Specifications

Input Ratings / Characteristics

Nominal Input Voltage 100-240Vac

Input Voltage Range 85-264Vac

Nominal Input Frequency 50-60Hz

Input Frequency Range 47-63Hz

DC Input Voltage Range* 120-375Vdc

Input Current < 0.95A @ 115Vac, < 0.55A @ 230Vac

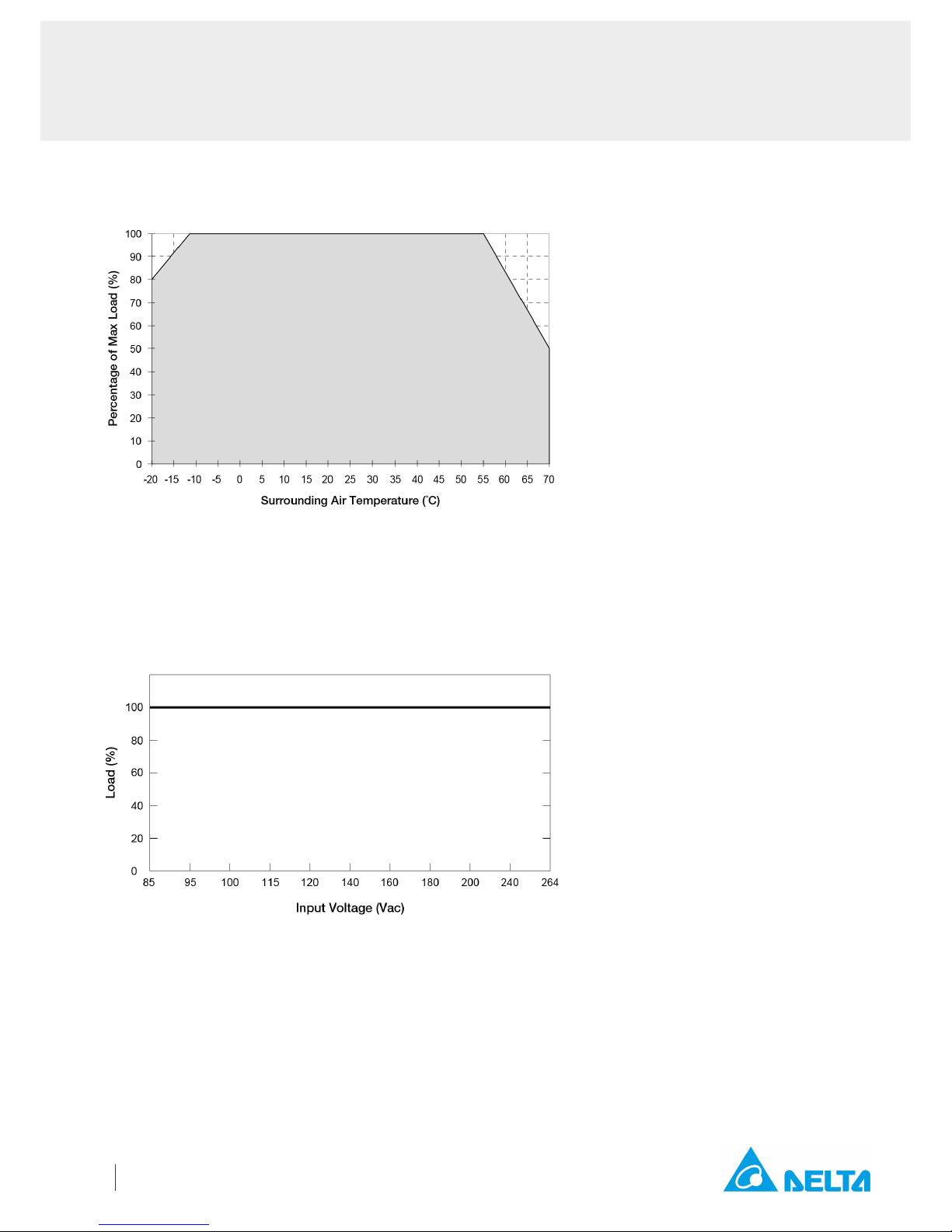

Efficiency at 100% Load > 89% @ 115Vac, > 90% @ 230Vac

Max Power Dissipation 0% load

100% load

< 0.3W @ 115Vac , < 0.5W @ 230Vac

< 6W @ 115Vac & 230Vac

Max Inrush Current (Cold Start) < 30A @ 115Vac, < 50A @ 230Vac

Leakage Current IEC/EN 60950-1 < 0.5mA @ 264Vac

(Neutral to PE terminal) IEC/EN 62368-1 < 1.0mA @ 264Vac

*Fulfills test conditions for DC input. Safety approval for DC input can be obtained upon request.

Output Ratings / Characteristics**

Factory Set Point Tolerance 24Vdc ± 2%

Output Voltage Adjustment Range 24-28Vdc

Output Current 2.1A (50W max.)

Output Power 50W

Line Regulation < 0.5% (@ 85-264Vac, 100% load)

Load Regulation < 1.0% (@ 85-264Vac, 0-100% load)

PARD*** (20MHz) < 70mVpp @ > 0°C to 70°C

< 100mVpp @ 0°C to -20°C

Rise Time < 30ms @ nominal input (100% load)

Start-up Time < 2,000ms @ 115Vac (100% load)

< 1,000ms @ 230Vac (100% load)

Hold-up Time > 20ms @ 115Vac (100% load)

> 100ms @ 230Vac (100% load)

Dynamic Response (Overshoot & Undershoot O/P Voltage) ± 5% @ 85-264Vac input, 0-100% load

(Slew Rate: 0.1A/μs, 50% duty cycle @ 5Hz to 1KHz)

Start-up with Capacitive Loads 3,000µF Max

Functional DC OK Relay Contact

(for DRS-24V50W1NR)

30V / 1A, resistive load

The relay contact are normally “ON” (closed) when the output

(Vout) is greater than 75% of its rated value and “OFF”

(opened) when the output (Vout) is less than 75% typ.

**For power de-rating from < -10°C to -20°C, and 55°C to 70°C, see power de-rating on page 3.

***PARD is measured with an AC coupling mode, 5cm wires, and in parallel with 0.1μF ceramic capacitor & 47μF electrolytic capacitor.