ISO 9001 CERTIFIED- 802 Clearwater Loop, Post Falls, ID 83854, Phone: 800 854-6019, 208 773-8048, FAX: 208 773-3021, www.tapmatic.com

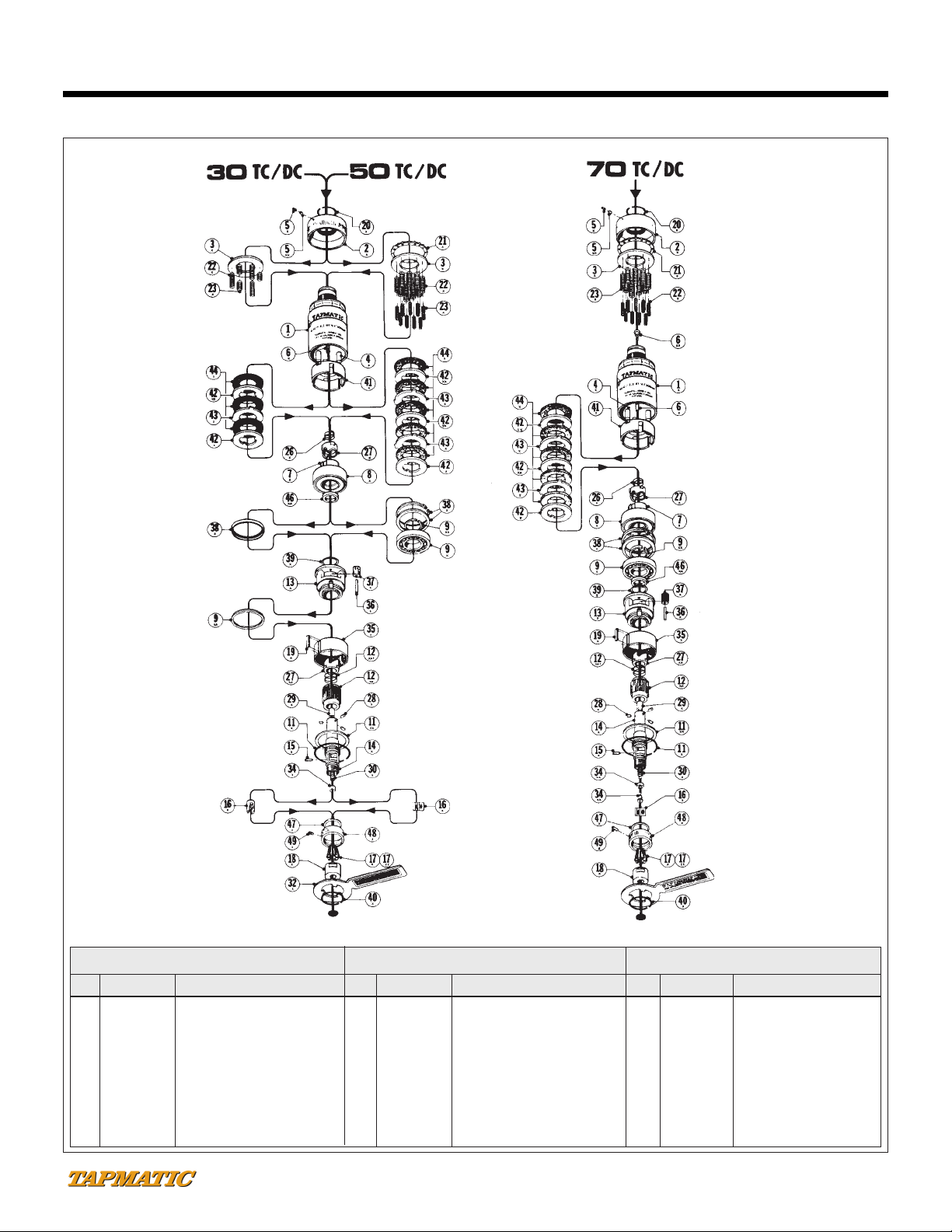

IDENT PART NAME 30TC/DC 50TC/DC 70TC/DC

1Housing - #6JT 54301 B (1) 54501 B (1) -

1Housing - DINB16 54301 G (1) 54501 G (1) -

1Housing - #33JT 54301 E (1) 54501 E (1) -

1Housing - DIN B 12 54301 F (1) - -

1Housing - 5/16-24 54301 H (1) - -

1Housing - 3/8-24

54301 I (1)

54501 I (1) -

1Housing - 1/2-20 54301 J (1) 54501 J (1) 54701 J (I)

1Housing - 5/8-16 54301 K (1) 54501 K (1) 54701 K (1)

1Housing - 3/4-16 54301 L (1) 54501 L (1) 54701 L (1)

1Housing - 7/8-20 - - 54701 M (1)

1Housing - #3JT - - 54701 C (1)

2X Clutch Adjustment Cap 50302 A (2) 56502 A (2) 50702 A (2)

3X Spring Plate 50303 56503 50703

4X Driver Pins 50304 (3 required) 50704 (3 required) 50704 (3 required)

5X Lock Set Screw 50305 A (3) 50305 A (3) 50305 A (3)

5XX Lock Set Screw Plug 503051 503051 503051

6X Guide Spindle 503061 56506 51720

6XX Upper Spring Hanger - -

60334

7X Clutch Sleeve 50307 50507 50707

8X Clutch Bearing 50308 56508 50708

9X Gear Carrier Bearing (Ball) - 50509 50709

9XA Gear Carrier Bearing (Nylon) 503091 - -

9XX Truarc Ring - 505091 507091

11X Retaining Ring 50311 50511 50711

11XX Gear Washer 503111 505111 507111

12XA Reversing Sleeve 503121 (4) 505121 (4) 507121 (4)

12 XA I Reversing Driver Spring 51312 505122 507122

13X Gear Carrier 503131 54513 54713

14X Drive Spindle 54314 A (5) 54514 A (5) 54714 A (5)

15X Back Jaw Retainer Screw

50715 (2 required) 50715 50715

16X Back Jaw or Tap Jaw 503161 56516 50716

17X Rubber Flex Collet (small)

21600

22100 24100

17XX Rubber Flex Collet (large)

21700

22200 24000

18X Tap Chuck Nut 50318 56518 50718

19X Key 50319 50319 50719

20X Stop Ring 50320 56520 50720

21X Adjustment Thrust Bearing -

565211+68439 (12 req) 64521+692205 (8 req)

22X Clutch Spring (large) 50322 (3 required)

50722 (9 required)

50722 (9 required)

23X Clutch Spring (small) 50323 (3 required 50723 (9 required) 50723 (9 required)

26X Cushion Spring 50326 565261 50726

27X Spring Cup Driver 503271 505271 507271

27XA Reversing Driver 503272 505272 507272

28X Drive Pins 50328 (3required) 56528 (3 required) 50728 (3 required)

29X Guide Spindle Bearing 50329 56529 50729

30X Return Spring 51328 51528 51628

31X Drive Spindle Bearing -(4) -(4) -(4)

32X Stop Arm 50332 56532 50732

33X Guide Spindle Washer 50333 - -

34X Guide Spindle Nut 503341 56534 -

34XA Spring Bearing - - 50734

34XX Spring Bearing Hanger - - 50706

35X Ring Gear 50335 50535 50735

36X Gear Pins 50336 (3 required) 50536 (3 required 50736 (3 required

37X Planet Gears 50337 (3 required) 50537 (3 required) 50737 (3 required)

38X Spacer (and Truarc Ring) 50338 54538 and 56511 54738 and 50611

39X Thrust Washer 50339 50539 50739

40X Truarc Ring 50340 56540 50740

41X Clutch Driver 50341 56541 50741

42X Primary Internal Clutch Plate 50342 56542 50742

42XX Internal Clutch Plate 503421 565421 (2 required 507421 (2 required)

43X External Clutch Plate 50343 56543 (2 required) 50743 (2 required)

44X Clutch Discs 50344 (3 required) 56544 (5 required) 50744 (5 required)

46XA Reversing Sleeve Bushing 503461 505461 507461

47X Friction Washer 50347 50547 50747

48X Depth Control Collar 50348 50548 50748

49X Lock Set Screw 50305 50305 50305

(1) Housing only available as an assembly with Ident. #4X and #6X.

(2) Clutch Adjustment Cap only available as an assembly with Ident #5X and #5XX.

(3) Lock Set Screw comes with Ident. #5XX.

(4) Reversing Sleeve and Drive Spindle Bearing available only as an assembly.

(5) Drive Spindle only available as an assembly with Ident. #29X.

INSTRUCTIONS FOR DISASSEMBLY

1. Remove stop ring (#20X) and unscrew clutch adjustment cap (#2X).

2. Hold unit in vertical position and remove adjustment thrust bearing (#21X). (Models

50 &70TC/DC.)

3. Lift off spring plate (#3X).

4. Carefully invert unit over a clean receptacle. Clutch springs (#22X & 23X) will drop out.

5. Remove tap chuck nut (#18X) and collet (#17X).

6. Remove back jaw retainer screw (#15X).

7. Remove back jaw (#16X).

8a. Remove return spring (#30X) by threading spring puller (supplied with unit) into

tapped hole in part (#34XX), and pulling out to expose spring for removal with spring hook

(also supplied with unit). (Model 70TC/DC.)

8b. Unscrew guide spindle nut (#34X) and remove return spring (#30X).

(Models 30 &50TC/DC.)

9. Remove truarc ring (#40X) and stop arm (#32X).

10. Remove truarc ring (#11X) and gear washer (#11XX).

11. Lift out drive spindle (#14X) and reversing sleeve (#12XA) subassembly from unit.

12. Lift out spacers (#46XA) and (#38X).

13. Lift out clutch sleeve (#7X), clutch driver (#41X), clutch plates (#42X, 42XX, 43X)

and clutch discs (#44X).

14. Lift out cushion spring (#26X) and spring cup driver (#27X).

15. Remove driver pins (#28X) from drive spindle (#14X).

16. Press drive spindle (#14X) out of reversing sleeve (#12XA) subassembly.

17. Do not disassemble planetary gear reversing subassembly (#13X).

REPLACEMENT OF FRICTION WASHER #47X

1. Remove tap chuck nut (#18X.)

2. Unscrew depth control collar all the way off.

3.) Using small screwdriver, flip out used washer (#47X) and insert new one.

INSTRUCTIONS FOR ASSEMBLY

1. Clean and lubricate all parts requiring lubrication thoroughly. Do not get clutch parts wet or oily.

2. Place internal clutch plate (#42X) on clutch sleeve (#7X), then clutch disc (#44X),

then external clutch plate (#43X), then another clutch disc (#44X), then internal clutch plate

(#42XX), and so forth, until you have all plates and discs on clutch sleeve, then line up external

dogs so that you can slip clutch driver (#41X) over complete subassembly.

3. Place cushion spring (#26X) and spring cup driver (#27X) in clutch sleeve (#7X).

4. Insert clutch sleeve (#7X) and clutch driver (#41X) subassembly into housing (#1X), making

sure that 3 holes in clutch driver mate with 3 pins in housing (#1X).

5. Insert spacers (#46XA) and (#38X) into housing (#1X).

6. Press drive spindle (#14X) into reversing sleeve (#12XA) subassembly and insert drive pins

(#28X).

7. Insert complete subassembly into housing (#1X) utilizing key (#19X).

8. Insert gear washer (#11XX) and snap in truarc ring (#11X).

9. Hook return spring (#30X) to spring hanger (#6X) and insert this subassembly into neck end of

housing (#1X) making certain spring hanger is seated properly. (Model 70TC/DC.)

10. Use spring hook (supplied with unit) to expose return spring (#30X) and attach spring

bearing hanger (#34XX) with bearing (#34XA) mounted. (Model 70TC/DC.)

11a. Thread spring puller (supplied with unit) into tapped hole in spring hanger (#34XX) and

carefully lower assembly into drive spindle (#14X) until bearing (#34XA) seats itself, then

unscrew spring puller. (Model 70TC/DC.)

11b Insert return spring (#30X) into drive spindle (#14X) and screw guide spindle nut on

to guide spindle (#6X). (Models 30 & 50TC/DC).

12. Place back jaws (#16X) in drive spindle (#14X) and install back jaw retainer screw (#15X).

13. Insert collet (#17X) into tap chuck nut (#18X) and screw tap chuck nut (#18X) on to

drive spindle (#14X).

14. Insert clutch springs (#22X & 23X) into unit.

15. Place spring plate (#3X) on springs.

16. Place adjustment thrust bearing (#21X) on spring plate (#3X). Models 50 & 70TC/DC.)

17. Screw on clutch adjustment cap (#2X).

18. Install stop ring (#20X).

19. Install stop arm (#32X) and snap on truarc ring (#40X).

7

Parts Listing: 30, 50 & 70TC/DC Self-Reversing Tapping Units