Operating hints Agricultural Knapsack Sprayer Model 289350

Dear Customer:

You have purchased one of the best knapsack sprayers on the market today. The Safety Hints from the label

on your sprayer are repeated here for your protection. We urge you to read and observe them.

FOR YOUR SAFETY AND COMFORT:

Before using, filling or cleaning any sprayer, read all parts of the operating hints.

Make sure to set up the sprayer exactly as described in printed operating hints, on reminder tags and/or

stickers.

Wear protective clothing, respirator, gloves, eye protection, etc., whenever using, filling or leaning the

sprayer.

Periodically re-grease the lid gasket, lid vent and piston sleeve where applicable.

To ensure good performance keep lid vent free of obstruction. Keep connections well thightened.

Service and replace worn parts as required. Make sure the hose loops freely without kinking.

Read and follow all instructions of chemical suppliers.

Do not mix chemical formula inside the sprayer. Use separate container and fill the sprayer from there.

Else - as when applying liquid fertilizers- add these after the water.

Always sift formula through a strainer. If there is none under the lid, use a screened funnel.

Never fill the sprayer with hot liquids. Max. 30°C = 85°F.

This sprayer is made for agrichemicals in their recommended water or oil solutions. Do not use caustic,

corrosive or flammable solutions.

Before cleaning or servicing the sprayer allow all pressure to scape. Do not store or transport the sprayer

under pressure.

Unless spraying is to be resumed within hours, drain chemical formula (dispose of it in proper fashion) after

use and wash the sprayer -including hose, lance and shut-off valve- with plenty of fresh water.

Never store formula in a sprayer for more than a few hours.

Use the sprayer only for jobs for which it was designed. If in doubt, ask your dealer.

Do not leave any sprayer in reach of children or persons not qualified to use it in correct fashion.

When not in use -and especially for prolonged storage- keep your sprayer in a protected place away from

direct solar heat.

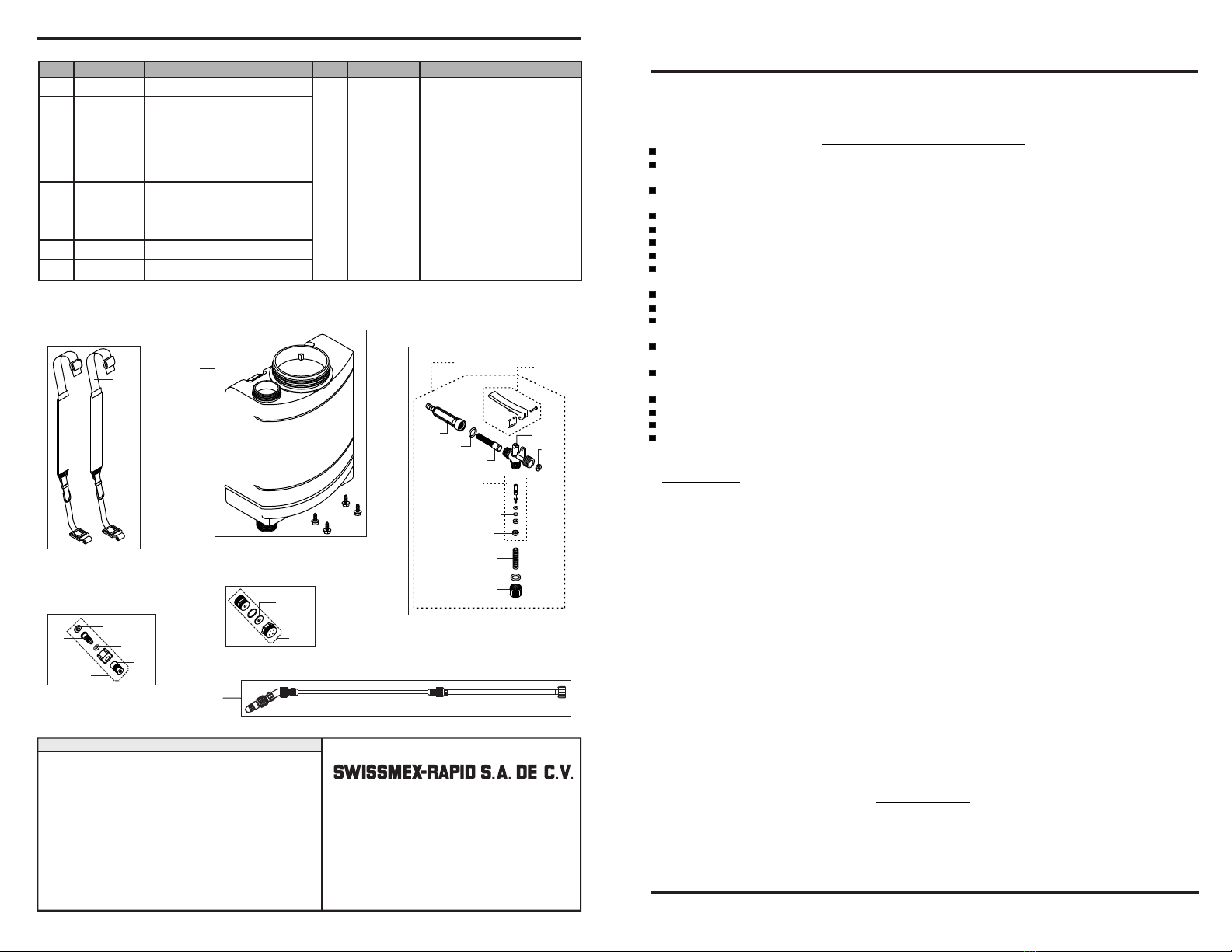

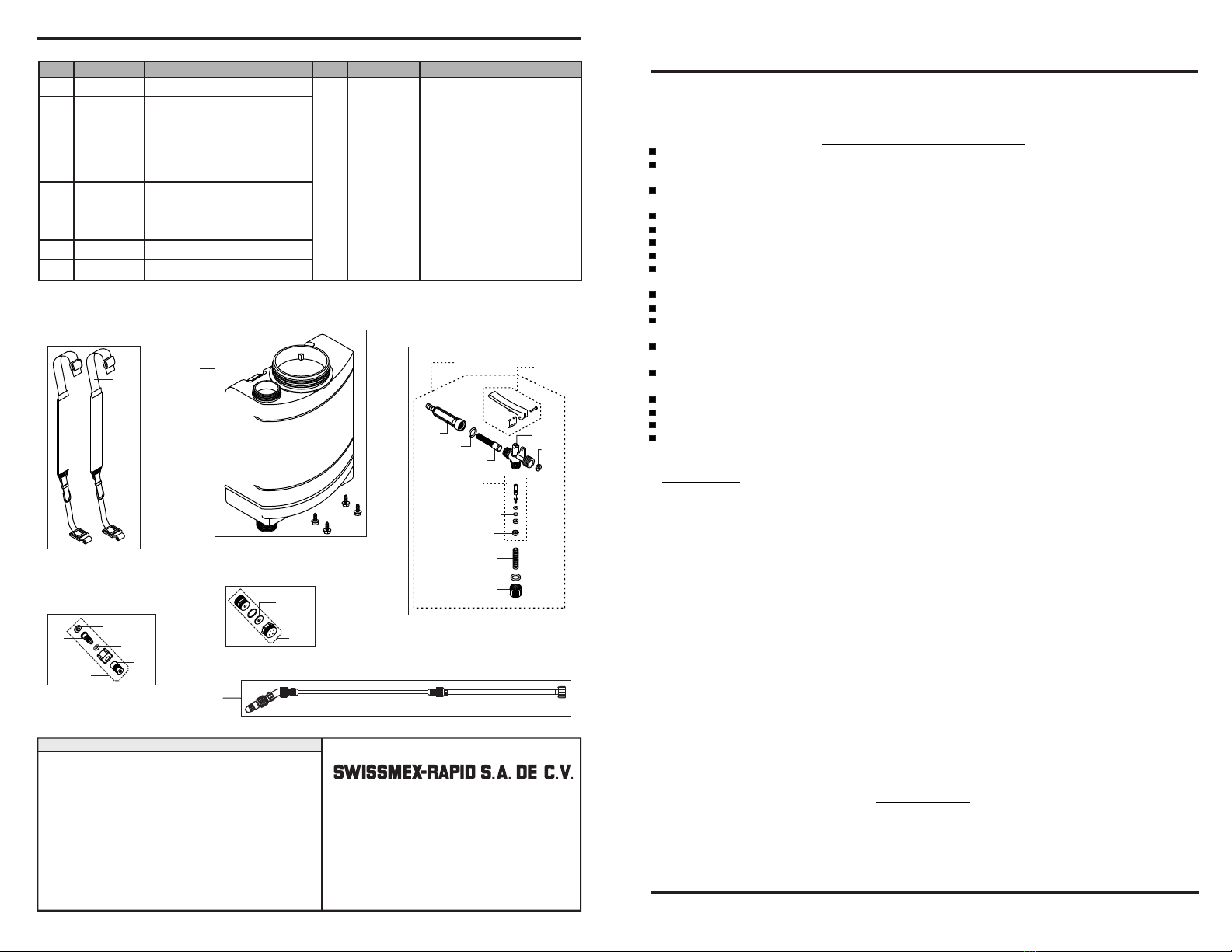

A S S E M B L Y

1. On opening the shipping box locate the following parts:

1 Pump handle

1 Pump lever

1 Spray lance

1 Tank lid (below the tank)

Inside the tank: 1 Strainer, 1 agitator, 1 cylinder holder nut, 1 cylinder, 1 pump holder nut, 1 bushing

guide, 1 felt ring, 1 pump tube with hose and shut-off valve, and a plastic bag with: 3 “C” lock pins, 1 cotter

pin, 3 small washers 1 big washer and 1 adjustable nozzle.

2. Take out the parts inside the tank; take the pump tube out carefully.

3. Lay down the sprayer over a table or a flat surface. Place the cylinder in the bottom opening of the tank

fix it firmly with the cylinder holder nut.

4. With the sprayer in vertical position, place the bushing guide and the pump holder nut with the felt ring on

the small tank opening. Grease the piston sleeve and the pumping tube and put it in the cylinder, guiding

carefully the piston sleeve to avoid damages. Tighten the pump holder nut.

5. Insert the pump lever in the pump tube placing a small washer on each side and fix it with an “C” lock pins.

6. Pass the pump handle through the holes on the base (the grip should be at the same side of the pump

lever). Fix the pump handle to the pump lever with a small washer and an “C” pin. On the other end of the

base fix the handle with a big washer and a cotter pin.

7. Attach the nozzle to the spray lance. Manually, tighten slightly.

8. Attach the spray lance to the shut-off valve and tighten it manually. Please check that the gasket is in

its place.

9. Attach the agitator to the pump tube.

O P E R A T I O N

(see section For Your Comfort and Safety)

Bear in mind that rubber parts on modern sprayer-e.g. piston sleeves, O´rings -resist virtually any

agrichemical. Yet improper use (formulas in greater-than-normal concentration, strong industrial solvents not

commonly known and/or used at the time of manufacture) may cause even the best materials to deform or

wear out prematurely. If this ever happens, call your supplier for support.

BN289350-1116E/EX Rev.03

Litho´d in México

Fax (474) 7420856

“ (474) 7424185

(474) 7412200

“ (474) 7412201

www.swissmex.com

Calle Swissmex No. 500

Col. Las Ceibas,

47440 Lagos de Moreno

Jalisco, México

58G

PADDED CARRYING

STRAP

FACTORY-INSTALLED UPGRADE OPTIONS

56

56a

56b

56c

56d

56G

57a

57b

57G

E803-092

E803-114

E803-083

E803-090

E803-087

E803-092-C

E219-134

E219-133

E219-610-C

55G E219-236-C Telescopic spray lance

58G

59

E501-230-C

E289-105

Padded carrying strap ass´y

Blue tank

Nozzle body

Gasket - N

O´ring

Nozzle nut (2pcs)

Nozzle cap

Nozzle body ass´y

Hi-volume nozzle gasket

Hi-volume nozzle nut

Hi-volume nzzle 11/16” trhead

aluminum

60

60a

60b

60c

60d

60e

60f

60g

60h

60i

60G

60G1

60G2

E807-173

E807-075

E803-060

E807-074

E803-114

E803-068

E803-063

E803-065

E803-067

E803-164

E807-075-C

E803-072-C

E803-067-C

Valve body

Filter housing

O´ring

Filter insert

Gasket - N

O´ring - V (2pcs)

Pin gasket - N

Metal support

Plunger spring

Cap

Shut-off valve

ass´y

Valve lever ass´y

Plunger ass´y

Part Part

Code Code

Description Description

SPARE PARTS LIST

60G1

60

60d

60f

65a

60b

60b

60c

60e

60g

60h

60i

60G2

60G

SHUT-OFF VALVE

WITH BARB HOSE

HI-VOLUME

NOZZLE

57G

57a

57b

56a

56

56c 56d

56b

56G

ADJUSTABLE BRASS

NOZZLE

55G

TELESCOPIC SPRAY LANCE

Please note that marked "=" have standard

ORANGE color. Unless a parts order states

otherwise they will be supplied in this standard

color.

For practical time-saving accessories, special

nozzle tips etc. please refer to spec sheet

“OPTIONAL SWISSMEX-RAPID

ACCESSORIES”.

In the interest of continued technologic progress

specifications are subject to change without

notice.

NOTE:

59

BLUE TANK