Table of content

1 Introduction .......................................................... 1

1.1 Product description ......................................1

1.2 Intended use ..............................................1

1.3 Document description...................................1

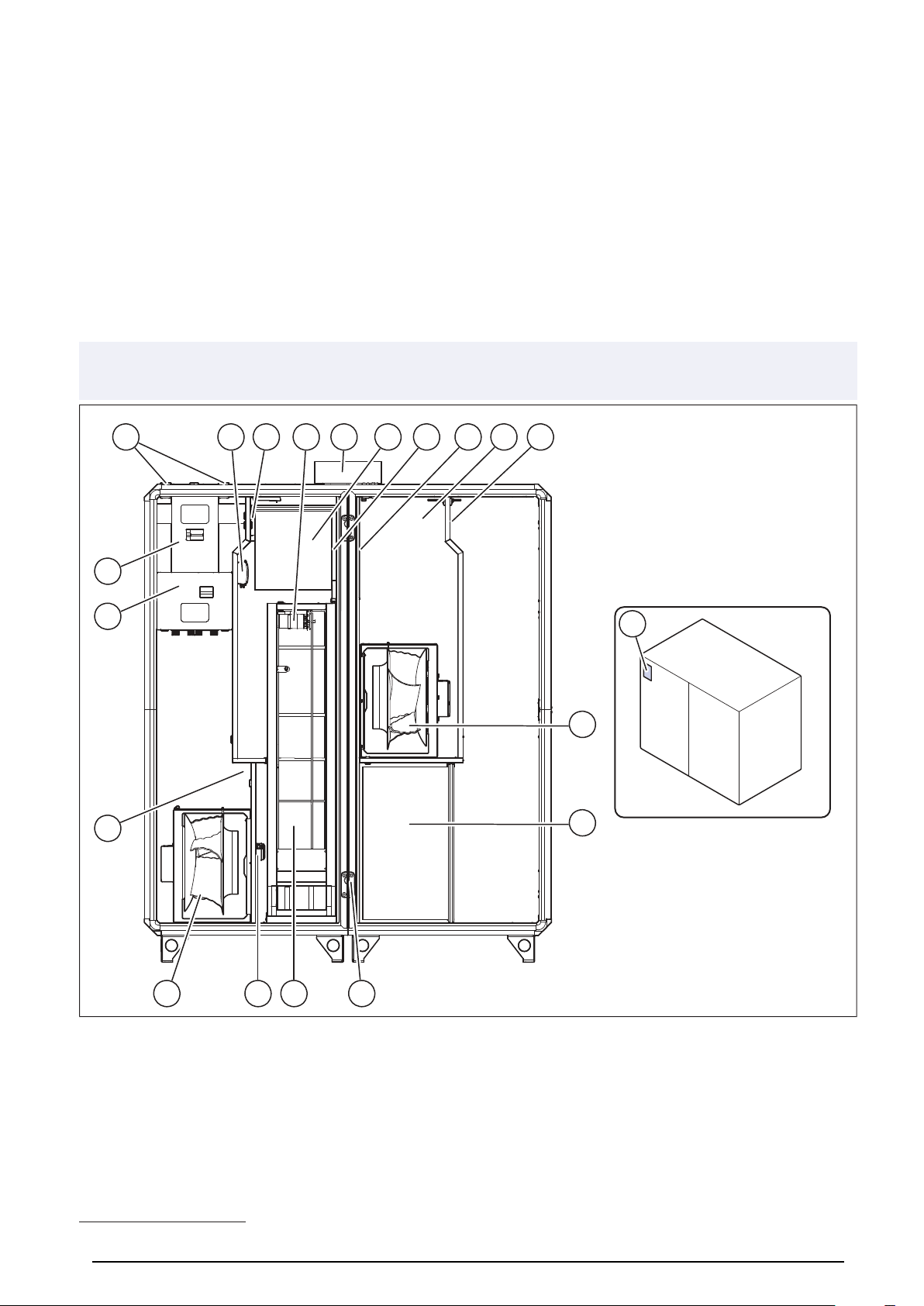

1.4 Product overview Topvex SR ......................... 1

1.5 Product overview Topvex TR.......................... 2

1.6 Overview of supplied parts............................. 3

1.7 Name plate ................................................3

1.7.1 Type designation ............................. 4

1.8 Product liability............................................ 5

2 Safety .................................................................5

2.1 Safety definitions......................................... 5

2.2 Safety instructions ....................................... 5

2.3 Personal protective equipment ....................... 6

2.4 Safety labels on the product........................... 6

3 Transportation and storage ...................................... 7

3.1 To move the product with a forklift truck ............ 7

3.2 To move products with more than 1 section

from the pallet............................................. 7

3.3 To lift the product with a lifting frame ................ 8

3.4 Disassembly for transport through a

standard door opening.................................. 9

3.4.1 To disassemble the product ...............9

3.4.2 To divide the product into

sections....................................... 10

3.5 To assemble the product ............................. 11

3.6 To assemble the product sections ................. 12

4 Installation.......................................................... 14

4.1 To do before the installation of the

product.................................................... 14

4.2 To make the product level............................ 14

4.3 To adjust the heat exchangers

position ................................................... 15

4.4 To connect the ducts to the product ............... 16

4.4.1 Duct connection overview................ 16

4.5 To install the supply air sensor...................... 17

4.6 To put insulation on the ducts ....................... 17

4.7 To connect the water heating coil .................. 17

4.7.1 Technical data for water heating

coil ............................................. 18

4.8 Purge sector............................................. 19

4.8.1 Overview of the purge sector............ 19

4.8.2 To measure the air pressure

difference in the product.................. 19

4.8.3 Purge sector settings...................... 19

4.8.4 To adjust the purge sector ............... 20

4.9 NaviPad .................................................. 20

4.9.1 To install the NaviPad holder ............ 20

4.9.2 To connect the NaviPad .................. 20

4.10 To install the ODK roof ................................ 21

4.11 To install the Access control cabinet .............. 22

5 Electrical connection............................................. 23

5.1 To do before the electrical connection ............ 23

5.2 To connect the product to the power

supply..................................................... 24

5.3 To open the Access control cabinet ............... 24

5.4 To connect the supply air sensor ................... 25

5.5 To connect accessories............................... 25

6 Commissioning ................................................... 28

6.1 To do before the commissioning.................... 28

6.2 To do the commissioning ............................. 28

7 Operation........................................................... 28

7.1 To operate the NaviPad .............................. 28

7.1.1 NaviPad button ............................. 28

7.1.2 Overview of the NaviPad

dashboard ................................... 29

7.2 To do the start-up wizard in the

NaviPad .................................................. 29

7.3 Symbols in the control unit CU27–C

menu ...................................................... 29

7.4 To log on to the NaviPad with the applicable

user mode................................................ 30

7.4.1 User modes.................................. 30

7.5 Overview of the NavidPad software

menu ...................................................... 31

7.6 Overview of the NaviPad home page ............. 33

7.7 Data and settings ...................................... 34

7.8 Flow chart ................................................ 34

7.8.1 To use the flow chart ...................... 34

7.9 Language ................................................ 34

7.9.1 To change the language.................. 34

7.10 Time and date........................................... 35

7.10.1 To set the operation time ................. 35

7.11 Configuration............................................ 35

7.11.1 To do a configuration ...................... 35

7.12 System information .................................... 35

7.12.1 To add or adjust system

information................................... 35

7.13 Alarms .................................................... 35

7.13.1 To operate the alarms ..................... 35

7.14 To connect the NaviPad if the connection to

the product is lost ...................................... 36

7.15 To use a computer to show the user

interface .................................................. 36

7.16 To stop the product for maintenance .............. 36

8 Maintenance....................................................... 36

8.1 Maintenance schedule................................ 37

8.2 To clean the product................................... 38

8.3 To replace the filters ................................... 38

8.4 To replace the fan module ........................... 38

8.5 To replace the heat exchanger...................... 39

8.6 To replace the battery of the control unit

CU27-C................................................... 40

8.7 To reset tripped fuses ................................. 41