5

www.synairgy-eu.com

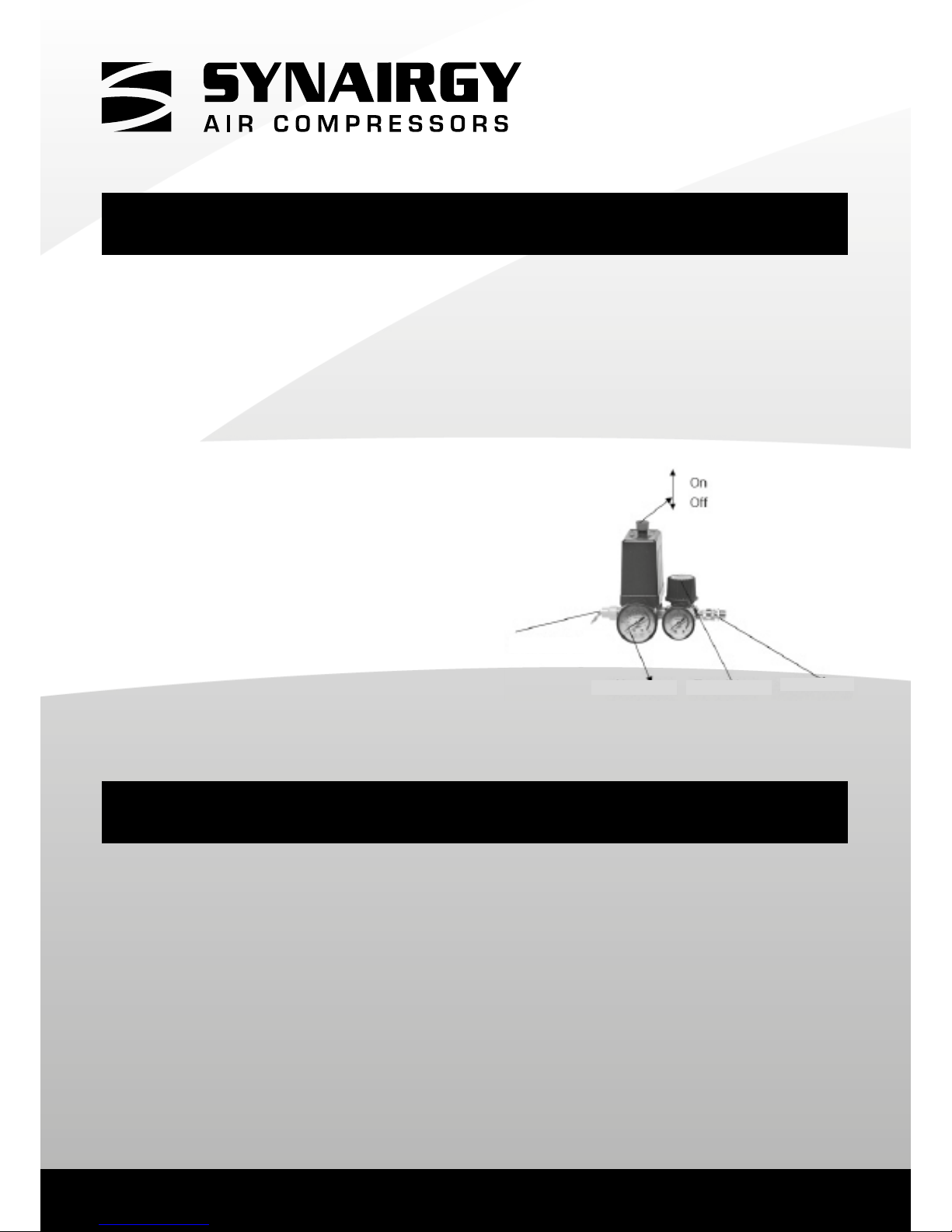

WARNING

1. Do not weld onto the air tank of this compressor. Welding on the air compressor tank will cause a

safety hazard and will void the product warranty

2. Never use an electric air compressor outdoors or on a wet surface; it may cause an electric shock

3. Please power off the air compressor when not in use

4.

Check the manufacturer’s maximum pressure rating for air tools and accessories. The compressor

outlet pressure must be regulated so as not to exceed the maximum pressure rating for the tools

5. High temperatures and moving parts are present under the outer cover. To prevent burns or

other injuries, DO NOT operate with the outer cover removed. Allow the compressor parts to cool

before handling or servicing

6. Ensure you read all labels when you are spraying paints or toxic materials; follow the safety

instructions provided, and use a respirator mask

7. Always wear safety goggles or glasses when using an air compressor. Never point any nozzle or

sprayer towards a person or any part of the body

8. Do not adjust the pressure switch or regulating valve for any reason; they have been pre-set at the

factory for the maximum pressure for this unit

CAUTION:

1. Drain the moisture from the tank on a daily basis. A clean, dry tank will help prevent corrosion

2. Pull off the pressure relief valve ring daily to ensure that the valve is functioning properly, and to

clear any obstructions

3. To provide adequate ventilation for cooling, the compressor must be kept a minimum of 0.3-0.5

metres from the nearest wall, in a well-ventilated area

4. Fasten the compressor down securely, and release the pressure from the tank before

transportation

5. Protect the air hose and electrical wire from damage and punctures. Inspect them weekly for

weak or worn spots, and replace them if necessary

Safety Guidelines