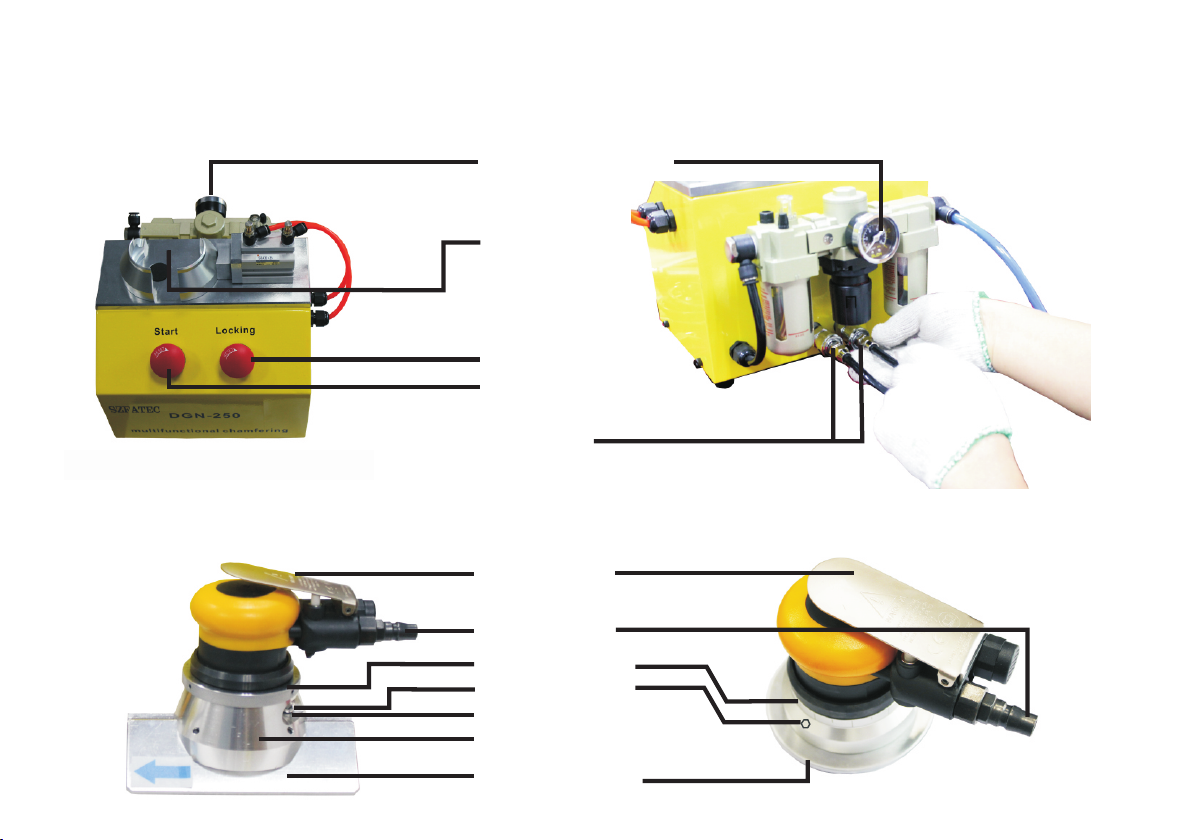

How to adjust FA150 chamfering depth:

1. Use the supplied 5mm inner hexagon spanner to LOOSEN the big screw in the

assistant jig;

2. Use the supplied 1.5mm inner hexagon spanner to TIGHTEN the inner screw inside

the assistant jig;

3. then the chamfer loosens, you can turn the indicator ring and adjust the up-down

position of the blades.

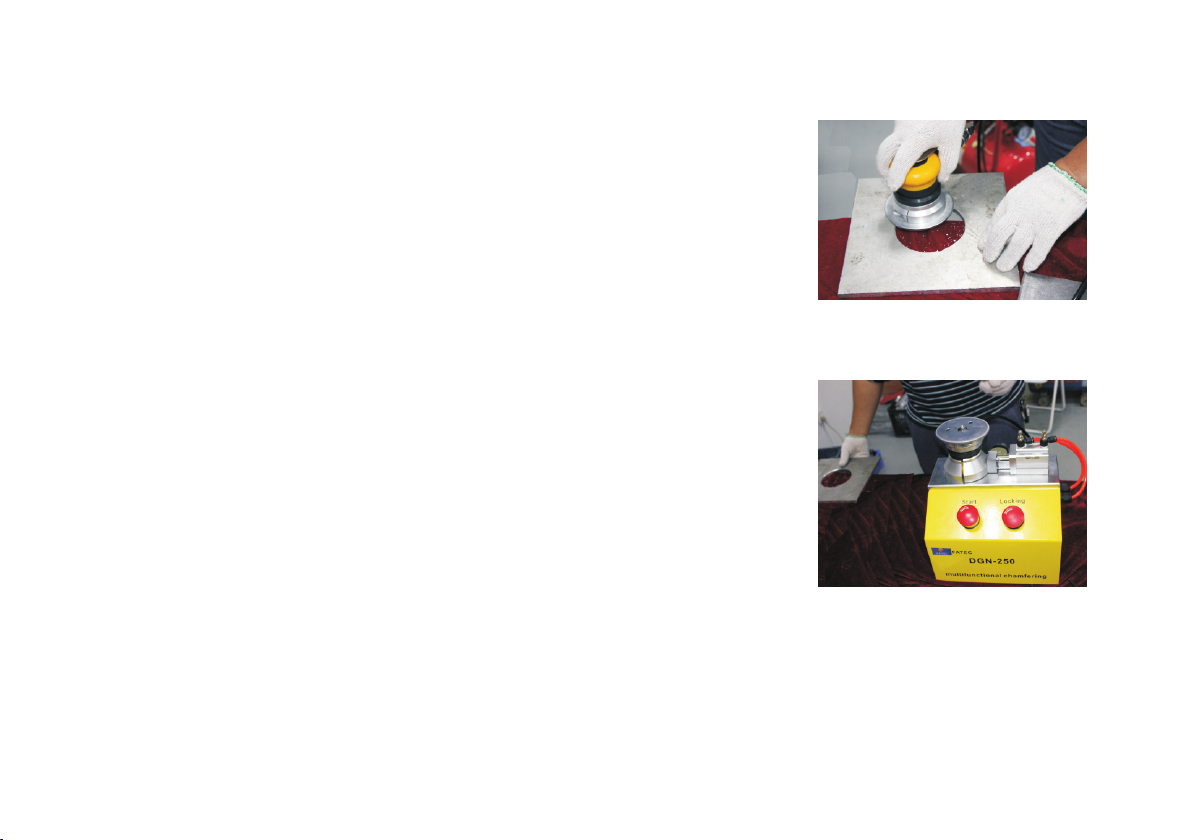

Continues - How to replace FA150 blades:

4. Take off the assistant plates together from the assistant jig (handle);

5. Use the supplied T-20 spanner to loosen the 3 screws in the blades base;

6. Then you can replace new blades.

Continues - How to re-install the blade and the assistant plates:

Basically we just revert the above steps.

1. Use the supplied T-20 spanner to tighten the blades;

2. Joint the blade base into the assistant jig (handle);

3. Adjust the depth by turning the indicator and mark the positioning to remember;

4. Use the supplied 1.5mm inner hexagon spanner to LOOSEN the inner screw inside

the assistant jig;

5. Use the supplied 5mm inner hexagon spanner to TIGHTEN the big screw in the

assistant jig;

6. Again use the supplied 1.5mm inner hexagon spanner to TIGHTEN the inner screw

inside the assistant jig.

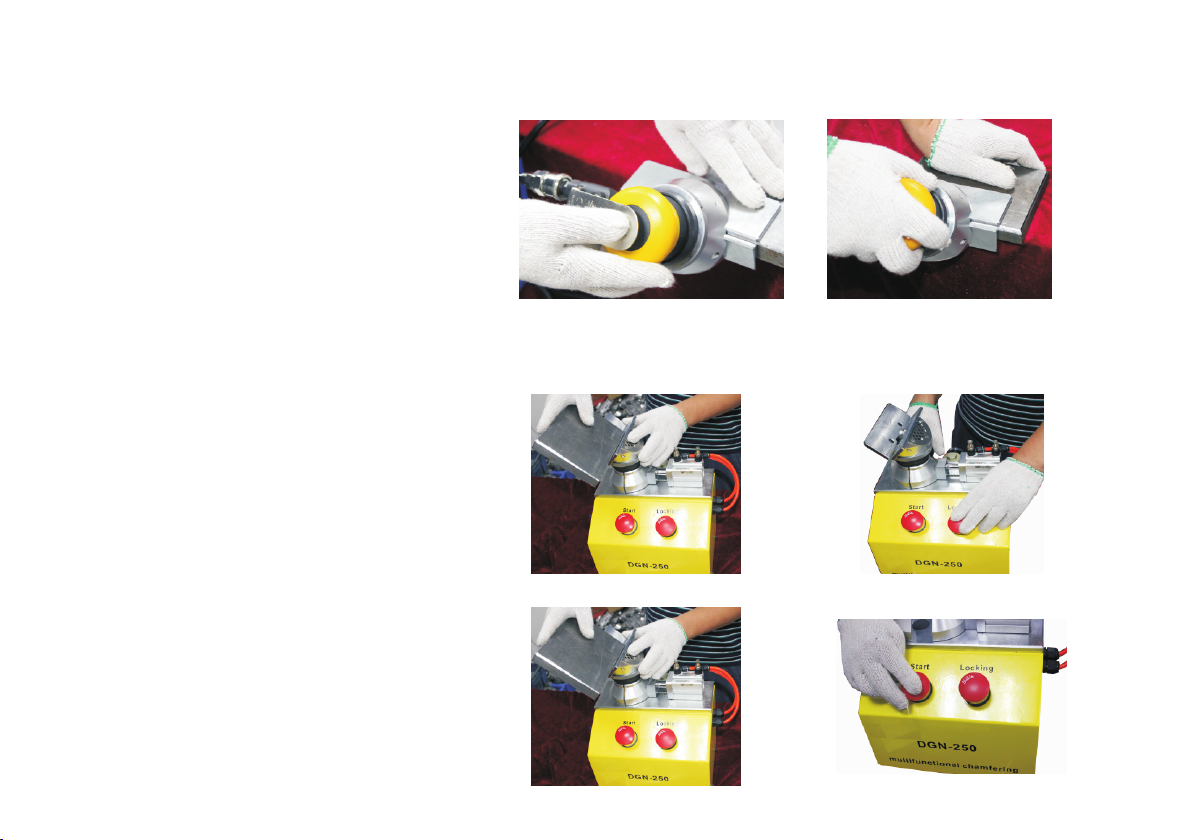

How to adjust CR-100 chamfering depth:

1. Use the supplied 5mm inner hexagon spanner to LOOSEN the big screw in the

assistant jig;

2. Then the chamfer loosens, you can turn the indicator ring and adjust the up-down

position of the blades.

Continues - How to replace CR-100 blades:

3. Take off the round assistant plates from the assistant jig (handle);

4. Use the supplied T-8 spanner to loosen the 3 screws in the blade base;

5. Then you can replace new blades.

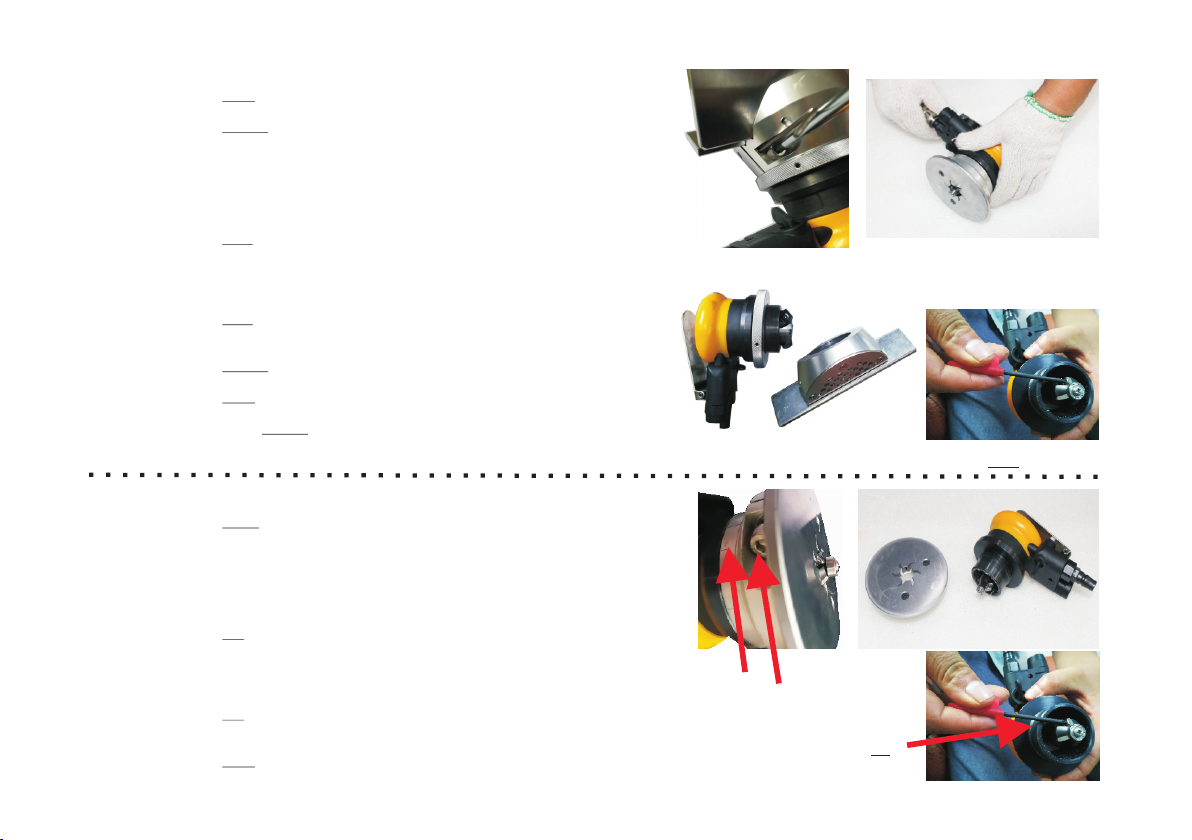

Continues - How to re-install the blade and the assistant plates:

Basically we just reverse the above steps.

1. Use the supplied T-8 spanner to tighten the blades;

2. Joint the blade base into the assistant jig (handle);

3. Adjust the depth by turning the indicator and mark the positioning to remember;

4. Use the supplied 5mm inner hexagon spanner to TIGHTEN the big screw in the

assistant jig.

Step.1-2 Step.3 (ref as CR-100)

Step.4 Step.5-6 (T-20 spanner)

Use 5mm inner hexagon

spanner to

loosen/tighten the big

screw in the assistant jig

Turn the

indicator ring and

adjust the up-

down position of

the blades.

Take off /re-joint the round assistant plates

from/into the assistant jig (handle)

Use the supplied T-8

spanner to loosen the 3

screws in the blades base

-5-