3 p250 Laser Quick Start Guide Version 3.1

p250 Quick Start Guide

When mounting the laser to a baseplate, use only one metric or SAE fastener per mounting tab on the base-

plate. Do not use any type of jackscrew arrangement as this will twist the baseplate and may distort the tube.

SYNRAD does not recommend mounting lasers in a vertical, (head and/or tail down)

position. Please contact the factory for limitations as a vertical orientation increases the

risk of damage to the lasers optics. Consult the factory for further mounting angle guid-

ance outside >75% from the horizontal.

Readying your Laser for use:

SYNRAD recommends performing the initial startup procedure located at the end of this guide at initial op-

eration for new lasers and/or after relocation of your laser.

Caution

Possible

Equipment

Damage

Mounting:

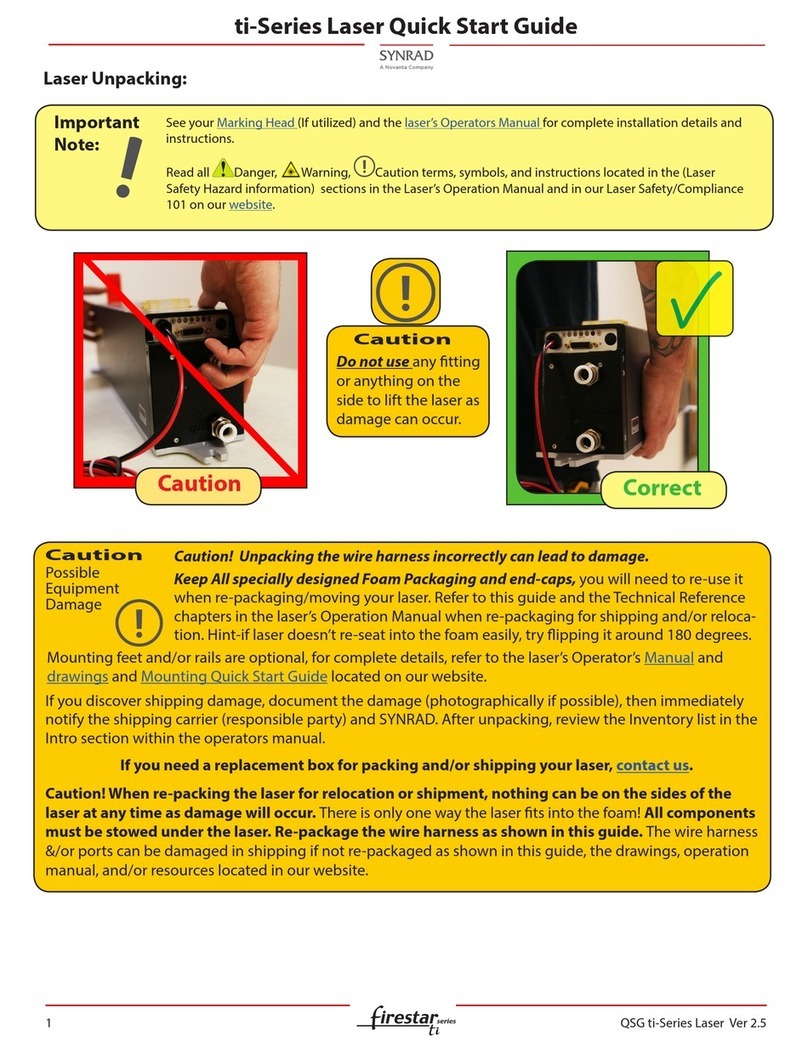

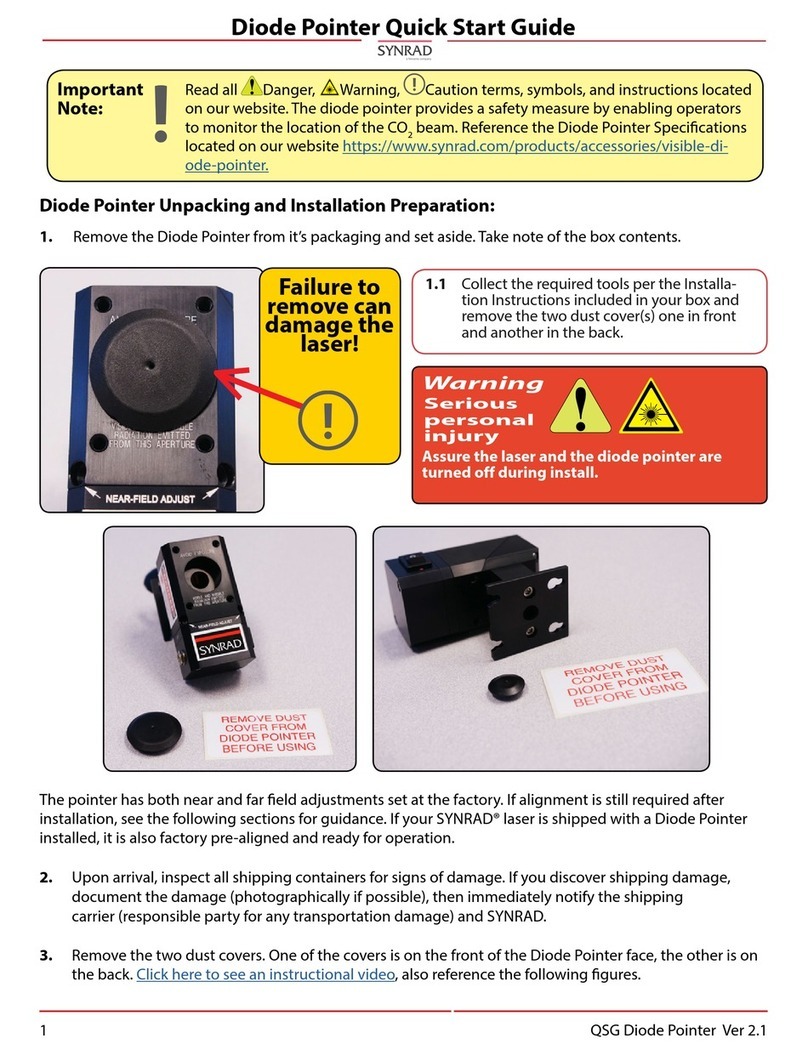

3. Choose your mounting type & refer to the Outline and Mounting drawings online.

a. Mounting from above (with mounting feet)- See the following gure, O&M drawings, torque,

thread engagement, and washer data below.

b. Mounting from below- Assemble three spherical washer sets as shown in Detail B in the O&M

drawing.

4. You will need to mount your laser to a mounting surface with three (3) M8 x 1.25 (Metric) or 5/16-18

mm (English) fasteners. Drill and tap three corresponding holes in the mounting surface. See

the gure below, Evenly tighten all three fasteners. Maximum torque 12 Nm (106 in-lb). Minimum

thread engagement should be 16 mm or 0.625 in. *Recommend using low-outgassing thread lock

Caution

Possible

Equipment

Damage

The spherical cup and washer sets are positioned between the laser’s mounting brackets

and the mounting surface to eliminate any possible distortion caused by variations in the

atness of the surface.

Variances in mounting surface will lead to tube distortion resulting in laser damage!

INVISIBLELASER RADI ATIO N

AVOID EYE OR SKIN EXPOSURE TO

DIRECTOR SC ATTERED RADI ATIO N

CLASS4 LASER PRODUC T

EN-60825-1,2007

xxxx WATTSMA X

10200-10800 NANOMETERS

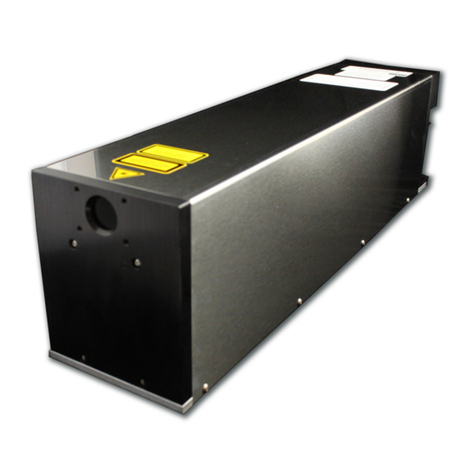

p250 Top View

A

MODEL #: PSP250SB

SERIAL #: P250136130001

TESTEDAT 48 Vo ltsMFG May16, 2013

Thislaser component does not comply with standards for complete

laserproducts as specified by 21 CFR 1040.10 or IEC 60825-1.

SYNRAD,Inc. 4600 Campus Place, Mukilteo WA 98275 425.349.3500

Note: Use metric or SAE fasteners with the laser’s mounting bracket/spherical washer set into a threaded

mounting surface.