Index

1Summary..................................................................................................................................4

1.1 Product Advantages...............................................................................................................4

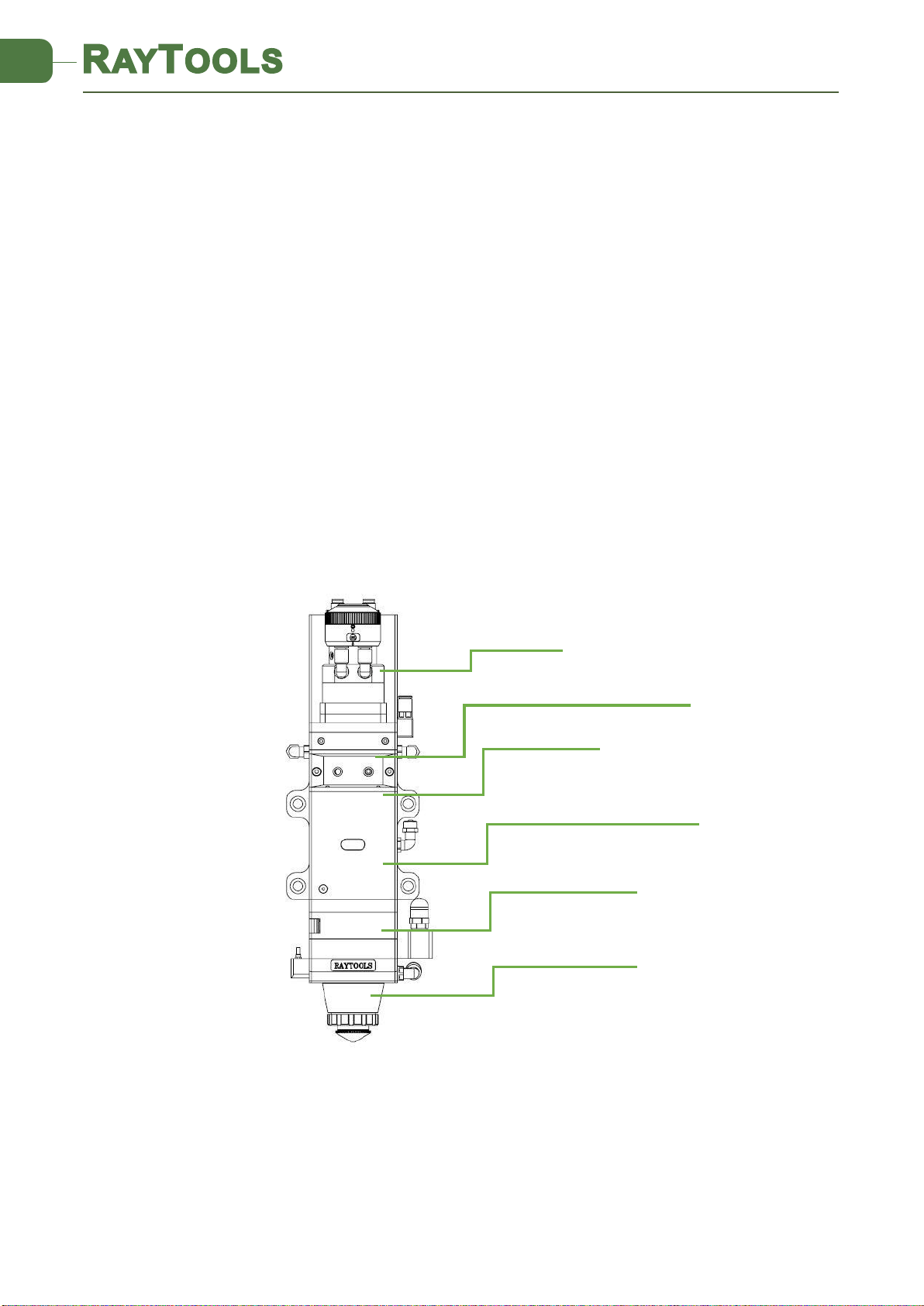

1.2 Structure & Function .............................................................................................................5

2Machinery Installation .............................................................................................................6

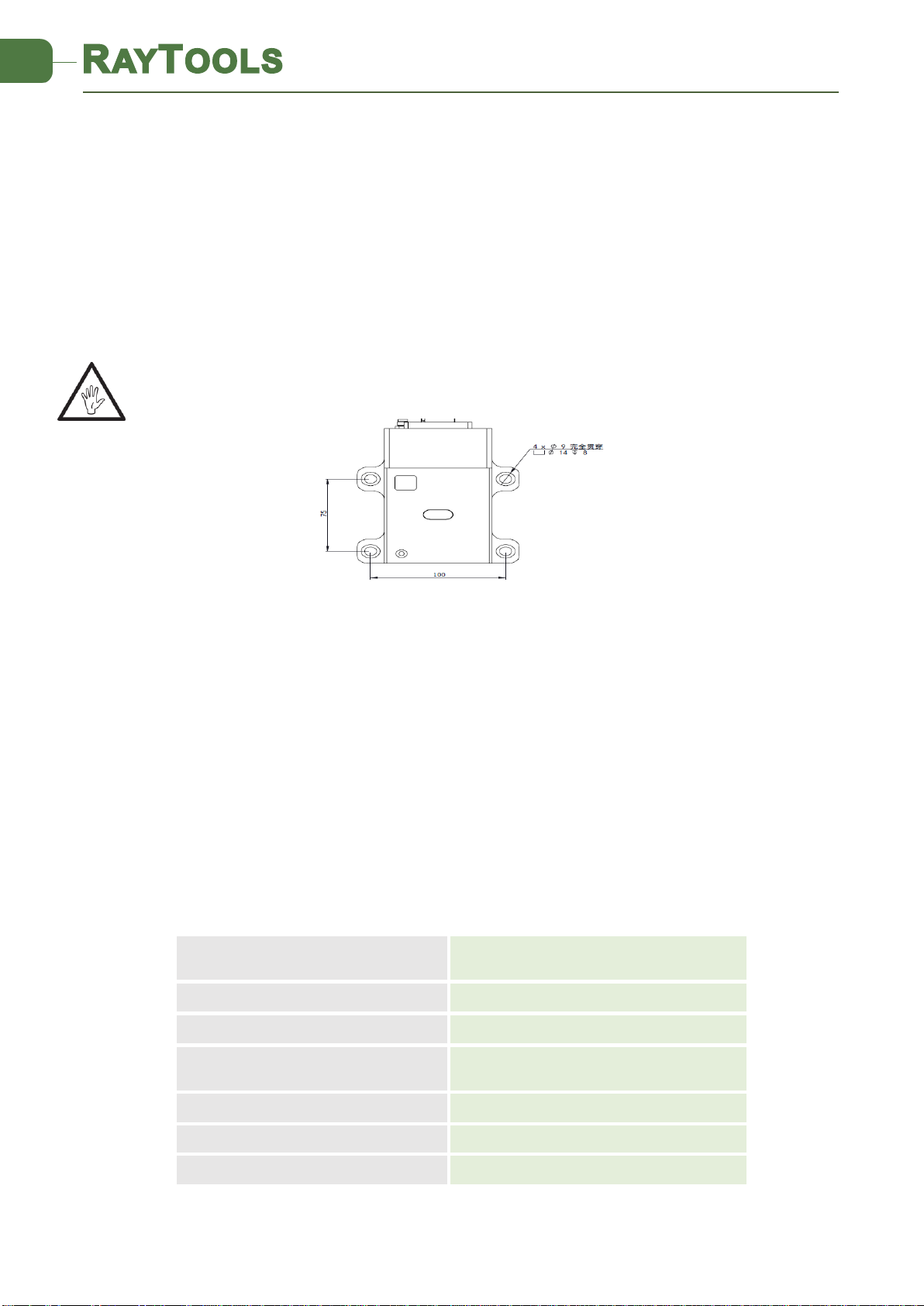

2.1 Mounting ...............................................................................................................................6

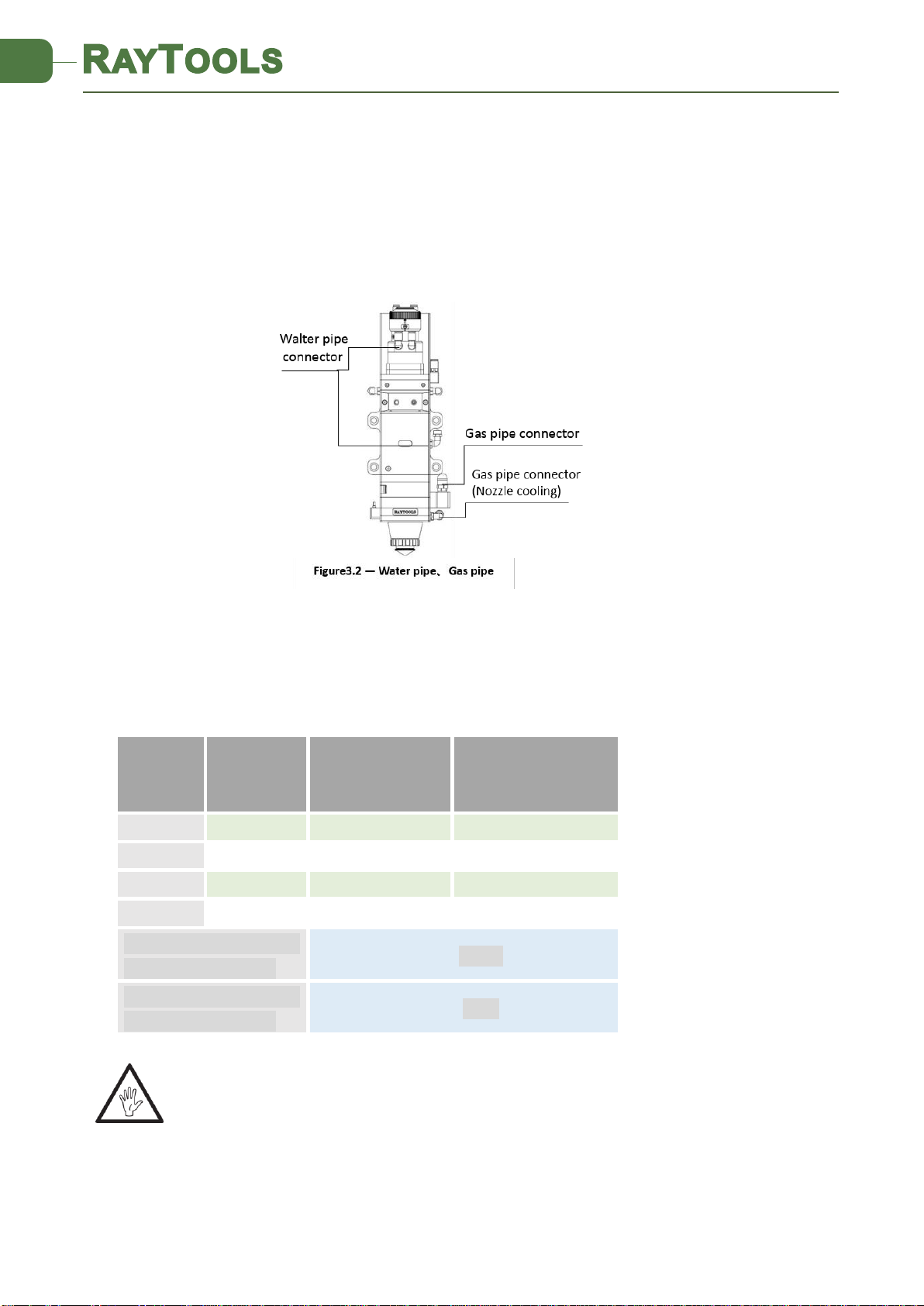

2.2 Connection of Water Pipe and Gas Pipe ...............................................................................6

2.2.1 Water-cooled interface.........................................................................................6

2.2.2 Assist gas interface ...............................................................................................7

2.3 Connection of Cutting Head Cable ........................................................................................8

2.3.1 Connection of Cutting Head and Cable ................................................................8

2.3.2 Cable connection and drive connection...............................................................8

2.4 Fiber Input Interface..............................................................................................................8

2.5 Fiber Insertion and Interface Direction Adjustment .............................................................9

3System Installation Commissioning .......................................................................................10

3.1 ETC_F100 Installation ..........................................................................................................10

3.1.1 Interface & Signal ...............................................................................................10

3.1.2 Wiring .................................................................................................................12

3.1.3 Dimension of ETC_F100......................................................................................13

1.1 Figure 4.3 —Overall size of ETC-F100 controller (unit: mm)...............................................13

3.1.4 Dimension of Drive.............................................................................................14

3.2 FSCUT (BC) with position mode...........................................................................................14

3.2.1 Wiring .................................................................................................................14

......................................................................................................................................15

3.2.2 Interface Operation ............................................................................................16

3.3 FSCUT (BC) with velocity mode ...........................................................................................16

3.3.1 Wiring .................................................................................................................16

3.3.2 Software settings................................................................................................17

3.3.3 Interface Operation ............................................................................................18

4Beam Adjustments and Focusing...........................................................................................18

4.1 Beam Adjustments (QBH interface) ....................................................................................18

4.2 The Focus Position Adjustment ...........................................................................................19

5Maintenance.......................................................................................................................... 20

5.1 Cleaning Lens.......................................................................................................................20

5.2 Removal and Installation of Lenses .....................................................................................20

5.2.1 Removal and Installation of Collimating Protective Lenses ...............................20

5.2.2 Removal and Installation of Collimating Lenses.................................................21

5.2.3 Removal and Installation of Collimating Lenses.................................................22

5.2.4 Removal and Installation of Focus Lenses..........................................................23