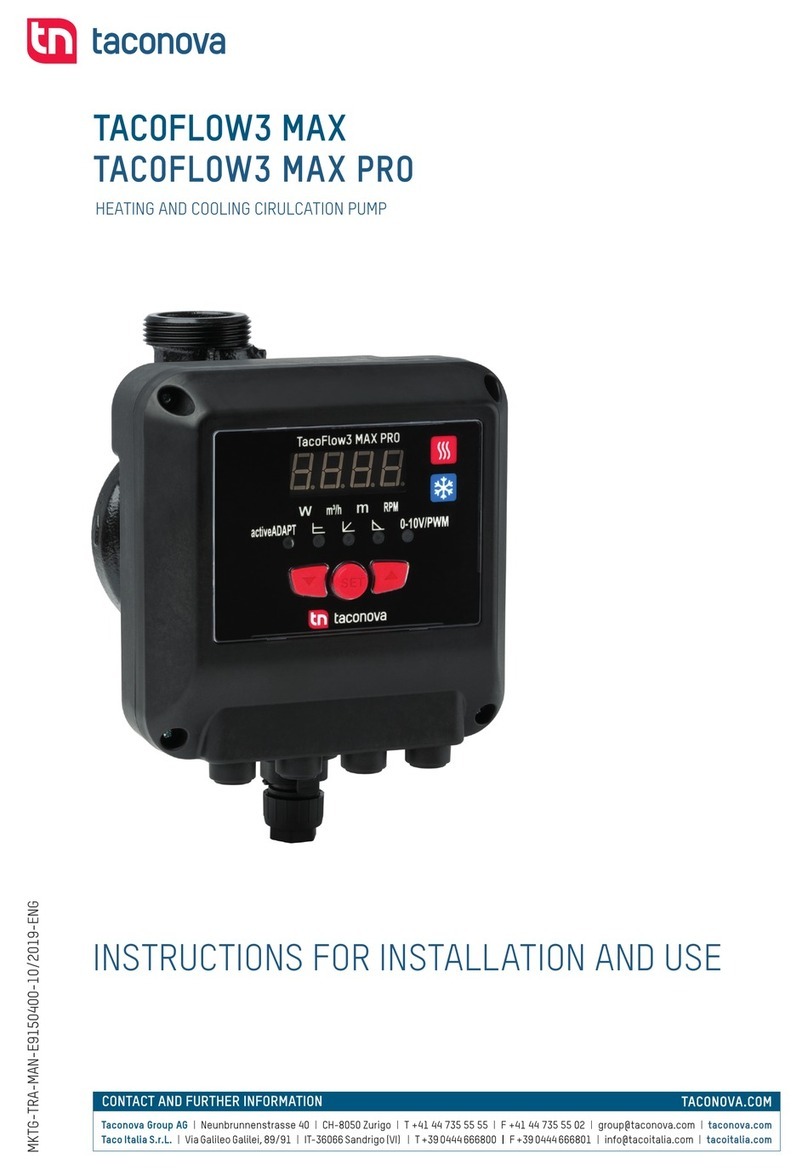

TACOFLOW3 MAX / MAX PRO

2Instructions for installation and use MKTG-TRA-MAN-E9135400-07/2019-ENG

8 PERSONAL PROTECTIVE EQUIPMENT (PPE)....................................................................................25

9 TRANSPORTAND HANDLING ............................................................................................................26

9.1 Packaging and packaging contents ....................................................................................................................26

9.2 Unpacking...........................................................................................................................................................26

10 STORAGE................................................................................................................................................27

11 INSTALLATION .......................................................................................................................................28

11.1 Mounting positions..............................................................................................................................................28

11.2 Motor body positions...........................................................................................................................................28

11.3 Assembly of pipes...............................................................................................................................................29

11.4 Isolation of the circulator body.............................................................................................................................30

11.5 Connection to the power source .........................................................................................................................30

12 USE OF THE CIRCULATOR...................................................................................................................32

12.1 Checks and operations before starting................................................................................................................32

12.2Startup ................................................................................................................................................................33

12.2.1 Vent of the system......................................................................................................................................33

12.2.2 Circulator setting MAX PRO Mod. .............................................................................................................34

12.2.3 Circulator setting Mod. MAX.......................................................................................................................35

12.2.4 External connection for 0-10 V / PWM signal.............................................................................................36

12.2.5 Standby mode (MAX PRO MOD.)..............................................................................................................37

12.2.6 Analogue input ..........................................................................................................................................37

12.2.7 Input 0-10v.................................................................................................................................................37

12.2.8 PWM input..................................................................................................................................................38

12.2.9 Analog output ............................................................................................................................................38

12.2.10 Errors list (MAX PRO MOD.)......................................................................................................................38

12.2.11 Technical menu (MAX PRO MOD.)............................................................................................................39

12.3Stop.....................................................................................................................................................................40

12.4 Emergency stop..................................................................................................................................................40

12.4.1 Reset after an emergency stop..................................................................................................................40

13 TROUBLESHOOTING.............................................................................................................................41

14 MAINTENANCE.......................................................................................................................................42

14.1 General warnings................................................................................................................................................42

14.2 Routine maintenance..........................................................................................................................................42

14.3 Periodic inspection of the effectiveness of guards and protection devices.........................................................43

14.4 Extraordinary maintenance.................................................................................................................................43

15 INSTRUCTIONS FOR OUT OF SERVICING, DISMANTLINGAND DISPOSAL....................................44

16 SPARE PARTS........................................................................................................................................45

16.1 How to order........................................................................................................................................................45

17 ANNEXES................................................................................................................................................46

17.1 Declaration of delivery of the instruction manual.................................................................................................46

17.2 Wiring diagram....................................................................................................................................................47