3

Tanis Technologies 36 Series Filtraon Unit Revised 07.20.2020

General Safety informaon

SAFETY GUIDELINES- DEFINITIONS

This manual contains informaon

that important for you to know and

understand. This informaon

relates to protecng YOUR SAFETY

and PREVENTING EQUIPMENT

PROBLEMS.

GENERAL SAFETY RULES

General Safety informaon

SAFETY GUIDELINES- DEFINITIONS

This manual contains informaon that

important for you to know and

understand. This informaon relates

to protecng YOUR SAFETY and

PREVENTING EQUIPMENT PROBLEMS.

GENERAL SAFETY RULES

!WARNING!

This machine was designed for

certain applicaons only. Tanis

Technologies strongly recommends

that this machine not be modied

and/or used for any applicaon

other than that for which it was

designed. If you have any

quesons relave to a parcular

applicaon, DO NOT use the

machine unl you have rst

contacted Tanis Technologies and

conrmed that the product is

suited for your applicaon.

!WARNING!

Failure to follow these rules may

result in serious personal injury.

1. For your safety, read and

understand the instrucon manual

before operang the unit. Learn

the unit’s applicaon and

limitaons as well as the specic

hazards, related to it.

2. Don’t use in dangerous

environment.

Don’t use this unit in damp or wet

locaons or expose to rain.

3. Disconnect unit before servicing.

4. Check damaged parts before

future use of the unit, properly

repair or replace any part that is

damaged.

ADDITIONAL SAFETY RULES FOR

AIR CLEANERS

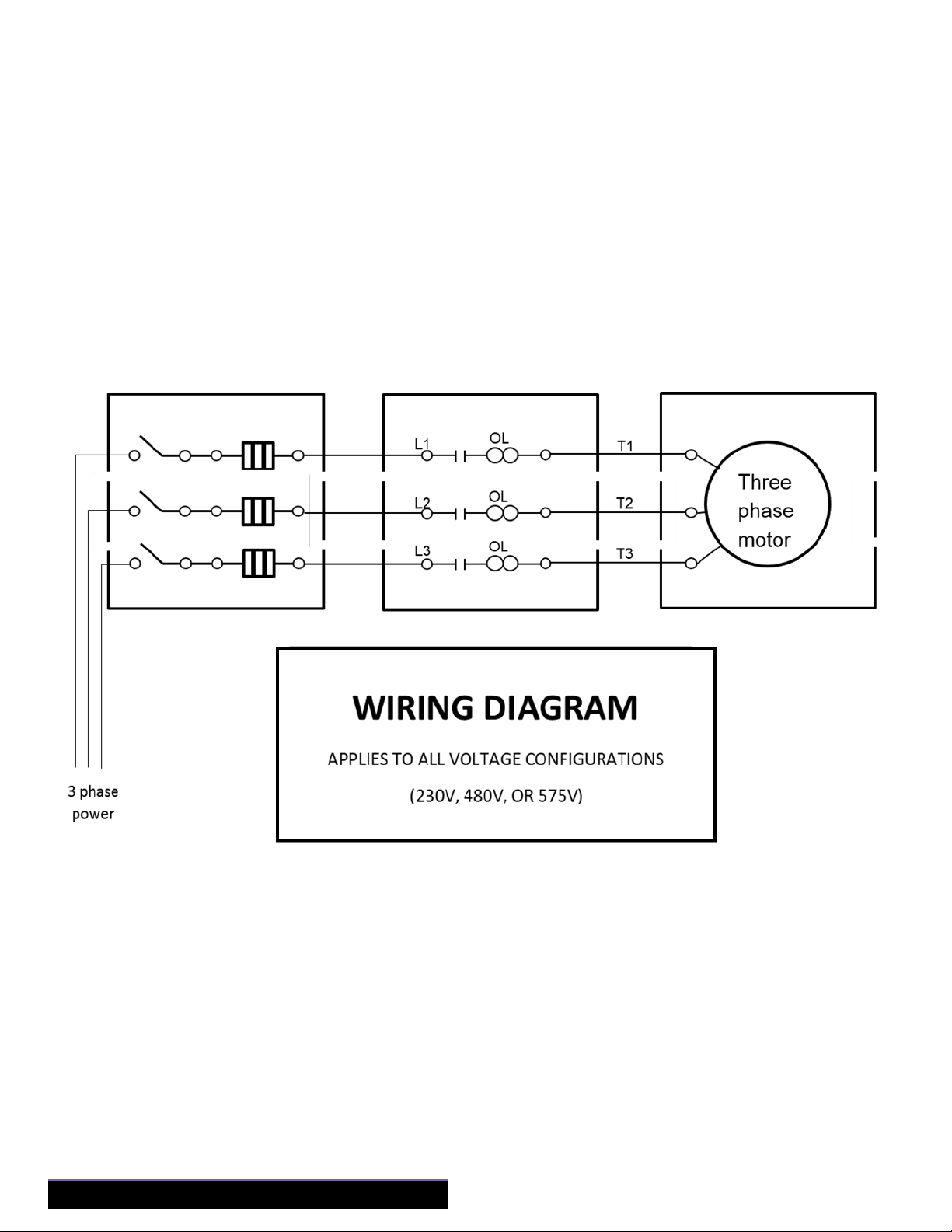

1. Install AF-36xx series air cleaners

according to all electrical and

safety codes as well as the Naonal

Electrical Code (NEC) Naonal Fire

Protecon Associaon (NFPA) and

the Occupaonal Safety and Health

Act (OSHA). Only someone who is

qualied to do electrical work

should wire the units in.

2. These air cleaners are intended

to be installed at least 8.2 feet (2.5

meters) above the oor.

3. Specic duct design and dust

collector conguraons are

required under standards set forth

by the Naonal Fire Protecon

Associaon (NFPA). These are

applicable when collecng

potenally reacve metal dusts

(like aluminum, magnesium and

other materials). NFPA also has

standards that cover other dusts

like grain and plascs, ect. For

guidelines on determining which

precauons should be taken,

please refer to NFPA

497. There may be other

specicaons that apply for your

parcular applicaon, so please

consult current NFPA standards

that may be acquired at:

NFPA

1 Baerymarch Park

Quincy, MA 02269

1-800-344-3555

This informaon may contain

safeguards that are required for

the installaon, operaon and

service of AF-36xx series products.

!WARNING!

4. Avoid mixing combusble

materials like (but not limited to)

the following: bung lint, paper/

wood dust, aluminum or

magnesium with dust generated

from the grinding of ferrous

materials. This creates a potenal

for res due to the mixing of sparks

and combusble materials.

5. A machine operator should

NEVER be allowed to put lit

cigarees or any burning object

into this or any dust control

system.

6. If there is a chance for heated

and/or ammable materials to

enter the unit, installaon of the

unit should be evaluated to

determine if a re protecon/

exhauson systems should be

installed. Federal, State or local

codes, as required by organizaons

such as NFPA and Factory Mutual

Insurance or your insurance carrier

may require such a system. Tanis

Technologies can oer basic

guidelines for such an installaon:

however, nal installaon design

is the responsibility of the

purchaser.

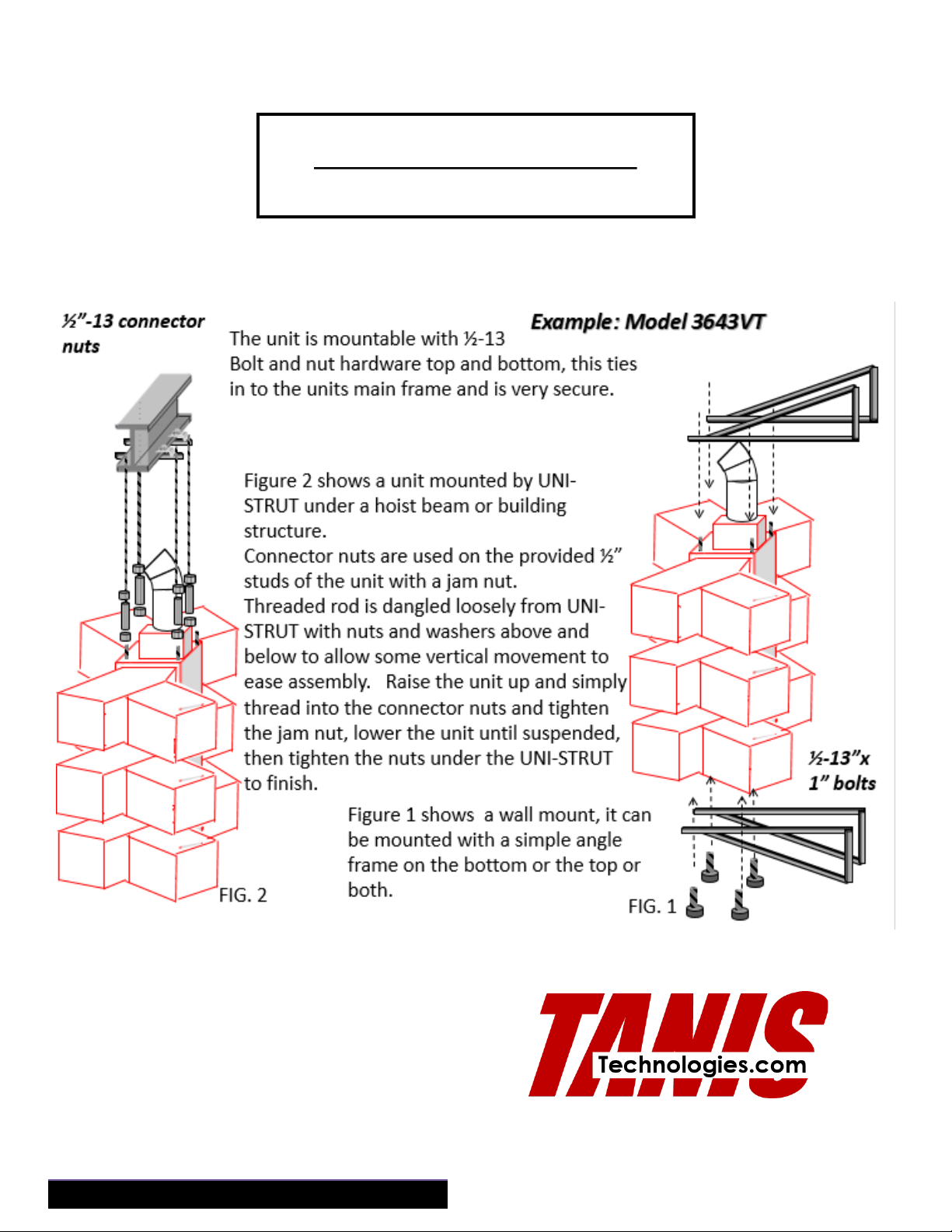

7. Securely anchor unit to a

permanent or xed supporng

structure, be sure the structure is

rated to hold the weight of the

unit.

8. Support this unit or clamp it to

the work surface when using it in a

portable applicaon to eliminate

potenal injury or damage to the