SWAN-MATIC C510 User manual

Need help with your Swan-Matic Torque Tester? Call 814-474-5561 or visit www.swanmatic.com

1 | P a g e

Need help with your Swan-Matic Torque Tester? Call 814-474-5561 or visit www.swanmatic.com

2 | P a g e

This manual is for the

C510A, C510B, C510C, C510D C510E and C510 DCI.

Contents

Bottling Line Control …………………………….…………………. 3

Correct Cap Tightening Procedure ………….…..……………….. 3

Maintenance ………………………………………..……………….… 4

The Swan-Matic C510D & C510DCI …………..…………………... 4

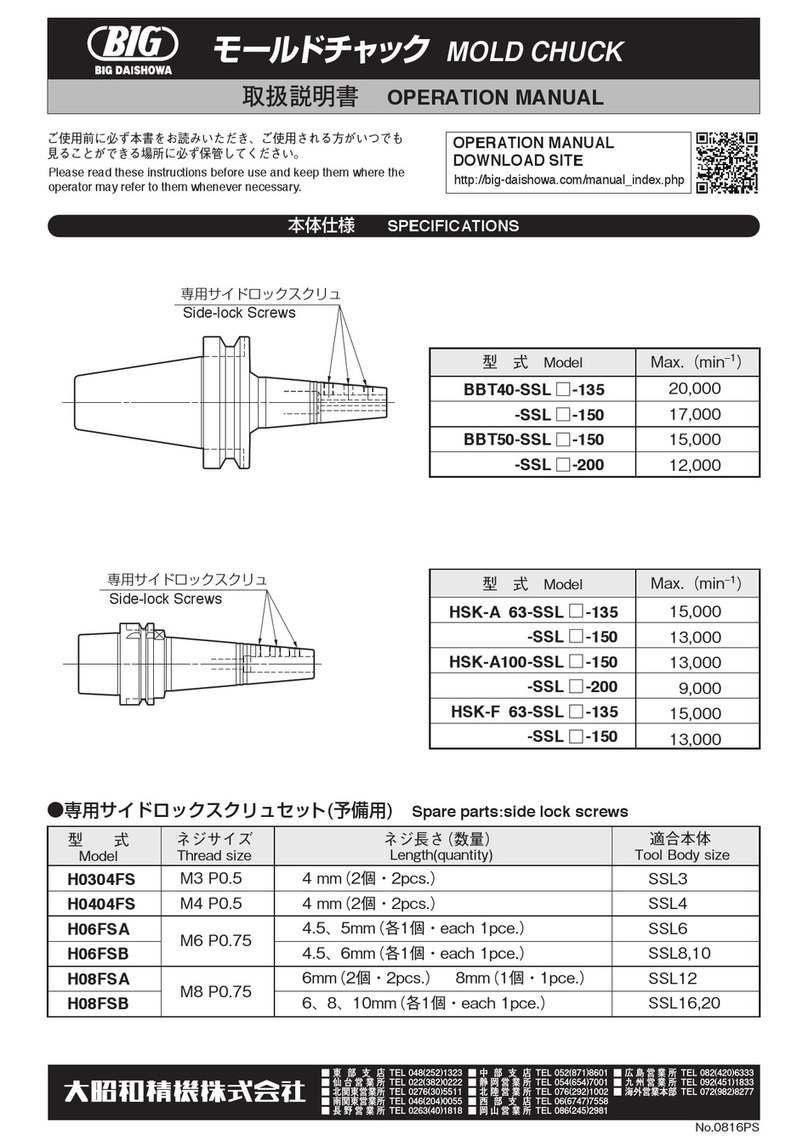

Spring Torque Tester - Parts List ……………..…………….…….. 7

Spring Torque Tester - Parts List Diagram ….…..…….………... 8

Digital Torque Tester - Parts List …………….….…….…………. 9

Digital Torque Tester - Parts List Diagram .............................… 10

C510 Calibration Kit …………………………………………………. 11

Need help with your Swan-Matic Torque Tester? Call 814-474-5561 or visit www.swanmatic.com

3 | P a g e

Bottling Line Control

Regular testing of packages from each bottling line makes certain correct tightness is maintained at all

times. Some bottlers make a check on each line each hour of operation.

Since capping machine chucks operate as independent units, it’s best to test packages from each chuck.

In routing checking, this may be accomplished by simply taking the requisite number of bottles from the

line.

To determine the amount of torque required to loosen the cap, follow the recommendations of your

closure manufacturer. Apply the torque gradually so as to read the maximum force used in loosening the

cap.

While at least five duplicate tests are necessary in order to establish a reliable average for any set of

conditions, adequate control of the line may be possible with fewer tests. For example, if testing of each

line is done once an hour, 1 to 3 tests from each chuck may be adequate to determine if adjustments are

needed. Experience with a specific operation can identify the amount and frequency of testing needed.

Correct Cap Tightness

Removal torque is affected by many factors other than how tightly the cap is applied. Such factors include

the style of caps and bottles used, type of liner, product being packed, and time after tightening and

conditions of storage. In other works, removal torque alone becomes a measure of how tightly the cap

was applied only when other factors are known and controlled.

The following procedure is recommended:

Select 10 bottles at random and apply a cap to each by hand, using an amount of torque estimated to be

correct for the case at hand or as indicated by the table on the following page. (In applying caps, bring the

torque up smoothly to the predetermined value and hold for approximately one second.) Then determine

and record removal torque for each of the 10 bottles. By comparing figures obtained in this method with

removal torque of packages from the line, it is possible to determine whether the capping machine is

applying caps at the required tightness.

Example: 10 duplicate bottles with 20-400 finish capped by hand using plastic closures and 10 inch

pounds torque gave removal torque values varying between 4 and 5 inch pounds. The same bottles

closed with duplicate caps using 15 inch pounds torque gave removal torques varying from 5 to 7 inch

pounds. If you need tightness equivalent to 10 to 15 inch pounds hand application, the capping machines

should be adjusted to give removal torques of 4 to 7 pounds. This procedure can also be measured in

Newton meters since these torque testers are calibrated in both inch pounds and Newton meters.

Since tightness obtained is a function not only of torque applied, but also of other factors such as head

pressure and the time cycle, figures obtained by the above process may not correspond to the exact

amount of torque actually applied by the capping machine.

In some instances (e.g. when packaging substances such as cough syrup), empty bottles should be

tested since some substances on the bottle finish will result in erratic figures which do not accurately

record performance of the capping machine.

Need help with your Swan-Matic Torque Tester? Call 814-474-5561 or visit www.swanmatic.com

4 | P a g e

CAUTION: Where removal torque is used as a measure of tightness of application, the figure should be

obtained within a few minutes of the time the cap is applied. If packages are allowed to stand for any

considerable time, removal torque may change markedly. Since removal torque is affected by time and

other factors, suggested tightness is not expressed directly in units of removal torque.

The closure on your container must be placed over the center of the table on your unit for proper testing.

If centering of closure on the table cannot be obtained by adjusting the bumpers and pins, special

brackets or fixtures are available.

Care of the Instrument

The Digital and Computer Interface Torque Testers are ruggedly built and should give long service

without maintenance or repair. None of the enclosed parts require oiling. An occasional drop of oil on the

screw thread of the chuck will keep it operating smoothly. The Digital and Computer Interface Torque

Testers should not be in areas where contamination of unit might occur. These units are not waterproof;

care should be used when cleaning.

Swan-Matic DIGITAL TORQUE TESTER C510D & DCI

Overview:

The Swan-Matic C510D & C510CDI Torque testers are used to test and measure applied torque. The unit

can display torque readings in inch pounds or Newton meters. The unit can display the highest torque in

either direction, the highest torque in both directions and real-time torque measurements. The unit will

display torque readings from 0.2 to 100 inch-pounds in the “RUN” mode and 0.1 to 100 inch pounds in the

“CAL” mode. A minus (-) sign on the LCD display indicates a “REMOVE” torque. When not in use, the unit

will automatically shut itself off after 30 seconds. The auto shut-off feature can be disabled. A positive tip

9 V.A.C. adapter (which should be purchased from Swan-Matic to insure proper voltage and connection)

or 9V alkaline battery can be used to power the unit. The unit will indicate a low battery/voltage with the

“LO BAT” indicator on the LCD display.

Operation:

This operational section assumes that all dipswitches are in the default position and the unit has been

initialized, calibrated and zeroed.

The default dipswitch settings are indicated in BOLD type.

RUN/CAL Selects run or calibration mode

IN*LBS/N*M Selects inch pound or Newton meter display

CWPOS/CWNEG Selects apply (pos) or remove (neg) for a clockwise torque

NORM/AUTO Selects normal or auto mode

SHDN/CONT Selects auto shut-off or continuous run mode

STD/ADV Selects standard or advanced communications mode

TERMS

An “APPLY” torque is in a clockwise direction.

A “REMOVE” torque is in a counter-clockwise direction.

A “PRESS” is a button press < 5 seconds.

A “HOLD” is a button hold > 5 seconds.

Need help with your Swan-Matic Torque Tester? Call 814-474-5561 or visit www.swanmatic.com

5 | P a g e

After power is applied, the operator should “PRESS” the “RESET” button to power up the unit. At

this point, the unit will display the highest torque applied in either direction. The torque will be displayed

until the “RESET” button is pressed again, at which time a new reading is initiated.(If other than “0” see

Auto Zero)

ERR Message:

The unit will need to be calibrated whenever it displays the “ERR” message. The “ERR” message is an

Error message and means the memory has been erased and the unit will need to be calibrated. In order

to calibrate this unit you will need a Swan-Matic Calibration Kit with instructions or the unit can be sent to

Swan-Matic for calibration.

Auto-Zero:

To “ZERO” the unit, the operator should remove any torque and “HOLD” the “RESET” switch and release

when the display starts counting down. The decimal point (.) will disappear to indicate the unit is in

“AUTO-ZERO” mode. During this time the chassis should not have any torque applied or be disturbed in

any way. The software will attempt to adjust the unit to the zero point. When the function is completed,

the decimal point (.) will return to the display and it should real “0.0”.

RUN/CAL Switch:

To operate the Digital Torque Tester the unit must be in Run mode. The Calibration mode is for

calibrating unit only. Proper weights and equipment are needed to calibrate this unit (See last page of this

manual)

CAUTION:

If the unit is left in “CAL” mode the operator can take real-time readings. In this mode, the operator should

not ”PRESS” or “HOLD” any button. If the operator should “PRESS” the “RESET” button, the unit will go

into auto-zero. If the operator should “HOLD” and “RESET” button, the unit will go into calibration. If any

buttons are pushed while the unit is in Calibration Mode, and the user is not calibrating the unit, the

Calibration values of the unit are void.

Dipswitches:

RUN/CAL

This switch will change the operating mode from the normal “RUN” mode to the “CAL” mode. The

“RESET” button has different functions in this mode as noted above.

INLBS/NM

This switch will change the display format from inch pounds to Newton meters.

CWPOS/CWNEG

This switch will change which side the (-) is on. CWPOS: the (-) sign will be on the remove side. CWNEG:

the (-) sign will be on the apply side. BE SURE TO HAVE THIS SWITCH IN THE CWPOS POSITION

WHEN CALIBRATING.

Need help with your Swan-Matic Torque Tester? Call 814-474-5561 or visit www.swanmatic.com

6 | P a g e

NORM/AUTO

This switch will change the readout mode. In the “NORM” mode the unit will display the highest torque

applied in either direction. In “AUTO” mode the display will alternate between and show both the highest

clockwise torque and the highest counter-clockwise torque.

SHDN/CONT

This switch will select whether the unit will automatically shut off after 30 seconds of inactivity or stay on

continuously. When the battery power, it is recommended the operator select “SHDN” mode to increase

the battery life.

STD/ADV

This switch has no function and should be left in the “STD” mode.

Care of the Instrument

The Digital and Computer Interface Torque Testers are ruggedly built and should give long service

without maintenance or repair. None of the enclosed parts require oiling. An occasional drop of oil on the

screw thread of the chuck will keep it operating smoothly. The Digital and Computer Interface Torque

Testers should not be in areas where contamination of unit might occur. These units are not waterproof;

care should be used when cleaning.

Need help with your Swan-Matic Torque Tester? Call 814-474-5561 or visit www.swanmatic.com

7 | P a g e

Spring Torque Tester – Parts List

Need help with your Swan-Matic Torque Tester? Call 814-474-5561 or visit www.swanmatic.com

8 | P a g e

Spring Torque Tester – Parts List Diagram

Need help with your Swan-Matic Torque Tester? Call 814-474-5561 or visit www.swanmatic.com

9 | P a g e

Digital Torque Tester – Parts List

Item Part No. Description Qty.

1 MR-1044 Bumper 4

2

MR

-

1043

Chuck Jaw Pin

4

3

MR

-

157

Chuck Screw

1

4 MR-1052 Chuck Jaw – R.H. 1

5

-----

¼

-

20x1/4” Cup Point Set Screw

2

6 ----- Round “U” #2x1/4” Drive Screw 4

7

D

-

1045

Direction Plate

1

8

D

-

1116

Plug

2

9 ----- 6-32x1/4” Round Head Machine Screw 8

10

MR

-

168

Sight Glass Gasket

1

11 D-167 Sight Glass (Lexan) 1

12

D

-

1114

Spring clip (Flush)

3

13 MR-1090 Handle 1

14

-----

8

-

32x3/8” Round Head Machine Screw

3

15

D

-

1115

Dial Spacer

2

16 D-0253 Electronic Board 1

17

-----

10

-

24x3/4” Socket Head Cap Screw

2

18 ----- 10-32x1/4” Cup Point Set Screw 1

19

MR

-

187

Instrument Knob

1

20

MR

-

160

Chuck Screw Spacer

1

21 ----- 10-24x3/8” Socket Head Cap Screw 2

22

MR

-

1072

Chuck Screw Bracket

1

23 MR-1057 Chuck Jaw – L.H. 1

24

D

-

230

Table

1

25

MR

-

184

Bearing (Top)

1

26 D32 Base 1

27

D

-

0258

Lever Arm Assembly

1

28 ----- 5/8-18 Nut 1

29

MR

-

185

Bearing (Bottom)

1

30

-----

Bearing Retaining Ring

1

31 MR-163 Washer 1

32

-----

5/16

-

18x1/2” Socket Head Cap Screw

1

33 D-260 Anchor Cap 1

34

-----

10

-

24x5/8” Socket

Head Cap Screw

3

35

D

-

1061

Flexure Arm

1

36 D-0240 Flexure Arm Assembly 1

37

-----

8

-

32x1/2” Socket Head Cap Screw

2

38 D-210 Bottom Plate 1

39

MR

-

1058

Rubber Foot

3

40 ----- 10-24x1/4” Round Head Machine Screw 6

41

D

-

168

Battery Holder

1

Need help with your Swan-Matic Torque Tester? Call 814-474-5561 or visit www.swanmatic.com

10 | P a g e

Digital Torque Tester

Need help with your Swan-Matic Torque Tester? Call 814-474-5561 or visit www.swanmatic.com

11 | P a g e

Table of contents

Other SWAN-MATIC Industrial Equipment manuals

Popular Industrial Equipment manuals by other brands

ABB

ABB TMAX XT XT6 ELECTRONIC Instruction handbook

KTR-Group

KTR-Group KTR-STOP S-A-F B Series Operating & assembly instructions

Baileigh Industrial

Baileigh Industrial SH-120250-HD Operator's manual

Cannon

Cannon CT-500 instruction & operation manual

Yamaha

Yamaha SIGMA-G5SII Service information

TriangleTube

TriangleTube PRESTIGE Excellence Series manual