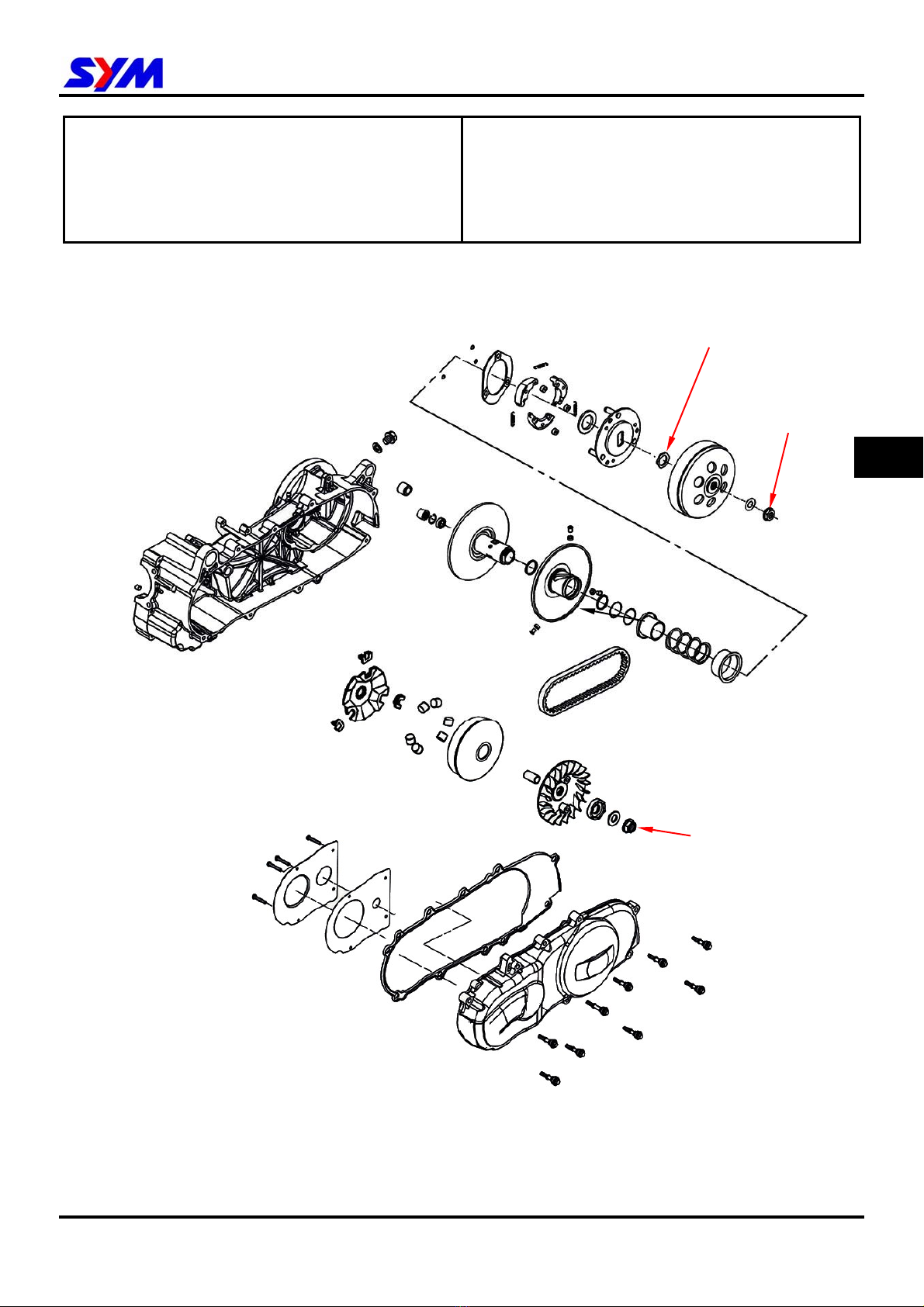

10. V-BELT DRIVING SYSTEM/KICK STARTER

10-2

Maintenance Description

Precautions in Operation

General Information

yDrive face, clutch outer, and driven pulley can be serviced on the motorcycle.

yDriving belt and driving pulley must be free of grease.

Specification Unit:mm

Item Standard value (mm) Limit (mm)

Driving belt width 19.500~20.500 18.500

ID of drive face boss 23.989~24.052 24.060

OD of drive face 23.960~23.974 23.940

OD of roller 17.920~18.080 17.400

ID of clutch outer 125.000~125.200 125.500

Thickness of clutch weight 4.000~4.100 1.200

Free length of driven pulley spring 168.900 163.700

OD of driven pulley 43.65~43.85 43.800

ID of drive face 39.000~39.025 39.060

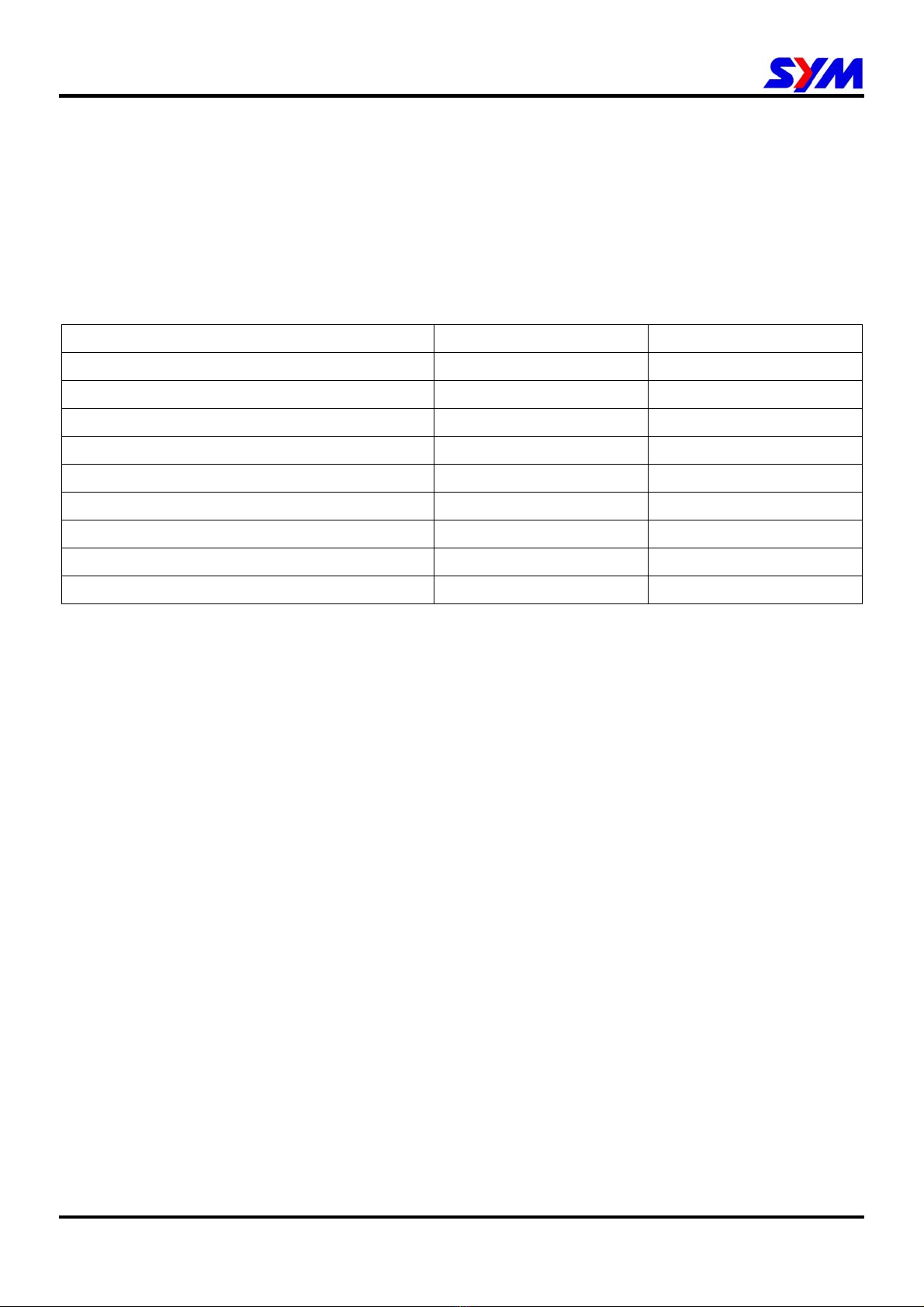

Torque value

yDriven face nut: 5.0~6.0kgf-m

yClutch outer nut: 5.0~6.0kgf-m

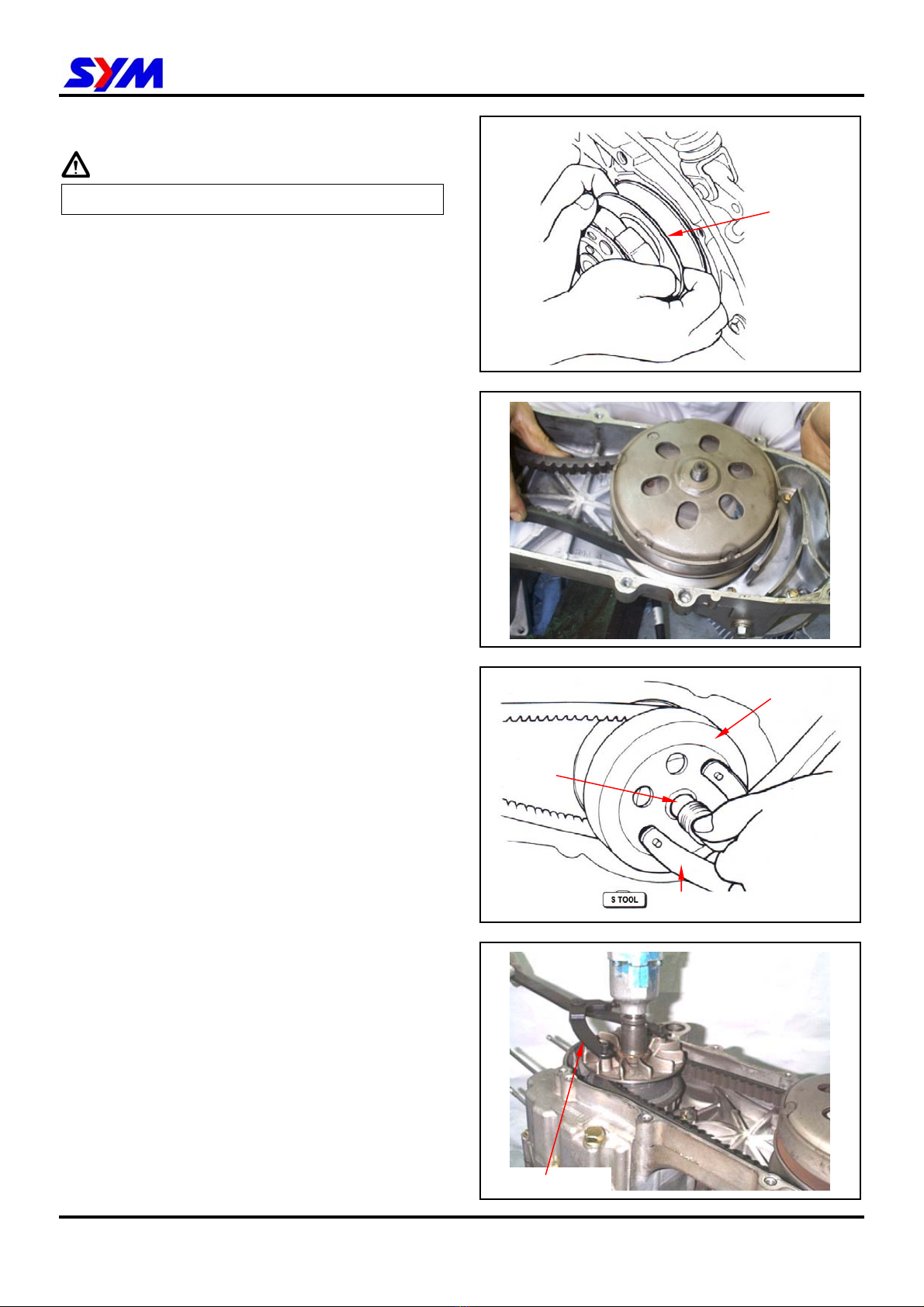

Special Service Tools

Clutch spring compressor: SYM-2301000

Inner bearing puller: SYM-6204002

Clutch nut wrench 39 x 41 mm: SYM-9020200

Universal holder: SYM-2210100

Bearing driver: SYM-9100100

Trouble Diagnosis

Engine can be started but motorcycle can

not be moved

1. Worn driving Belt

2. Worn drive face

3. Worn or damaged clutch weight

4. Broken driven pulley

Shudder or misfire when driving

1. Broken clutch weight

2. Worn clutch weight

Insufficient horsepower or poor high

speed performance

1. Worn driving belt

2. Insufficient spring force of driven pulley

3. Worn roller

4. Driven pulley operation un-smoothly