SWAN-MATIC C300 User manual

1

Need help with your Swan-Matic Capper? Call 814-474-5561 or visit www.swanmatic.com

2

Need help with your Swan-Matic Capper? Call 814-474-5561 or visit www.swanmatic.com

Contents

Set-up & Torque Adjustment ………..…………………….. 3

Maintenance & Oil Seal Replacement ……………………. 4

Clutch Adjustment ………………………………………….. 5

Swan-Matic Capper Upgrade Options ….……………….. 6

Bottles and Vial Holders ……….………………………….. 7

Insert Sizing Cart and Cap Toque Spec Guide …………. 8

Inserts and Driver Shells …………………………………. 9

Frequently Asked Questions & Troubleshooting ….……. 10

Swan-Matic Warranty …..……………………………………….. 12

3

Need help with your Swan-Matic Capper? Call 814-474-5561 or visit www.swanmatic.com

Important Note: The shell and clutch should

always stop momentarily near the end of each

stroke when contact is made with the cap.

Excessive rotation after contact will cause

premature insert wear and damage to the cap.

Benchtop Capper Setup & Operation

Carefully unpack the Capper and any other associated equipment which may be

in the container and check for damage. Set the machine on a level surface and

remove the red fill plug located on the top left rear of the capper head. Add the two

quarts of Gear Oil ( P/N C095 supplied ) into the housing through the fill plug hole

(Figure 1.1). The capacity is two quarts Maximum.

Attach the proper sized driver shell with a rubber insert on the

lower end of the clutch and fasten it securely with the wrenches

provided (Figure 1.2). Connect power to the electric motor after

checking to make sure that the voltage marked on the nameplate is the same as the

power supply to which the capper will be connected. Run the capper for several

minutes at room temperature to thoroughly lubricate the mechanism. The capper

should run free and easy with no effort. If it does not, inspect the capper for shipping

damage.

Accurate alignment of the container cap to the insert and proper

height and torque settings are critical for optimum capping results.

Rotate the spindle until it reaches the bottom of its stroke. Place an

already capped container under the insert, adjusting the capper

height so that the container cap just contacts the insert. The height

of the capper head is adjusted by loosening the column locking handle

(Figure 1.3) and rotating the adjustment handle (Figure 1.4). With

the capped container directly under the insert, slide the backstop

assembly (Figure 1.5) up against the container and tighten. Rotate

the spindle until you can remove the container. Readjust the capper

height directly down 1/8 to 1/4 inch (depending on the dimensions of the cap and

container) to allow for over travel. Securely tighten the column locking handle.

TORQUE ADJUSTMENT

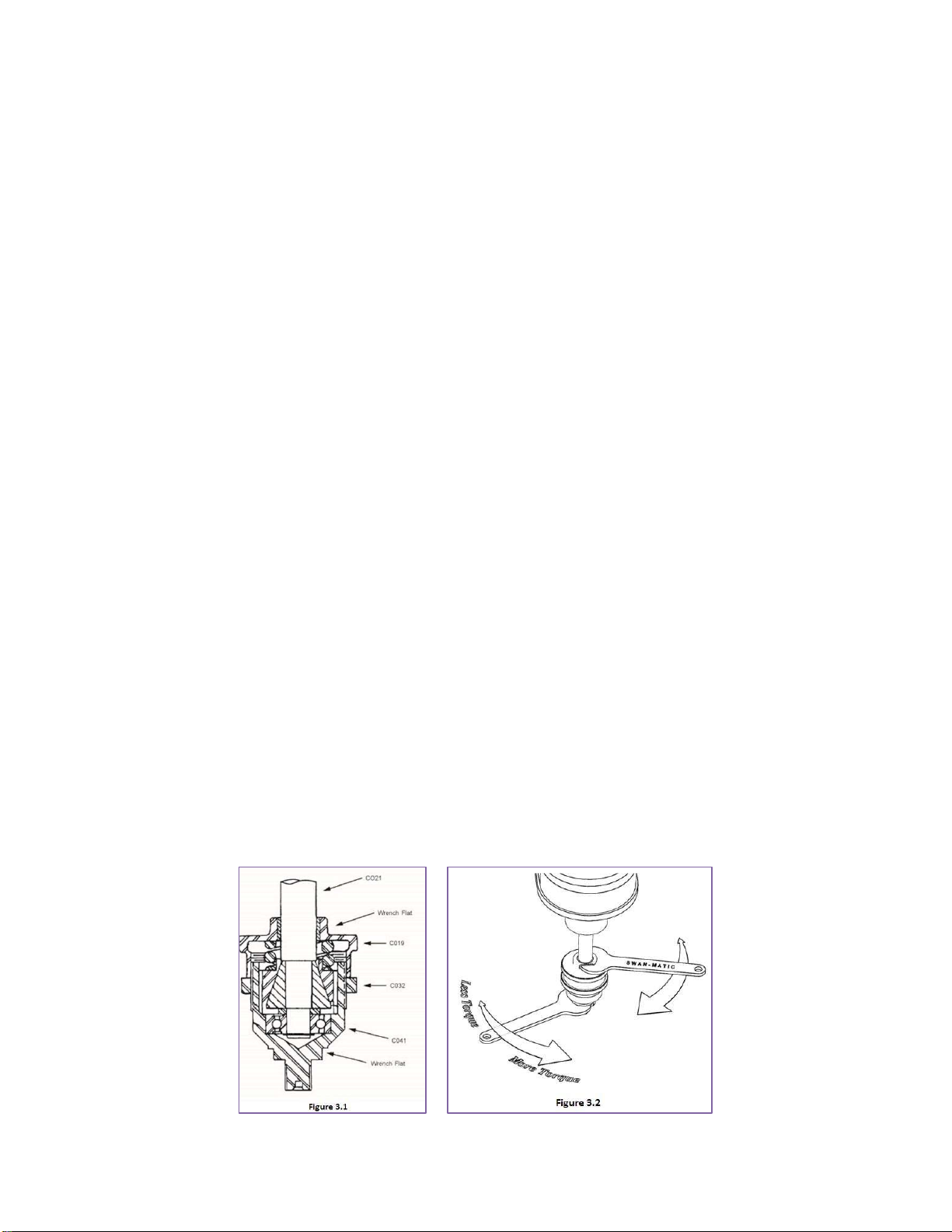

Adjust the clutch to set the capper for the desired torque. Hold the clutch cap (the

upper section), either by hand or by using the wrench supplied, and loosen the center

lock ring several turns (Figure 1.2). To increase the torque, turn the lower clutch section

into the clutch cap. To decrease the torque, back the lower section away from the clutch

cap (Figure 3.2). When the proper torque setting has been obtained, tighten the

center lock ring (C032) to retain the setting.

4

Need help with your Swan-Matic Capper? Call 814-474-5561 or visit www.swanmatic.com

MAINTENANCE OF YOUR SWAN-MATIC CAPPER

Periodic inspection of the oil level in the capper head housing is recommended to ensure that sufficient

lubrication is present. The high oil level should be 2 3/8” from the top edge of the housing. We recommend

E.P. SAE 80/90 weight gear oil (our P/N CO95) or equivalent. Approximately once every six months, it is

recommended that the clutch be disassembled, cleaned, and a good grade of lithium grease be

applied to the clutch lining to ensure long life and consistent torque. Excessive grease may seep out

of the clutch during operation.

REPLACING SPINDLE OIL SEAL

Always exercise extreme caution when removing the shaft seal to

ensure the shaft itself is not permanently marked or scored.

Unscrew and remove the lower section (C041) of the clutch

from the clutch cap (C019) (upper section). This will expose

a bearing (C065) on the lower end of the spindle shaft. This

bearing is held in place with a snap ring on the underside.

Remove the snap ring and press the bearing downward to

remove the bearing from the spindle.The fiber clutch cone

(C016) is held in place with a 3/16” diameter roll pin (C083).

In removing the roll pin, be sure to use a

punch of the proper diameter. Be careful to

support the spindle shaft (C021) to

assure that it is not damaged or bent.

After the roll pin is removed, the fiber cone

and the remaining clutch parts can be removed from the spindle. The factory

recommends draining the oil before removing the seal to prevent oil loss. The shaft

seal (C059D seen in Figure 2.1) can be removed by puncturing the metal section on the

lower side of the seal and then prying the seal out of its seat. The seal can also be

removed by drilling several small holes in the metal section of the seal, inserting sheet

metal screws part way in, and then prying the seal out.

After removing the seal from its seat, thoroughly clean the seat and shaft to remove

all oil and foreign material. Inspect the shaft for score marks which could cause

premature seal failure. If any marks cannot be removed by polishing the spindle,

replacement will be required. If this is the case, contact the factory for parts and the

proper procedure at 814-474-5561.

Before installing the new shaft seal, it is recommended that the lower end of the

spindle shaft be covered with a thin coating of oil. This will allow the shaft seal to

slide along the shaft without damaging the seal. The seal should be installed with

the open side up. Before seating the seal, apply a layer of gasket sealer (i.e.,

Permatex or equivalent - our P/N C111) to the seat. Gently tap the shaft seal into

place with a hammer and a block of wood or use the optional Swan-Matic tool

C059T (Figure 2.2). Make sure that the shaft seal is not misaligned and bound in the

casting before attempting to seat it. Replace the clutch in a reverse manner from

how it was removed. Lubricate the clutch face with a good grade of bearing grease.

5

Need help with your Swan-Matic Capper? Call 814-474-5561 or visit www.swanmatic.com

SWAN-MATIC CLUTCH ADJUSTMENT TO REDUCE

DRIVER INSERT WEAR

One of the main contributing factors to insert wear is improper clutch adjustment. Each Swan-Matic capper has an adjustable

clutch above the driver shell. Proper clutch torque adjustment is essential for an insert’s proper wear time. Another

contributing factor that shortens insert life is dirt, oil or any liquids. Wipe out the insert occasionally with isopropyl alcohol and a

clean cloth. Many solvents in the products will attack the rubber insert also, causing it to swell and then break off when used

for tightening. In some cases, this can be overcome with the use of a metallic serrated driver shell instead of rubber inserts.

For a quotation, send 12 sample caps and two bottles to the Swan-Matic Division at our Fairview address.

TO ADJUST THE CLUTCH:

Loosen the clutch lock nut (C032) two turns.

Standing in front of the machine with a wrench in each hand. Place your right hand wrench on the

wrench flat at the top of C019 and left right hand wrench on the wrench flats at the bottom on of

C041. Bring the two wrenches together to decrease torque and push them apart to increase

torque on your cap. (See fig. 3.2)

To increase the applied torque, tighten either wrench. To decrease the torque, loosen each wrench. (Clutch cap,

body and lock nut have right-hand threads.)

After each adjustment, hand tighten the clutch lock nut.

To adjust the height of the capping head to allow for different sized containers, stop the spindle at its lowest point

and lower the machine head until the insert touches a hand-tightened cap.

Tighten the column clamp (Page 1 Fig. 1.3) to hold the head in position.

Raise the spindle (C021) and the insert by turning on the machine, and then remove the container and cap.

Lower the machine head about 1/8 inch and retighten it.

Cycle the capper to tighten a cap onto a container. The shell and insert will stop rotating when the

cap is tight.

If the clutch does not stop rotating at the bottom of the stroke and the cap is tight, the insert will

wear rapidly. If this happens, loosen the clutch slightly. If you cannot see the shell stop, draw

vertical lines on it with a marker to help you see when the shell stops turning.

This manual suits for next models

1

Other SWAN-MATIC Industrial Equipment manuals