-

a

WOW: W.

R.M.S.:

7t/z ips - better than 0,07

o/o

33/rips - better than 0,140/o

17le

ips - better than 0,280/o

DtN 45511:

71/z

ips - better than 0,1

o/o

33/r ips - better lhan O,2o/o

17le

ips - better than 0,40lo

CROSSTALK At 1OOO

Hz:

ATTENUATION: Mono ) 60 dB Stereo ) SOOA

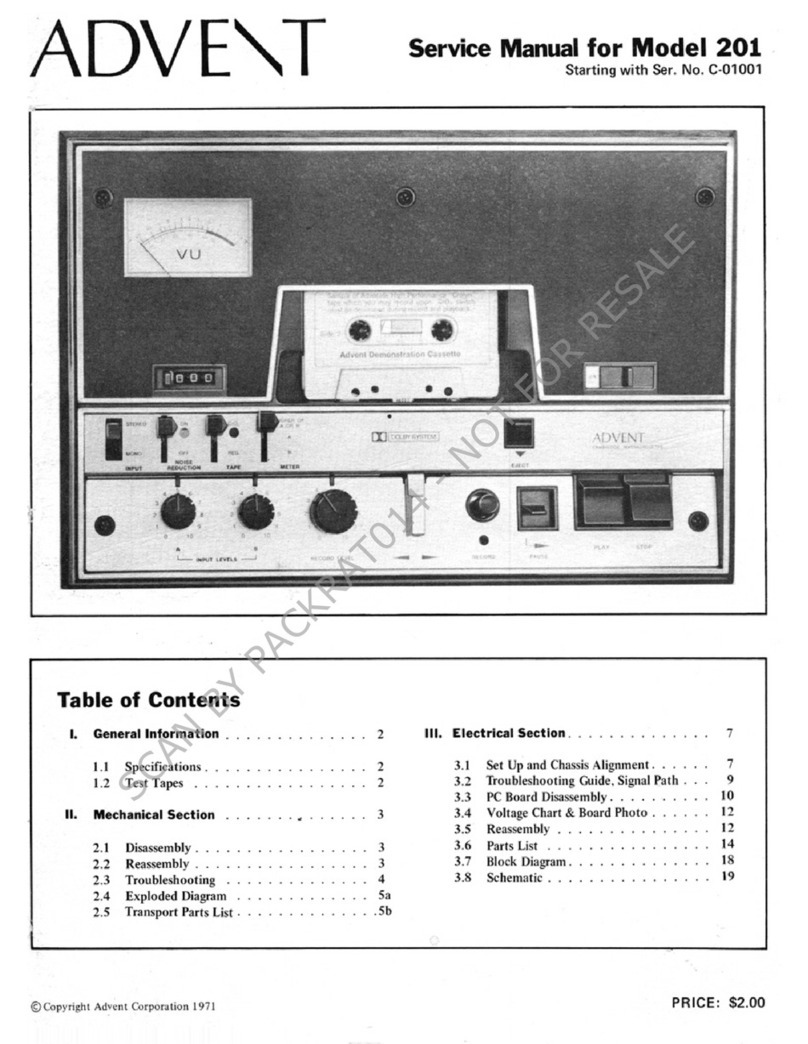

INPUTS: Each channelhas the following inputs:

1. Microphone input for dynamic low impedance microphone. lmpedance:

200-700 ohm. Sensitivity

at 400 Hz: 0,1 mV. Maximum input level: 25 mV.

DINsocket.

US-version,

Telephone

jack.

2. Line input for high impedancesource. lmpedance: 1 Mohm. Sensitivityat

400 Hz: 100mV. Maximum input level:20 V. Phono sockets,LINE lNpUTS.

3. Line input for low impedancesource. lmpedance:

57 kohm. Sensitivity

at

400 Hz: 5 mV. Maxirnuminput level: 1 V. DIN socket RADIO: Pin 1, left

channel:Pin 4, right channel.

US-version:

Phono sockets LOW lN.

OUTPUTS: Emitterfollower outputs,RADIO DIN socket pins 3 and 5. US-version:

phono

SocKetS,

OUTPUT

LEFT and RIGHT.

Minimumload impedance:

100ohm. Output level:

A tape recordedwith 400 Hz

signal at 0 dB level,

gives approx.0,75V in playback.HEADPHONES,

stereo

jack for connection

of headphones.

Stereojack is connected in parallelwith RADIOsocket pins 3 and 5. On US-

version stereo jack is connected parallel with phono sockets OUTPUT LEFT

and RIGHT.

SfGNALTAPE/NOISE Peak value measured

according to DIN 45511

at tape speed 71/zips and 5olo

WEIGHTED tape distortion:

(GERAUSCHSPANNUNG): 4-track 2-track

54 dB 56 dB

SIGNALTAPE/NOISE Peak value measured

accordingto DIN 45511

at tape speed 7t/z ips and 5o/o

UNWEIGHTED distortion:

(FREMDSPANNUNG): 4-track 2-track

51 dB 51 dB

SIGNAL/TAPE

NOISE: Measuredlinear R.M.S.

at tape speed 7'lz ips and 5o/o

distortion:

4-track 2-track

57 dB s7 dB

SfGNAL/TAPE

NOISE: Measuredat tape speed

7t/zips and 50/o

distortion:

Wetonreo 4-track z-track

(lEC A-CURVE)

R.M.

S.: 62 dB 64 dB

Note: At 30/o

distortion all signal to noise ratio measurements(Signal/tape

noise)

are reducedby 2 dB.

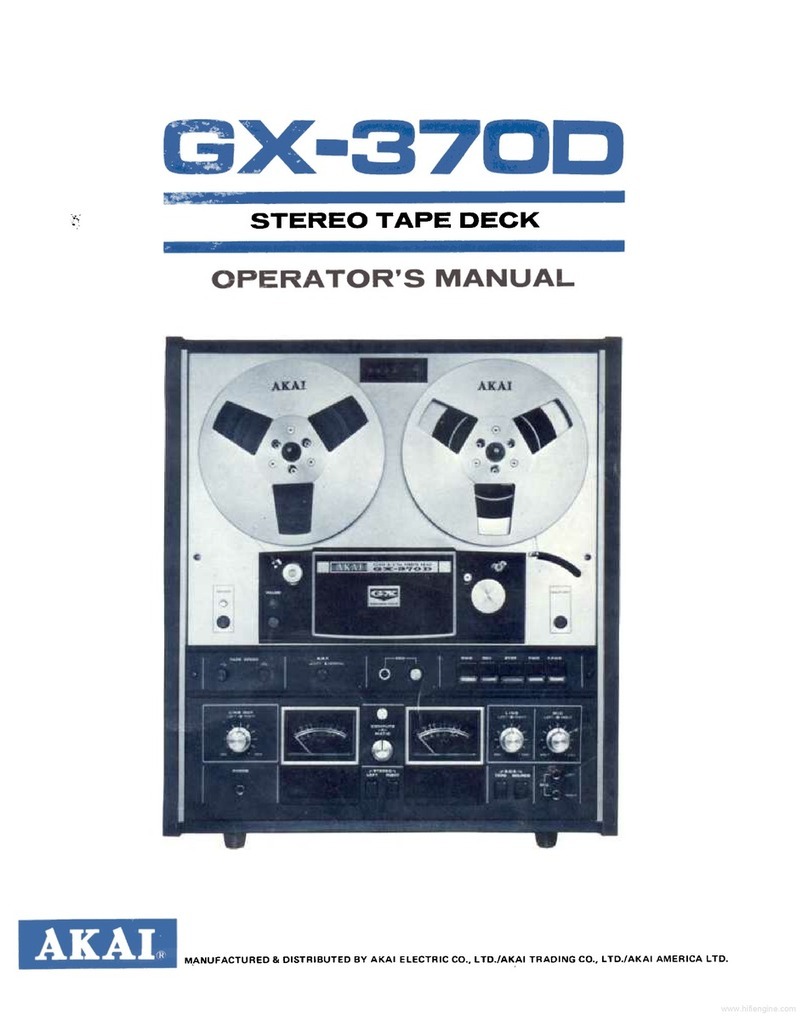

DfMENSIONS: Length: 151/2"

(39,4

cm), heigth: 6t/2" (16,5cm) and depth: 123la"

(31,6cm).

WEIGHT: 20lbs(9,1

kg).