requirements.....................................................................................................2

2.2.1 Installation Position.................................................................................................... 2

2.2.2 Temperature and Humidity.............................................................................................. 2

2.2.3 Air........................................................................................................................................ 3

2.2.4 Power Supply...................................................................................................................... 3

2.3 Installation Tools...................................................................................................................3

2.4 Unpacking and Inspection.......................................................................................................4

3 Inspection................................................................................................................................................ 6

3.1 Inspection Before Installation...........................................................................................6

3.2 Precautions.................................................................................................................................6

4 Installation............................................................................................................................................ 7

4.1 Installing the Electric Steering Wheel...........................................................................7

4.1.1 Components.......................................................................................................................... 7

4.1.2 Installation Steps.......................................................................................................... 8

4.2 Installing the GNSS Receiver.............................................................................................12

4.2.1 Components........................................................................................................................ 12

4.2.2 Installation Steps........................................................................................................ 12

4.3 Installing the Angle Sensor .............................................................................................14

4.3.1 Components........................................................................................................................ 14

4.3.2 Installation Steps........................................................................................................ 14

4.4 Installing the Radio Antenna.............................................................................................15

4.4.1 Components........................................................................................................................ 15

4.4.2 Installation Steps........................................................................................................ 15

4.5 Installing the Control Terminal.......................................................................................16

4.5.1 Components........................................................................................................................ 16

4.5.2 Installation Steps........................................................................................................ 16

4.6 Installing the SIM Card.......................................................................................................17

4.6.1 Components........................................................................................................................ 17

4.6.2 Installation Steps........................................................................................................ 18

4.7 Installing Wiring Harness...................................................................................................18

4.7.1 Components........................................................................................................................ 18

4.7.2 Installation Steps........................................................................................................ 19

5 System Commissioning.......................................................................................................................... 21