TP-50BS (Rev 1.0)

TALON TECH CO. LTD.

1. System Configurations……………………………….………………………………………………………………………………………….

2. System Specifications…………………………………………………………………………………………………………………………….

2-1. Pump [TP-50BS]…….………………………………………………………………………………………………………………………….

2-2. Controller [TPC-5002].………..…………………………………………………………………………………………………………….

2-3. Touch Pad [TTP-5016]……………………………………………………………………………………………………………………….

3. System In/Exterior Names…….………………………….…………………………………………………………………………………..

3-1. Pump Exterior Names…………………………………………………………………………………………….…………………………

3-1-1. Pump Name Explanation……………………………………………………………………………………….………………….

3-2. Controller Exterior Names....…………………………………………………………………………………………………………..…

3-2-1. Controller Name Explanation..……..…………………………………………………………………………………………...

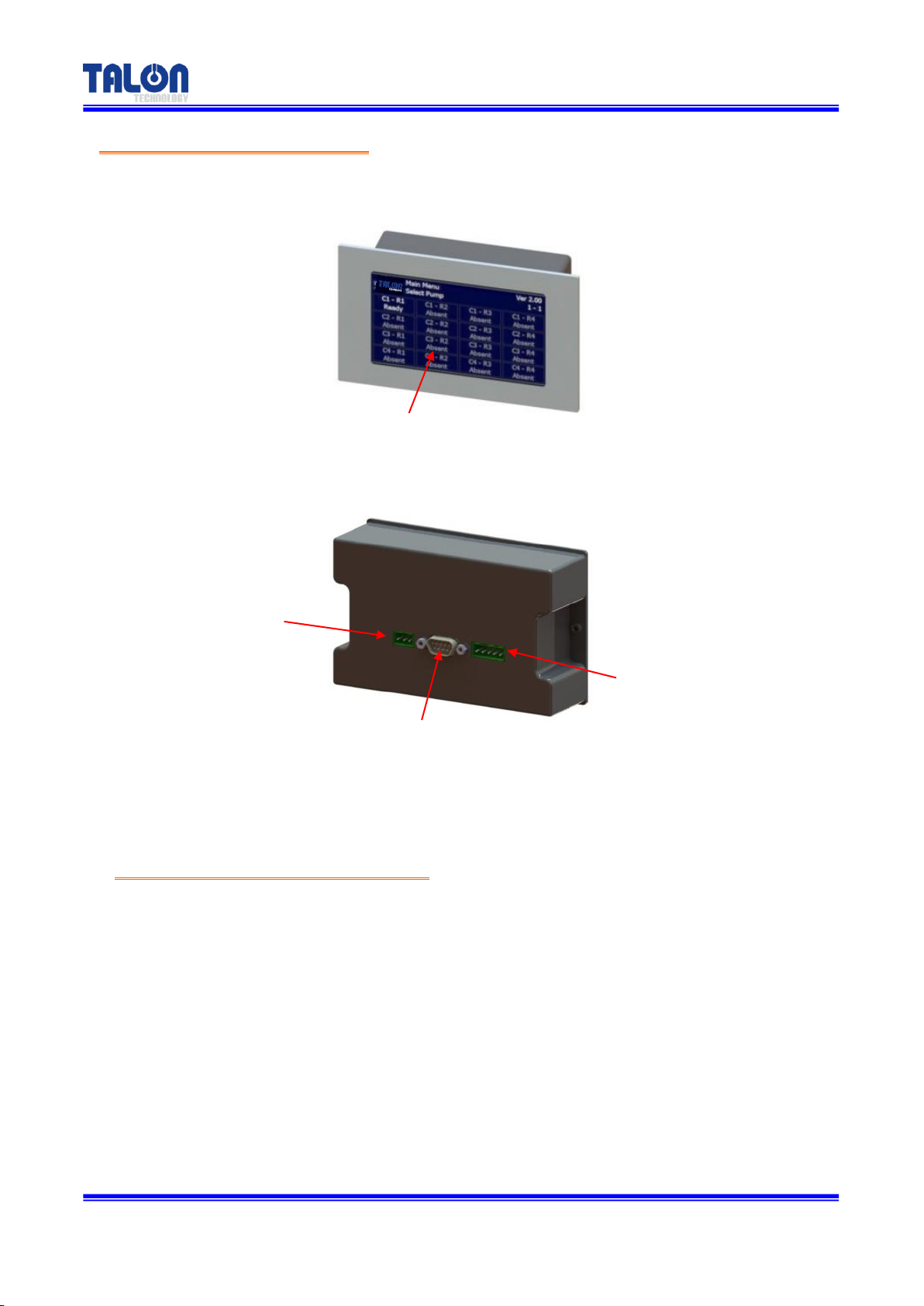

3-3. Touch Pad Exterior Names..……..………………………………………………………………………………..……………………..

3-3-1. Touch Pad Name Explanation.……..…………………………………………………………..………………………………..

4. Track/Auxiliary Interface………….……………………………………………………………………………………………………………

4-1. Track Interface Signal……….……………………………………………………………………………………………………………….

4-2. Track Interface Wiring……………………………………...……………………………………………………………………………….

4-3. Cable Pin Assign……………..………………………………………………………………………………………………………………..

5. External Cable Length……………………………………………………………………………………………………………………………

5-1. Pump Cable..……………………………………………………………………………………………………………………………………..

5-2. Track Cable………………………………………………………………………………………………………………………………………..

5-3. Touch Pad Cable……..………………………………………………………………………….………………………………………….…

6. Touch Pad Operation……………………………………………………………………………………………………………………………..

6-1. Operation……………………………………………………………………………………….…………………………………………………

6-1-1. Initial Screen ………………………………………………………………………….………………………………………………….

6-1-2. Pump Condition Indicate In Use..…..…………………………………………………………………………………………

6-1-3. Select Function…….…………………………………………………...……………………………………………………………….

6-1-4. Dispense…………………………………………………………………………………………………………………………………….

6-1-5. Recipe Setting……………………………………………………………………………………………………………………………

6-1-6. Configuration of Pump……………………………………………………………………………………………………………...

6-1-6-1. ID Setting………………….………………………………………………………………………………………………………...

6-1-6-2. Maint Mode, Run Mode, Pump Reset Setting……….………………………………………………………….

6-1-7. Calibration………………………………………………………………………………………………………………………………….

6-2. Example..……..…………………………………………………………………………………………………………………………………….

6-2-1. Dispense Test….………………………………………………………………………………………………………………………….