7

2 SAFETY INSTRUCTIONS

• Machine operation and maintenance is allowed to qualified persons older then 18 years of age, only!

• Before starting the work, the machine must be placed in a stable position,!

• Use only P.T.O.shafts of appropriate strength (min.25kW ), with undamaged outer plastic protective

cover (RCA 320-2)!

• Never use damaged, cracked or deformed cutting chains!

• Always wear personal protective equipment (safety glasses, hearing protectors, gloves and forestry

boots)!

• When troubleshooting, replacing the chain or any service procedure, always disengage P.T.O.shaft and

shut down the tractor (RCA 320-2)or unplug the power cord from the electrical outlet (RCA 320-2 E)!

• Do not wear loose clothes!

• Keep the working environment clean and tidy!

• Always use caution when operating the machine! Rotating chain can cause serious injuries in case of

incorrect use of the machine.

• Never leave the machine running without supervision!

• Do not reach into the working area, while the machine is in operation!

• Before removing a wedged piece of wood, shut down the machine drive (RCA 320-2)or turn off the

machine using »START-STOP«Switch(RCA 320-2E)!

• Whentransportingthemachineonpublicroadsitisnecessarytoinstalllightsonthereadendofthe

machine!

• Foryourownsafetyuseonlyoriginalsparepartsandaccessorieswhichareapprovedbythemanufac-

turer!

• Themachinemustbegroundedaccordingtoregulations(RCA 320-2E)!

• Damagedpowercordorplugmustbereplacedimmediately(RCA 320-2E)!

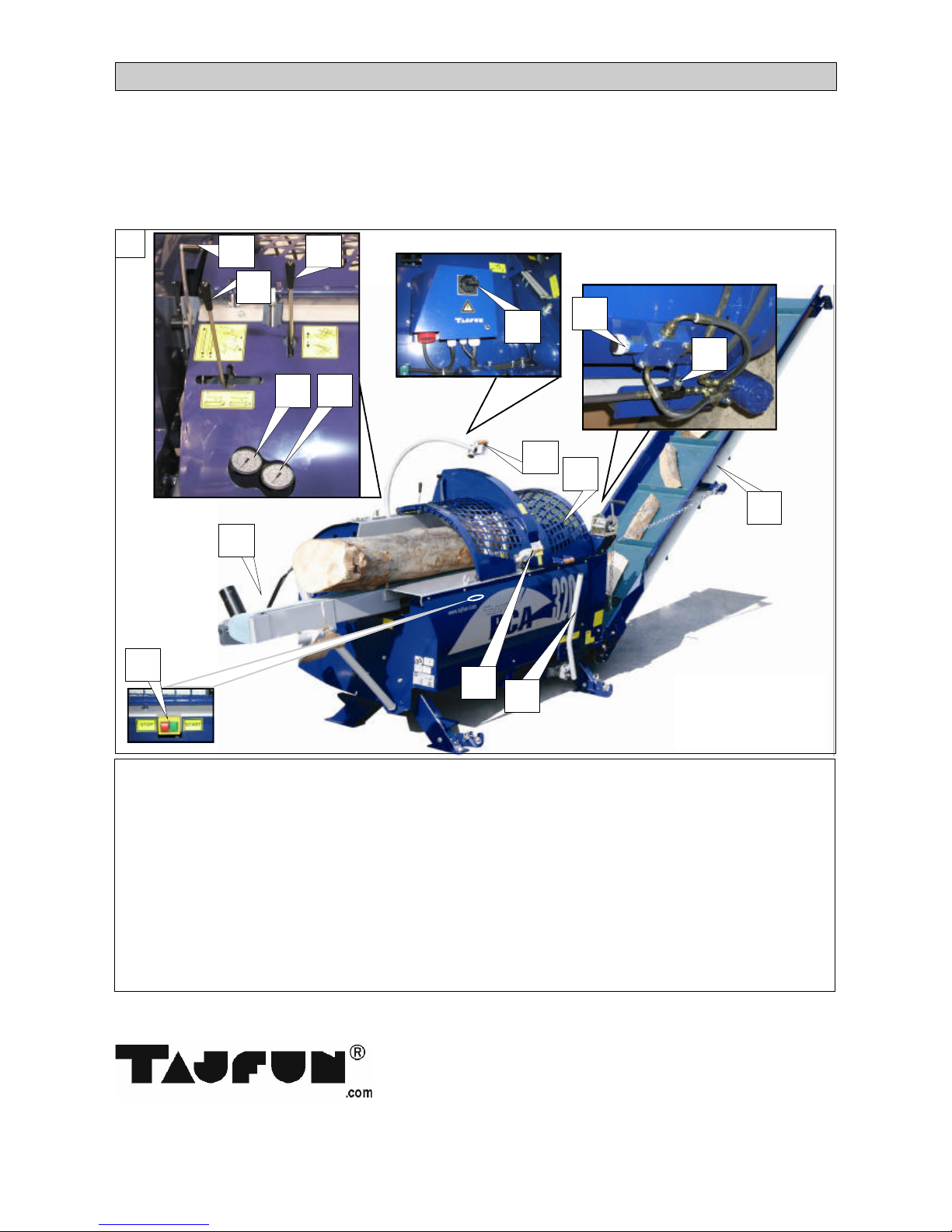

3 M ACHINE SETUPAND OPERATION

• Mount the firewood processor to the three-point tractor system usingbolts.Lower tractor connectinghan-

dles must be fixed with tensioningscrews,so the machine can move transversely.W hen transportingthe

machine,consider the weight of the whole machine (Chapter 1.5).

• Connect the P.T.O.shaft to the cardan shaft and secureit usingthe safetychain.

BeforethefirstinstallationalsochecktheP.T.O.shaftlength.

Checkthe P.T.O.shaft length byraisingand loweringthe machine to determine the position with the

shortest distance amongconnectingshafts.Tubes should be in this position,when the P.T.O.shaft is

connected,app.20mm shorter.

In case the P.T.O.shaft is too long,it must be shortened:

• Saw of steeland plastic tubes on both ends to the same length.Afterwards file down,clean and grease

the edges.

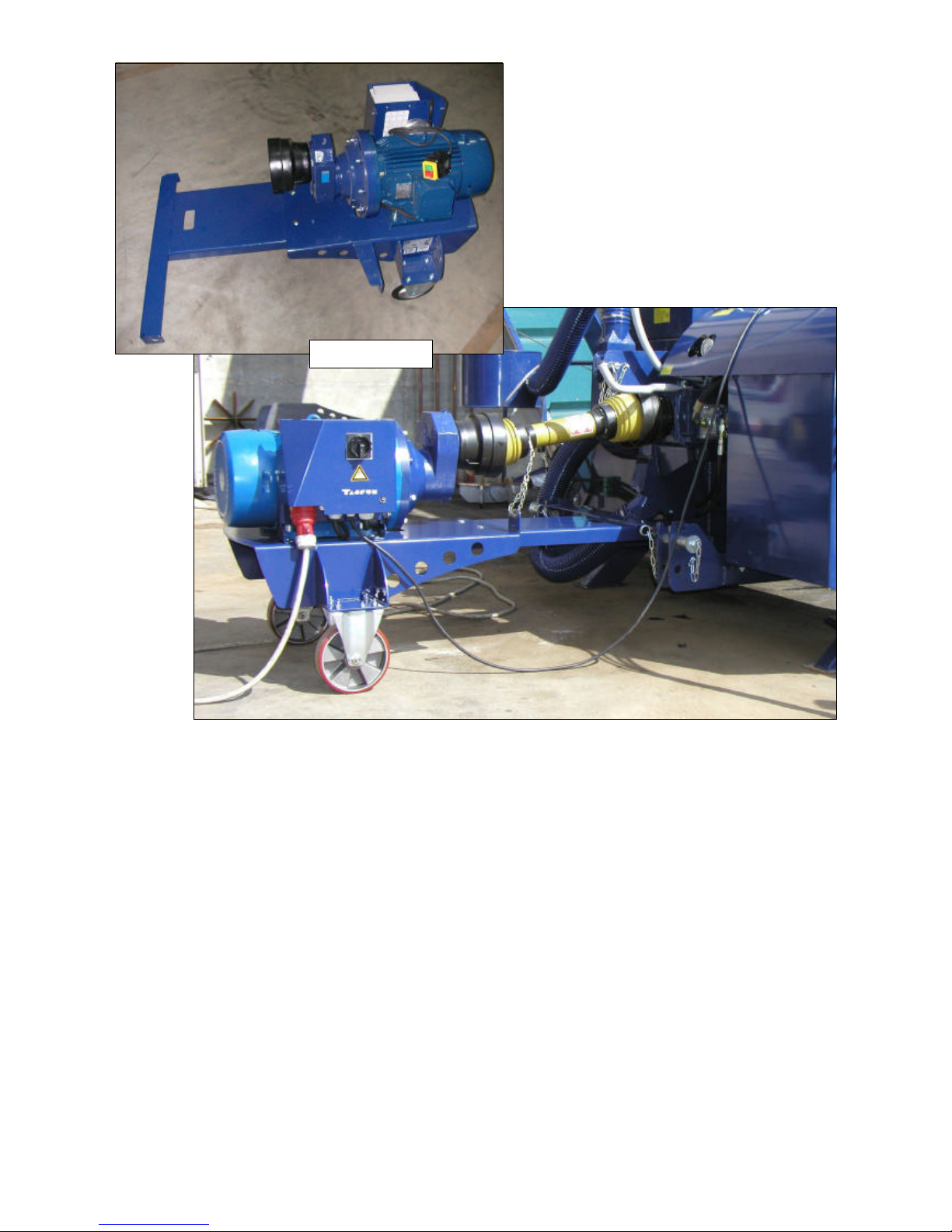

RCA 320-2:

P.T.O.shaft must be connected to the machine as perpendicular as possible!Therefore,it is recommended the

machine is connected to the three point tractor system,duringthe operation.