.

SV~TADN

~DONNER

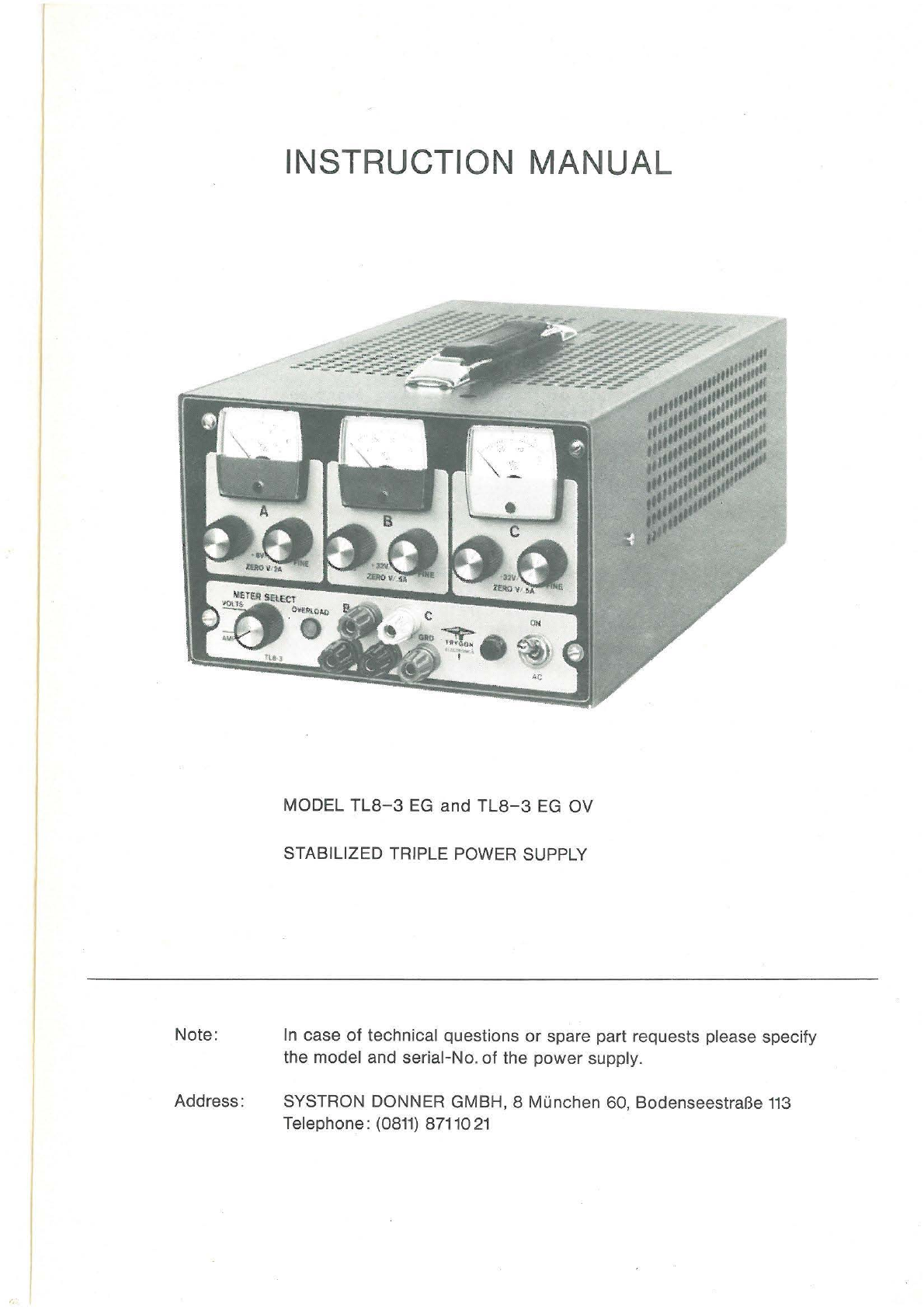

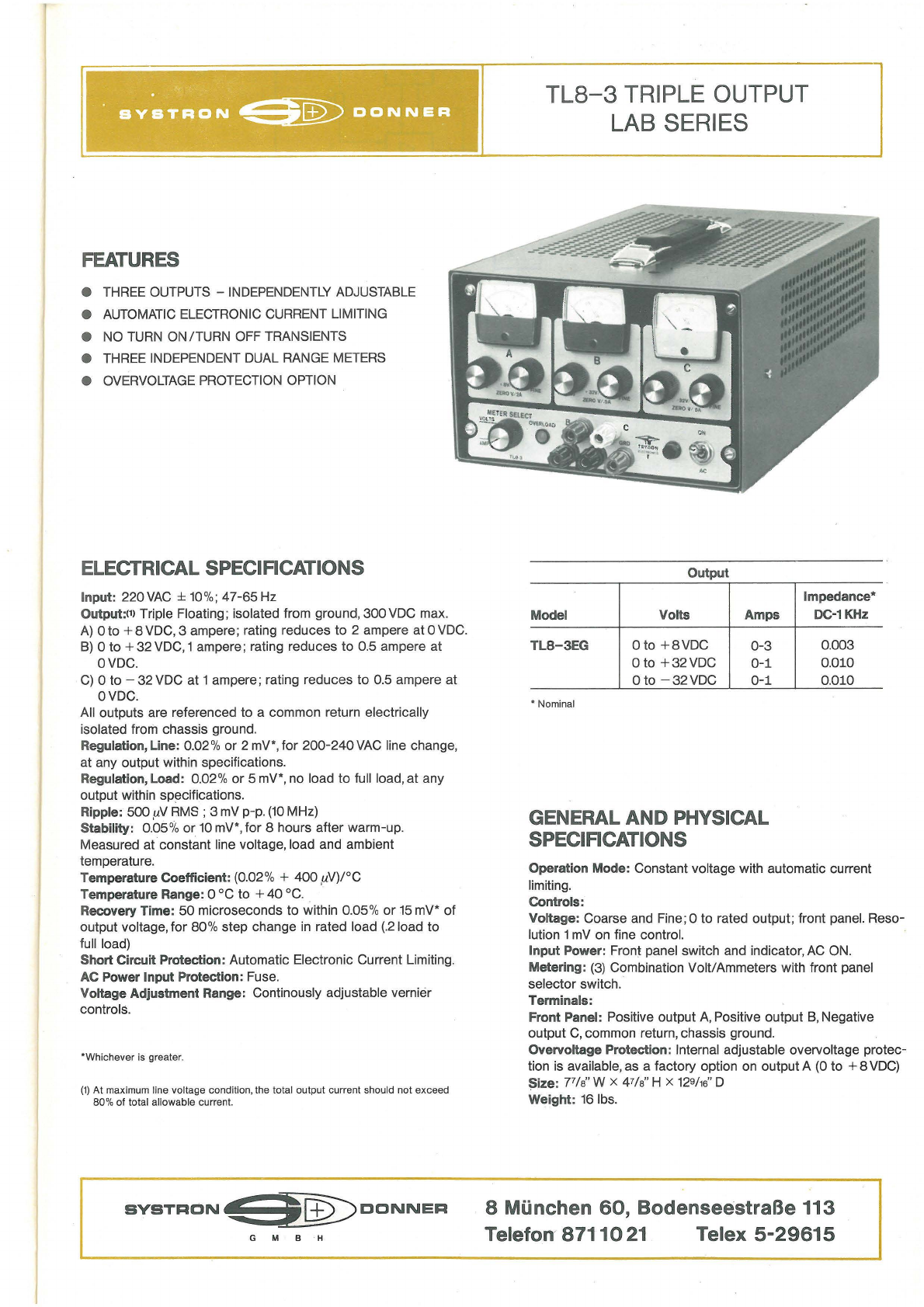

FEATURES

e THREE OUTPUTS -

IND

E

PENDENTLY

ADJUSTABLE

e AUTOMAT

IC

EL

ECTRON

IC

CURREN

T

LI

M

IT

ING

e NO TURN

ON

/TURN OFF TRAN

SI

ENTS

e THREE INDEPENDENT DUAL RANGE M

ET

ERS

e OVE

RVOLTAGE

PROTECTION OPTION

ELECTRICAL SPECIFICATIONS

Input: 220

VAC

± 10%; 47-65Hz

Output

:<1>

Triple Floating; isolated from ground, 300

VDC

max.

A)

0 to + 8 VDC, 3 ampere; rating reduces to 2 ampere at 0

VDC

.

B)

0 to + 32 VDC, 1ampere; rating reduces to 0.5 ampere at

OVDC.

C)

0 to -32VDC at 1ampere; rating reduces to 0.5 ampere at

OVDC.

All outputs are referenced to a common return electrica

ll

y

isolated from chassis ground.

Regulation,Line: 0.02% or 2 mV*, for 200-240VAC line change,

at any output within specifications.

Regul

at

ion, Load: 0.02%

or

5 mV*, no load to full load, at any

output within specifications.

Ripple: 500

pV

RMS

; 3

mV

p-p.

(10

MHz)

Stab

ili

ty: 0.05% or

10

mV*, for 8 hours after warm-up.

Measured at constant line voltage, load and ambient

temperature.

Tem

perature

Co

effi

ci

ent: (0.02% + 400 ,uVWC

Temperature Range: 0

oc

to + 40 °C. ·

Recove

ry

Time: 50 microseconds to within 0.05%

or

15

mV

* of

output voltage, for 80% step change

in

rated load (.21oad to

full load)

Short Circuit Protection: Automatic Electronic Current

Li

miting.

AC Power Input Protection: Fuse.

Voltage Adjustment Range: Continously adjustable vernier

controls.

*Whichever is greater.

(1)

At maximum line voltage condition, the total output current should not exceed

80%

of

total allowable current.

SVSTRCN

rlf£?.:)

CONNER

G M B H

TL8-3

TRIPLE OUTPUT

LAB

SERIES

Output

Impedance*

Model Volts Amps

TL8-3EG

0 to

+8VDC

0-3

0 to

+32

V

DC

0-

1

Oto

-32VDC

0-

1

• N

omi

nal

GENERAL AND PHYSICAL

SPECIRCATIONS

DC-1

KHz

0.003

0.010

0.010

Operation Mode: Constant voltage with automatic current

limiting.

Controls:

Voltage: Coarse and Fine;0 to rated output; front panel. Reso-

lution 1

mV

on fine contr

ol.

Input Power: Front panel switch and indicator,

AC

ON.

Metering:

(3)

Combination Volt/Ammeters with front panel

selector switch.

Terminals:

Front Panel: Positive output

A,

Positive output

B,

Negative

output

C,

common return, chassis ground.

Overvoltage Protection: Inte

rn

al

adjustable overvoltage protec-

tion is available, as a factory option on output A (0 to + 8

VDC)

Size: 77/a" W x 47/a" H x

12e/1e"

D

Weight: 16 lbs.

8 Mi.inchen

60,

BodenseestraBe 113

Telefon

87110

21

Telex

5-29615