CONTENTS

l.

l.l

r.2

,

2.1

99

3.

3.1

3.2

3.3

3.4

c.c

3.6

4.

4.1

4.2

4.3

4.4

4.5

5.

5.1

5.2

5.3

5.4

c.5

6.

6.1

6.2

6.3

6.4

6.5

7.

7.1

19

7.3

8.

8.1

8.2

8.3

8.4

9.

9.1

9.2

10.

11.

11.1

rt.2

11.3

Page

Introduction.... ..,....3

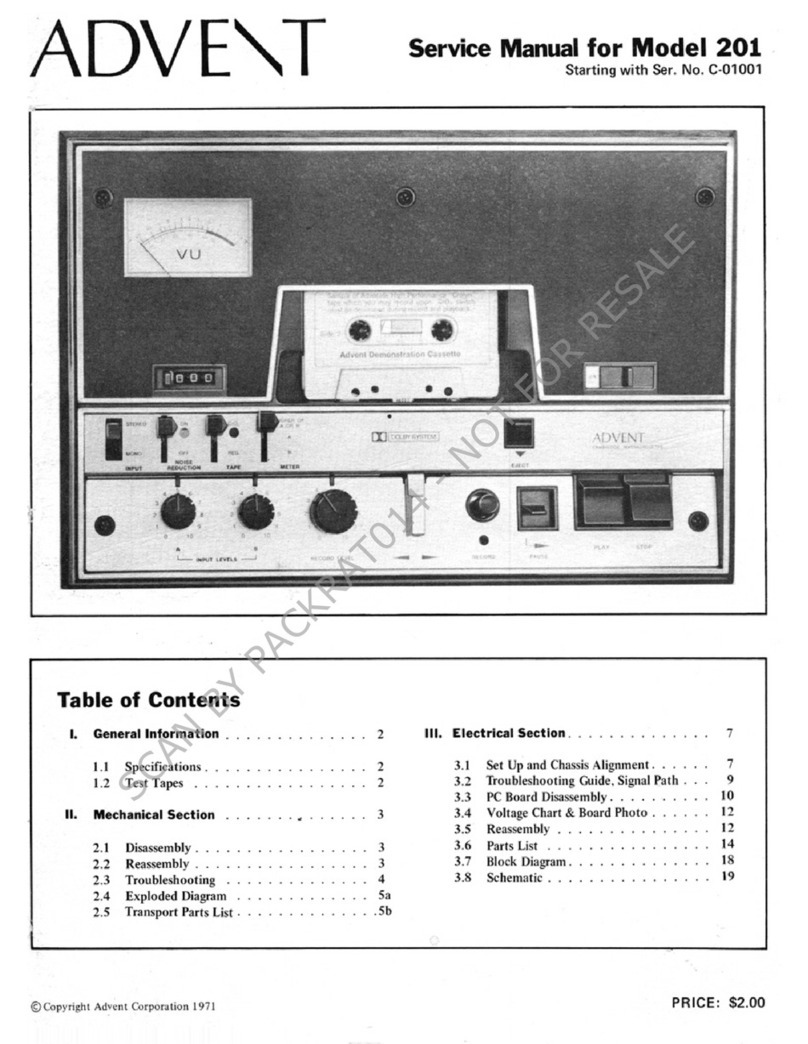

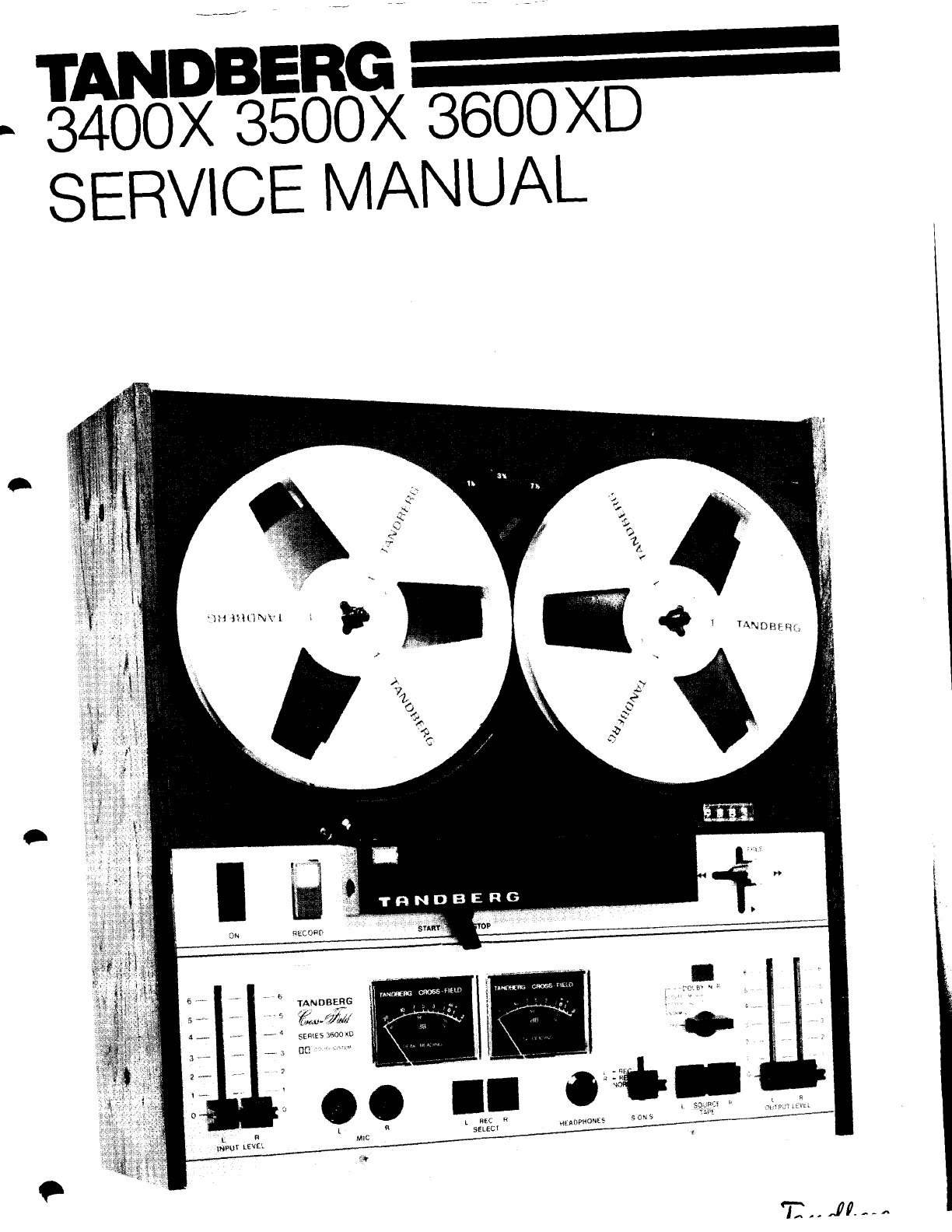

General ....3

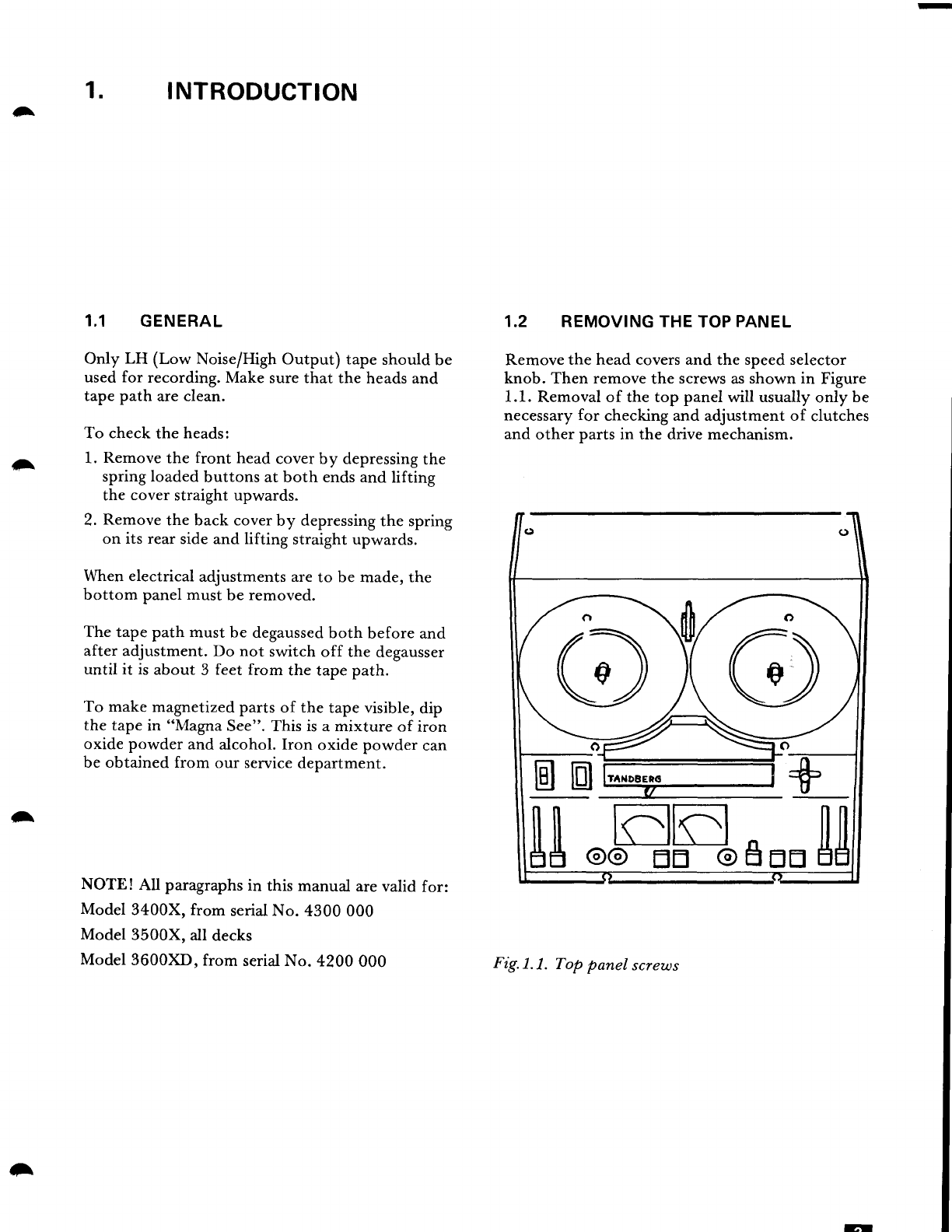

Removingthetoppanel . ......3

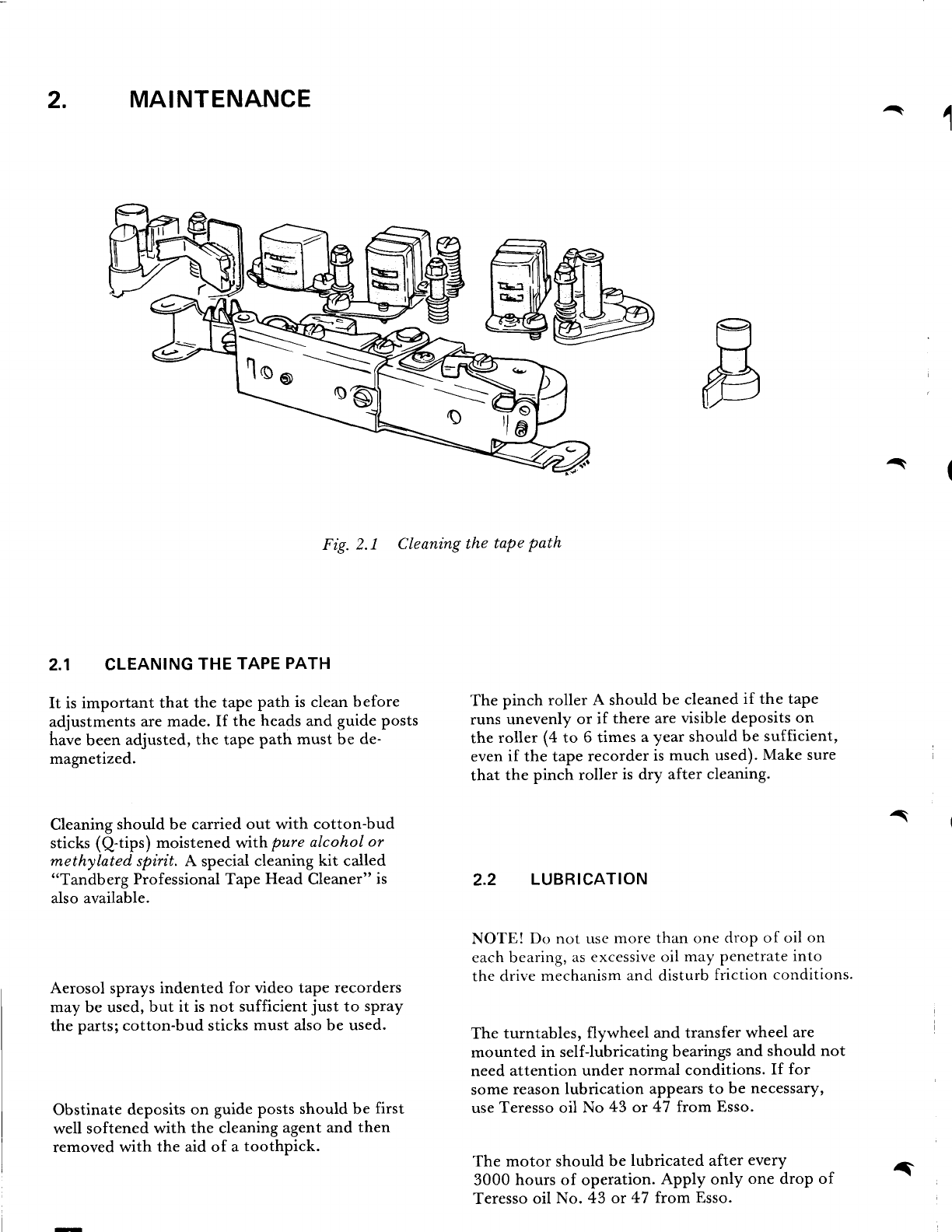

Maintenance.... ...,.,.4

Cleaningthetapepath.. .......4

Lubrication .......4

Mechanicalchecksandadjustments.. .......5

Checking

the take-upforce andwinding force. . . . . . 5

Adjustingthetake-upforce. ....5

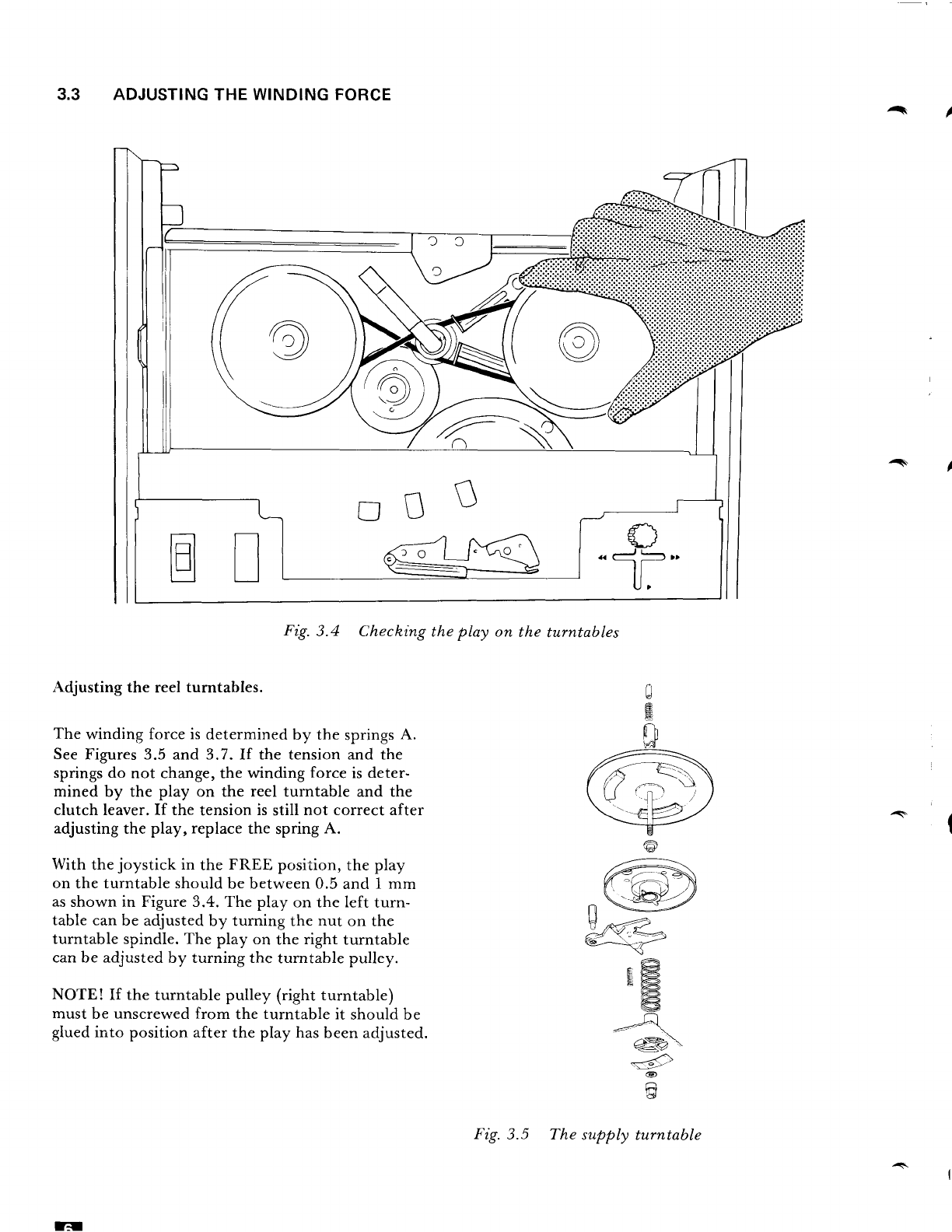

Adjustingthewindingforce. ...6

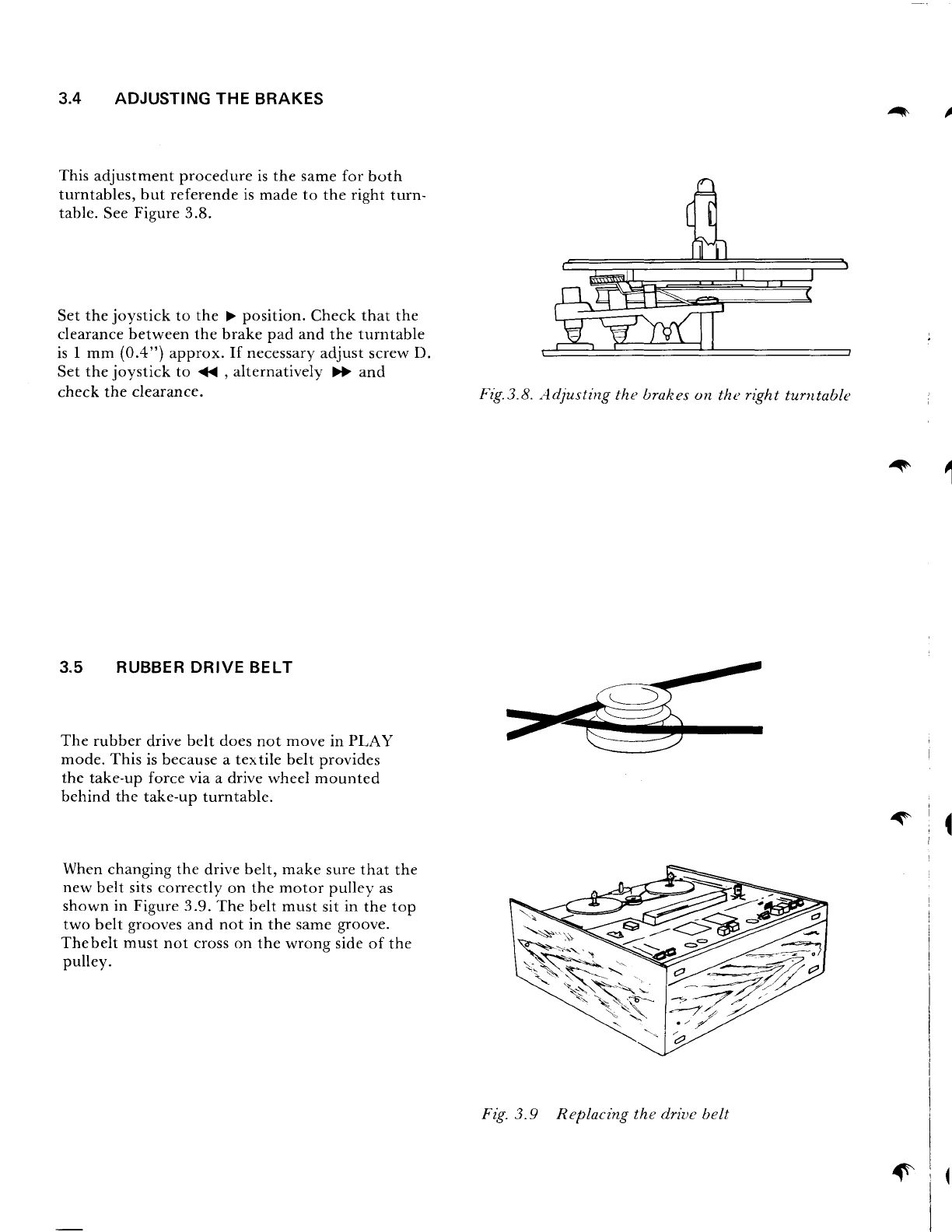

Adjustingthebrakes .....8

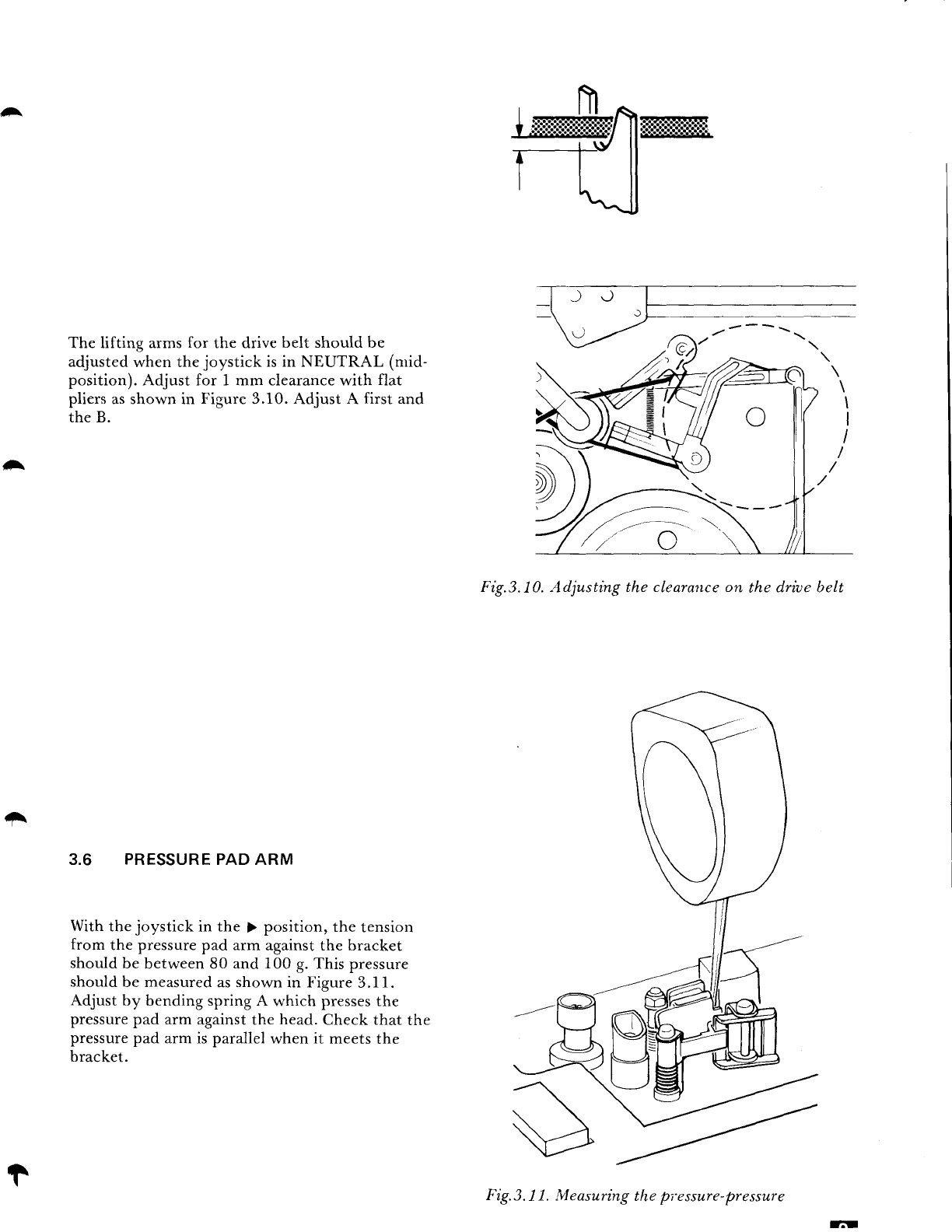

Rubberdrivebelt .......8

Pressurepadarm ...9

Tapepath ...10

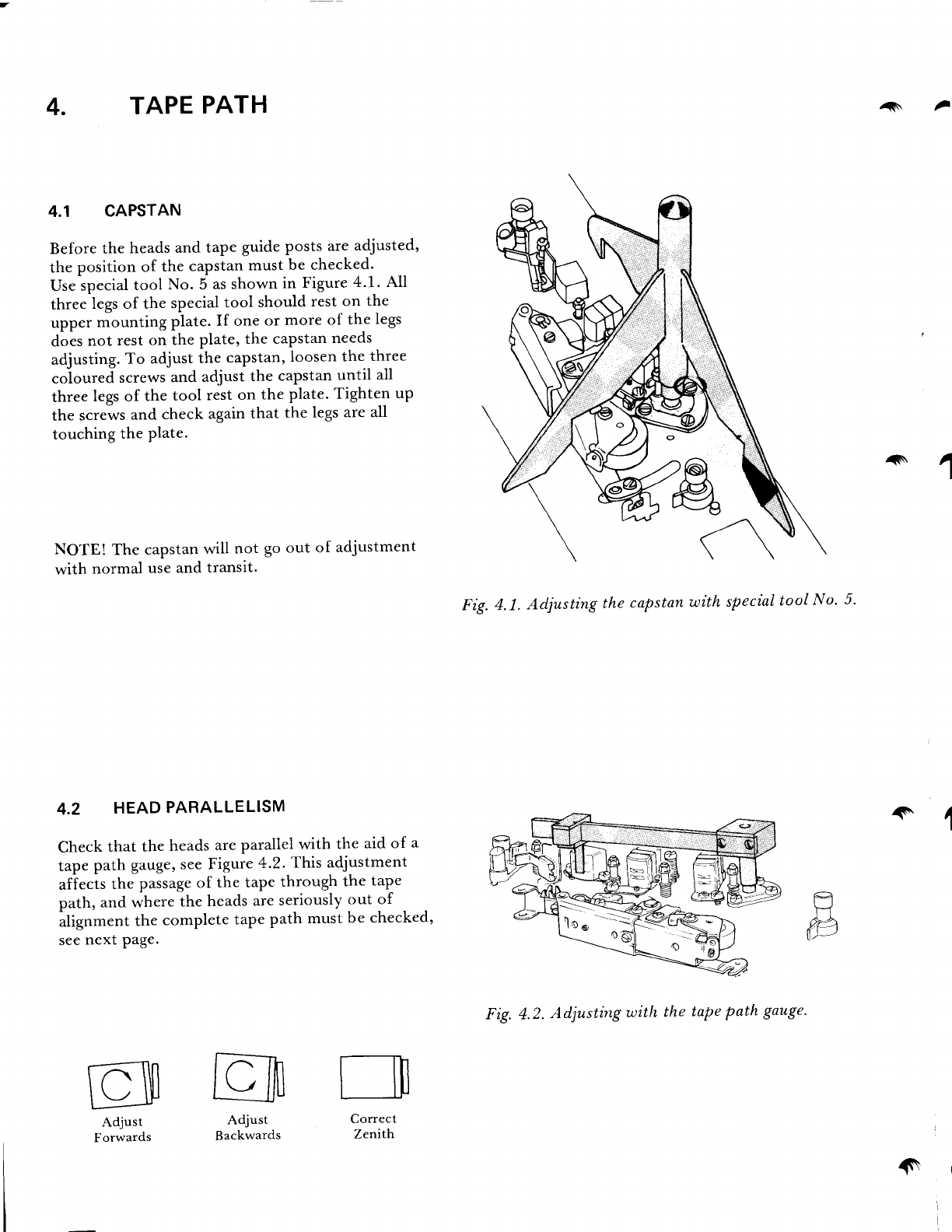

Capstan .....10

Headparallelism. .......10

Tapeguideposts

and

guide

screws.

.. .. .. . . .11

Pinchroller .......11

Flutterroller. .....12

Head

alignment

with Tandberg

test tapes,

four tracks . . . . .13

Playbackhead. ....13

Recordhead. .....13

Height

adjustmentby

trackmeasurement... ......13

Biashead ....I4

Erasehead ...I4

Headalignment

without Tandbergtest tapes,

four tracks . . . . . . .15

Playbackhead. ....15

Recordhead. .....15

Biashead ....15

Erasehead. .......15

Aligning the hum shieldfor the playback head. . . . .15

Headalignment,two

tracks .....16

Playbackhead. ...16

Recordhead. .....16

Erasehead ........17

Circuits .....77

Oscillator. . . .I7

Photoend-stop ........I7

Recordandplaybackfrequencyresponses . . .18

Faultinthetotalresponse

curve,onechannel..... ......19

Modifications... .......20

Changingthelinevoltageand

frequency... .......20

Changingfrom four tracksto two tracksversion . . . .20

Blockdiagrams ....20

Electricaladjustments.... .....22

Outputamplifiers

(3400X) .....22

Dolby*leveladjustments

(3600XD). .......22

Adjustments,allmodels.... ...23

Circuitdiagrams .... from page24

* Theword Dolby isa Trade

Mark of Dolby LaboratoriesInc., USA

-----.....-

-

t

a