T-MAG AMX Series Instruction Manual

Enhance your process

Engineering

Operation &

Maintenance

Mag

Drive

1/2HP

through

5HP

TM4, TM6 & TM10

AMX SERIES

SECTION 1 CAUTIONS—READ FIRST!

.............................................

1

SECTION 2 PUMP DESIGNATION SYSTEM

.........................................

3

SECTION 3 HOW IT WORKS

.......................................................

4

SECTION 4 DIMENSIONAL DRAWINGS

............................................

5

SECTION 5 PERFORMANCE

A. 1/2 HP (0.4 kW) Performance Curves

50 Hz

..............................................................

6

60 Hz

..............................................................

7

B. 1 HP (0.75 kW) Performance Curves

50 Hz

..............................................................

8

60 Hz

..............................................................

9

C. 2 HP (1.5 kW) Performance Curves

50 Hz

.............................................................

10

60 Hz

.............................................................

11

D. 3 HP (2.2 kW) Performance Curves

50 Hz

.............................................................

12

60 Hz

.............................................................

13

E. 5 HP (3.7 kW) Performance Curves

50 Hz

.............................................................

14

60 Hz

.............................................................

15

F. 5 HP (3.7 kW) Oversize Inlet Performance Curves

50 Hz

.............................................................

16

60 Hz

.............................................................

17

SECTION 6 SUGGESTED INSTALLATION, OPERATION & TROUBLESHOOTING

....

18

SECTION 7 ASSEMBLY / DISASSEMBLY

..........................................

21

SECTION 8 EXPLODED VIEW & PARTS LISTING

Glass-Filled Polypropylene Models 28

Carbon-Fiber Reinforced ETFE Models

......................................

30

TABLE OF CONTENTS

......................................

1

TEMPERATURE LIMITS

Glass-Filled Polypropylene

32°F (0° C) to 175°F (79°C)

Carbon-Fiber Reinforced ETFE

Viton -40°F (-40°C) to 350°F (177°C)

EPDM -60°F (-51°C) to 280°F (138°C)

CAUTION:

Operating Temperature: °F (°C) 68 (20) 104 (40) 140 (60) 176 (80)

Maximum Pressure: psig (bar)

1/2 HP (0.40 kW) 50 (3.4) 47 (3.2) 43 (2.9) 36 (2.5)

1 HP (0.75 kW) 71 (4.9) 64 (4.4) 54 (3.7) 43 (2.9)

2 HP (1.5 kW) & 3 HP (2.2 kW) 85 (5.9) 78 (5.4) 64 (4.4) 50 (3.4)

5 HP (3.7 kW) 85 (5.9) 78 (5.4) 64 (4.4) 50 (3.4)

(Above data based on water)

CAUTION:

Operating Temperature °F (°C) 68 (20) 104 (40) 140 (60) 176 (80)

1/2 HP (0.40 kW) 15 (4.0) 20 (5.3) 25 (6.6) 30 (7.9)

1 HP (0.75 kW) 15 (4.0) 15 (4.0) 20 (5.3) 20 (5.3)

2 HP (1.5 kW) & 3 HP (2.2 kW) 20 (5.3) 20 (5.3) 30 (7.9) 40 (10.6)

5 HP (3.7 kW) 30 (7.9) 30 (7.9) 50 (13.2) 75 (19.8)

(

Above data based on water)

CAUTION:

CAUTION:

CAUTION:

WARNING:

WARNING:

WARNING:

CAUTION:

WARNING:

WARNING:

Section 1

CAUTIONS—READ FIRST!

Minimum Flow: GPM (LPM)

The pump’s maximum operating

pressure will change with variations in operating

temperature and size of the pump. Please refer

to table below for the recommended maximum

operating pressures for T-MAG™ pumps.

0°F (-17°C) to 212°F (100°C)

Operating a T-MAG™ pump below the

minimum ow rates shown below may result in a

signicant rise in temperature within the interior

of the pump. Operation of the pump below these

minimum levels may also result in increased radial

and axial forces on the shaft, bushing and impeller

assembly. These resulting conditions may aect the

pump’s performance and service life.

Do not run the pump without uid

for extended periods of time. Depending upon

application conditions, dry-running the pump may

cause the temperature of the internal components to

rise, resulting in damage to the pump internals.

When selecting a pump for a specic

application be sure to consider the concentration

of the uid being pumped. Changes in uid

concentration may aect viscosity and specic

gravity. Other physical properties, such as

corrosiveness, may also change with variations in

uid concentration.

Mag-drive pumps are generally intended

for use with uids with little or no particulate in the

process. Excessive or large particulates in the process

media will adversely aect pump performance and

service life. For process media with more than 5%

by volume particulates or with solids larger than

50µ (microns), it is recommended that you use

another pump technology. For process media with

5% or less by volume particulates and with solids

smaller than 50µ, it is recommended that you use the

Sintered SiC bearing option in the T-MAG™ pump.

However, please note that a reduced service life may

still be experienced versus a uid process with no

particulate.

Always perform an exterior inspection of

the pump prior to installation. Look for damage that

may have been inicted during shipment. Also, check

the free rotation of the pump by using a small at

head screwdriver to turn the fan motor.

Inspect the pump nameplate prior

to installation to insure the proper materials of

construction, motor power rating, impeller dimesion

and uid connection sizes.

Always prime pump before start-up. Lack

of uid at start-up may cause excessive heat buildup

within the pump which may cause a reduction in

service life of the components. Also, insure that all

inlet process valves are open at start-up.

At initial start-up of the pump, after

complete and proper wiring of the unit, check the

pump rotation by quickly turning on and then o the

pump power. After shut down, inspect the fan rotation

through the back fan guard. While looking through

the rear motor fan guard, the fan should be rotating

clockwise. Once proper rotation has been established,

follow all start-up procedures for the system.

During a systems or plant wide power

failure, always turn o all rotating equipment to

prevent sudden increases in system pressures once

power is restored.

Before normal shut down of the pump for

service or at the completion of a process run, always

slowly close the discharge valve of the pump to

prevent reverse ow from the discharge lines. Once the

discharge valve is closed, immediately shut down

the pump.

2

CAUTION:

CAUTION:

CAUTION:

WARNING:

CAUTION:

CAUTION:

CAUTION:

CAUTION:

CAUTION:

Section 1

CAUTIONS - READ FIRST! CONT.

Periodically inspect the interior of the

pump for damage or wear, especially when the

pump is being used with a uid near its freezing

point. In some cases the uid may crystallize even

when the pump is only shut down for a short

period. Use of an automatic drain system or heat

tracing may be used to counter this process.

When choosing pump materials, be

sure to check the temperature limits for all wetted

components. Example: Viton® has a limit of 350°F

(177°C), but Glass-Filled Polypropylene has a maximum

limit of only 175°F (79°C).

Maximum temperature limits are based

upon mechanical stress only. Certain chemicals

will signicantly reduce maximum safe operating

temperatures. Consult Chemical Resistance Guide for

chemical compatibility and temperature limits.

Prevention of static sparking - If static

sparking occurs, re or explosion could result.

Pump, valves, and containers must be grounded to

a proper grounding point when handling ammable

uids or whenever discharge of static electricity is

a hazard. For T-MAG™ pumps, only ETFE models oer

statically dissipative materials. Check with your local,

state or government agencies for grounding requirements

for your area.

The process uid and cleaning uids

must be chemically compatible with all wetted components

See a chemical compatibility guide for details.

Never disconnect any uid process lines

that may contain pressurized uid. Be sure to close

any isolation valves and safely drain any line presssure

before servicing pump. Failure to do so may result in

process uid being sprayed from a loosened connection.

Never attempt to reuse damaged pump

components. If the impeller, casing, bushing or any

other internal parts show signs of wear, replace

them immediately with factory approved spare parts.

Using damaged parts may result in process uid leaks

or bodily injury.

With an increase in specic gravity the

required torque to turn the impeller increases as

well. The increase in torque needed can exceed the

magnet’s ability rotate the impeller of pump resulting

in little or no ow.

When installing a Mag-Drive pump into

an application requiring an ATEX pump, an ATEX

certied motor must be used.

MAG-DRIVE

SPECIALTY CODES

Section 2

DESIGNATION SYSTEM

LEGEND

TMXXX /XX /XX /XXX /XX / XXX

MOTOR

VOLTAGE

MAG-DRIVE

PUMP IMPELLER DIAMETER

O-RINGS / GASKETS

BEARING

PUMP

SIZE

CASING MATERIAL

SPECIALTY

CODE

(if applicable)

BEARING/BUSHING DETAIL*

Bearing Shaft Wear Ring Front Thrust Ring Rear Thrust Ring

CCarbon 995 Al Ceramic Carbon 995 Al Ceramic 995 Al Ceramic

RRulon 995 Al Ceramic Rulon 995 Al Ceramic 995 Al Ceramic

A995 Al Ceramic 995 Al Ceramic Rulon 995 Al Ceramic 995 Al Ceramic

SSintered Sic Sintered Sic Sintered Sic Sintered Sic Sintered Sic

MATERIAL CODES

NOTE:For IEC B5 frame motors,

replace “C” with “E” in the pump

size designation. See chart below

for E-Frame configuration.

SIZE FRAME

1/2 HP D71D

1 HP D80D

2 HP D905D

3 HP D90LD

5 HP DF112MD

NOTE: All pump flanges are ANSI, DIN and JIS Combination

*C is the standard bearing/bushing configuration as this is the only configuration with the dry-run option

+ Pump head only is a complete wet end kit with no motor, no mounting bracket, no outer magnet and no base.

**VT is the standard elastomer.

PUMP SIZE

4HC = 1-1/2" (38mm) Inlet and

Discharge,1/2 HP (0.40 kW),

C-Face Mount,

56C Frame

4KC = 1-1/2" (38mm) Inlet and

Discharge,1 HP (0.75 kW),

C-Face Mount,

56C Frame

6LC = 2" (51mm) Inlet, 1-1/2"

(38mm) Discharge, 2 HP

(1.50 kW), C-Face,

145TC Frame

6MC = 2" (51mm) Inlet, 1-1/2"

(38mm) Discharge, 3 HP

(2.20 kW), C-Face Mount,

145TC Frame

6NC = 2" (51mm) Inlet, 1-1/2"

(38mm) Discharge, 5 HP

(3.70 kW), C-Face Mount,

184TC Frame

10NC = 2-1/2" (64mm) Inlet, 2"

(51mm) Discharge, 5 HP

(3.70 kW), C-Face Mount,

184TC Frame

CASING MATERIAL

P = GLASS-FILLED

POLYPROPYLENE - BLACK

E = CONDUCTIVE ETFE - BLACK

BEARING*

C = CARBON

R = RULON* (FILLED PTFE)

A = 995 CERAMIC (AL2O3)

S = SINTERED SiC

O-RINGS / GASKETS**

VT = VITON

ND = EPDM

IMPELLER DIAMETER

FULL TRIM IN MM SHOWN

NOTE::

1) Standard orders are shipped

with impellers that have not been

trimmed and are at maximum size.

2) All impeller diameters shown in

“mm” size and are variable in one

(1) millimeter increments.

3) Proper impeller selection is

determined by the system

parameters. Consult factory

for details.

4) Proper impeller size is eected by

motor rpm.

5) Orders for units with trimmed

impeller will be changed out at the

factory before shipment.

MOTOR VOLTAGE

AA = 110/220V -

1 PHASE - 60 HZ - TEFC

BA = 208-230/460V 3 PHASE -

60 HZ – TEFC

CA = 575V 3 PHASE - 60 HZ - TEFC

XX = SPECIAL MOTOR

(CONSULT FACTORY)

YY = PUMP HEAD ONLY+

ZZ = NO MOTOR, WITH

MOUNTING BRACKET

AND OUTER MAGNET

3

TF = TEFLON ENCAP. VITON

4

Max Impeller Diameter Chart

Model Size POWER Max Impellar Diameter (mm)

Kw Hp 50HZ 60HZ

TM4H 0.4 1/2 102 90

TM4K 0.75 1 125 108

TM6L 1.5 2 142 123

TM6M 2.2 3 156 135

TM6N 3.7 5 165 150

TM10N 3.7 5 145 125

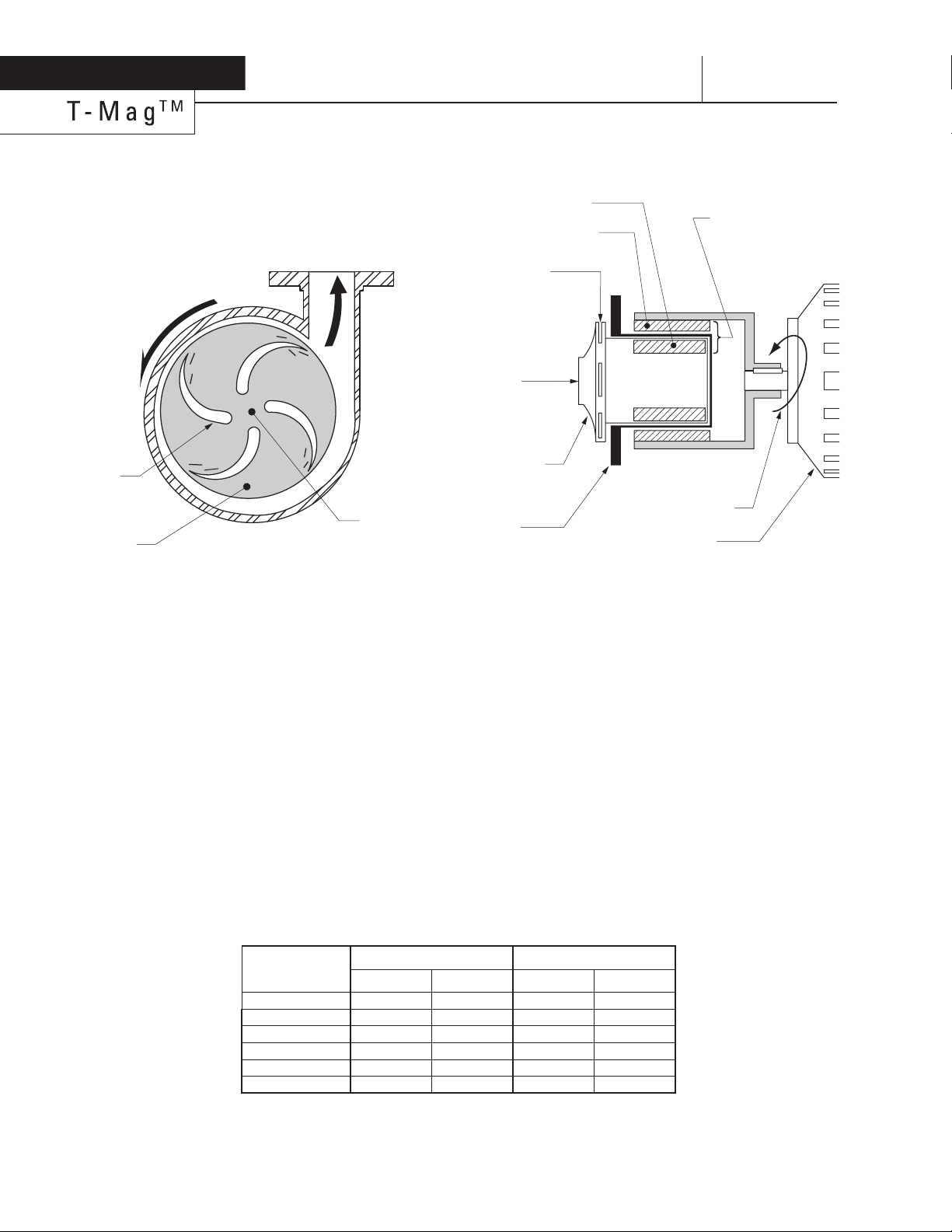

FIGURE 1: PUMP LIQUID END

Fluid is moved by a centrifugal pump through the use of centrifugal

force. Fluid is taken into the center of the impeller through the inlet

connection. Most centrifugal pumps prefer a positive inlet pressure

to prevent cavitation (lack of enough positive inlet pressure to

prevent liquid vaporization). This fluid is then caught by the vanes

of the impeller as it spins. This rotation of the fluid mechanically

by the vanes “throws” the fluid to the outside of the impeller and

toward the discharge port of the liquid end of the pump. This

mechanical movement of the fluid creates the discharge pressure

of the pump. Variables like inlet fluid supply pressure, impeller

diameter, motor horsepower and closed face versus open face all

effect the flow and pressure of the pump. Each of these variables

can be manipulated to achieve a desired flow and/or pressure.

FIGURE 2: PUMP MAGNETIC DRIVE

A magnetic drive pump uses a balanced magnetic field to create

the rotation of the fluid impeller. Unlike a traditional centrifugal

pump which has a direct drive connection between impeller and

motor, a mag-drive pump eliminates the direct drive mechanism

and replaces it with a magnetic field. An outer magnetic bell

housing is mounted on the end of the pump shaft. This outer bell

is aligned on the outside of the rear casing. The pump impeller

is connected to a smaller magnet assembly and rides on an

internal shaft and bushing assembly. (The liquid end parts are all

isolated within the fluid head of the pump without the need for a

mechanical seal.) The smaller magnet assembly is mounted within

the center of the magnetic field of the outer bell housing. Although

these two magnet assemblies are separated by a fluid barrier, the

magnetic fields are aligned. When the pump motor is started the

outer bell housing begins to rotate. As the outer bell rotates, the

rotating magnetic field effects the inner impeller magnet. As the

two magnets begin to turn together, the impeller begins turning

and displacing fluid.

Section 3

HOW IT WORKS—PUMP

$)3#(!2'%

)-0%,,%2

6!.%3

2/4!4)/.

&,/7

&,5)$

%.4%23

&2/-

#%.4%2

)..%2-!'.%43

/54%2-!'.%43

-/4/2

2/4!4)/.

-!'.%4)#&)%,$

2/4!4%3)-0%,,%2

2%!2

#!3).'

)-0%,,%2

&,5)$

).,%4

&,5)$%8)4

&2/-)-0%,,%2

5

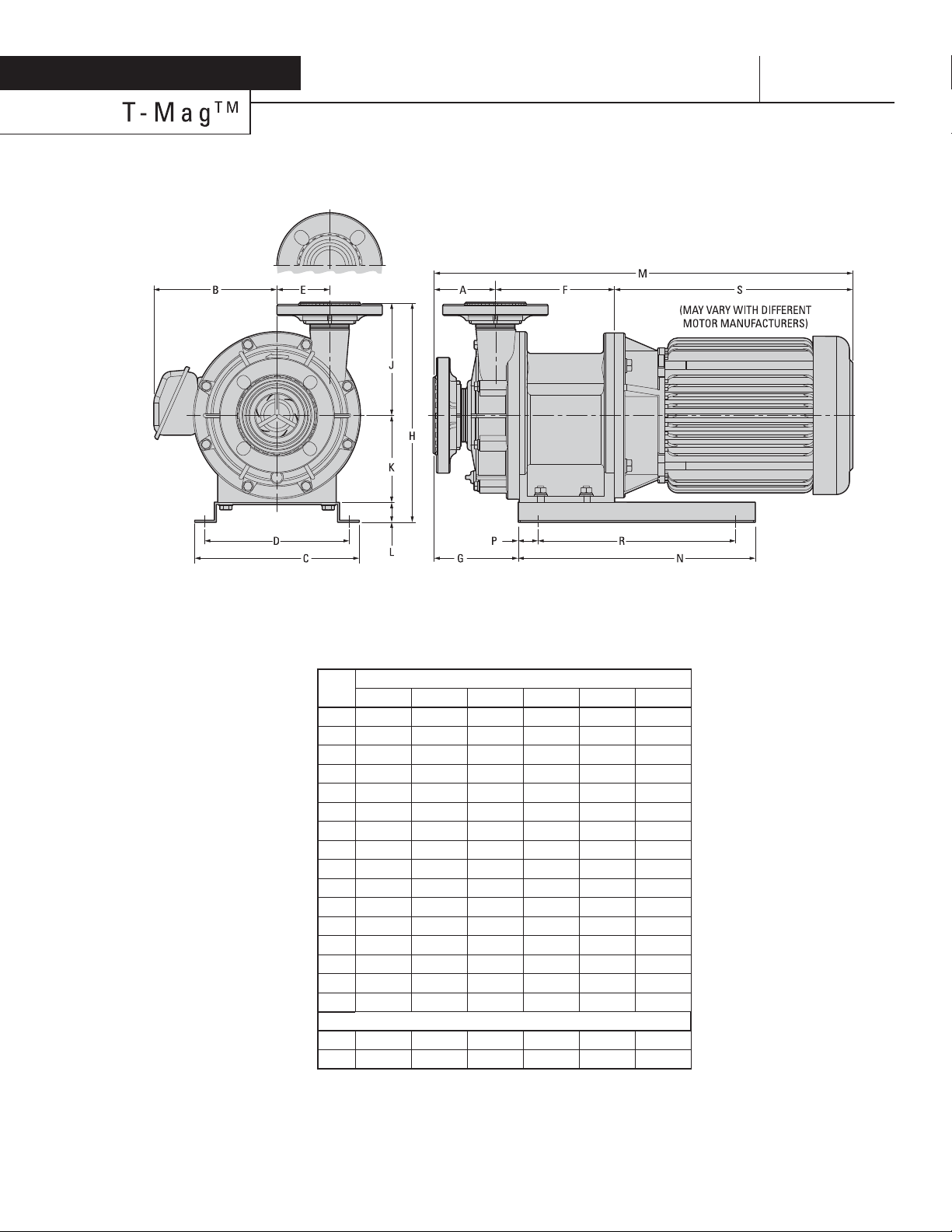

Section 4

DIMENSIONAL DRAWINGS

Note: The total length & weight of the pump will differ depending on the brand of the motor.

in

(mm)

Model Size

1/2 HP 1 HP 2 HP 3 HP 5 HP 5 HP

A

3.5 (89) 5.2 (131) 3.5 (90) 3.5 (90) 3.5 (90) 3.7 (94)

B

5.1 (130) 5.6 (142) 6.1 (155) 6.1 (155) 7.4 (187) 7.4 (187)

C

8.9 (225) 6.3 (160) 10.2 (260) 10.2 (260) 9.8 (250) 9.8 (250)

D

7.7 (195) 5.1 (130) 8.0 (204) 8.0 (204) 8.7 (220) 8.7 (220)

E

2.4 (60) 2.8 (72) 3.1 (80) 3.1 (80) 3.1 (80) 3.1 (80)

F

5.6 (142) 5.7 (146) 6.3 (160) 6.3 (160) 6.9 (175) 7.1 (180)

G

4.6 (116) 5.9 (150) 5.4 (138) 5.4 (138) 4.7 (119) 5.0 (128)

H

11.3 (286) 10.1 (256) 11.1 (281) 11.1 (281) 12.7 (323) 12.7 (323)

J

5.6 (141) 5.6 (141) 6.3 (161) 6.3 (161) 6.3 (161) 6.7 (171)

K

4.6 (118) 3.3 (85) 3.5 (90) 3.5 (90) 5.2 (132) 5.2 (132)

L

1.0 (25) 1.2 (30) 1.2 (30) 1.2 (30) 1.2 (30) 1.2 (30)

M

18.4 (467) 18.9 (481) 22.2 (564) 22.2 (564) 24.7 (627) 25.0 (636)

N

9.1 (230) 8.3 (210) 11.8 (300) 11.8 (300) 14.2 (360) 14.2 (360)

P

1.0 (25) 1.4 (35) 0.8 (20) 0.8 (20) 1.2 (30) 1.2 (30)

R

7.1 (180) 5.1 (130) 7.9 (200) 7.9 (200) 11.8 (300) 11.8 (300)

S

9.3 (236) 9.1( 232) 12.2 (311) 12.2 (311) 14.3 (362) 14.3 (362)

Flange (ANSI, DIN & JIS Combo)

In 1-1/2 (40) 1-1/2 (40) 2 (50) 2 (50) 2 (50) 2-1/2 (65)

Out 1-1/2 (40) 1-1/2 (40) 1-1/2 (40) 1-1/2 (40) 1-1/2 (40) 2 (50)

DIMENSIONS

6

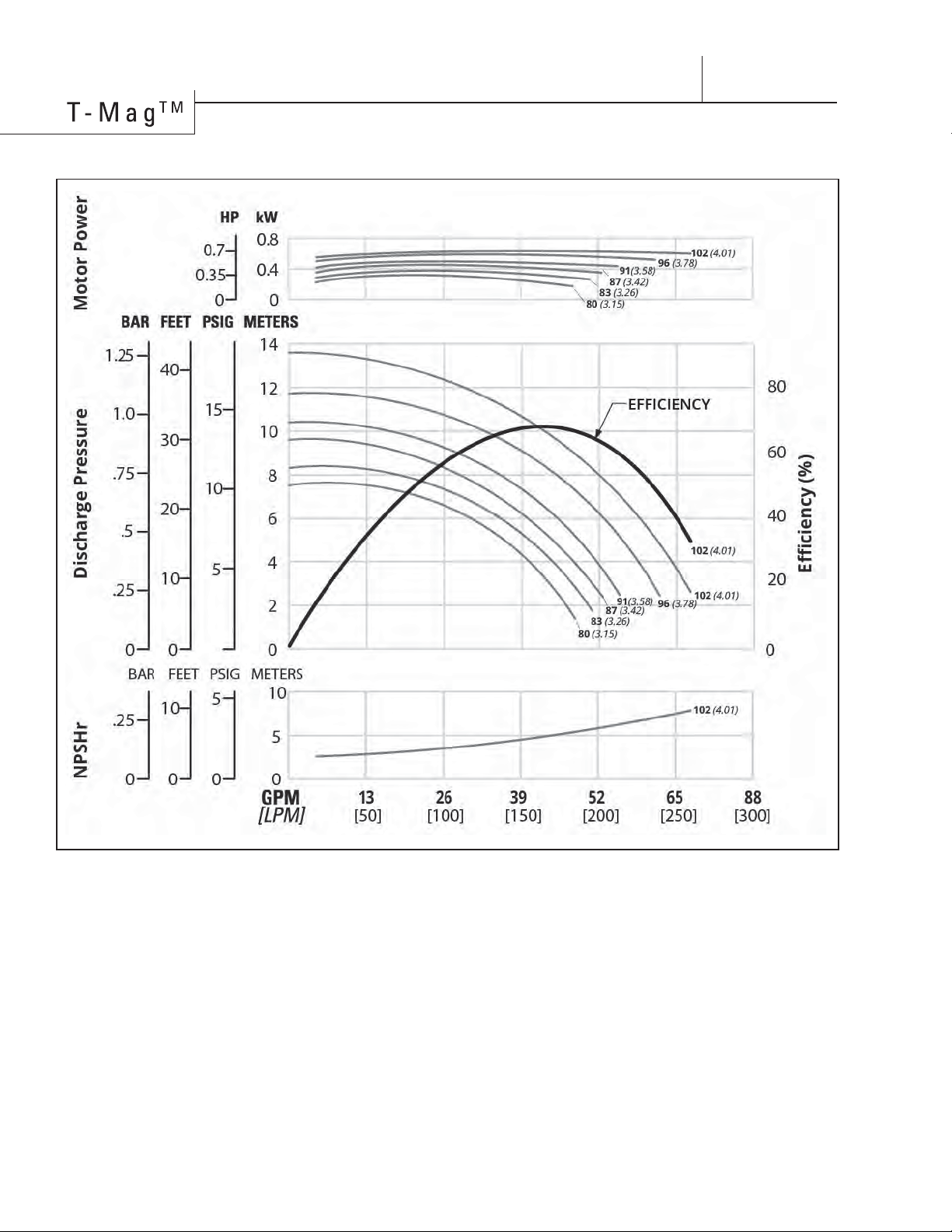

PERFORMANCE

1/2 HP (0.40 kW) - 50 Hz - 2900 RPM [TM4H]

Height

....................................

11.3" (286 mm)

Width

..................................

10.2" ( 260 mm)

Length

..................................

18.4" (467 mm)

Ship Weight

GF-PP

................................

40 lbs (18 kg)

CFR-ETFE

............................

42 lbs (19 kg)

Fluid Inlet

..............................

1-1/2" (38 mm)

Fluid Discharge

.....................

1-1/2" (38 mm)

Rated Point

......................

43 gpm (195 lpm)

All curves based upon pumping water

at sea level, specific gravity 1.0 ambient

temperature 20˚C (68˚F).

NOTE: Numbers shown to far right of all

performance lines denote the diameter of

the pump impeller [millimeters (inches)].

Consult factory for availability of impeller

trim sizes other than shown.

14.0 psig (0.96 bar)

7

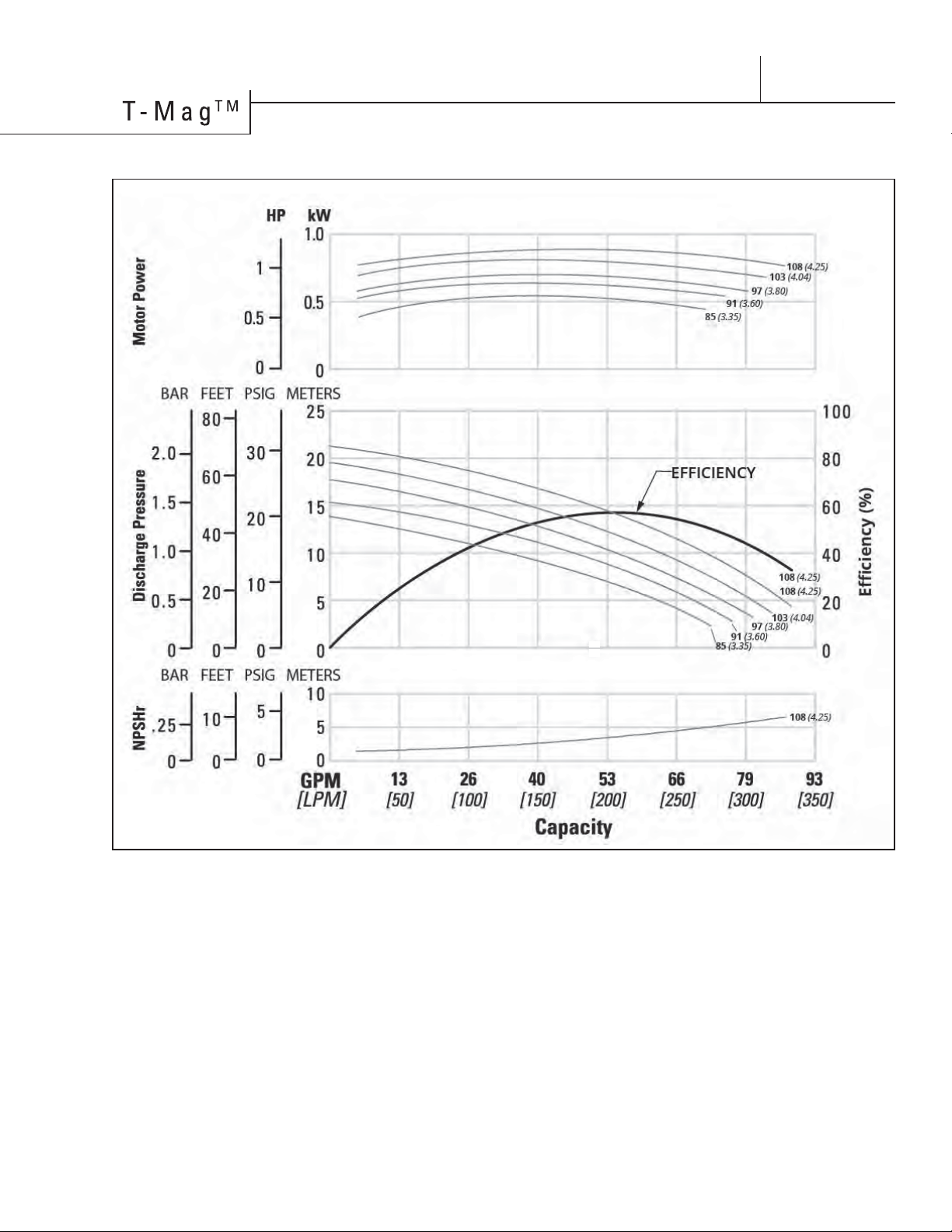

1/2 HP (0.40 kW) - 60 Hz - 3600 RPM [TM4H]

Height

....................................

11.3" (286 mm)

Width

..................................

10.2" ( 260 mm)

Length

..................................

18.4" (467 mm)

Ship Weight

GF-PP

................................

40 lbs (18 kg)

CFR-ETFE

............................

42 lbs (19 kg)

Fluid Inlet

..............................

1-1/2" (38 mm)

Fluid Discharge

.....................

1-1/2" (38 mm)

Rated Point

......................

4 3 gpm ( 195 l pm)

14.0 psig (0.96 bar)

All curves based upon pumping water

at sea level, specific gravity 1.0, ambient

temperature 20˚C (68˚F).

NOTE: Numbers shown to far right of all

performance lines denote the diameter of

the pump impeller [millimeters (inches)].

Consult factory for availability of impeller

trim sizes other than shown.

PERFORMANCE

8

1 HP (0.75 kW) - 50 Hz - 2900 RPM [TM4K]

BAR FEET PSIG METERS

1

0.5

0

10

5

0

.25

0

10

0

5

0

Height

....................................

10.1" (256 mm)

Width

...................................

11.2" (284 mm)

Length

..................................

18.9" (481 mm)

Ship Weight

GF-PP

...............................

53 lbs (24 kg)

CFR-ETFE

............................

55 lbs (25 kg)

Fluid Inlet

..............................

1-1/2" (38 mm)

Fluid Discharge

.....................

1-1/2" (38 mm)

Rated Point

..................

45 gpm (204 lpm)

22.8 psig (1.57 bar)

All curves based upon pumping water

at sea level, specific gravity 1.0, ambient

temperature 20˚C (68˚F).

NOTE: Numbers shown to far right of all

performance lines denote the diameter of

the pump impeller in [millimeters (inches)]

Consult factory for availability of impeller

trim sizes other than shown.

P ERFORMANCE

9

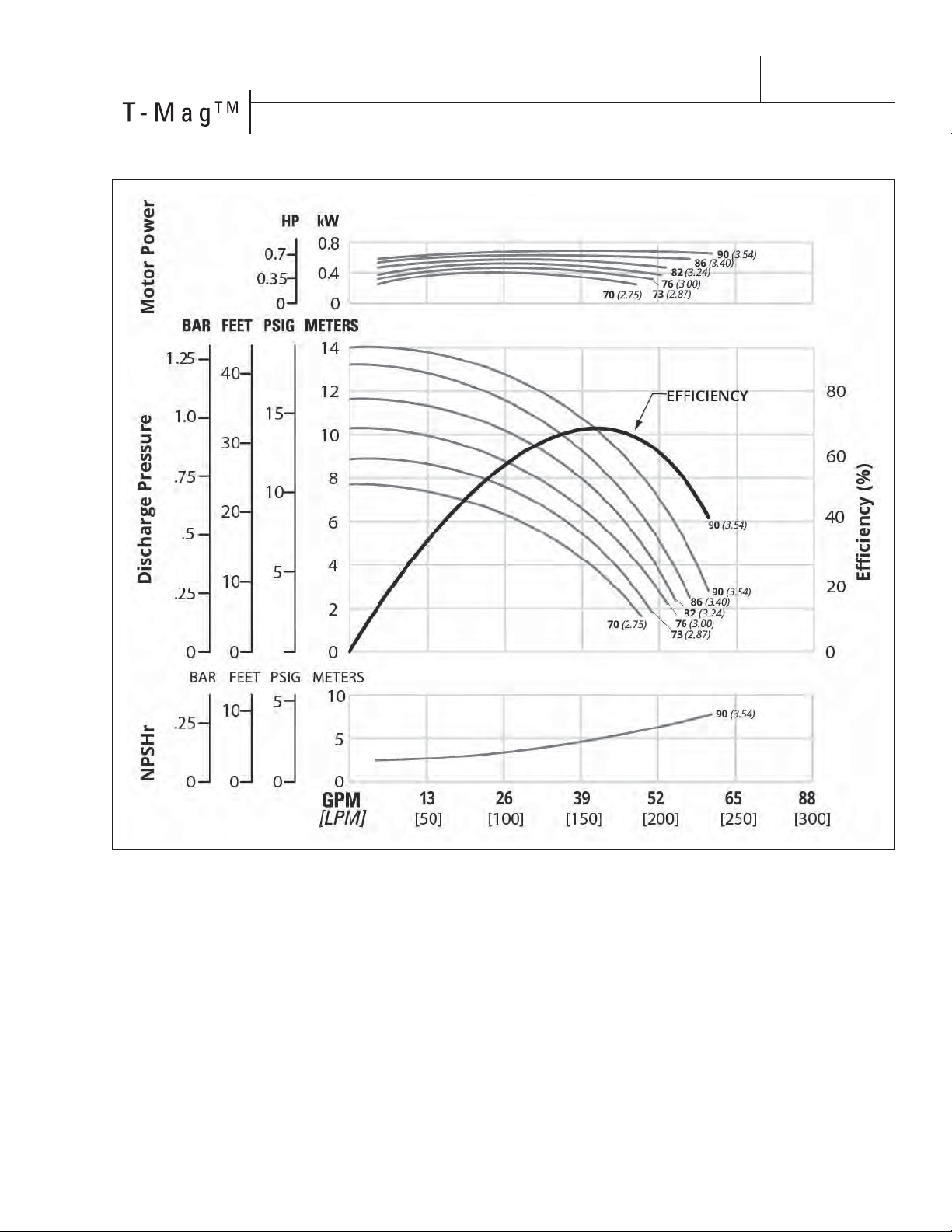

1 HP (0.75 kW) - 60 Hz - 3600 RPM [TM4K]

Height

....................................

10.1" (256 mm)

Width

...................................

11.2" (284 mm)

Length

..................................

18.9" (481 mm)

Ship Weight

GF-PP

...............................

53 lbs (24 kg)

CFR-ETFE

............................

55 lbs (25 kg)

Fluid Inlet

..............................

1-1/2" (38 mm)

Fluid Discharge

.....................

1-1/2" (38 mm)

Rated Point 53 gpm ( 240 lpm)

21.9 psig (1.51 bar)

All curves based upon pumping water

at sea level, specific gravity 1.0, ambient

temperature 20˚C (68˚F).

NOTE: Numbers shown to far right of all

performance lines denote the diameter of

the pump impeller in [millimeters (inches)].

Consult factory for availability of impeller

trim sizes other than shown.

PERFORMANCE

........................

10

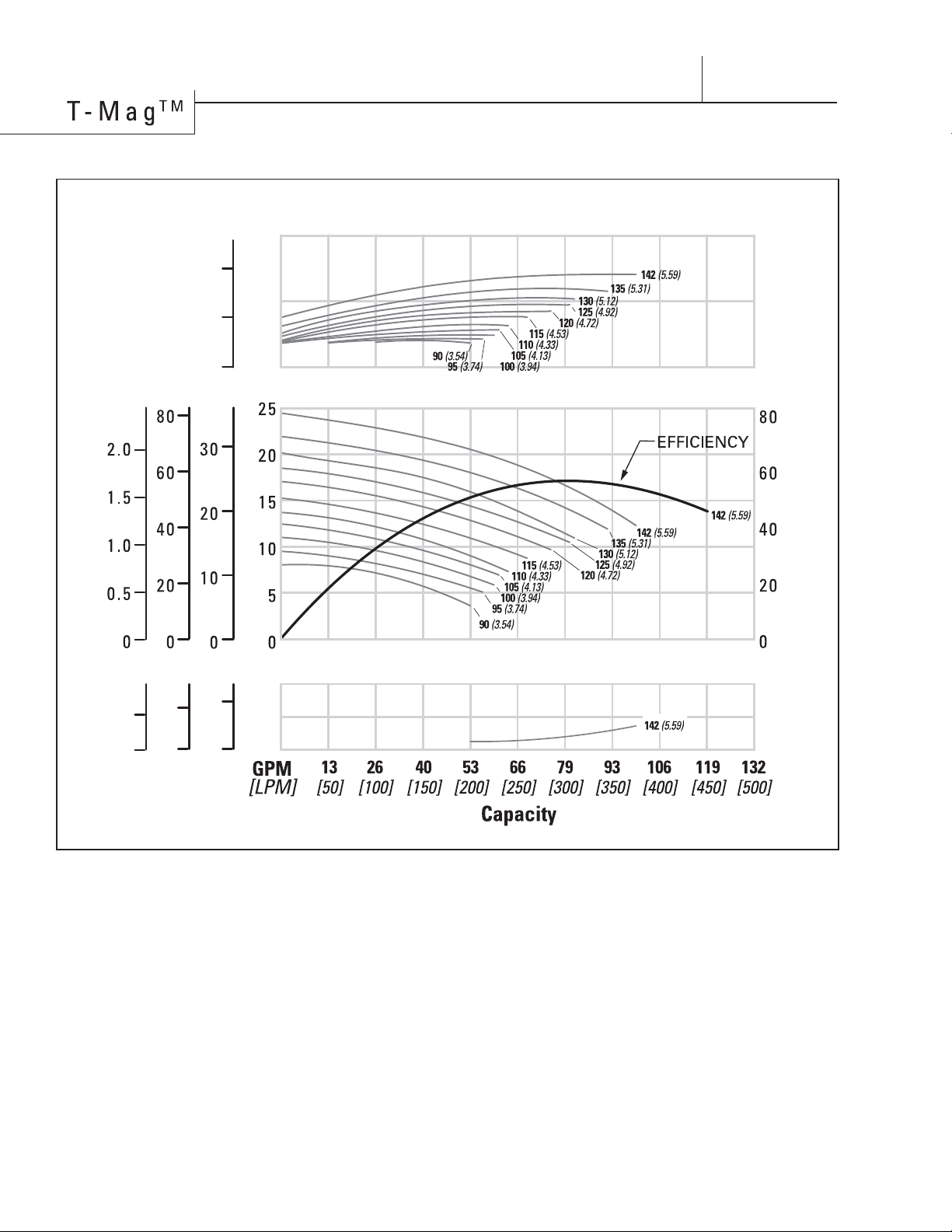

Height

....................................

11.1" (281 mm)

Width

......................................

12.0" (305 mm)

Length

.................................

22.2" (564 mm)

Ship Weight

GF-PP

................................

77 lbs (35 kg)

CFR-ETFE

............................

79 lbs (36 kg)

Fluid Inlet

....................................

2" (51 mm)

Fluid Discharge

........................

1-1/2" (38 mm)

Rated Point

...................

75 gpm (340 lpm)

25 psig (1.72 bar)

All curves based upon pumping water

at sea level, specific gravity 1.0, ambient

temperature 20˚C (68˚F).

NOTE: Numbers shown to far right of all

performance lines denote the diameter of

the pump impeller in [millimeters (inches)]

Consult factory for availability of impeller

trim sizes other than shown.

2 HP (1.5 kW) - 50 Hz - 2900 RPM [TM6L]

BAR FEET PSIG METERS

Discharge Pressure

(ɝFLHQF\

BAR FEET PSIG METERS

.25

0

10

0

5

0

2

1

0

HP kW

NPSHr Motor Power

10

5

0

2

1

0

PERFORMANCE

11

Height

....................................

11.1" (281 mm)

Width

......................................

12.0" (305 mm)

Length

.................................

22.2" (564 mm)

Ship Weight

GF-PP

................................

77 lbs (35 kg)

CFR-ETFE

............................

79 lbs (36 kg)

Fluid Inlet

....................................

2" (51 mm)

Fluid Discharge

........................

1-1/2" (38 mm)

Rated Point

...................

85 gpm (386 lpm)

26 psig (1.79 bar)

All curves based upon pumping water

at sea level, specific gravity 1.0, ambient

temperature 20˚C (68˚F).

NOTE: Numbers shown to far right of all

performance lines denote the diameter of

the pump impeller in [millimeters (inches)].

Consult factory for availability of impeller

trim sizes other than shown.

2 HP (1.50 kW) - 60 Hz - 3600 RPM [TM6L]

PERFORMANCE

12

3 HP (2.2 kW) - 50 Hz - 2900 RPM [TM6M]

BAR FEET PSIG METERS

Discharge Pressure

(ɝFLHQF\

80

60

40

20

0

BAR FEET PSIG METERS

.25

0

10

0

5

0

3.0

1.5

0

HP kW

NPSHr Motor Power

10

5

0

4

2

0

PERFORMANCE

Height

....................................

11.1" (281 mm)

Width

......................................

12.0" (305 mm)

Length

.................................

22.2" (564 mm)

Ship Weight

GF-PP

................................

82 lbs (37 kg)

CFR-ETFE

............................

84 lbs (38 kg)

Fluid Inlet

....................................

2" (51 mm)

Fluid Discharge

........................

1-1/2" (38 mm)

Rated Point

...................

77 gpm (350 lpm)

36.7 psig (2.53 bar)

All curves based upon pumping water

at sea level, specific gravity 1.0, ambient

temperature 20˚C (68˚F).

NOTE: Numbers shown to far right of all

performance lines denote the diameter of

the pump impeller in [millimeters (inches)]

Consult factory for availability of impeller

trim sizes other than shown.

13

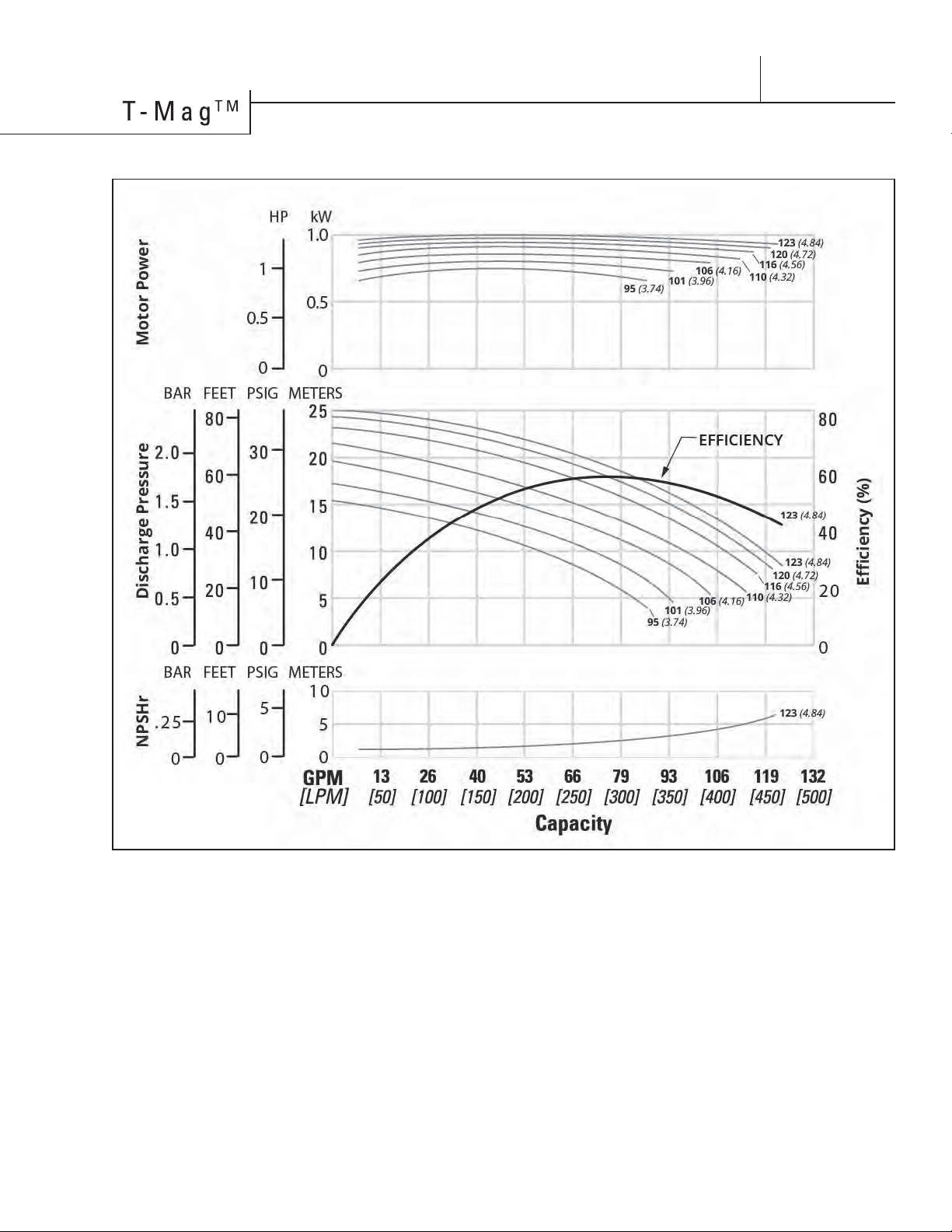

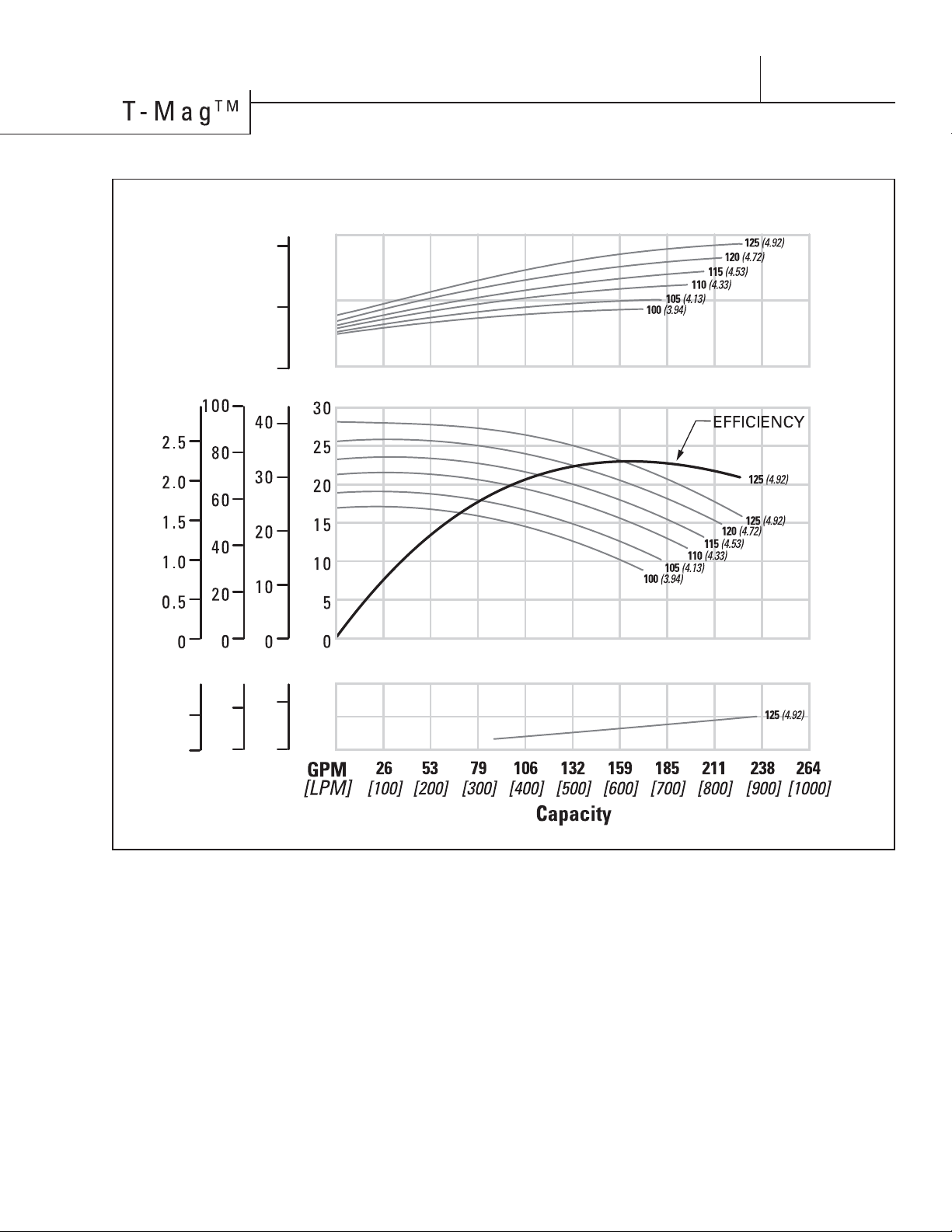

3 HP (2.20 kW) - 60 Hz - 3600 RPM [TM6M]

PERFORMANCE

Height

....................................

11.1" (281 mm)

Width

......................................

12.0" (305 mm)

Length

.................................

22.2" (564 mm)

Ship Weight

GF-PP

................................

82 lbs (37 kg)

CFR-ETFE

............................

84 lbs (38 kg)

Fluid Inlet

....................................

2" (51 mm)

Fluid Discharge

........................

1-1/2" (38 mm)

Rated Point

...................

90 gpm (409 lpm)

37.3 psig (2.57 bar)

All curves based upon pumping water

at sea level, specific gravity 1.0, ambient

temperature 20˚C (68˚F).

NOTE: Numbers shown to far right of all

performance lines denote the diameter of

the pump impeller in [millimeters (inches)].

Consult factory for availability of impeller

trim sizes other than shown.

14

5 HP (3.7 kW) - 50 Hz - 2900 RPM [TM6N]

BAR FEET PSIG METERS

Discharge Pressure

(ɝFLHQF\

80

60

40

20

0

4.0

2.0

0

HP kW

NPSHr Motor Power

5

2.5

0

10

5

0

BAR FEET PSIG METERS

.25

0

10

0

5

0

PERFORMANCE

Height

...................................

12.7" (323 mm)

Width

......................................

13.3" (337 mm)

Length

..................................

24.7" (627 mm)

Ship Weight

GF-PP

..............................

117 lbs (53 kg)

CFR-ETFE

...........................

119 lbs (54 kg)

Fluid Inlet

....................................

2" (51 mm)

Fluid Discharge

......................

1-1/2" (38 mm)

Rated Point

..................

100 gpm (454 lpm)

35 psig (2.41 bar)

All curves based upon pumping water

at sea level, specific gravity 1.0, ambient

temperature 20˚C (68˚F).

NOTE: Numbers shown to far right of all

performance lines denote the diameter of

the pump impeller in [millimeters (inches)]

Consult factory for availability of impeller

trim sizes other than shown.

15

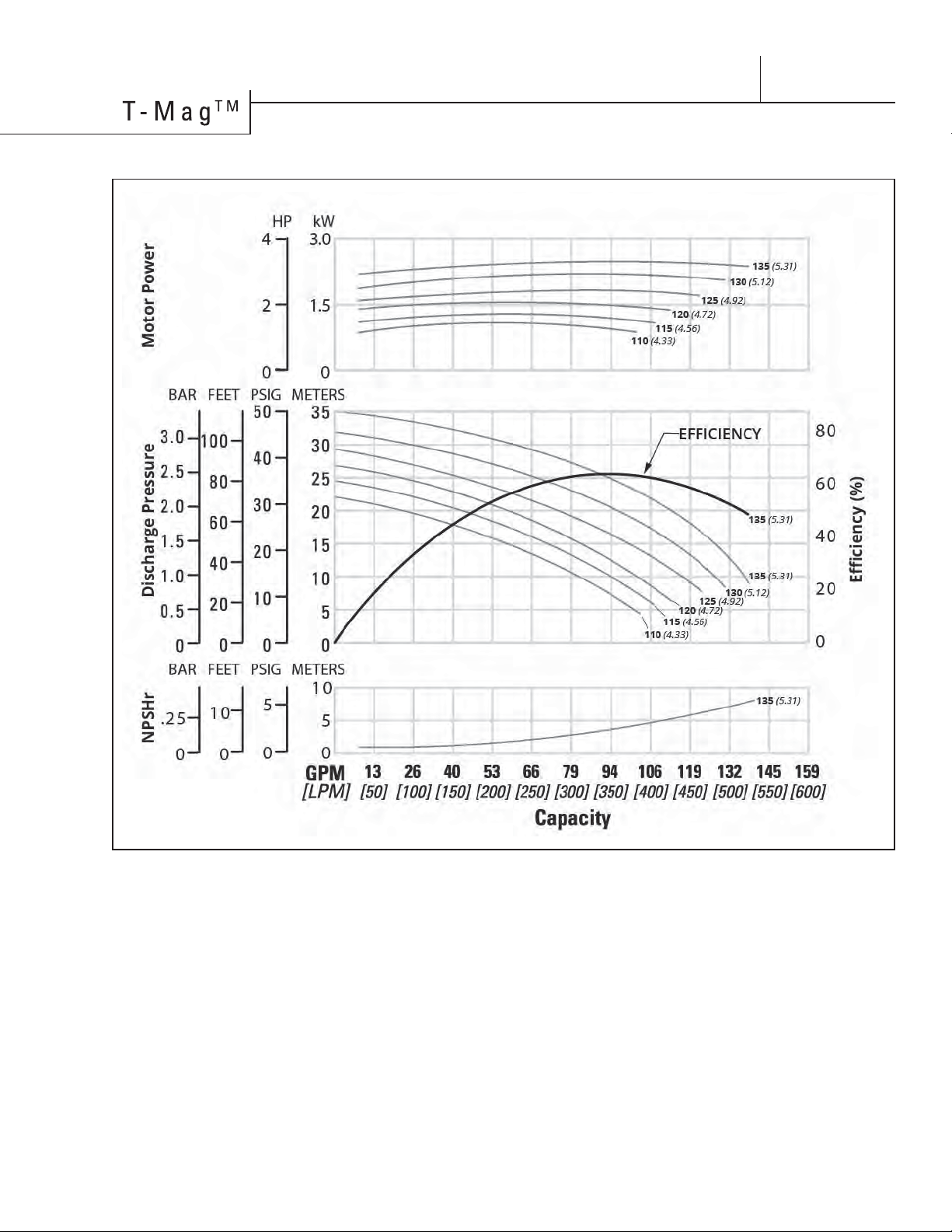

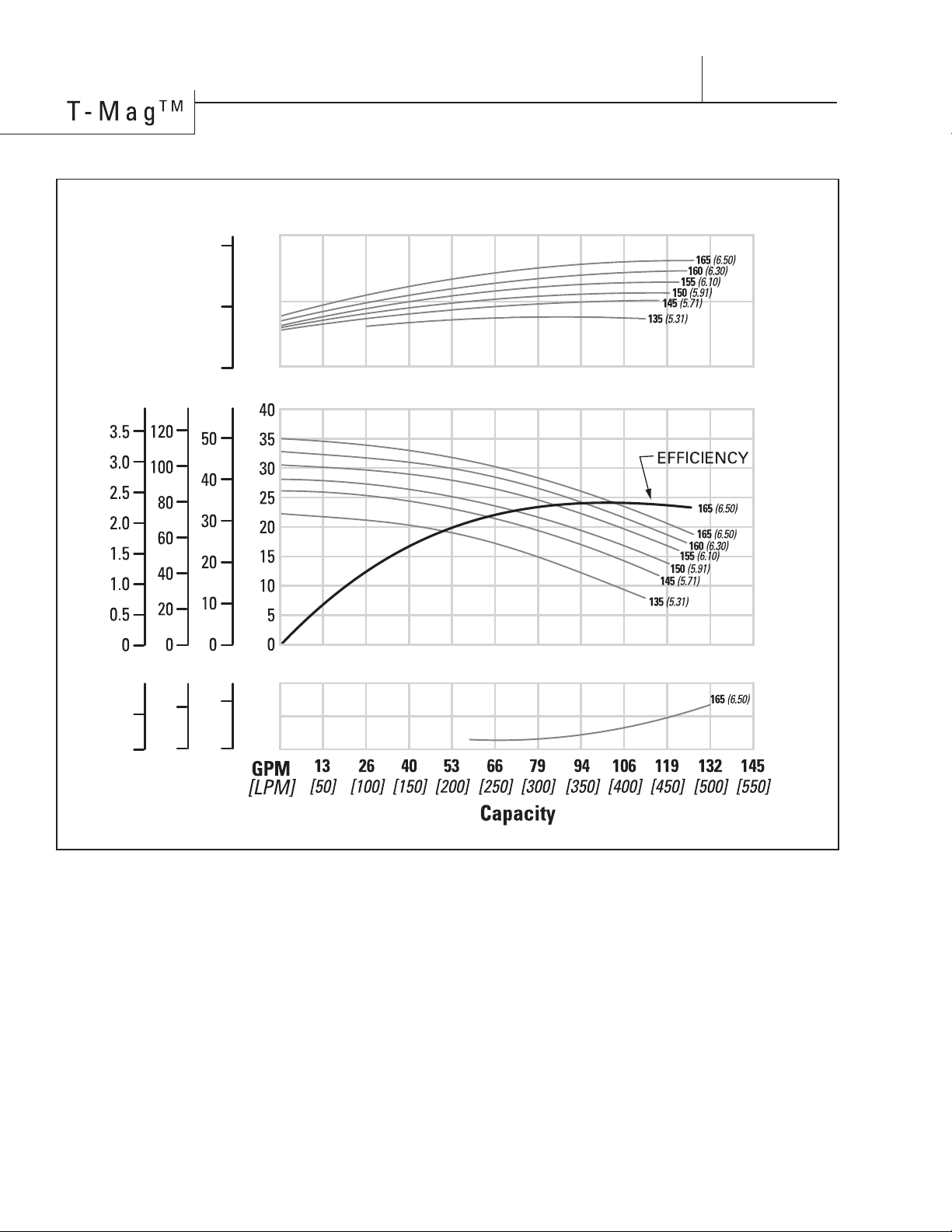

5 HP (3.7 kW) - 60 Hz - 3600 RPM [TM6N]

BAR FEET PSIG METERS

Discharge Pressure

4.0

2.0

0

HP kW

NPSHr Motor Power

5

2.5

0

10

5

0

BAR FEET PSIG METERS

.25

0

10

0

5

0

PERFORMANCE

Height

...................................

12.7" (323 mm)

Width

......................................

13.3" (337 mm)

Length

..................................

24.7" (627 mm)

Ship Weight

GF-PP

..............................

117 lbs (53 kg)

CFR-ETFE

...........................

119 lbs (54 kg)

Fluid Inlet

....................................

2" (51 mm)

Fluid Discharge

......................

1-1/2" (38 mm)

Rated Point

..................

105 gpm (477 lpm)

40.0 psig (2.75 bar)

All curves based upon pumping water

at sea level, specific gravity 1.0, ambient

temperature 20˚C (68˚F).

NOTE: Numbers shown to far right of all

performance lines denote the diameter of

the pump impeller [millimeters (inches)]

Consult factory for availability of impeller

trim sizes other than shown.

16

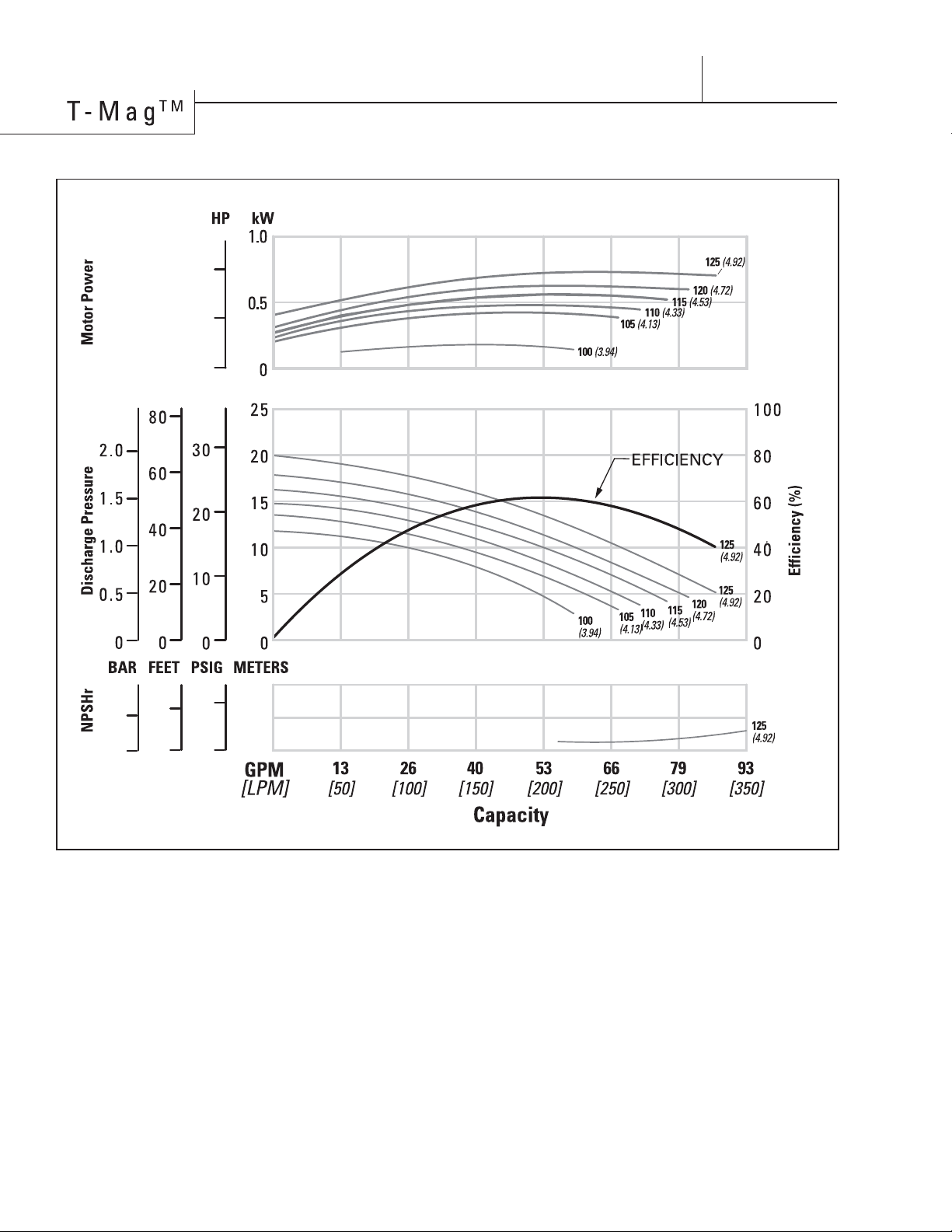

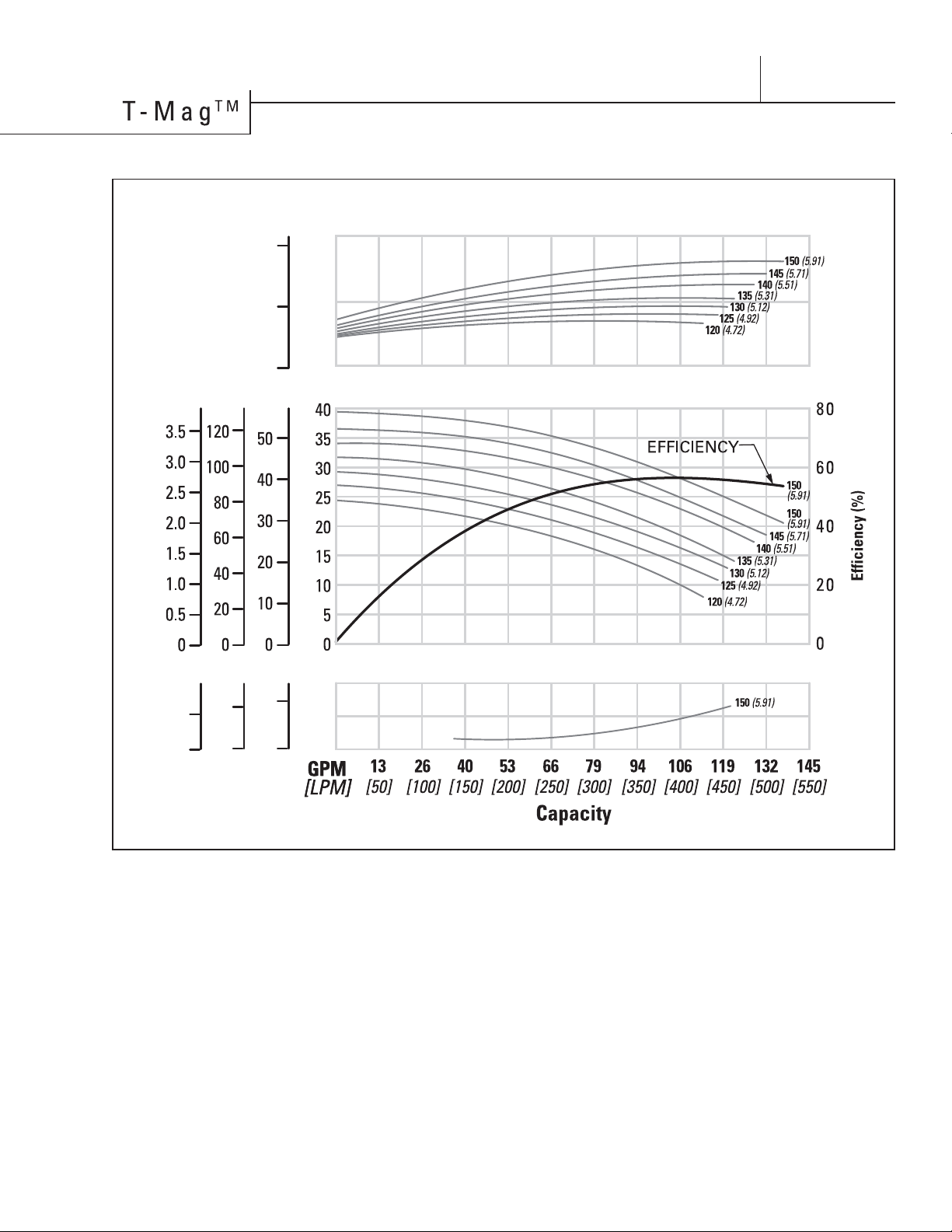

5 HP (3.7 kW) - 50 Hz - 2900 RPM Oversize Inlet [TM10N]

BAR FEET PSIG METERS

Discharge Pressure

(ɝFLHQF\

80

60

40

20

0

4.0

2.0

0

HP kW

NPSHr Motor Power

5

2.5

0

10

5

0

BAR FEET PSIG METERS

.25

0

10

0

5

0

PERFORMANCE

Height

...................................

13.1" (333 mm)

Width

...................................

13.7" (347 mm)

Length

.................................

25.0" (636 mm)

Ship Weight

GF-PP

..............................

117 lbs (53 kg)

CFR-ETFE

..........................

119 lbs (54 kg)

Fluid Inlet

.............................

2-1/2" (64 mm)

Fluid Discharge

..........................

2" (51 mm)

Rated Point

...................

34.0 psig (2.34 bar)

All curves based upon pumping water

at sea level, specific gravity 1.0, ambient

temperature 20˚C (68˚F).

NOTE: Numbers shown to far right of all

performance lines denote the diameter of

the pump impeller in [millimeters (inches)]

Consult factory for availability of impeller

trim sizes other than shown.

150 gpm (681 lpm)

17

Height

...................................

13.1" (333 mm)

Width

...................................

13.7" (347 mm)

Length

.................................

25.0" (636 mm)

Ship Weight

GF-PP

..............................

117 lbs (53 kg)

CFR-ETFE

..........................

119 lbs (54 kg)

Fluid Inlet

.............................

2-1/2" (64 mm)

Fluid Discharge

..........................

2" (51 mm)

Rated Point

...................

33.0 psig (2.34 bar)

All curves based upon pumping water

at sea level, specific gravity 1.0, ambient

temperature 20˚C (68˚F).

NOTE: Numbers shown to far right of all

performance lines denote the diameter of

the pump impeller [millimeters (inches)]

Consult factory for availability of impeller

trim sizes other than shown.

PERFORMANCE

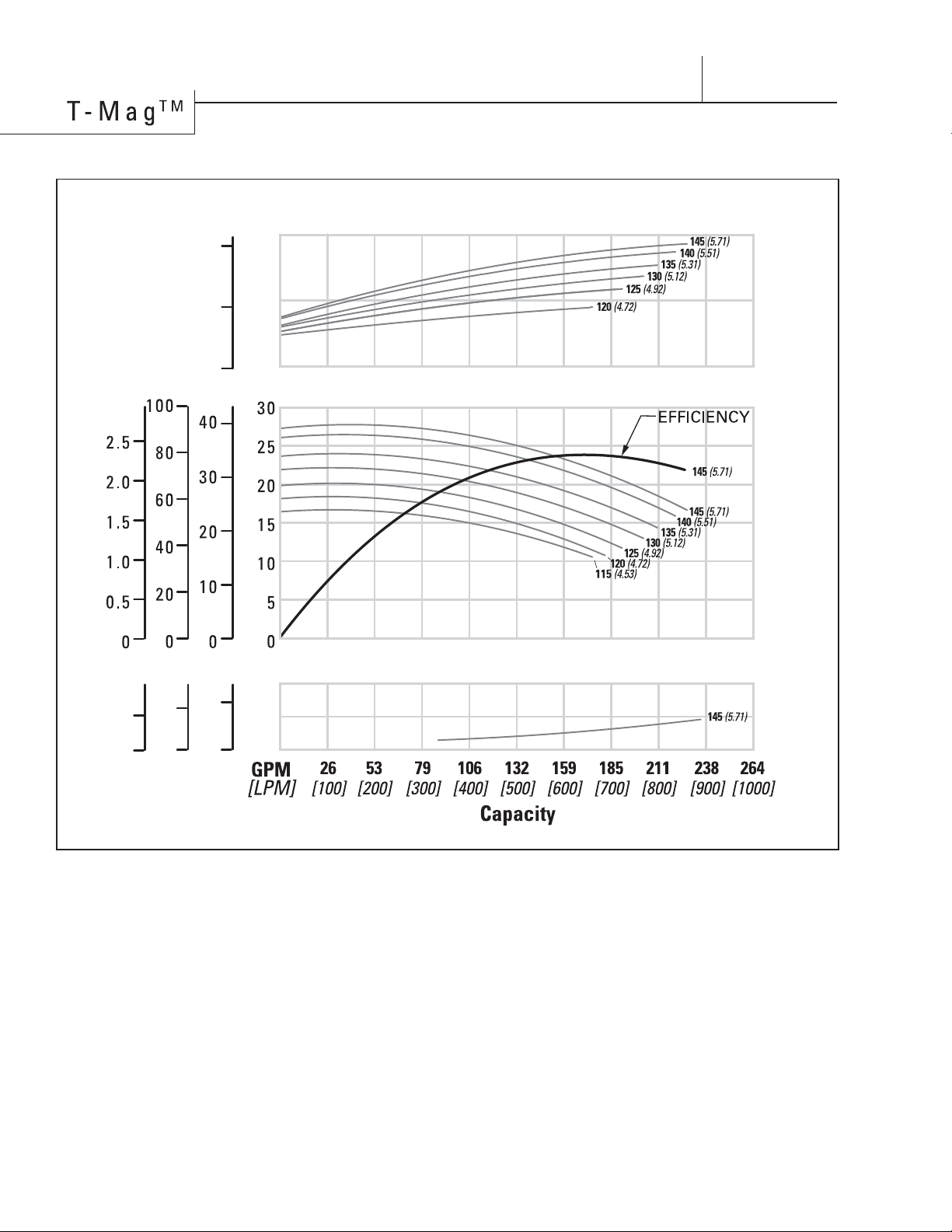

5 HP (3.7 kW) - 60 Hz - 3600 RPM Oversize Inlet [TM10N]

BAR FEET PSIG METERS

Discharge Pressure

(ɝFLHQF\

80

60

40

20

0

NPSHr

4.0

2.0

0

HP kW

Motor Power

5

2.5

0

10

5

0

BAR FEET PSIG METERS

.25

0

10

0

5

0

159 gpm (722 lpm)

13

Section 6

SUGGESTED INSTALLATION

T-MAG™ pumps are designed to meet the performance

requirements of even the most demanding pumping

applications. They have been designed and manufactured

to the highest standards and are available in a variety of

liquid path materials to meet your chemical resistance

needs. Refer to the performance section of this manual

for an in-depth analysis of the performance characteristics

of your pump. The suction pipe size should be at least

the equivalent or larger than the diameter size of the

suction inlet on your T-MAG™ pump. The suction hose/

pipe must be non-collapsible. Discharge piping should

also be the equivalent or larger than the diameter of the

pump discharge which will help reduce friction losses. It

is critical that all ttings and connections are airtight to

reduce the rist of cavitation which may damage the pump.

INSTALLATION: Months of careful planning, study, and

selection eorts can result in unsatisfactory pump

performance if installation details are left to chance.

Premature failure and long term dissatisfaction can be

avoided if reasonable care is exercised throughout the

installation process.

LOCATION: Noise, safety, and other logistical factors

usually dictate where equipment will be situated on the

production oor. Multiple installations with conicting

requirements can result in congestion of utility areas,

leaving few choices for additional pumps. Within the

framework of these and other existing conditions, every

pump should be located in such a way that the 8 key

factors are balanced against each other to maximum

advantage.

ACCESS: First of all, the location should be accessible. If

it’s easy to reach the pump, maintenance personnel will

have an easier time carrying out routine inspections and

adjustments. Should major repairs become necessary,

ease of access can play a key role in speeding the repair

process and reducing total downtime.

ELECTRICAL SUPPLY: Every pump location should have

all power lines, conduit and switches mounted in such

a way as to avoid any risk or hazard to the user or work

area. Keep in mind that while pumping some uids it

is required to ground the pump to prevent discharge of

any static buildup. For best results, ensure a licensed

professional performs any necessary installation work.

PUMP INLET: To optimize pump life it is important to

install the pump in a position that will ensure a constant

supply of process uid. Running the unit dry will cause

cavitation which could result in unnecessary vibration.

This vibration can result in internal component damage

that could diminish the life of the pump. Also, although

the pump is designed to run dry without damage in the

carbon / ceramic conguration, running dry on a regular

basis can shorten the overall mean time between failure

(MTBF) of the pump.

CONTROLS: All pumps should be outtted with the

appropriate safety shut o and controls to meet the

local, state or federal requirements for the application in

the area the pump is being used. To better understand

the performance of the pump it is recommended that

gauges be placed on the inlet and discharge lines of the

pump, isolation gauges be installed for isolation and

repairs and a ow meter be used to monitor the pump’s

performance over time.

PUMP DISCHARGE: Be sure that the discharge

capabilities of the pump meet the required pressure to

overcome the friction loss across the discharge piping,

lters and valving. Do not close the downstream

isolation valve of the pump while in operation. Doing so

will cause the pump head to overheat and may damage

the internals of the pump.

PIPING: Final determination of the pump site should not

be made until the piping challenges of each possible

location have been evaluated. The impact of current

and future installations should be considered ahead of

time to make sure that inadvertent restrictions are not

created for any remaining sites.

The best choice possible will be a site involving

the shortest and straightest hook-up of suction and

discharge piping. Unnecessary elbows, bends, and

ttings should be avoided. Pipe sizes and type should

be selected to keep friction losses within practical

limits. All piping should be supported independently of

the pump. In addition, the piping should be aligned to

avoid placing stress on the pump ttings.

Flexible hose can be installed to aid in absorbing the

forces created by the natural vibration of the pump. If the

pump is to be bolted down to a solid location, a mounting

pad placed between the pump and the foundation will

assist in minimizing pump vibration.

When pumps are installed in applications involving

ooded suction or suction head pressures, a gate valve

should be installed in the suction line to permit closing

of the line for pump service.

SUBMERSIBLE APPLICATIONS: T-MAG™ pumps can

not be submerged for use.

T-MAG™ PUMPS ARE CAPABLE OF PASSING SOLIDS

BELOW 50 (microns), ALTHOUGH ANY SOLIDS WITHIN

THE PROCESS STREAM OF A T-MAG™ PUMP COULD

WEAR CRITICAL COMPONENTS.

This wear will diminish performance or cause failure

of the pump. Standard carbon tted T-MAG™ Mag-

Drive pumps are suited for limited dry run conditions

only. Other materials such as Rulon® and SSIC tted

pumps are not suitable for dry run conditions.

This manual suits for next models

3

Popular Water Pump manuals by other brands

Gormann-Rupp Pumps

Gormann-Rupp Pumps 82E-GX240 Installation, operation, and maintenance manual with parts list

McKINLEY

McKINLEY T34 Operation manual

GORMAN-RUPP

GORMAN-RUPP AMT 5586-H6 manual

Clarke

Clarke IVP13A Operating & maintenance instructions

KSB

KSB Hya-Rain Installation & operating manual

Speck pumpen

Speck pumpen V Series operating instructions

Grundfos

Grundfos SPRING N Series Service instructions

Pontec

Pontec PondoGarden 3200 operating instructions

Torishima Pump

Torishima Pump ETA-N Operation and maintenance manual

Grundfos

Grundfos Liftaway B Installation and operating instructions

Varian

Varian Turbo-V 2K-G instruction manual

Whale

Whale Supersub Series Installation guides