Prepare the Hot-LinkPlus Circulator for Operation:

PUMP CONTROL OPTIONS:

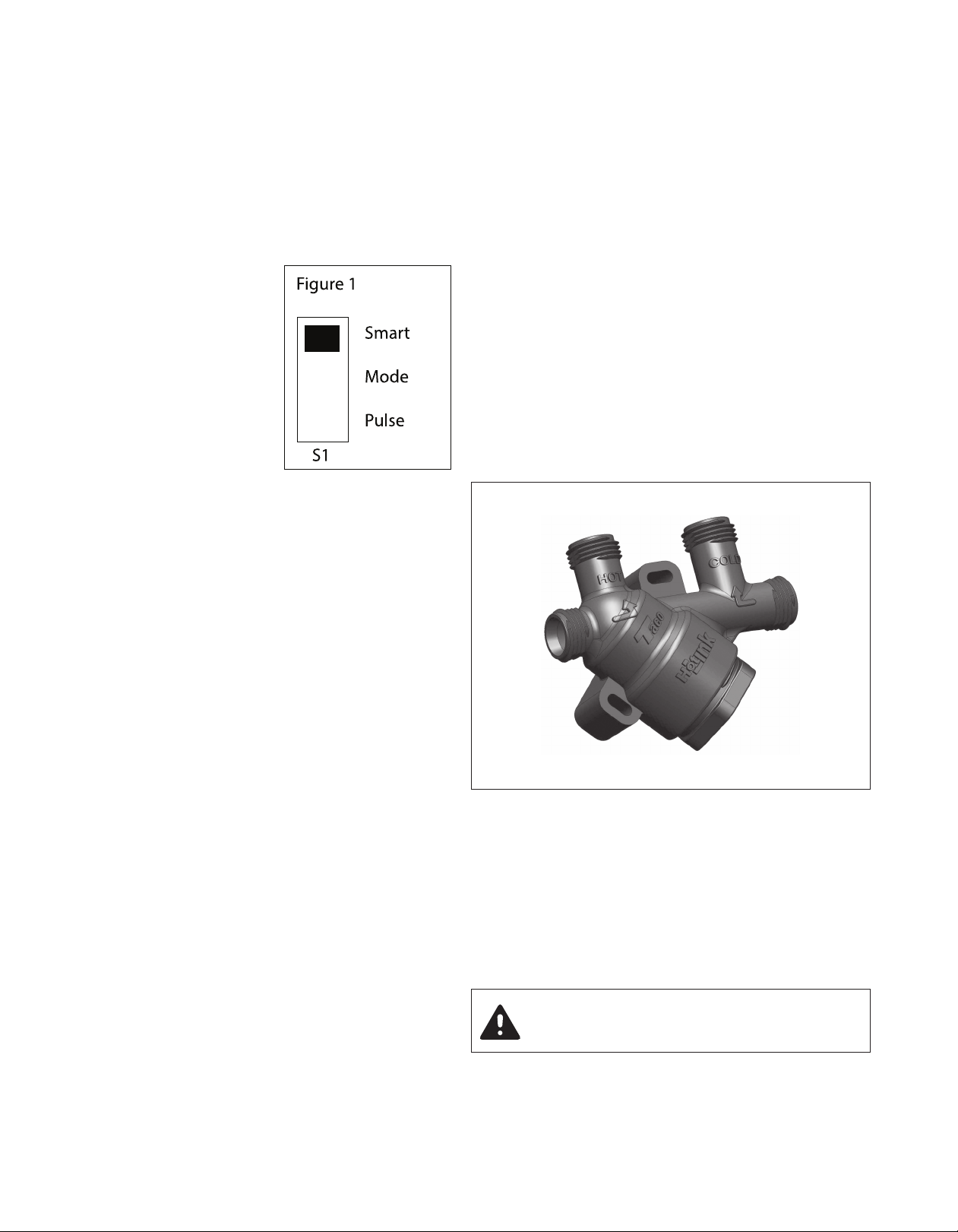

The circulator has a “Mode Select” toggle switch that allows

for 2 operation modes. “Pulse” or “Smart” mode can be

selected using the toggle switch located on the capacitor

base mounted electronic control board (See Fig. 1). A yel-

low LED indicates which mode is selected. All operation is

automatic, no manual timer or temperature setting is

required.

• “Pulse Mo e”

When set for “Pulse” operation,

the circulator will run for 5 min-

utes every 10 minutes to main-

tain hot water at all fixtures.

• “Smart/Learn” Mo e

When set for “Smart/Learn”

operation, the circulator will

run in “Pulse” mode as above

for the first 7 days. During this

time, the circulator will monitor

and record the home’s hot

water usage pattern. For the

next 7 days, the circulator will

then use the preceding week’s

usage pattern to cycle the

pump. This process will be repeated every 7 days. The

pump will run in “Pulse” mode from 1 hour before to 1 hour

after each recorded hot water demand.

1. The circulator is shipped from the factory in “Smart”

mode. To switch the pump to “Pulse” mode, remove the

2 capacitor cover screws and cover. Change the posi

tion of the toggle switch on the circuit board to “Pulse”

(see Fig.1 ). Install the capacitor cover and secure the

2 screws.

2. Plug the external temperature sensor connector pro-

vided into the the ”TEMP SENS R” receptacle on the

side of the capacitor base. Attach the sensor to the hot

water supply pipe downstream of the pump using the

black zip-tie connector provided.

3. nce the system is filled and air is purged, plug in the

circulator power cord.

N TE: The temperature sensor must be installed and

connected in either “Pulse” or “Smart” mode.

N TE: The circulator must be installed and supported

by the circulation piping.

WARNING: All local plumbing an electrical co es

shoul be followe when installing this pro uct.

WARNING: Risk of electrical shock. This pump is sup-

plie with a groun ing con uctor an groun ing-type

attachment plug. To re uce the risk of shock, be cer-

tain that it is connecte only to a properly groun e

groun ing-type receptacle.

CAUTION: Do not plug in the circulator power cor until

the system is fille with water an purge of air.

THER SPECIAL FEATURES F THE Hot-LinkPlus

CIRCULAT R:

1. Vacation Function - If no hot water usage is detected for

36 hours, the pump will remain off until hot water

usage is detected. nce detected, the pump will

resume operation.

2. Exercise Function - While in vacation mode, the pump

will come on every 7 days and run for 10 seconds

to prevent corrosion or scale buildup.

3. Power Outage - When power is restored, pump will

revert to its mode setting, either “Pulse” or “Smart.”

If in “Smart” mode, previously recorded data will not

be saved and the pump will begin a new 7-day

usage learning cycle.

4. LED - The circulator is provided with 3 LED’s located

on the side of the capacitor base.

Green LED - Illuminated - Power on.

Yellow LED - Flashing - Pump in “Pulse” mode.

Illuminated (not flashing) - Pump is in “Smart” mode.

Red LED - LED off - Sensor is connected properly.

LED flashes once every 5 seconds - Shorted sensor.

LED flashes twice every 5 seconds - pen sensor.

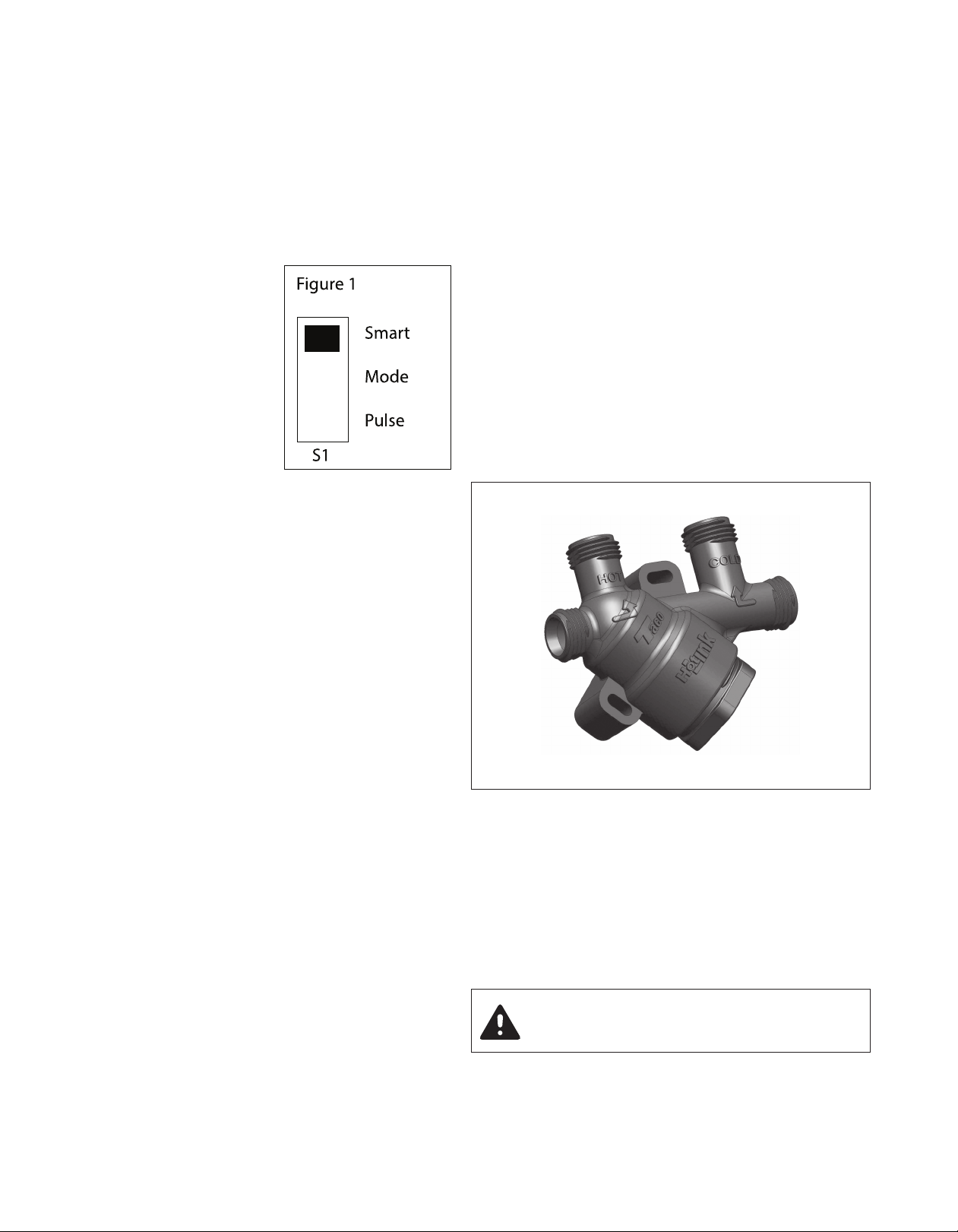

Installing the Hot-Link Valve:

1. Select the hot water faucet furthest from the water

heater. If your plumbing system branches in two differ-

ent directions, another Hot-Link Valve may need to be

installed at the end of each run.

2. Shut off the hot and cold angle stop valves below the

sink.

3. pen the hot and cold faucets to purge water from the

lines.

CAUTION: Do not use pipe dope or teflon

tape on the valve ody threads.